Diamond grinding wheel and preparation method thereof

A diamond grinding wheel and diamond technology, used in metal processing equipment, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of variability of abrasive tools, low life of diamond grinding wheels, low grinding efficiency, etc., to reduce damage, The effect of reducing processing cost and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

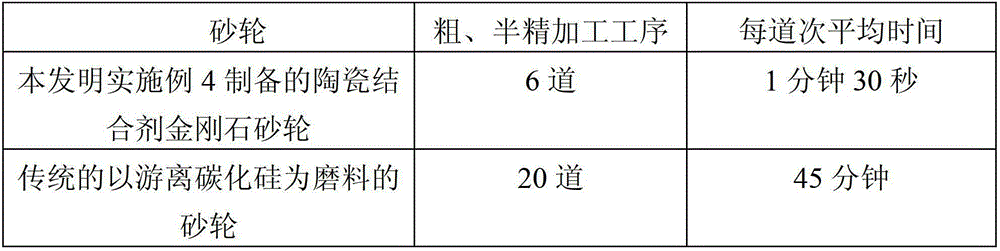

Examples

preparation example Construction

[0029] The preparation method of the above-mentioned vitrified bond is to mix the above-mentioned raw materials evenly, melt at 1300°C for 100 minutes, water quench, crush, dry, and sieve to obtain a fine vitrified bond of 200 mesh or more.

[0030] The vitrified bond diamond grinding wheel provided by the present invention comprises a substrate and a grinding block. The raw material of the grinding block contains the above-mentioned vitrified bond, and also includes diamond abrasives and fillers. The vitrified bond, diamond abrasives and fillers are collectively referred to as powder crystals. The raw material of the grinding block can also include a pore-forming agent and a temporary bonding agent. The pore-forming agent and the temporary bonding agent are additional additives, which can be used as pore-forming and forming aids. Most of the time, the pore-forming agent is fired And the temporary binder will volatilize or burn away. The matrix may be a steel matrix, an aviati...

Embodiment 1

[0046] Raw material ratio of vitrified bond: SiO 2 : 40wt%, Al 2 o 3 : 12wt%, B 2 o 3 : 20wt%, Na 2 O: 10wt%, CaF 2 : 12wt%, Li 2 O: 5wt%, TiO 2 : 1wt%;

[0047] The preparation method of the above-mentioned vitrified bond: mix the above-mentioned raw materials evenly according to the proportion, then melt at 1300°C for 100 minutes, water quench, crush, dry, and sieve to obtain a vitrified bond with a particle size of no more than 75 μm (screened with a 200-mesh sieve) .

Embodiment 2

[0049] Raw material ratio of vitrified bond: SiO 2 : 45wt%, Al 2 o 3 : 9wt%, B 2 o 3 : 20wt%, Na 2 O: 8.5wt%, CaF 2 : 11wt%, Li 2 O: 5wt%, TiO 2 : 1.5wt%;

[0050] The preparation method of the above-mentioned vitrified bond is the same as in Example 1, and the particle size of the obtained vitrified bond is not greater than 75 μm.

[0051] Several examples of the vitrified bond diamond grinding wheel of the present invention and the preparation method thereof are enumerated below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com