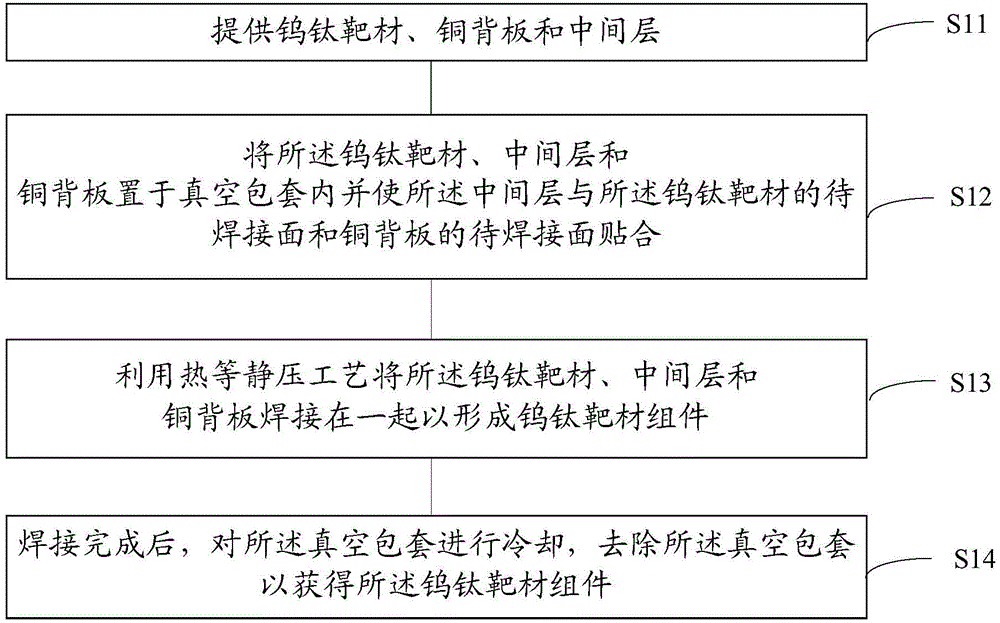

Welding method of target module

A welding method and component technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of fragile, long-term stable production and use of tungsten-titanium target components, large deformation, low welding strength, etc., to achieve Meet the effects of long-term stable production and use of target components, high welding strength and high welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

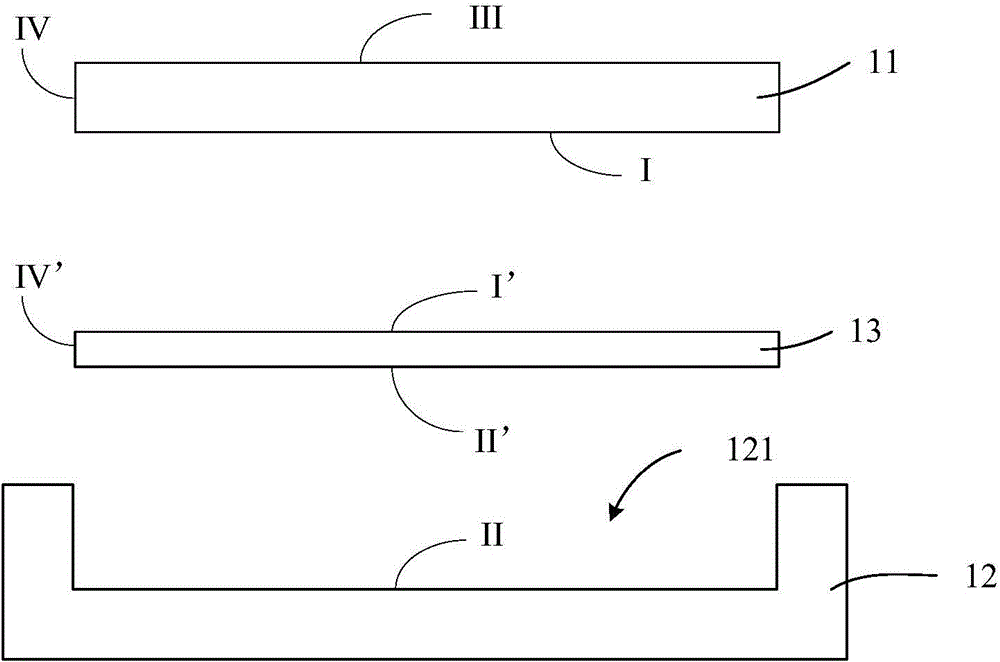

[0034] The technical problem to be solved by the present invention is that in the prior art, the target assembly formed by the tungsten-titanium target and the copper back plate has low welding strength and large deformation. In severe cases, the tungsten-titanium target is easily broken during the welding process, which cannot meet the long-term stable production and use of tungsten-titanium target components. The reasons are as follows:

[0035] High-purity tungsten-titanium targets have high hardness and poor toughness, and are fragile under high pressure. In the prior art, a brazing method is used to realize the welding of the tungsten-titanium target and the copper back plate. In the process of welding the above-mentioned tungsten-titanium target material and the copper backing plate, the expansion coefficient of the copper backing plate is high, and the expansion coefficient of the tungsten-titanium target material is low. Therefore, the cooling process after the welding i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com