Method and system for producing hybrid composite parts

A composite material, production method technology, applied in the direction of coating, etc., can solve problems such as increasing manufacturing time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

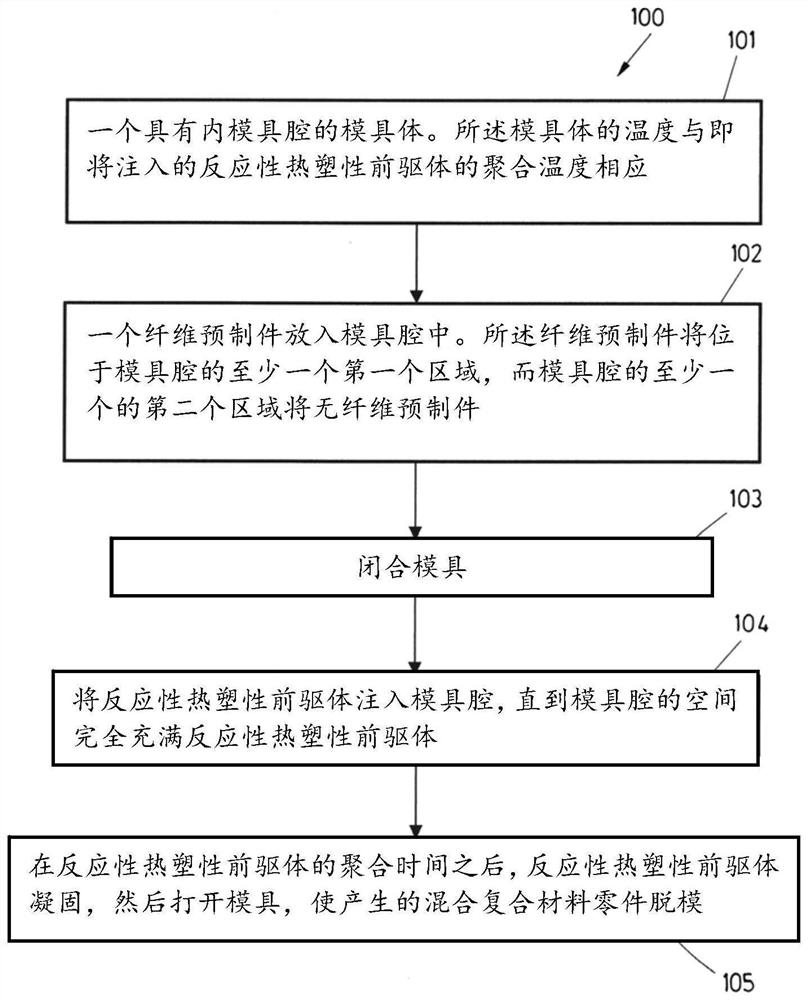

[0050] figure 1 A flow diagram of a method 100 for producing a hybrid composite part using a particular apparatus according to the present invention is shown.

[0051] In step 101 of method 100, a mold body having an inner mold cavity is provided. The temperature of the mold body corresponds to the polymerisation temperature of the reactive thermoplastic precursor to be injected. The mold cavity in the mold body is defined by the inner mold walls. In some examples, the reactive thermoplastic precursor may be polymerized at room temperature, while in other examples, the polymerization temperature will be above room temperature. The geometry of the mold cavity will define the shape and geometry of the resulting molded part. For example, the mold body includes an upper mold and a lower mold. The mold body contains heating cylinders, other heating devices, which are inserted into it and distributed in the mold body.

[0052] In step 102 of method 100, a fiber preform is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com