Laser and variable polarity plasma hybrid welding method for magnesium alloy with medium thickness

A hybrid welding and plasma welding technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems that magnesium alloy plate welding cannot be applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

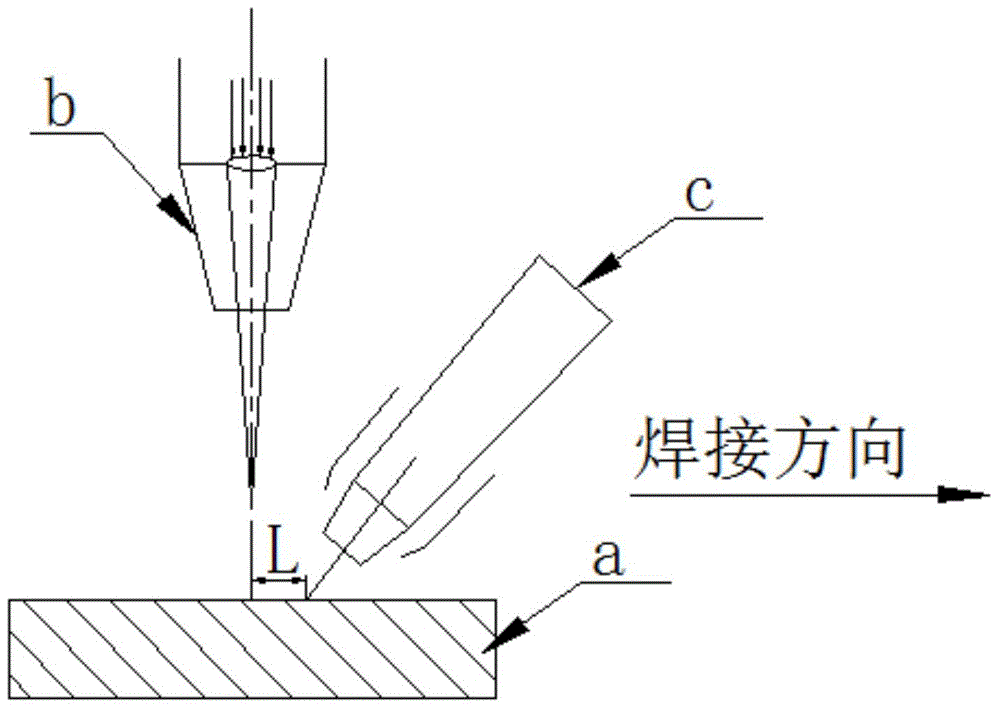

[0024] Such as figure 1 As shown, the laser-variable polarity plasma hybrid welding method of the medium-thickness magnesium alloy of the present embodiment comprises the following steps:

[0025] (1) The thickness of the magnesium alloy plate a to be welded is 10 mm, butt the adjacent two magnesium alloy plates to be welded, and the gap between the two magnesium alloy plates after the butt joint is 1 mm;

[0026] (2) Under the protection of argon gas with a purity of 99.99%, align the above gap for welding; during welding, the laser beam b and the polarity-changing plasma arc c are located on the same side of the weld, and the polarity-changing plasma arc c is in the welding direction Located on the front side of the laser beam b, the distance L between the action point of variable polarity plasma welding and the action point of laser welding is 4mm;

[0027] Single-sided non-groove welding is adopted, the flow rate of argon gas is 15L / min, the current and time of variable p...

Embodiment 2

[0029] Such as figure 1 As shown, the laser-variable polarity plasma hybrid welding method of the medium-thickness magnesium alloy of the present embodiment comprises the following steps:

[0030] (1) The thickness of the magnesium alloy plate a to be welded is 25mm, and two adjacent magnesium alloy plates to be welded are butted, and the gap between the two magnesium alloy plates after the butt joint is 1mm;

[0031] (2) Under the protection of the mixed gas of argon and helium, aim at the above-mentioned gap for welding, the volume ratio of argon and helium is 1:1; during welding, the laser beam b and the variable polarity plasma arc c are located at the welding position The seam is on the same side, and the variable polarity plasma arc c is located on the front side of the laser beam b in the welding direction, and the distance L between the action point of the variable polarity plasma welding and the action point of the laser welding is 5mm;

[0032] Single-sided non-groo...

Embodiment 3

[0034] Such as figure 1 As shown, the laser-variable polarity plasma hybrid welding method of the medium-thickness magnesium alloy of the present embodiment comprises the following steps:

[0035] (1) The thickness of the magnesium alloy plate a to be welded is 30mm, butt the adjacent two magnesium alloy plates to be welded, and the gap between the two magnesium alloy plates after the butt joint is 2mm;

[0036] (2) Under the protection of the mixed gas of argon and helium, aim at the above-mentioned gap for welding, the volume ratio of argon and helium is 1.5:1; when welding, the laser beam b and the variable polarity plasma arc c are located at the welding position seam on the same side, and the variable polarity plasma arc c is located in front of the laser beam b in the welding direction, and the distance L between the action point of the variable polarity plasma welding and the action point of the laser welding is 6mm;

[0037] Double-sided non-groove welding is adopted,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com