Numerical control workbench for ultra-high-pressure water cutting machining

A technology of ultra-high pressure water cutting and workbench, which is applied in the direction of metal processing equipment, manufacturing tools, used abrasive processing devices, etc. It can solve the problems of difficult repair, poor versatility, and long manufacturing cycle, etc., and achieves convenient clamping and positioning , reduce R&D costs, and have a long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

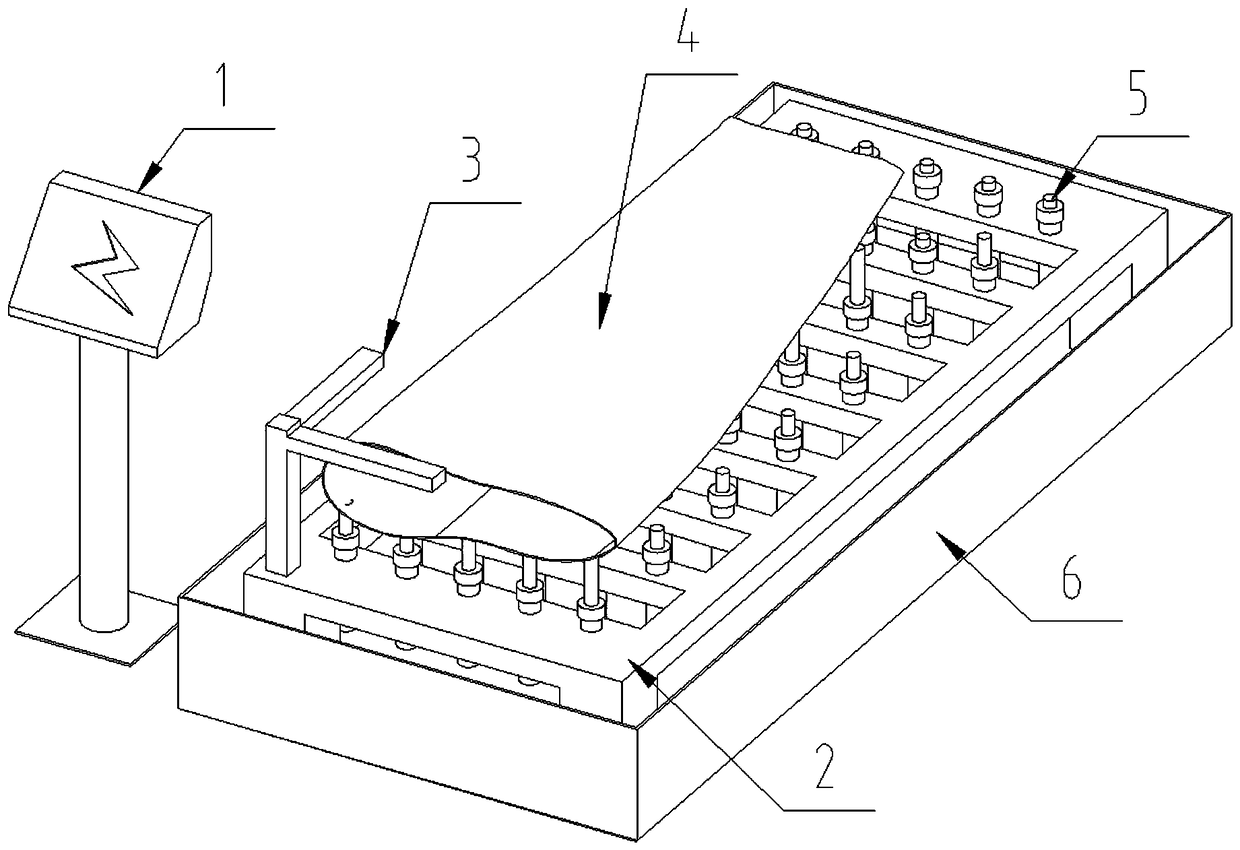

[0017] A numerical control workbench for ultra-high pressure water cutting processing, comprising an electric control cabinet 1, a platform 2, a reference scale 3, a plurality of electric cylinders 5 with position sensors on piston rods, and a water tank 6, and is characterized in:

[0018] The water tank 6 is arranged horizontally, the platform 2 is installed inside the water tank 6, the working surface of the platform 2 is a hollow shape, a plurality of electric cylinders 5 are evenly installed on the platform 2 in a lattice manner, and the electric cylinder 5 is fixed by a frame structure. The reference ruler 3 is a bracket composed of three two-by-two vertical straight rods. Each straight rod of the reference ruler 3 is equipped with a grating ruler. The reference scale 3 is installed on the set position of the working surface of the platform 2. The electric control cabinet 1 is installed on the left side of the water tank 6.

[0019] The electric cylinder 5 is made of stainle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com