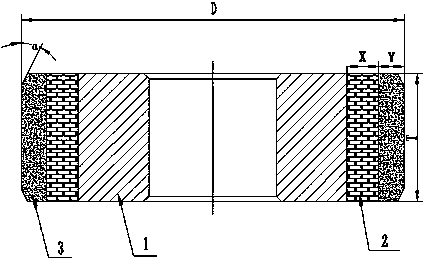

Grinding wheel applied to coaxiality grinding of ceramic ferrule and preparation method thereof

A ceramic ferrule and concentricity technology, which is applied in the direction of grinding/polishing equipment, grinding devices, abrasives, etc., can solve the problems of high frequency of thimble breakage, broken wires, high production costs, etc., to ensure the consistency of coaxiality , avoid broken needle or thread, increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A preparation method for a grinding wheel applied to ceramic ferrule coaxiality grinding, comprising the steps of:

[0043] (1) Add the diluted modified phenolic resin solution, zirconia hollow microspheres and calcium fluoride to ethyl acetate at a mass ratio of 1:20:30, and the mass of ethyl acetate is the diluted modified phenolic resin solution , 5 times the total weight of zirconia hollow microspheres and calcium fluoride, stirred in a water bath at 50°C for 3 hours, and added 45wt% sodium chloride solution (the amount of sodium chloride solution was diluted modified phenolic 5 times the total weight of the resin solution, zirconia hollow microspheres and calcium fluoride), heated at 80°C for 60 minutes to obtain a dry block mixture, according to the mass ratio of block mixture and modified polyimide resin 1:2 Add modified polyimide resin, ball mill, and pass through a 100-mesh sieve to obtain a binder, wherein the diluted modified phenolic resin solution refers to a...

Embodiment 2

[0048] A preparation method for a grinding wheel applied to ceramic ferrule coaxiality grinding, comprising the steps of:

[0049] (1) Add the diluted modified phenolic resin solution, zirconia hollow microspheres and calcium fluoride to ethyl acetate at a mass ratio of 1:20:30, and the mass of ethyl acetate is the diluted modified phenolic resin solution , 3 times the total weight of zirconia hollow microspheres and calcium fluoride, stirred in a 90°C water bath for 1 hour, and added 50wt% sodium chloride solution (the amount of sodium chloride solution was diluted modified phenolic 8 times the total weight of the resin solution, zirconia hollow microspheres and calcium fluoride), heated in a water bath at 75°C for 90 minutes to obtain a block mixture, and added according to the mass ratio of block mixture and modified polyimide resin 1:1.5 Modified polyimide resin, ball milled, passed through a 1200-mesh screen to obtain a binder, wherein the diluted modified phenolic resin ...

Embodiment 3

[0054] A preparation method for a grinding wheel applied to ceramic ferrule coaxiality grinding, comprising the steps of:

[0055] (1) Add the diluted modified phenolic resin solution, zirconia hollow microspheres and calcium fluoride to the mass fraction of ethyl acetate at a mass ratio of 1:18:32 (the mass of ethyl acetate is the diluted modified phenolic resin 8 times the total weight of the resin solution, zirconia hollow microspheres and calcium fluoride), stirred in a water bath at 70°C for 2 hours, and added 40wt% sodium chloride solution (the amount of sodium chloride solution was diluted The modified phenolic resin solution, zirconia hollow microspheres and calcium fluoride are twice the total weight)), heated in a water bath at 85°C for 45 minutes to obtain a dry block mixture, according to block mixture and modified polyimide The resin mass ratio is 1:2, adding modified polyimide resin, ball milling, and passing through a 100-mesh screen to obtain a binder, wherein ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com