Method for production of high-strength threaded steel bar through on-line quenching and tempering, and heating blackening coating processes

A threaded steel bar and coating process technology, applied in heat treatment furnaces, manufacturing tools, heat treatment equipment, etc., can solve problems such as inability to complete coating anti-corrosion treatment, insufficient quenching and heat preservation time, high rolling heating temperature, etc., to achieve mechanical properties and The effect of anti-corrosion requirements, stable product quality, and high toughness level index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The weight percentages used are: C: 0.37%, Si: 0.3%, Mn: 0.8%, Cr: 0.8%, Mo: 0.25%, P: 0.035%, S: 0.002%, and the balance is a steel rod of Fe.

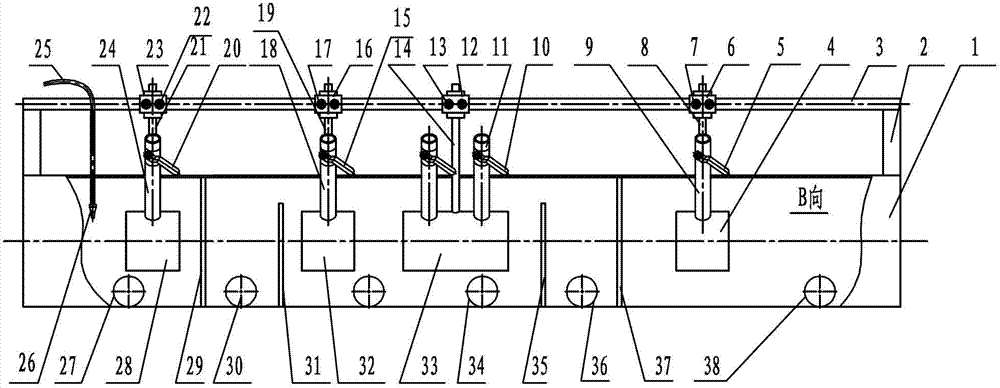

[0033] The threaded steel bar formed after the steel bar is peeled and rolled is subjected to 3-stage induction quenching heating, that is, 3 induction heaters are used, the first 2 induction heaters are used for preheating heating, and the last induction heater is used for heat preservation heating. Control the temperature of the threaded steel bars in the quenching preheating zone to 700~750°C, and control the temperature of the threaded steel bars in the latter one of the two preheating induction heaters to be 50°C higher than that in the previous one (that is, the first and second sets The temperatures of the rebars in the preheated induction heaters were 700°C and 750°C, respectively). The temperature of the threaded steel bar in the quenching and heat preservation zone is 820~850°C, the time for the threaded steel bar to...

Embodiment 2

[0035] The weight percentages used are: C: 0.39%, Si: 0.35%, Mn: 0.65%, Cr: 1.08%, Mo: 0.25%, P: 0.025%, S: 0.035%, and the balance is a steel rod of Fe.

[0036] The threaded steel bar formed after the steel bar is peeled and rolled is subjected to 5-stage induction quenching heating, that is, 5 induction heaters are used, the first 4 induction heaters are used for preheating heating, and the last induction heater is used for heat preservation heating. Control the temperature of the threaded steel bars in the quenching preheating zone to 700~850°C, and control the temperature of the threaded steel bars in the latter set of 4 preheating induction heaters to be 50°C higher than that in the previous set (that is, the first set and the second set , 3rd and 4th preheating induction heaters, the temperatures of the rebars are 700°C, 750°C, 800°C and 850°C, respectively). The temperature of the threaded steel bars in the quenching and heat preservation zone is 850-870 °C, and the ti...

Embodiment 3

[0038] The weight percentages used are: C: 0.45%, Si: 0.17%, Mn: 0.69%, Cr: 1.17%, Mo: 0.22%, P: 0.014%, S: 0.014%, and the balance is a steel rod of Fe.

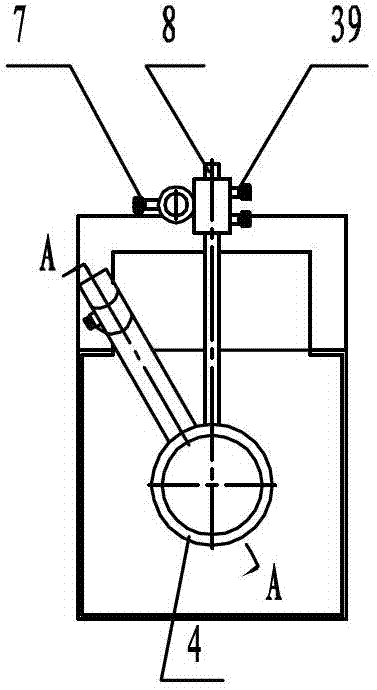

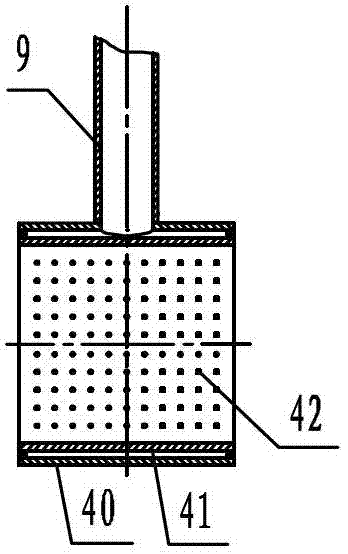

[0039] The threaded steel bars formed by peeling and rolling the steel bars are subjected to 6-level induction quenching heating, that is, 6 induction heaters are used, the first 4 induction heaters are used for preheating, and the last 2 induction heaters are used for heat preservation. Control the temperature in the quenching preheating zone to 800-850°C, the temperature in the quenching and holding zone to 850-910°C, and the time for the threaded steel bars to pass through the quenching and holding zone is 12 minutes. The speed of quenching and heating is 0.2m / min, and the threaded steel bar enters the graded spray ring for cooling within 25s after coming out of the quenching and heat preservation zone, and performs quenching treatment, cooling at a cooling rate of 70°C / s, and the temperature of the spray ring cooling dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com