Pole core assembling mechanism for automatic production of lithium battery

An assembly mechanism and lithium battery technology, which is applied in primary batteries, assembled battery machines, electrochemical generators, etc., can solve the problems of material waste processing, positive electrode film, separator, and negative electrode film are prone to dislocation and elongation, and achieve improved The effect of processing efficiency, avoiding shedding, and avoiding misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

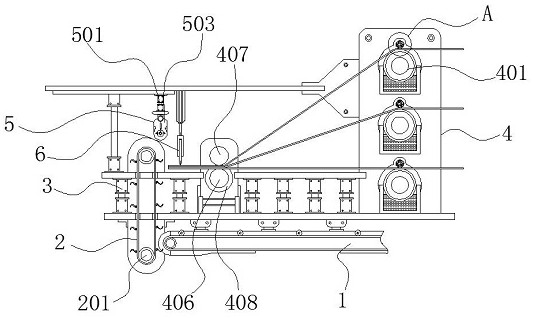

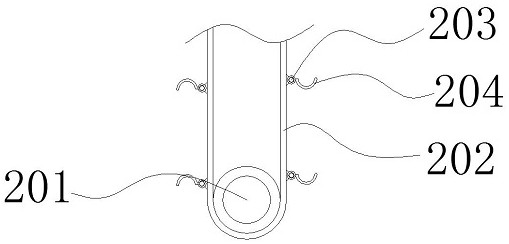

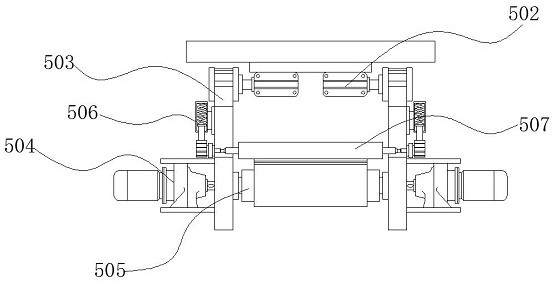

[0054] Such as Figure 1-2 As shown, a pole core assembly mechanism for automatic production of lithium batteries includes: a conveyor belt 1; the conveyor belt 1 is used to transport and load containers filled with battery fluid; The left side of the transmission belt 1; the assembly platform 3, the assembly platform 3 is arranged on the top of the transmission belt 1; the feeding mechanism 2 includes: the motor wheel 201, the motor wheel 201 is a roulette with the motor as the power source; the feeding belt 202, The feeding belt 202 is connected to the outside of the motor wheel 201; the torsion spring 203, and the torsion spring 203 is arranged on the surface of the feeding belt 202; It forms an elastic structure with the feeding belt 202, and the torsion spring 203 is equidistantly distributed on the surface of the feeding belt 202, and the supporting piece 204 forms a loop structure through the feeding belt 202 and the motor wheel 201, and the supporting piece 204 It is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com