Manufacturing method of touch screen metal wire

A manufacturing method and metal wire technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve problems such as poor undercut, short circuit of metal wires, glue rejection, etc., so as to improve etching speed and improve Good adhesion and climbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

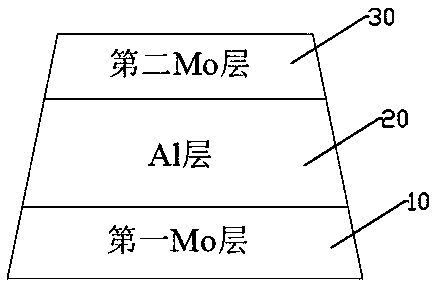

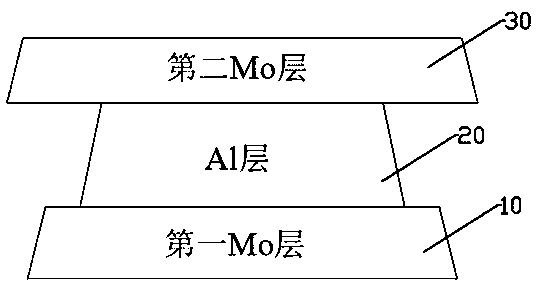

[0029] Such as figure 1 As shown, it is Embodiment 1 of the present invention. This specific embodiment provides a method for manufacturing a metal wire of a touch screen, and the method includes the following steps:

[0030] a. Argon is used as the working gas, oxygen is introduced into the sputtering system as the reaction gas, and the first Mo layer 10 (Mo1) is sputtered on the glass substrate;

[0031] Using argon as the working gas, sputtering the middle Al layer 20 on the first Mo layer 10;

[0032] Argon is used as the working gas, oxygen is introduced into the sputtering system as the reaction gas, and the second Mo layer 30 (Mo2) is sputtered on the middle Al layer 20;

[0033] B. adopt nitric acid-phosphoric acid-acetic acid system etchant to etch the sputtered Mo-Al-Mo layer;

[0034] Wherein, the ratio of oxygen gas and argon gas that is fed in when the second Mo layer is sputtered is equal to the ratio of oxygen gas and argon gas that is fed in when the second M...

Embodiment 2

[0052] The specific embodiment of the present invention provides a kind of manufacturing method of touch screen metal wire, and this manufacturing method comprises the following steps:

[0053] a. take argon as the working gas, feed oxygen into the sputtering system as the reaction gas, and sputter the first Mo layer 10 on the glass substrate;

[0054] Using argon as the working gas, sputtering the middle Al layer 20 on the first Mo layer 10;

[0055] Argon is used as the working gas, oxygen is introduced into the sputtering system as the reaction gas, and the second Mo layer 30 is sputtered on the middle Al layer 20;

[0056] b. using etchant to etch the sputtered Mo-Al-Mo layer;

[0057] Wherein, when sputtering the first Mo layer 10 and the second Mo layer 30 respectively, the volume flow rate of the oxygen gas that is passed into the sputtering system is 10 sccm (ml / min), and the volume flow rate of the argon gas that is passed into the sputtering system The volumetric f...

Embodiment 3

[0065] The difference from Example 2 is that the nitric acid-phosphoric acid-acetic acid system etching solution used in this example has a mass percentage of nitric acid less than 5%. For example, the mass percentages of nitric acid, acetic acid, and phosphoric acid are 4%, 5%, and 68%. According to this embodiment, the obtained cross-sectional scanning diagram of a touch screen metal wire is as follows: Figure 5 As shown, the structure of the metal line has a slight undercut phenomenon, and the distance from the second Mo layer 30 protruding from the middle Al layer 20 on one side is 450-600 nm.

[0066] Compared with the prior art, the first embodiment of the present invention has the following beneficial effects:

[0067] In the present application, when sputtering the first Mo layer and the second Mo layer respectively, oxygen gas is also passed into the sputtering system, so that the deposited first Mo layer and the second Mo layer contain molybdenum oxide, which not o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com