High-precision electron beam radiation field stop block

An electron beam, high-precision technology, applied in auxiliary welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of long molding time, cumbersome post-finishing, and high technical level requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

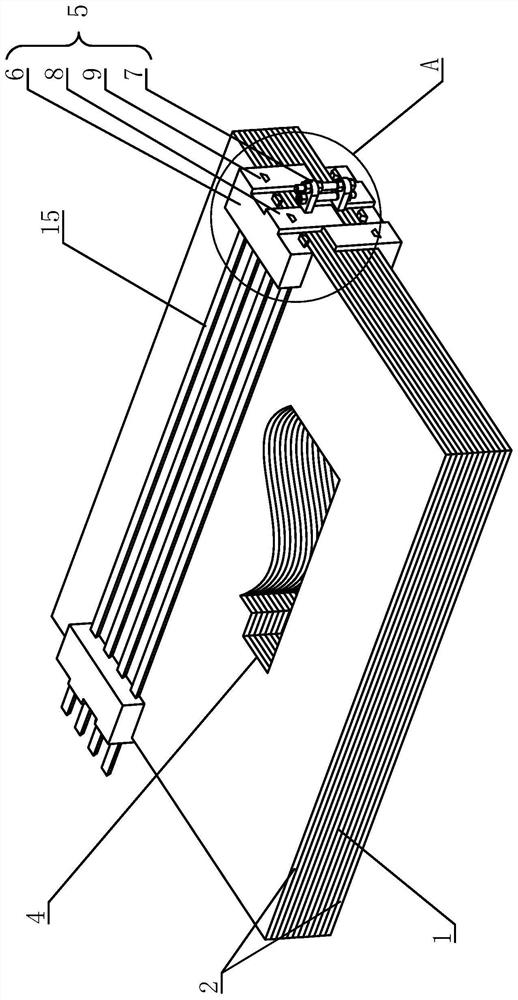

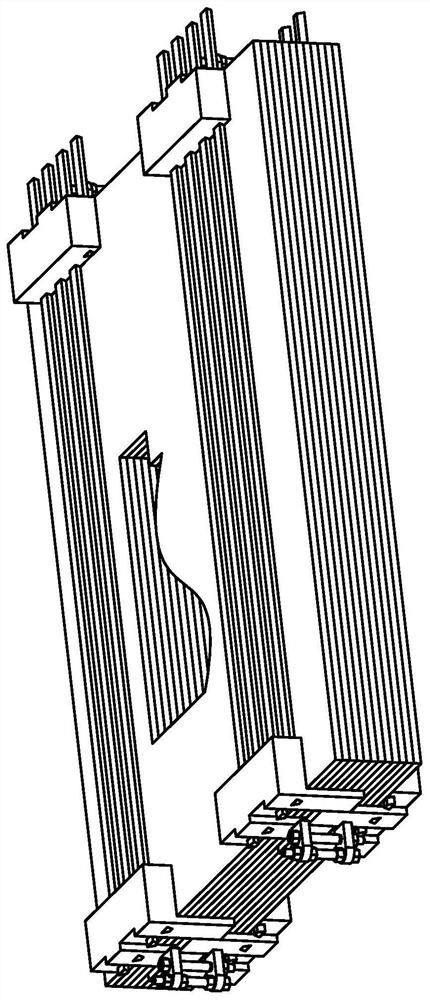

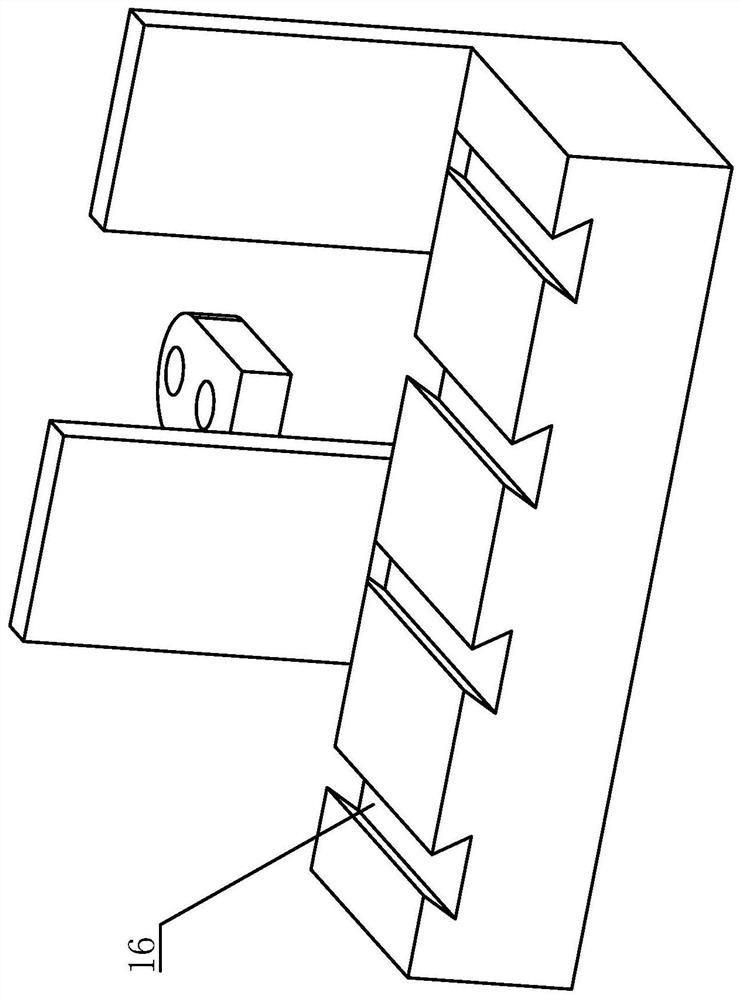

Image

Examples

Embodiment

[0027] Manufacturing method of traditional electron beam field stopper (lead window)

[0028] 1) Converted to the ratio of the lower edge of the electron beam line tube, draw or print the outline of the irradiation area on the planning sheet or DRR map on paper to form a foam positive mold outline template for the electronic field stopper

[0029] 2) Cutting and forming on the electronic wire manual or automatic hot wire cutting machine

[0030] 3) Put the above foam male mold on the electronic stopper mold, stack it and fix it for low melting point lead pouring

[0031] 4) After the casting is cooled, it is trimmed and polished, and the identification mark is made

[0032] 5) Quality Verification

[0033] In the traditional scheme, the field stopper is formed by flip casting. Whether it is the steam formed by melting lead or the powder formed by the later modification of the field stopper, it will be harmful to the human body. In addition, the precision of the reverse mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com