Method for welding Fe-Al intermetallic compound microporous material and welding part thereof

An intermetallic compound and welding method technology, which is applied in the field of welding and welding of Fe-Al intermetallic compound microporous materials and dense stainless steel, and welding of iron-aluminum-based intermetallic compound microporous materials. The mechanical properties of the joint and the discontinuity of the molten pool, etc., can achieve the effect of full and uniform welds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

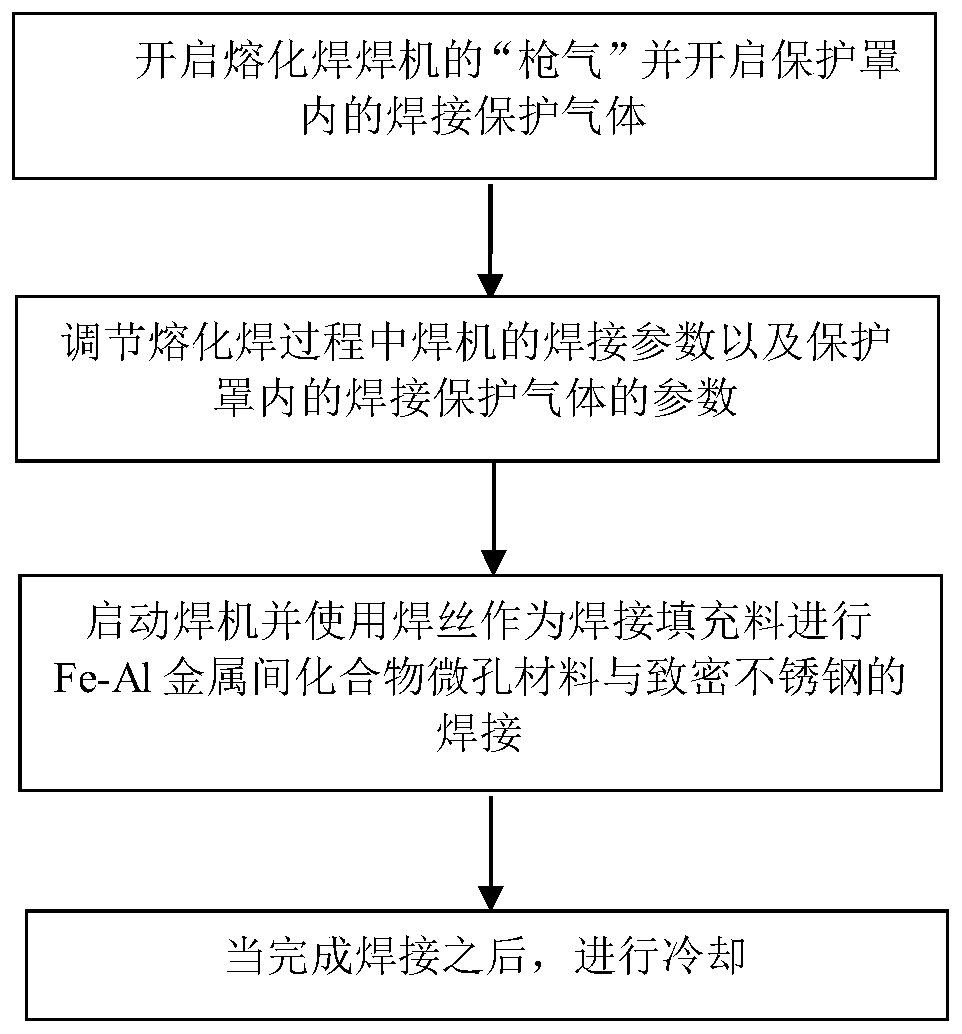

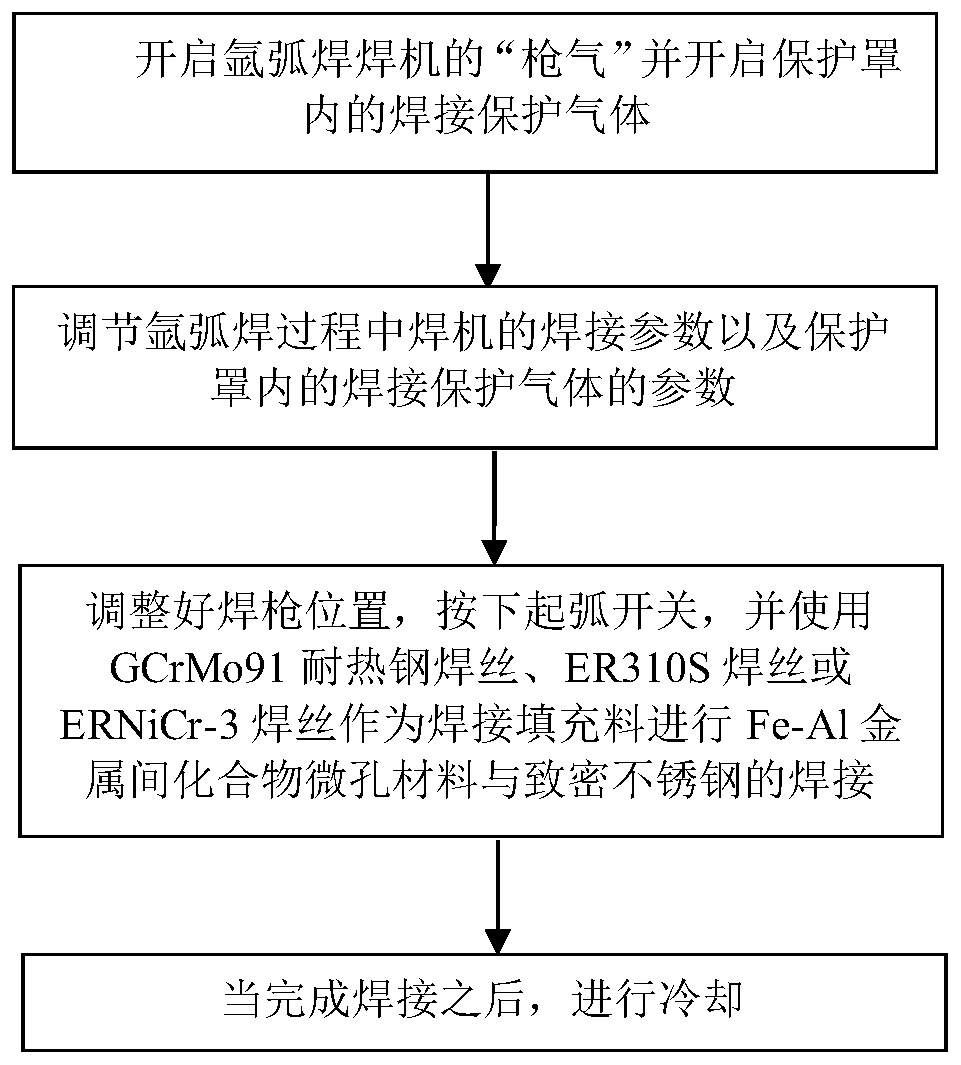

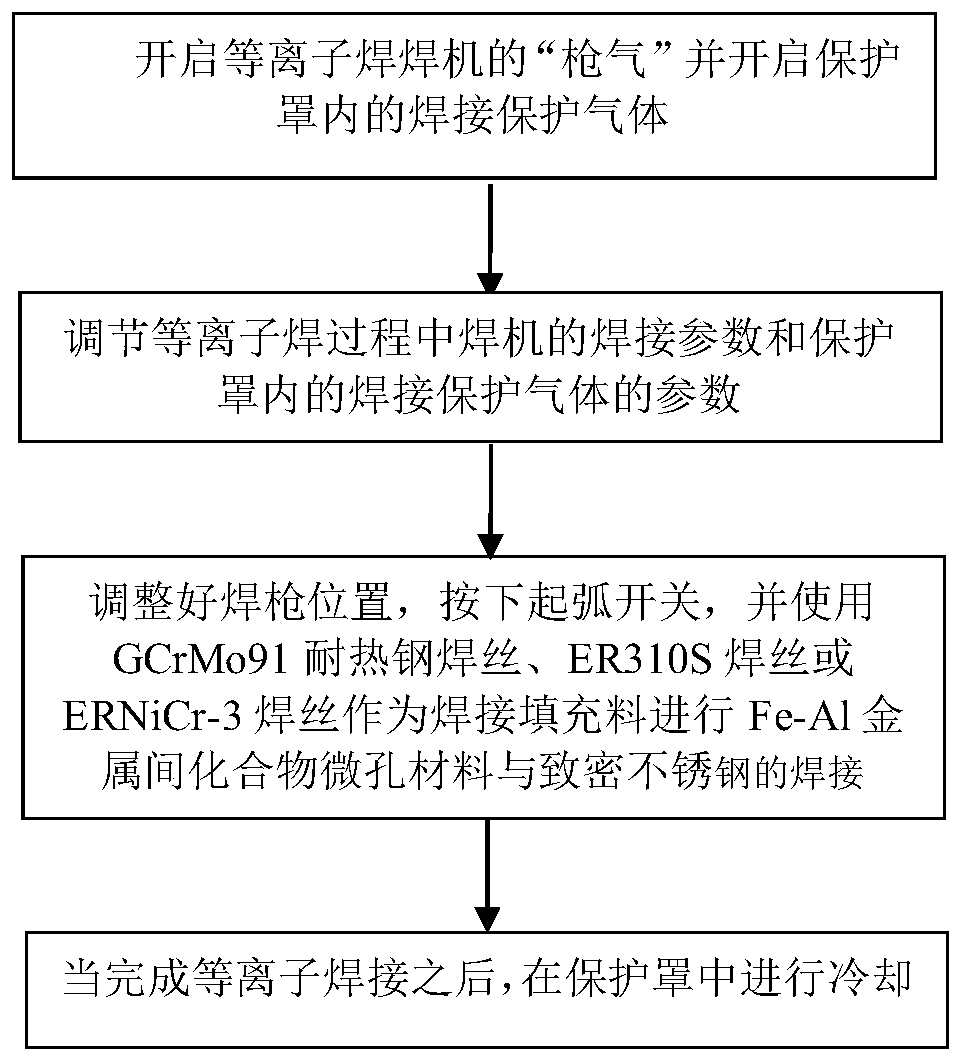

Method used

Image

Examples

example 1

[0037] Fe 3 Al intermetallic compound pipes and 310S stainless steel connecting rings are welded. The argon arc welding welding process parameters are: current 65A, voltage 12.4V, welding speed 150mm / min, argon flow rate 20L / min, protective cover argon flow rate 10-15L / min, the wire material is GCrMo91 (C<0.1%wt, Cr<8~10%wt, Mo<1%wt) heat-resistant steel wire as welding filler. The weld seam is full and uniform, without undercut, surface cracks, lack of meat, obvious weld bumps, internal cracks, inclusions and other defects. The welding tensile strength is 37MPa.

example 2

[0039] Fe 3 Al intermetallic compound pipes and 310S stainless steel connecting rings are welded. The welding process parameters of argon arc welding are: current 70A, voltage 12.4V, welding speed 180mm / min, argon gas flow rate 20L / min, protective cover argon gas flow rate 10-15L / min, the welding wire material uses ER310S welding wire as welding filler. The weld seam is full and uniform, without undercut, surface cracks, lack of meat, obvious weld bumps, internal cracks, inclusions and other defects. The welding tensile strength is 39MPa.

example 3

[0041] Fe 3 Al intermetallic compound pipes and 304 stainless steel connecting rings are welded. The argon arc welding welding process parameters are: current 75A, voltage 12.4V, welding speed 210mm / min, argon gas flow rate 20L / min, protective cover argon gas flow rate 10-15L / min, the wire material uses ERNiCr-3 wire as the welding filler. The weld seam is full and uniform, without undercut, surface cracks, lack of meat, obvious weld bumps, internal cracks, inclusions and other defects. The welding tensile strength is 36MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com