Patents

Literature

44results about How to "Uniform and beautiful appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

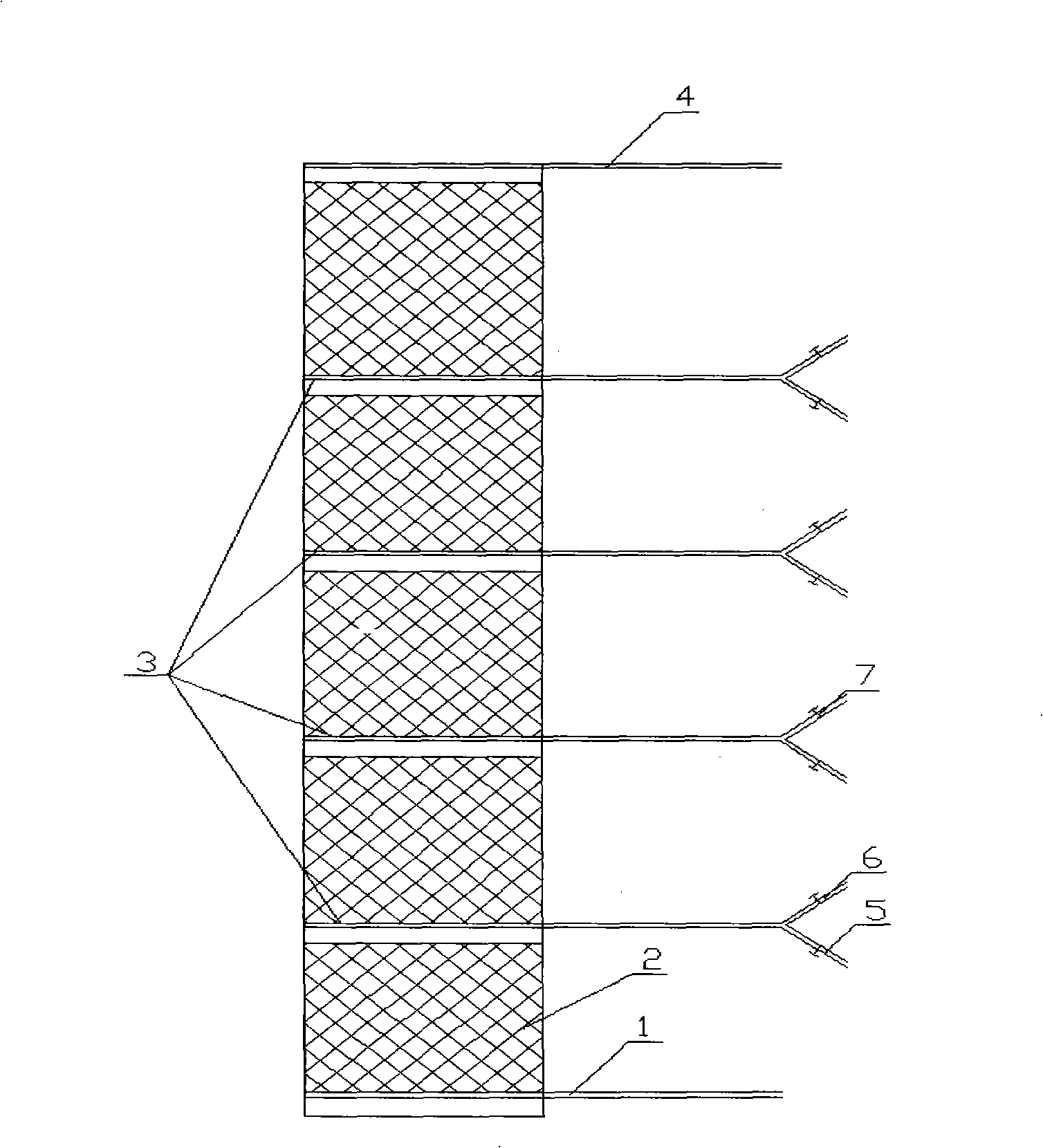

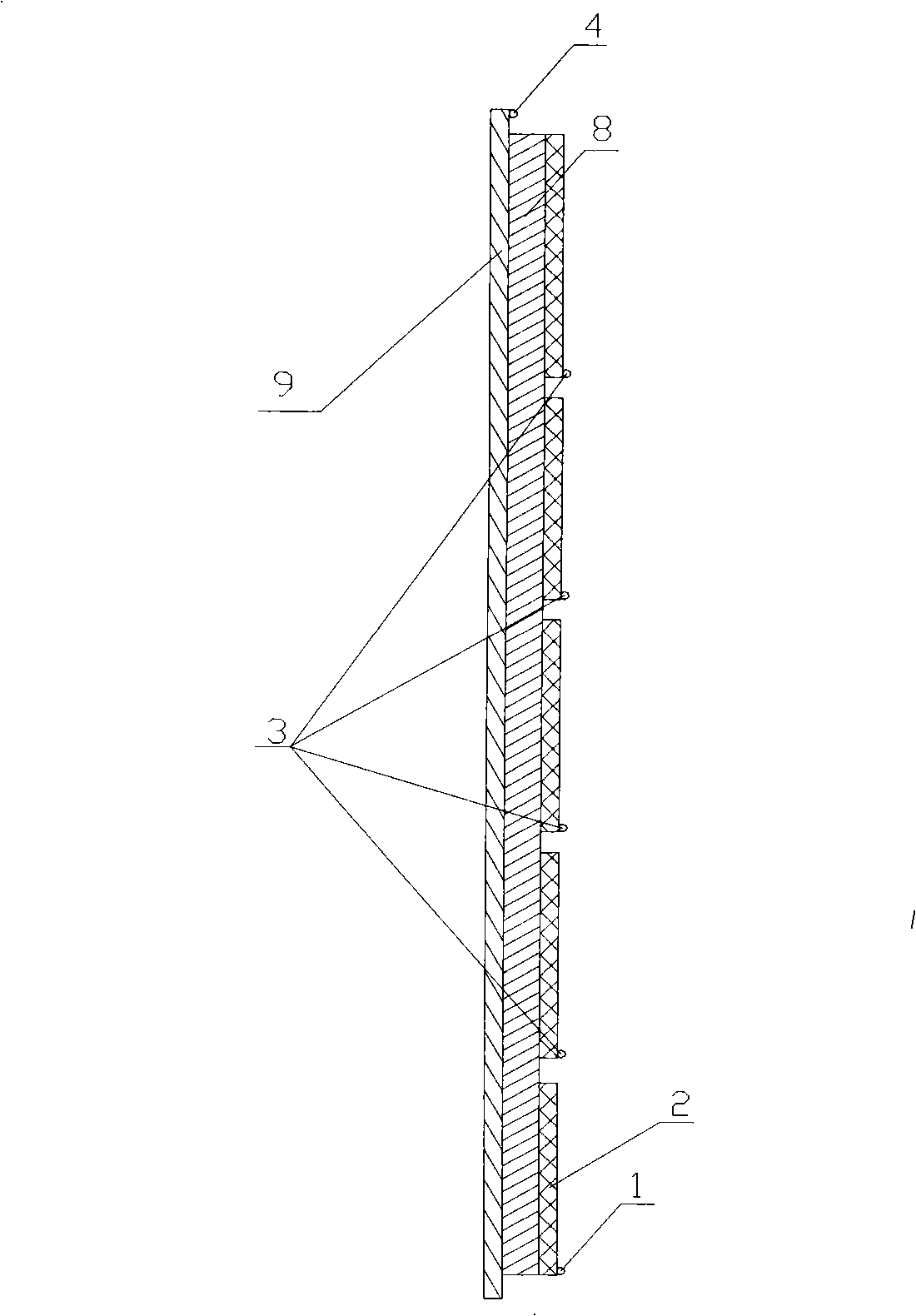

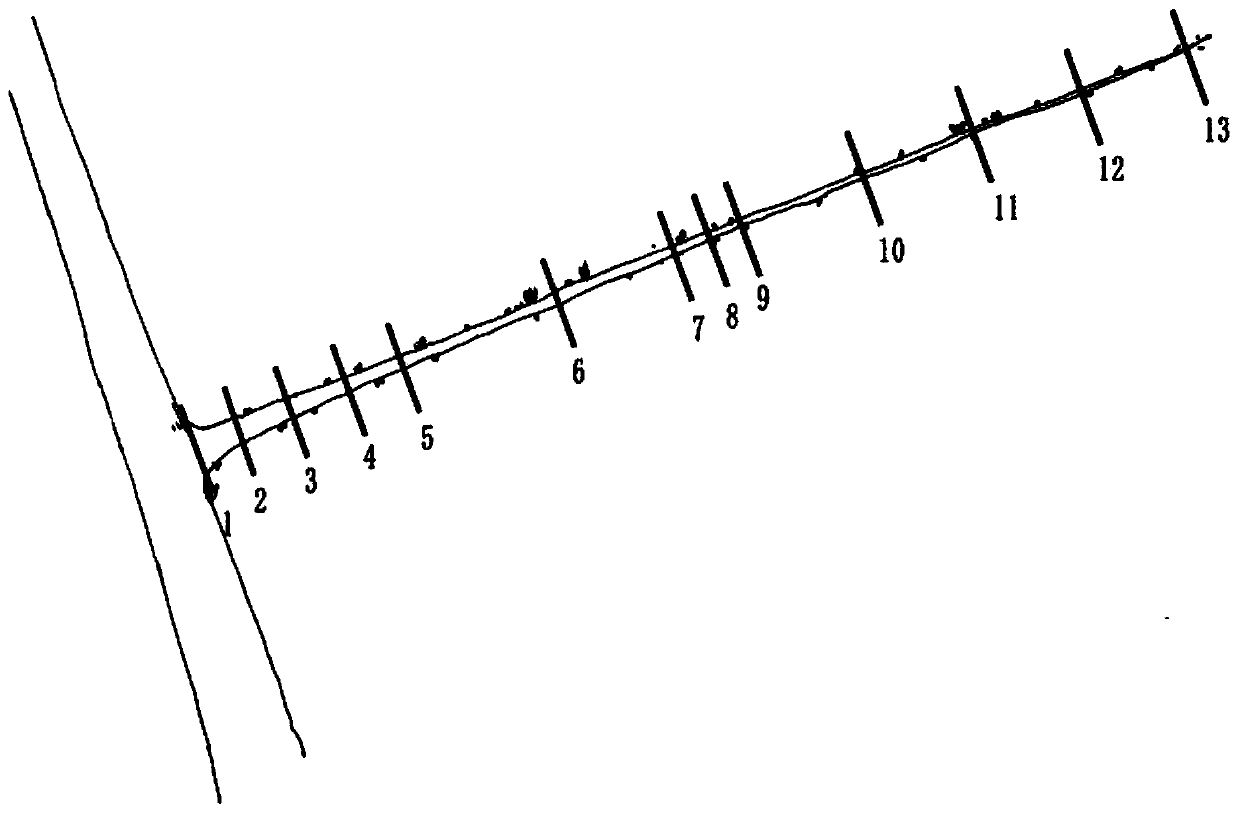

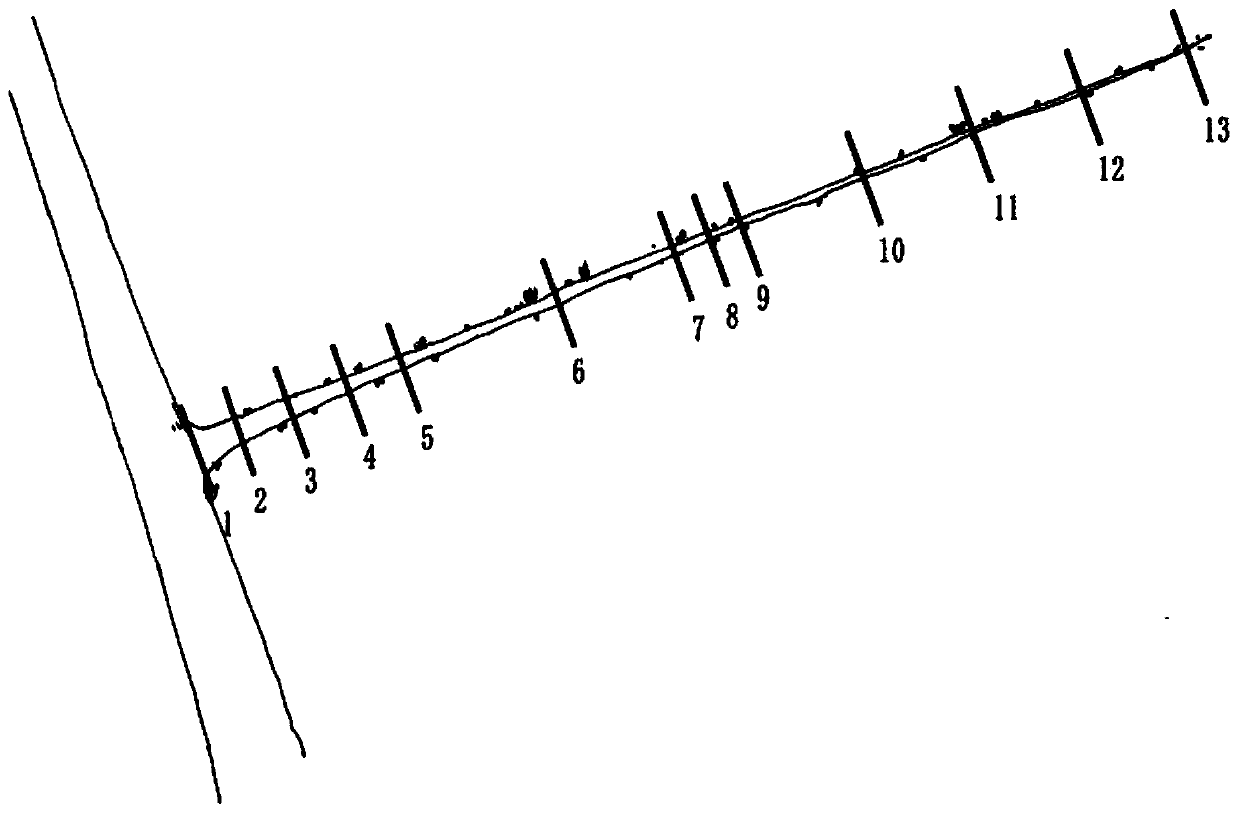

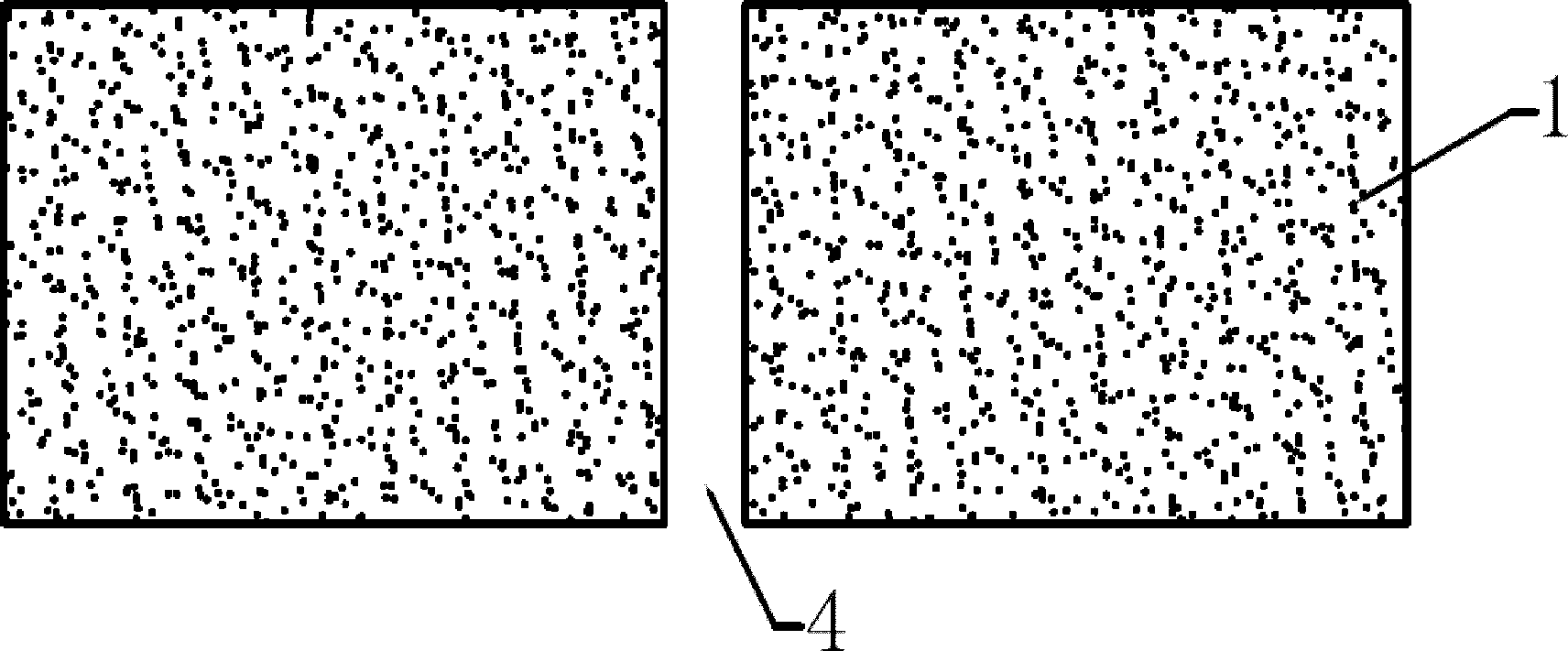

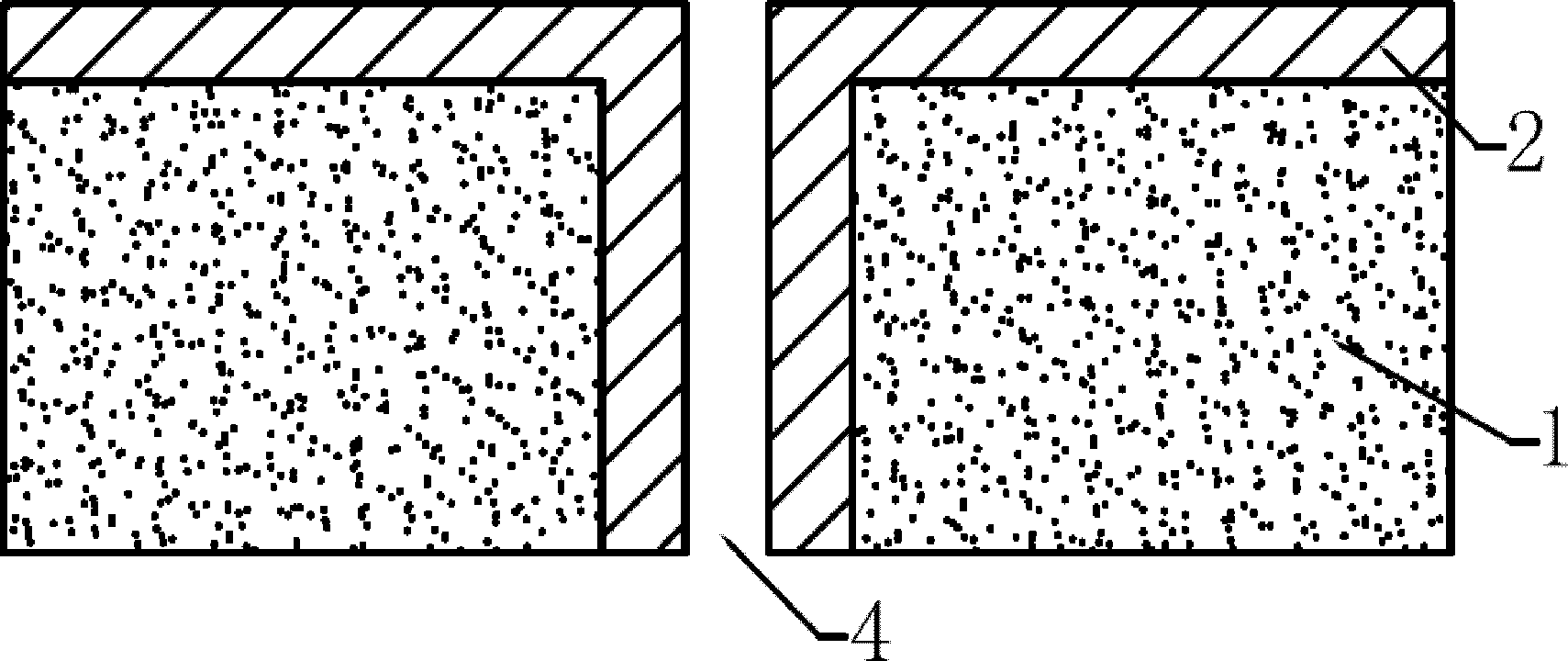

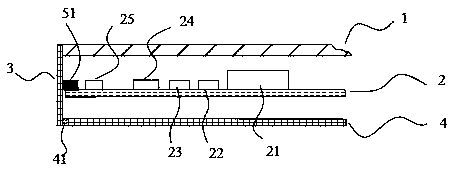

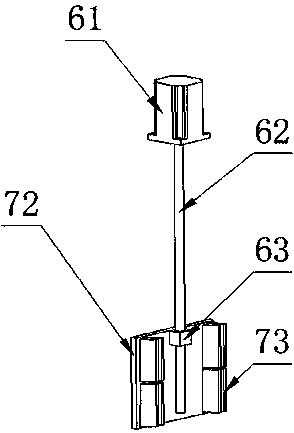

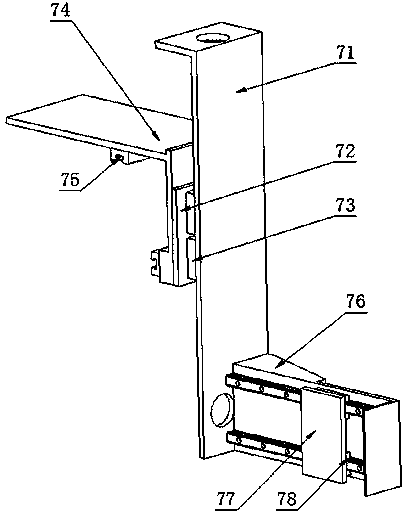

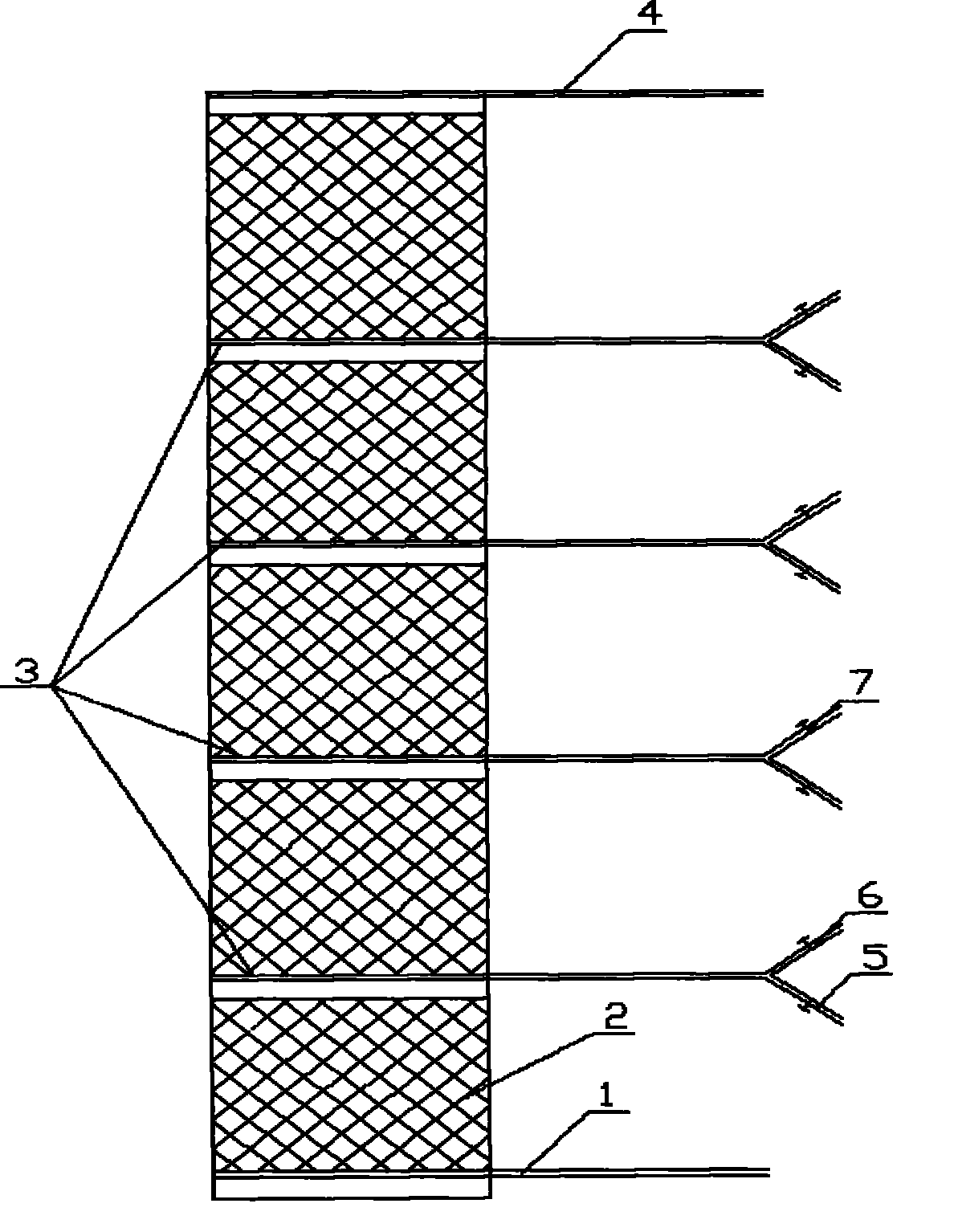

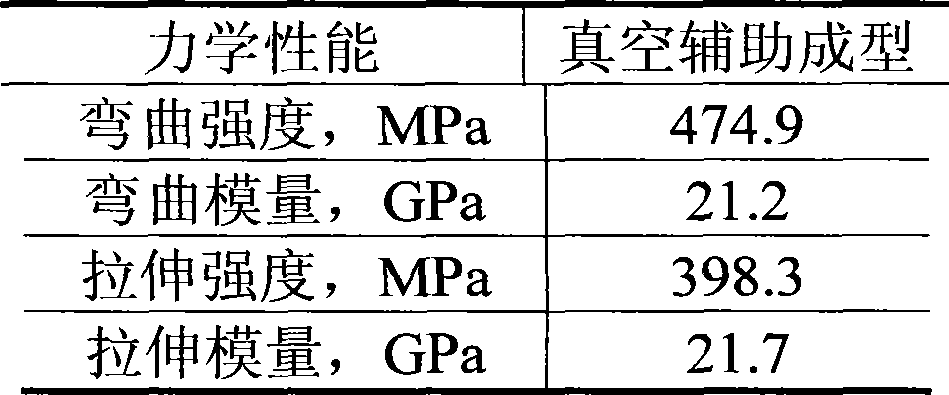

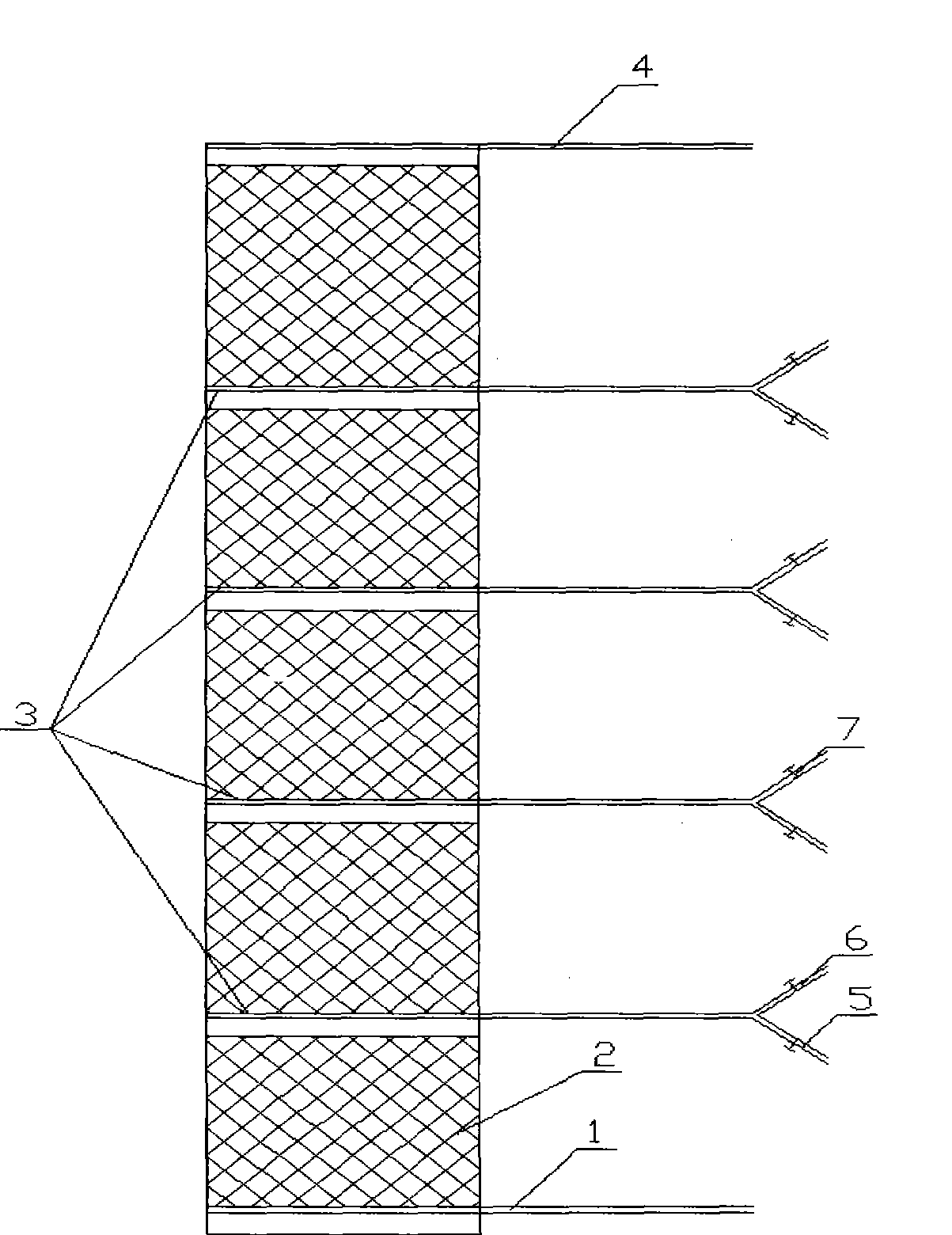

Vacuum auxiliary molding technique produced by high-facade composite material for ship

The invention discloses a vacuum assistant resin infused method for molding a high elevation part of composite materials used on ship and comprises the working procedures of raw material preparation, forming process, etc. The invention is characterized in that in the forming process, the direction of a resin channel is the same as the height direction of the product; a plurality of glue-injection pipes or exhaust pipes parallel to the width direction of the product are arranged in the height direction of the product; the product is divided into a plurality of forming units by the glue-injection pipes or exhaust pipes in the height direction; the distance between the edge of permeable medium and the glue-injection pipes or exhaust pipes is controlled and each unit comprises a flood protection material system of stream guidance, glue injection and gas exhaust, and the like; in the forming process, each unit is immersed successively from bottom to top in a relay style. The invention is used for molding the high elevation part of composite materials used on ship, increases the penetration degree and uniformity of the resin, raises the product quality, and gives good mechanical and sea-water proof property to the product with greatly reduced weight, thereby improving the loading capacity and ample stability of the operation platform on water surface and under water.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Aluminum alloy strip for LED (Light-Emitting Diode) back plate and manufacturing method thereof

The invention discloses an aluminum alloy strip for an LED (Light-Emitting Diode) back plate and a manufacturing method thereof. The strip comprises the following components in percentage by weight: 0.10-0.30 percent of iron, 0.05-0.12 percent of silicon, 0.01-0.04 percent of copper, 0.01-0.04 percent of manganese, 0.12-0.18 percent of chromium, 1.85-2.15 percent of magnesium, 0.010-0.030 percent of titanium and the balance of aluminum. The components are subjected to cast-rolling, cold rolling, washing, annealing, shearing and the like, so that the problems of poor surface quality, plate shape quality, poor mechanical performance and the like of the aluminum alloy strip for the conventional LED back plate are solved.

Owner:JIANGSU ALCHA ALUMINUM CO LTD

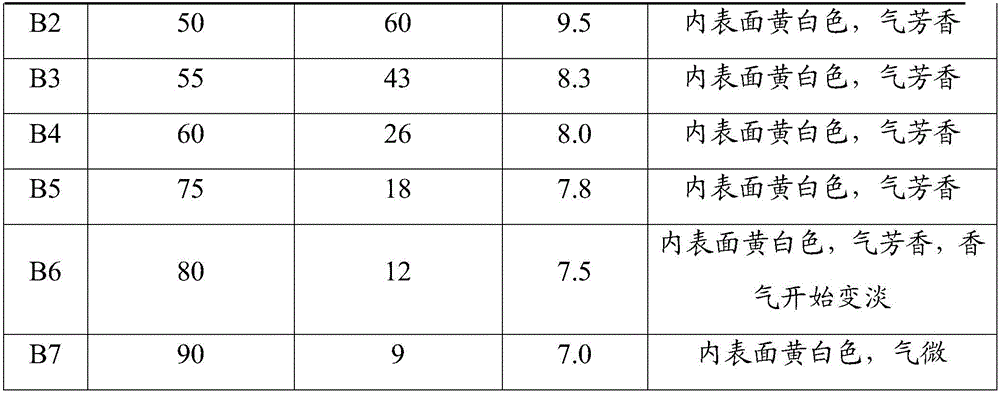

Pummelo peel decoction pieces as well as processing method and application thereof

ActiveCN105726723ABeautiful appearanceUniform and beautiful appearanceRespiratory disorderPlant ingredientsBULK ACTIVE INGREDIENTActive ingredient

The invention relates to pummelo peel decoction pieces as well as a processing method and application thereof. The processing method of the pummelo peel decoction pieces comprises the following steps: (1) performing choosing, classification and impurity removal; (2) cleaning; (3) performing water removal and cutting; and (4) drying. The processing method provided by the invention shortens the production and processing cycle, improves the production efficiency, reduces the production cost, reduces the loss of active ingredients in medicinal materials at the same time, and improves the quality stability, and the decoction pieces are more beautiful and uniform in appearance.

Owner:GUANGZHOU XIANGXUE PHARMA CO LTD +1

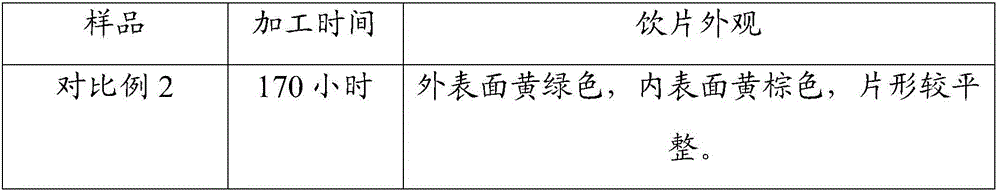

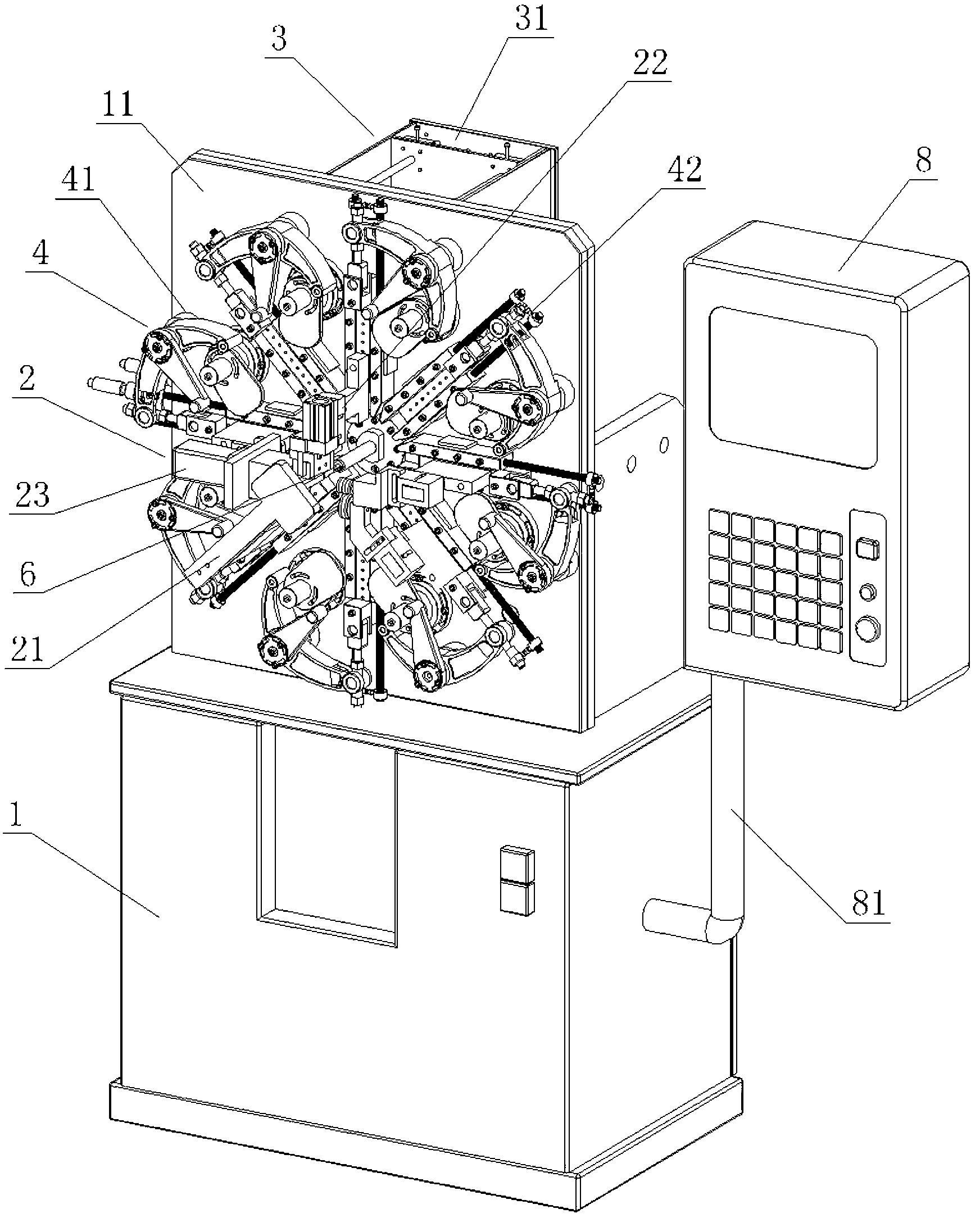

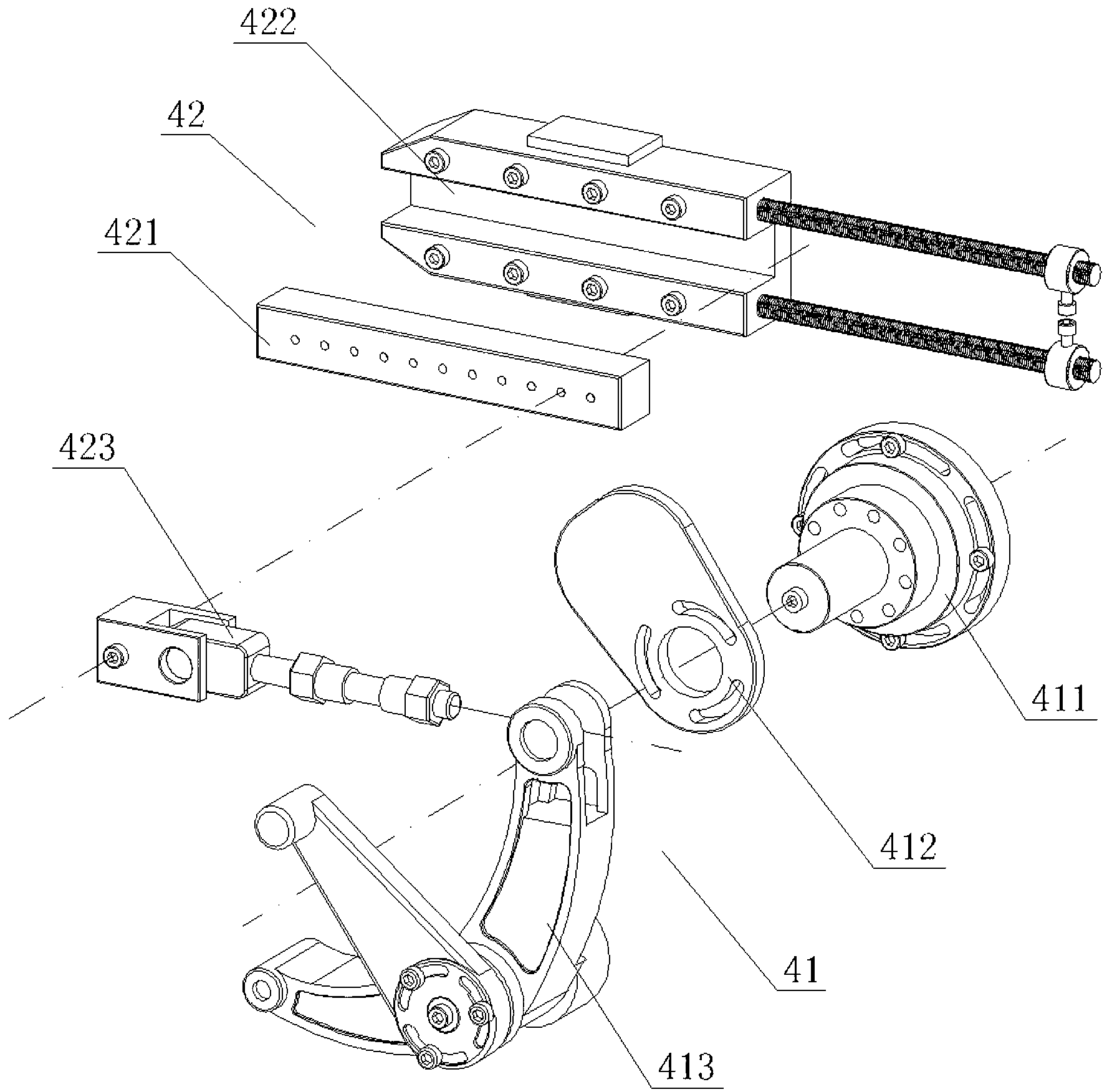

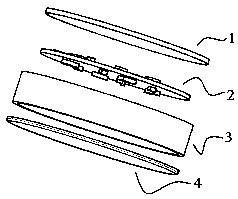

Heat pipe bending machine

InactiveCN103223429AStrong applicabilityImprove machining accuracyMetal-working feeding devicesPositioning devicesAutomatic controlEngineering

The invention provides a heat pipe bending machine. The heat pipe bending machine comprises a baseframe, a feeding device and a bending device, and is characterized in that a vertical seat board is arranged at the upper part of the baseframe; the feeding device is arranged behind the vertical seat board; a plurality of transmission connection mechanisms are arranged in front of the vertical seat board; the bending device is selectively mounted on the transmission connection mechanisms, so that a heat pipe can be bent into different shapes to meet the customer demands and to achieve strong applicability; and a motor is arranged in the baseframe and used for driving the feeding device to convey the heat pipe to the front end of the vertical seat board and further driving the transmission connection mechanism to act so as to bend the heat pipe via the bending device, so that the heat pipe can be repeatedly bent into the required shapes in one-step transportation. The heat pipe bending machine achieves automatic control of the whole process, is high in machining precision, and is provided with a control device used for controlling the reducing direction of the heat pipe, so that the two reducing ends of the bent heat pipe face to the inner side, accordingly, unified and attractive appearance is obtained, and customer demands are met. The heat pipe bending machine is widely applied to the heat pipe bending technology.

Owner:游本俊

Pruning method capable of promoting walnut tree internal branching

InactiveCN110012768AAvoid pruningEasy to manage in the fieldCultivating equipmentsFruit treeMain branch

The invention provides a pruning method capable of promoting walnut tree internal branching. The method includes: dividing to-be-pruned objects into annual young trees, biennial young trees, triennialyoung trees, quadrennial first-fruiting trees, fruiting big trees more than five years old and perennial scattered trees according to tree ages; according bud features and culture targets, determining a plurality of pruning parts on a complete branch; determining pruning periods which include winter pruning and / or summer pruning; pruning, to be more specific, for the annual young trees, determining a main branch and culturing the main branch and auxiliary branches; for the biennial young trees, expanding the crowns; for the triennial young trees, expanding the crowns and culturing fruiting branches; for the quadrennial first-fruiting trees, culturing extension branches or fruiting branch groups; for fruiting big trees more than five years old, culturing and rejuvenating fruiting branch groups; for the perennial scattered trees, culturing internal fruiting branch groups. The method has the advantages that fruiting parts cover the periphery and the interior, fruiting volume is increasedgreatly, three-dimensional fruiting is achieved, and fruit tree yield is doubled.

Owner:宜昌市林木种苗推广中心

Preparation method for back contact type silicon solar cell

ActiveCN102403406AReduce holesAvoid shading lossFinal product manufactureSemiconductor devicesHeat conductingSilicon solar cell

The invention discloses a preparation method for back contact type silicon solar cell, which comprises the following steps of: (1) etching texture on the illuminated surface of silicon chips, and setting holes; (2) coating, diffusing and forming junctions on the illuminated surface of the silicon chips; forming PN junctions on the illuminated surface and in the holes; (3) setting transparent heat conducting film on the PN junctions on the illuminated surface and in the holes; (4) etching the circumference; plating antireflection films on the transparent heat conducting film on the illuminated surface of silicon chips; and (5) preparing through hole electrode, back metal electrode and back passivation field on the non-plating film surface of the silicon chips to obtain the back contact type silicon solar cell; and the through hole electrode is electrically communicated with the transparent conducting film. The illuminated surface of the back contact type silicon solar cell is not covered by electrode, so shading loss is avoided and the photoelectric conversion efficiency is greatly improved. The quantity of to-be-opened holes is greatly reduced so as to dramatically reduce the fragmentation rate and simplify the preparation processes.

Owner:CSI CELLS CO LTD +1

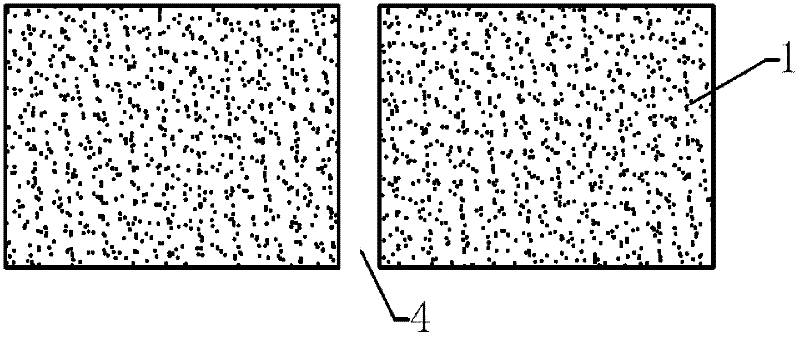

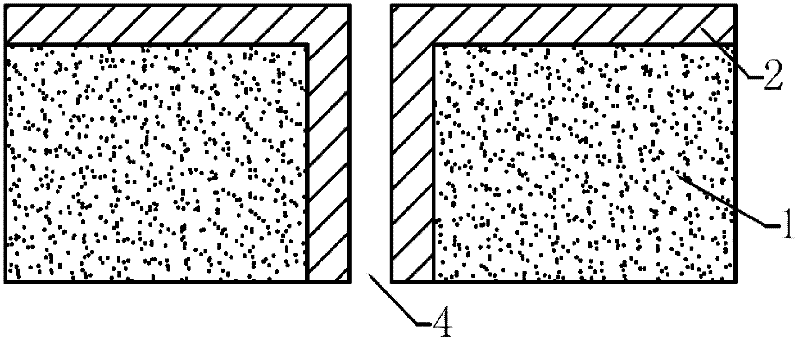

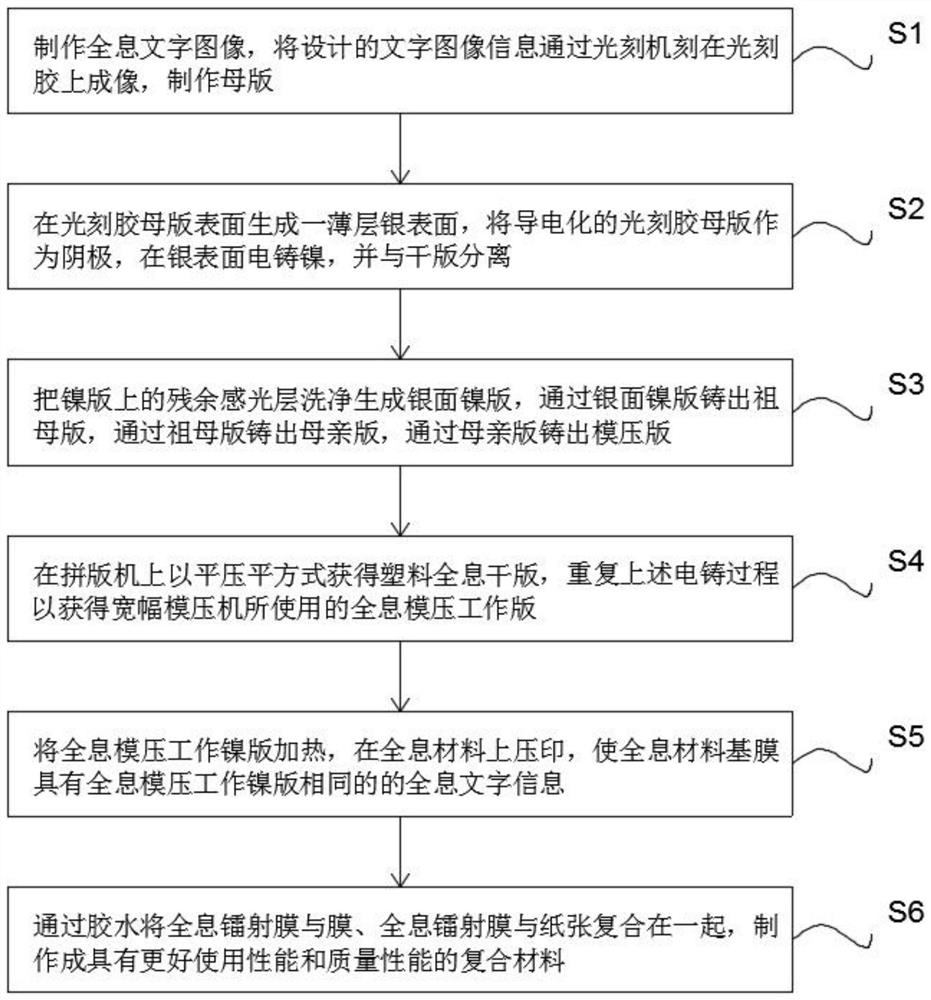

Preparation method of laser film with character holography

PendingCN113232445AReduce distortionHigh fastnessDecorative surface effectsSpecial ornamental structuresHolographyPhotoresist

The invention relates to the technical field of laser films, and discloses a preparation method of a laser film with character holography. The preparation method comprises the following steps that 1, a holographic character image is designed and manufactured through pre-printing software Photoshop or Coreldraw; 2, a thin-layer silver surface is generated on the surface of a photoresist master mask by using a chemical spraying method; 3, after a residual photosensitive layer on a nickel plate is cleaned with sodium hydroxide, the master mask cast through the silver-surface nickel plate serves as a grandmother plate, the master mask cast through the grandmother plate serves as a mother plate, and a molded plate is cast through the mother plate; 4, on a makeup machine, a plastic holographic dry plate with the required size is obtained from the minimum unit character patterns in a flat-pressing manner; 5, fine embossment type interference fringes on the holographic molded working nickel plate are transferred to the surface of a holographic material, and the laser film with the character holography is prepared. and 6, compounding is conducted. According to the preparation method of the laser film with the character holography, the manufacturing process is simple, the manufacturing cost is low, the process is simple, and a processed product is not prone to damage.

Owner:昆山景鹏包装材料有限公司

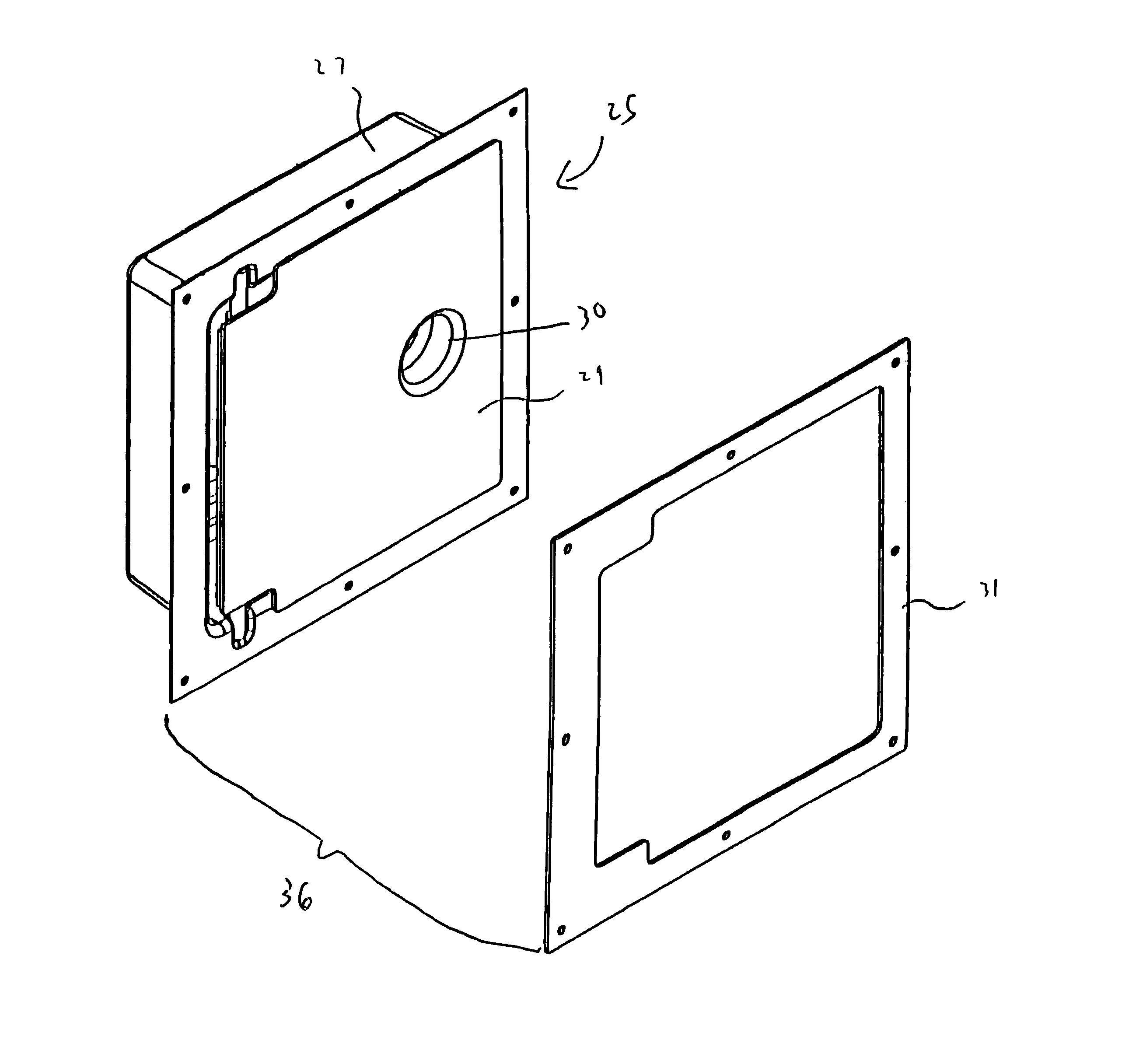

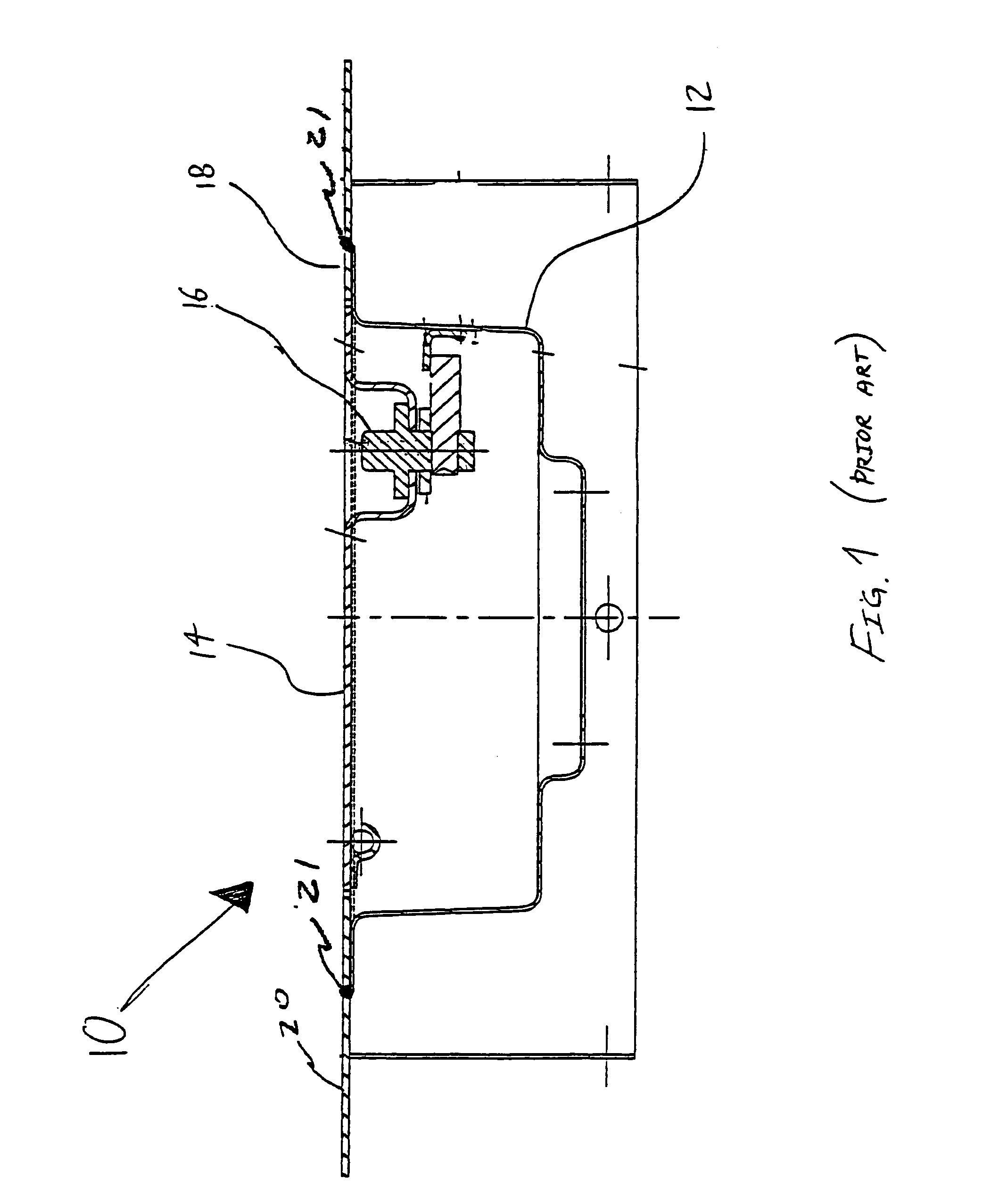

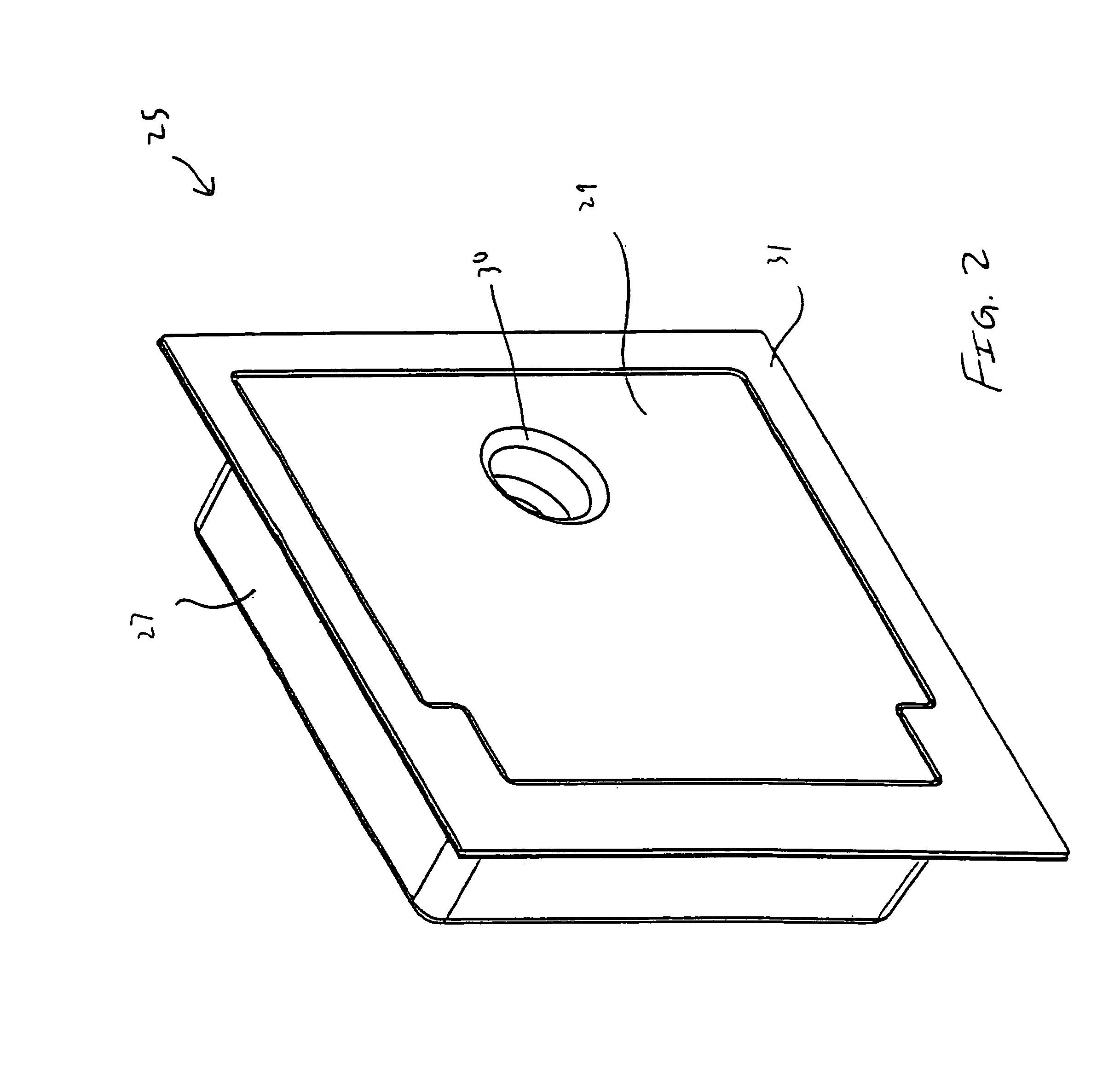

Hydrant box

ActiveUS7395834B1Uniform and beautiful appearancePipesDomestic plumbingEngineeringMechanical engineering

Owner:ZURN INDS

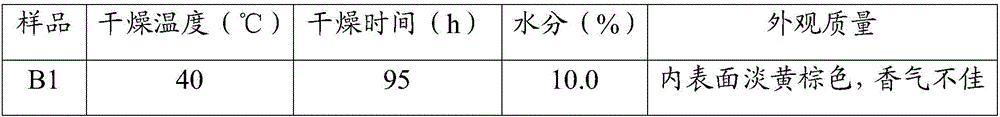

Exocarpium citri grandis tea and preparation method thereof

InactiveCN107279349ANot easy to moldEasy to storePre-extraction tea treatmentAlcoholismsChest tightness

The invention discloses exocarpium citri grandis tea and a preparation method thereof. The exocarpium citri grandis tea is prepared by the following steps of containing unfermented or slightly fermented high-quality tea with crushed dried peel of exocarpium citri grandis in baked and sterilized shells of exocarpium citri grandis; and then, carrying out baking, pressing and re-baking so as to prepare the exocarpium citri grandis tea. According to the preparation method of the exocarpium citri grandis tea, the unfermented or slightly fermented high-quality tea are selected and contained in the shells of the exocarpium citri grandis together with the crushed dried peel of the exocarpium citri grandis so that the tea leaves are not liable to get mildewed and are easy to store; moreover, ratio of the crushed dried peel of the exocarpium citri grandis is increased so that functions of the exocarpium citri grandis and the tea leaves are given full play. The exocarpium citri grandis tea has good health-caring functions for treating the symptoms of cough due to wind cold, itching throat, excessive phlegm, indigestion, alcoholism, vomiting and chest tightness; moreover, the exocarpium citri grandis tea also has the effects of stopping cough, reducing phlegm, clearing away heat, detoxifying, reducing fat, slimming, preventing arteriosclerosis, resisting senescence, and so on.

Owner:曾怀燕 +1

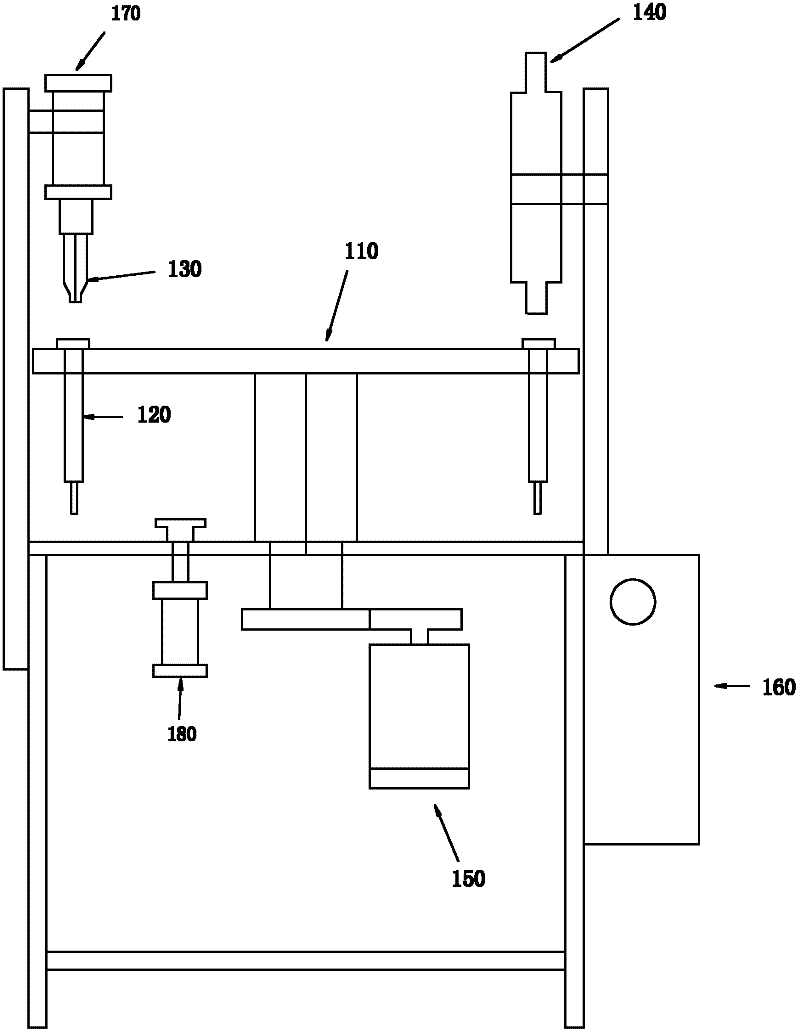

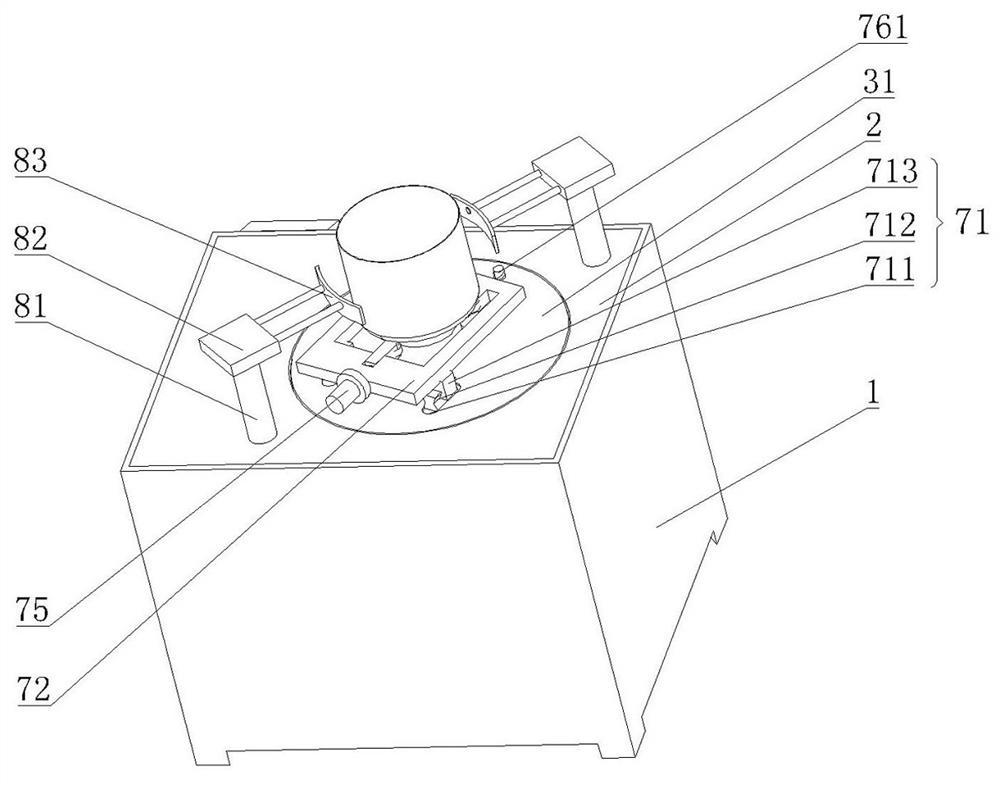

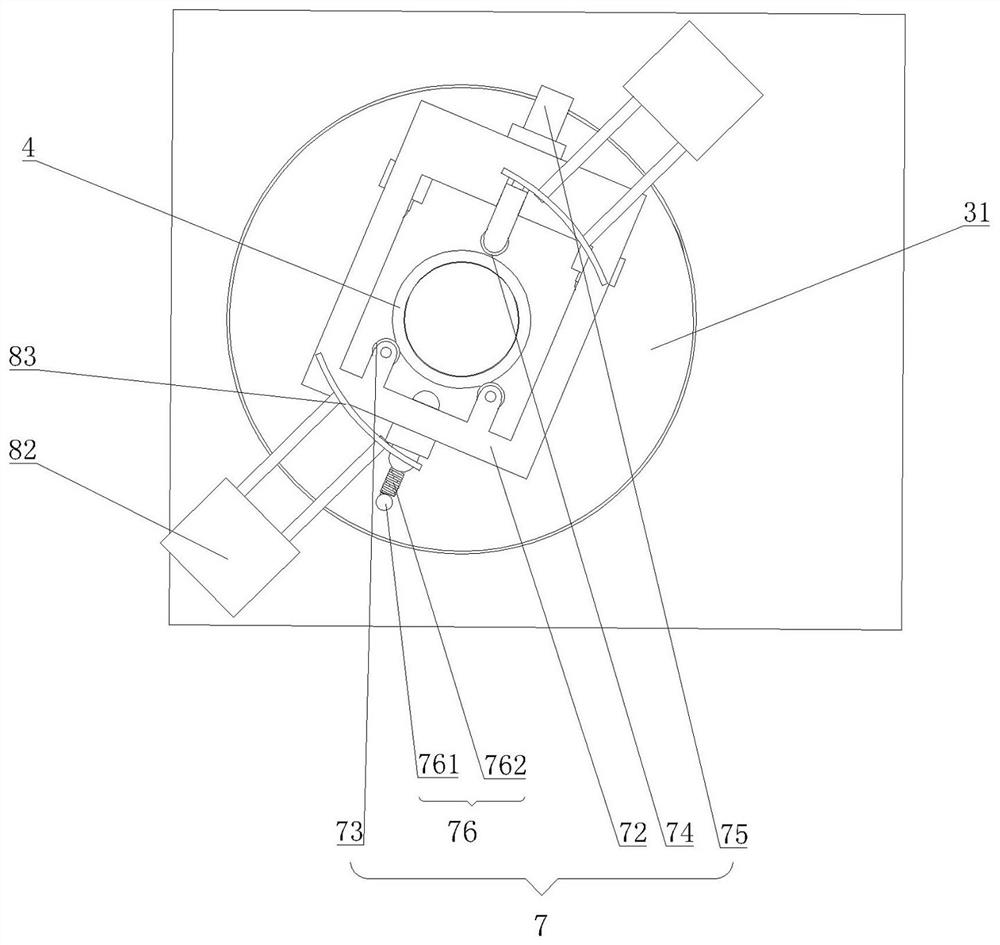

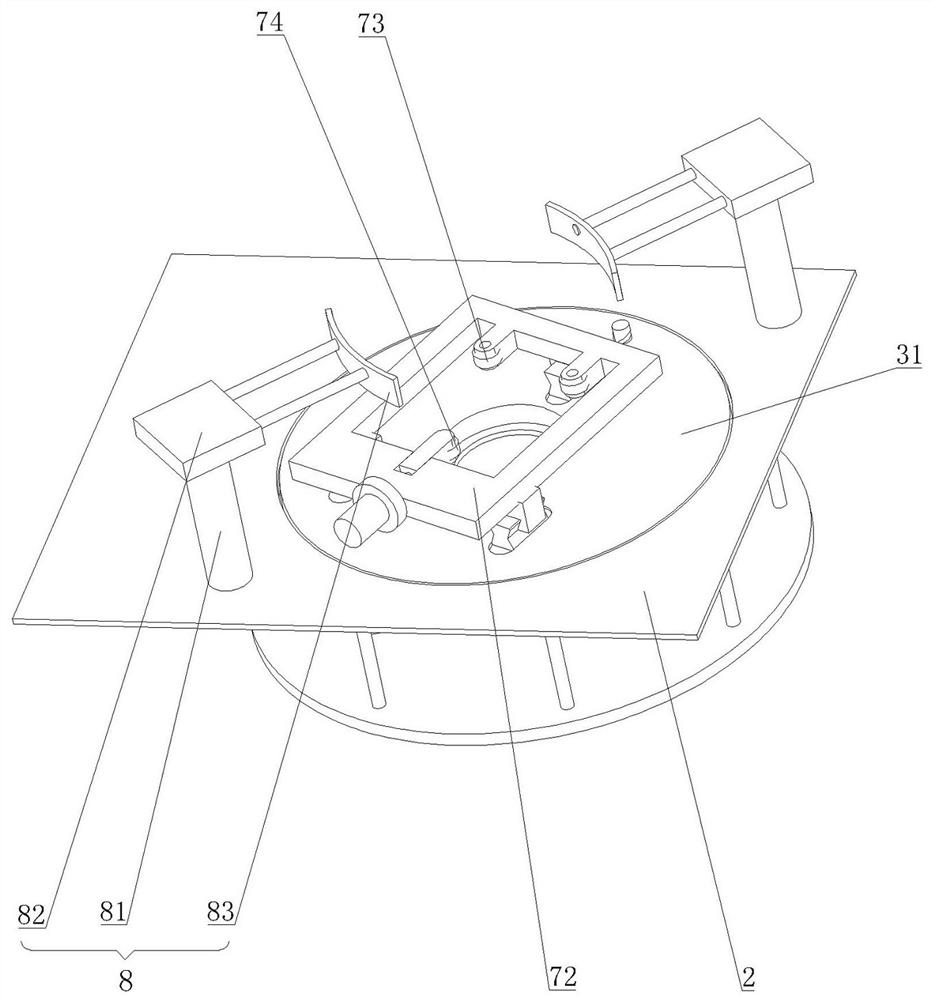

Pipe fitting expanding device

InactiveCN102225617ARealize automatic pipe fittings flaring processReduce labor costsPipe fittingHeating temperature

The invention discloses a pipe fitting expanding device, which comprises: a work bench; a bottom mold which is disposed on the work bench and is used to store a pipe fitting to be expanded; an upper mold which is disposed above the work bench; a heater which is disposed above the work bench; a rotary motor which is connected to the work bench; a controller which controls the rotary motor to drive the work bench to rotate so as to move the bottom mold to a position below the upper mold or the heater, controls the heating temperature and time of the heater, and controls both the upper mold and the bottom mold to extrude the orifice of the pipe fitting to be expanded. The device realizes an automatic expanding process of pipe fittings, and can reduce labor cost and increase production efficiency, and products processed by the device has uniform and beautiful appearances.

Owner:SHANGHAI CHANGYUAN ELECTRONICS MATERIAL +1

Pig-blood balls and production method thereof

ActiveCN104171018AImprove the preparation effectImprove qualityCheese manufactureBiotechnologyIsolated Soy Protein

The invention discloses pig-blood balls and a production method thereof. The pig-blood balls comprise fresh pig blood, soy isolate proteins, pig lean, frozen fat and auxiliary materials and specifically is prepared from the following ingredients in parts by weight: 15-20 parts of dehydrated cooked pig blood, 45-50 parts of emulsified material, 30 parts of pig lean, 3.7-6.4 parts of auxiliary materials and 3 parts of water. The production method comprises the following steps of: selecting raw materials according to the ingredients in the formula at first, and then pre-treating pig blood to obtain cooked pig blood and dehydrating the cooked pig blood; emulsifying, chopping and mixing the soy isolate proteins and smashed fat so as to change the soy isolate proteins and smashed fat into the emulsified material; and then placing the pig lean in a chopping and mixing device, chopping and mixing the pig lean at a high speed to obtain fine smashed material, then adding the dehydrated cooked pig blood, the emulsified material and the auxiliary materials, and continuing chopping and mixing at a high speed to obtain a uniform mixture; finally guiding the mixture into a shaping die for forming, and roasting to prepare the formed pig-blood ball products.

Owner:湖南唐人神肉制品有限公司

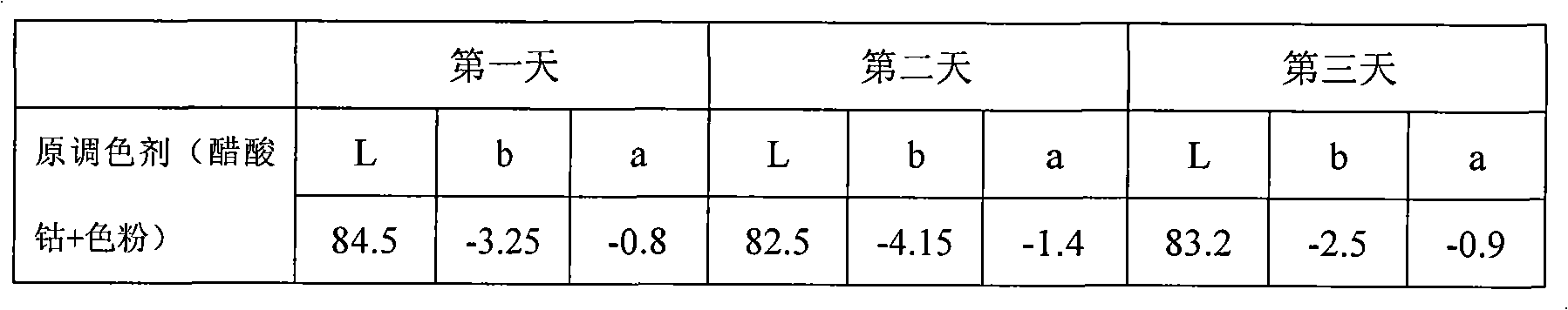

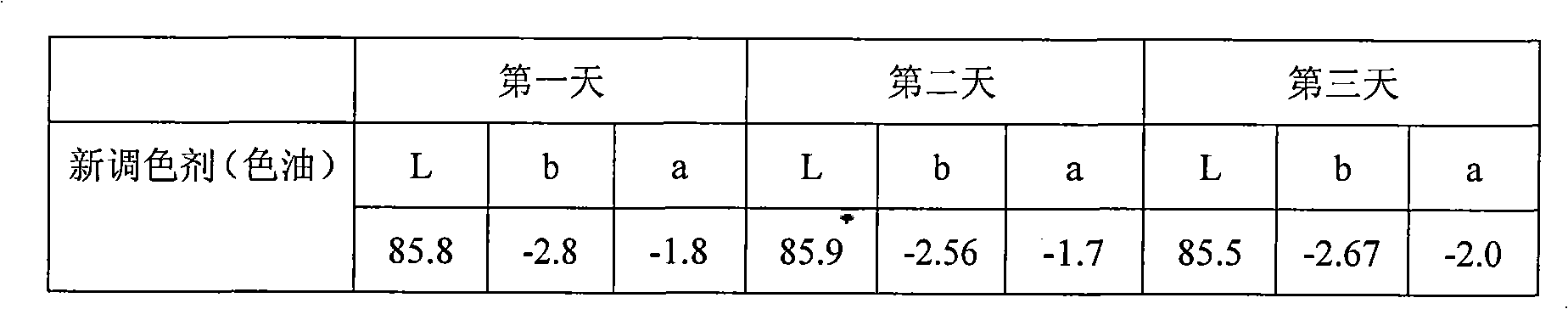

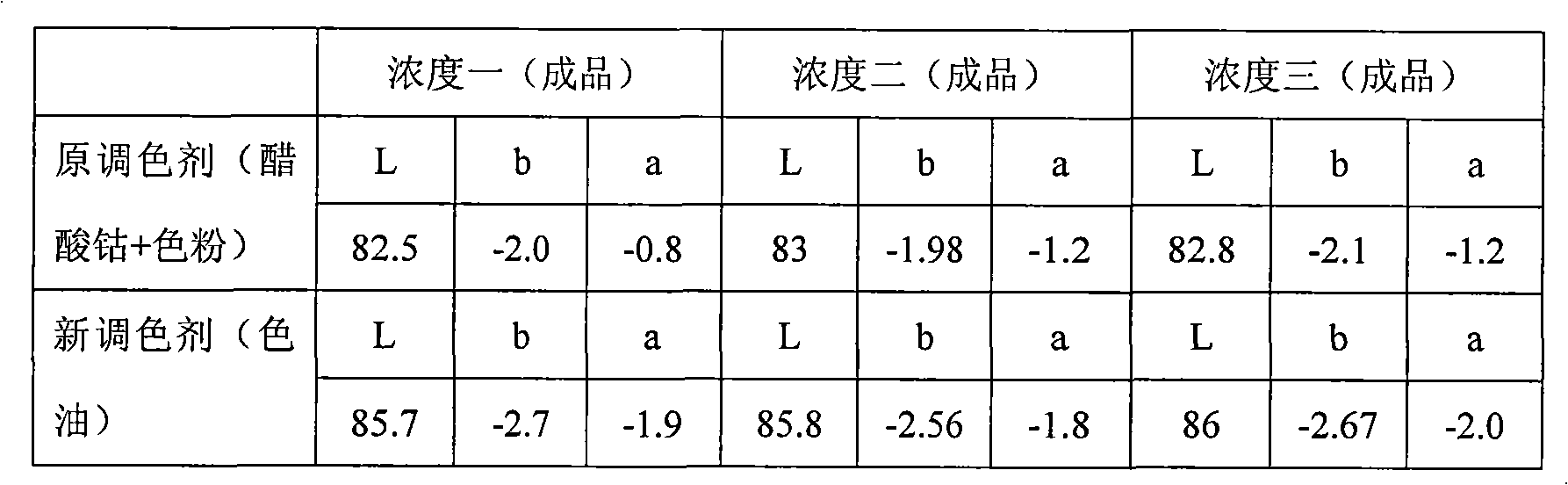

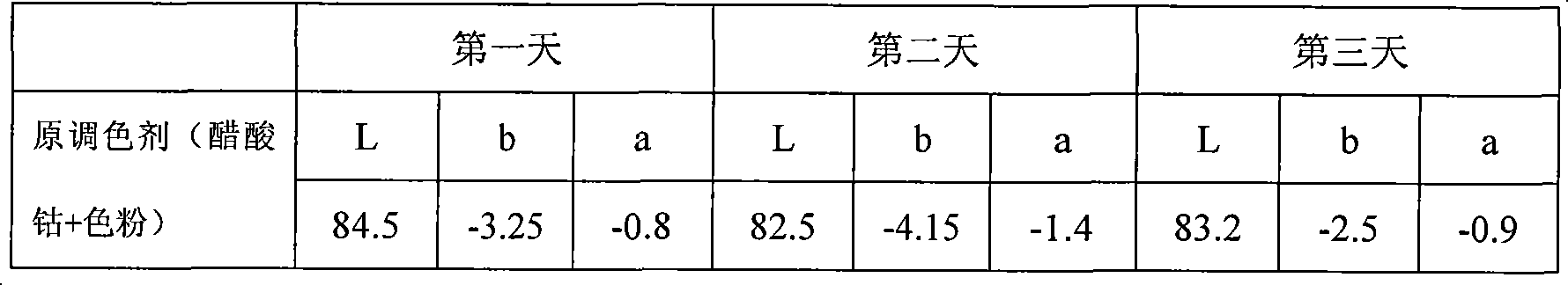

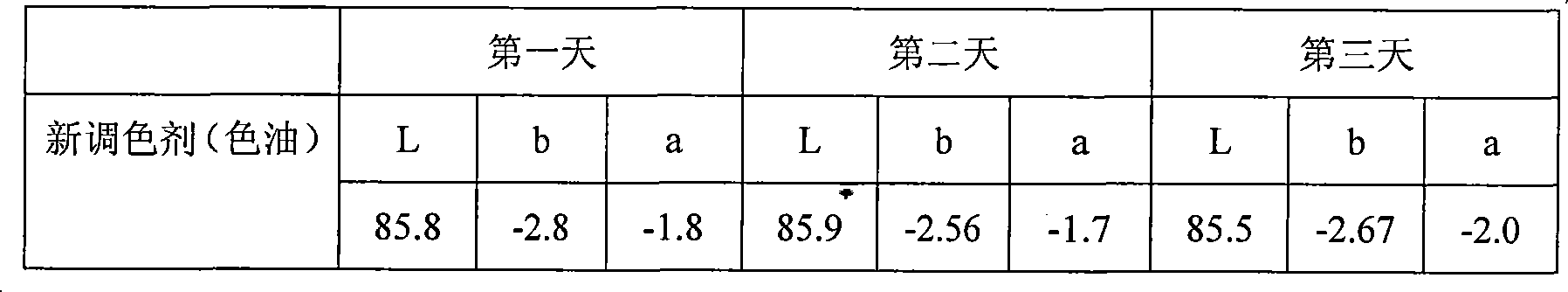

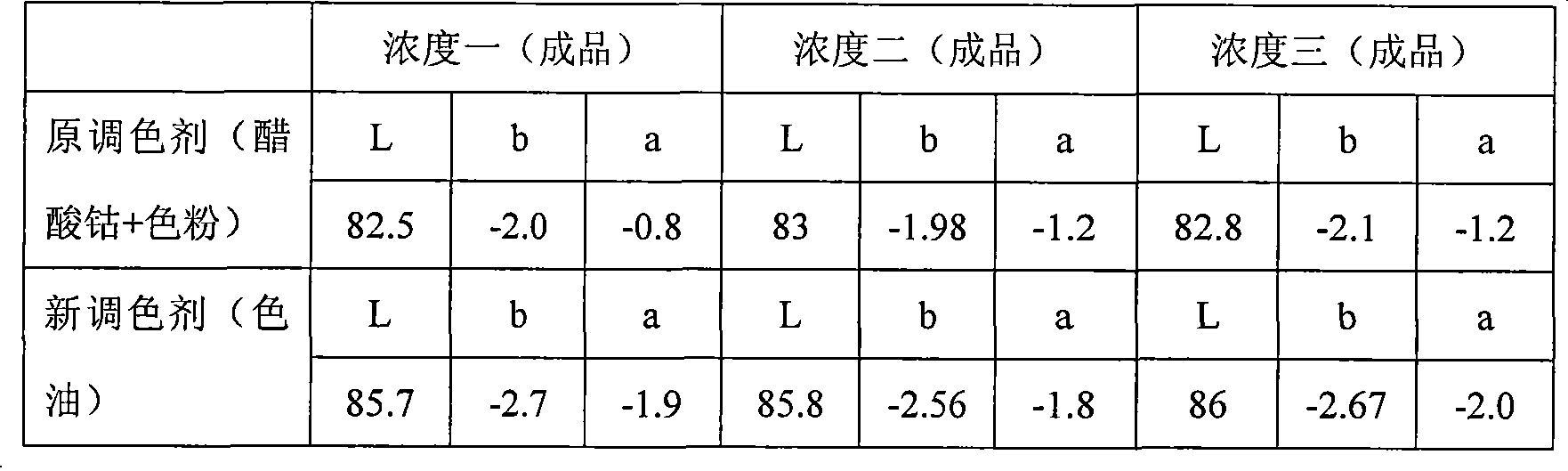

Toning method for PET bottle-grade polyester chip

The invention discloses a toning method of PET bottle class polyester chip. During preparing the PET bottle class polyester chip, the ethylene glycol as carrier is added into blending jar and then the oil is added into ethylene glycol and the mixture is uniformly blended and then conveyed to a supplying jar to store, and the mixture is continuously added to the production of bottle class polyester by tube, so that the purple agent content of the product is 1-5ppm, the purple agent content is 1-5ppm. The technological process is simple and oil blending temperature is low, suitable for reducing the energy consumption, and the cost is saves, therefore the brightness of the product is good and the appearance color is more uniform, beautiful and stable.

Owner:海南盛之业高新技术有限公司

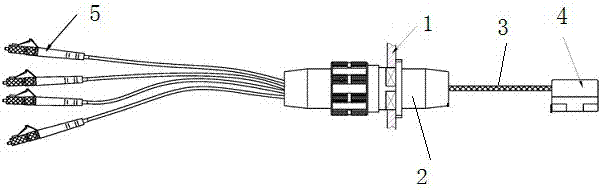

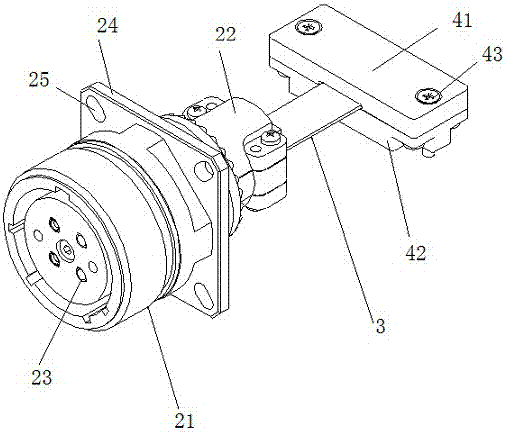

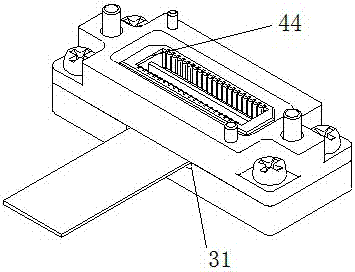

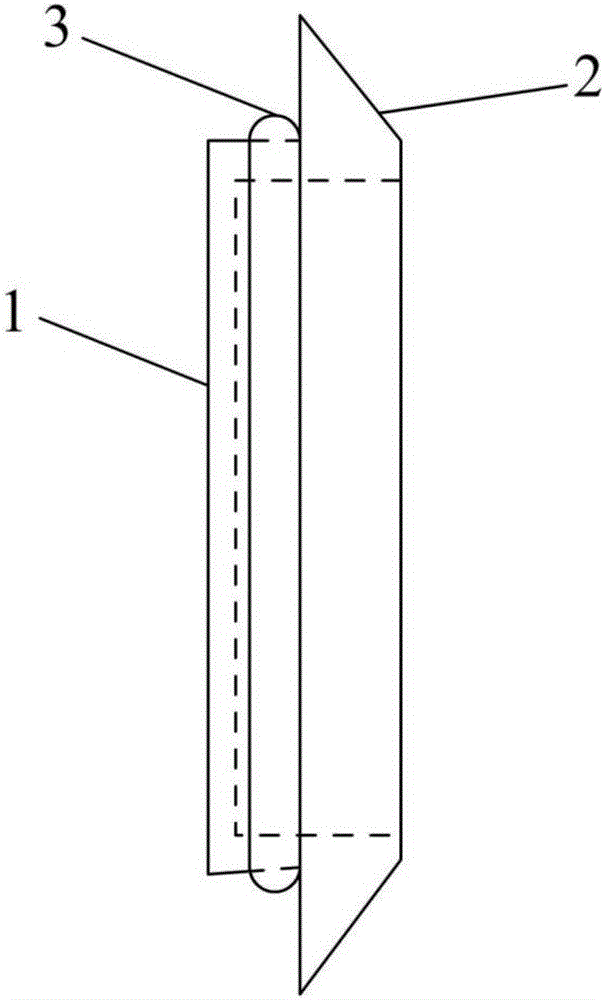

Wall-penetrating installation dual-channel 10-gigabit miniaturization photovoltaic conversion method

InactiveCN107219594AEasy to installUniform and beautiful appearanceCoupling light guidesFlexible circuitsGigabit

The invention is a double-channel 10G miniaturized photoelectric conversion method installed through the wall, comprising the following steps: opening an assembly hole at the installation position of the warehouse wall; inserting the optical signal interface from the inner side of the warehouse wall, so that the installation plate and the warehouse The inner wall of the wall is attached, and the fixing piece is inserted into the mounting hole so that the optical signal interface is fixed to the warehouse wall; one end of the high-speed flexible circuit board is connected through the connector, and the other end of the high-speed flexible circuit board is connected to the high-speed point interface; the optical fiber interface Connect with LC connector; perform photoelectric conversion through the built-in dual photoelectric conversion circuit. The present invention adopts the through-wall design, as long as an assembly hole as large as the size of the module needs to be opened at the installation position, it does not require professionals to analyze and design the waveguide, and at the same time, the small volume does not take up a lot of space, and the installation is convenient and simple. Uniform and beautiful.

Owner:JIANGSU ALLRAY

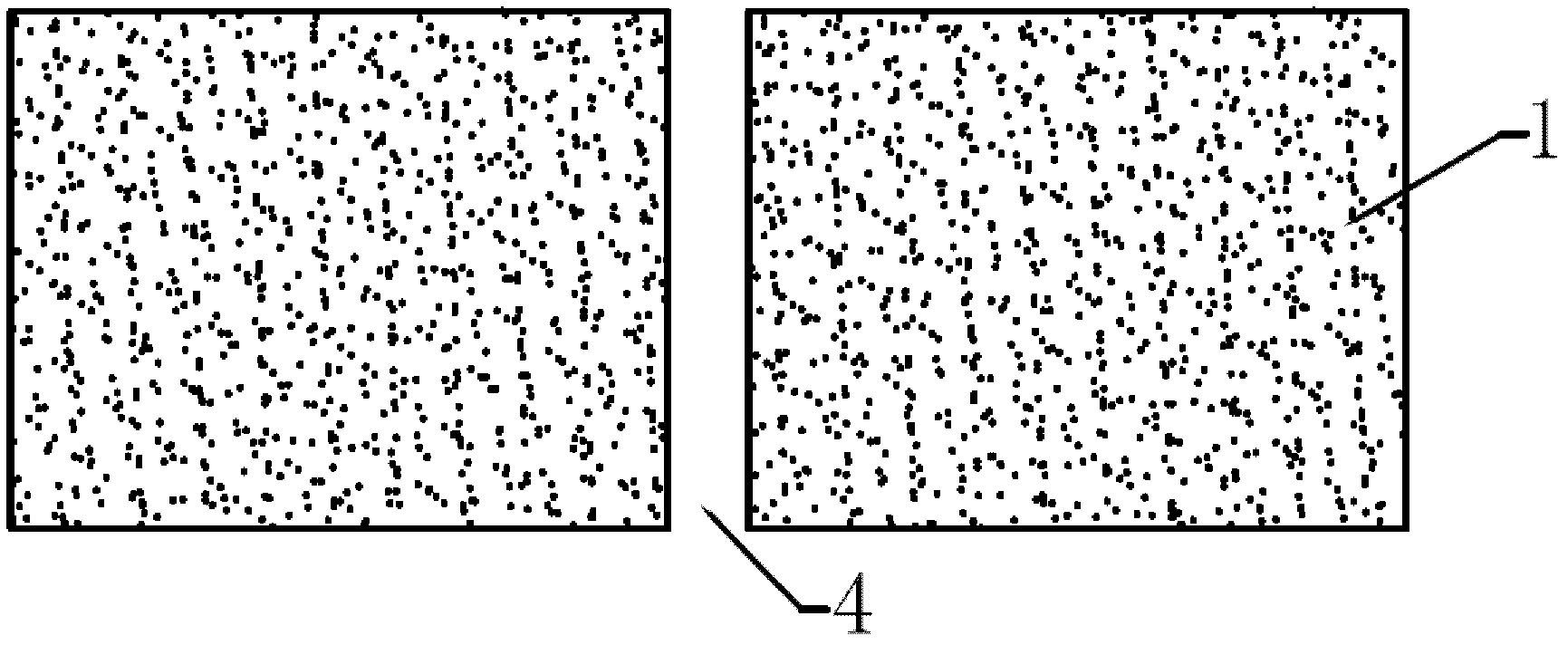

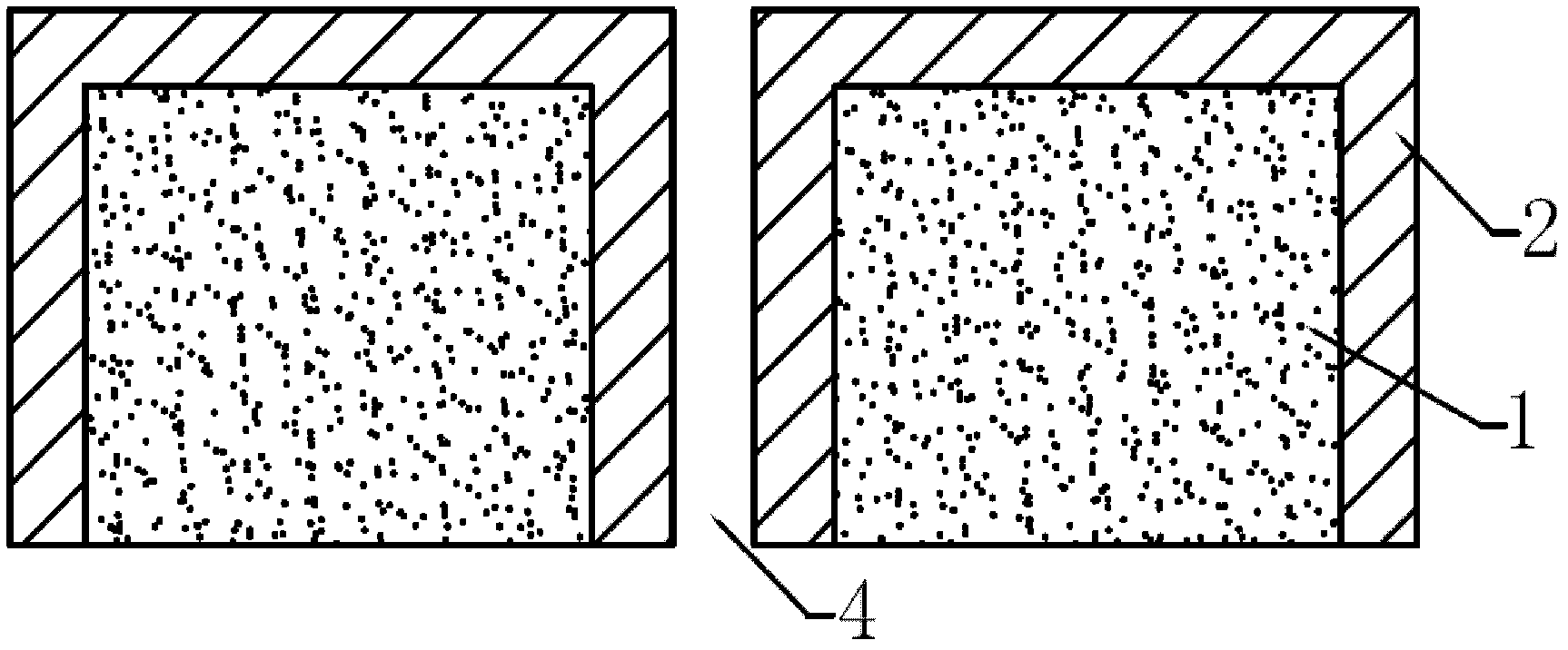

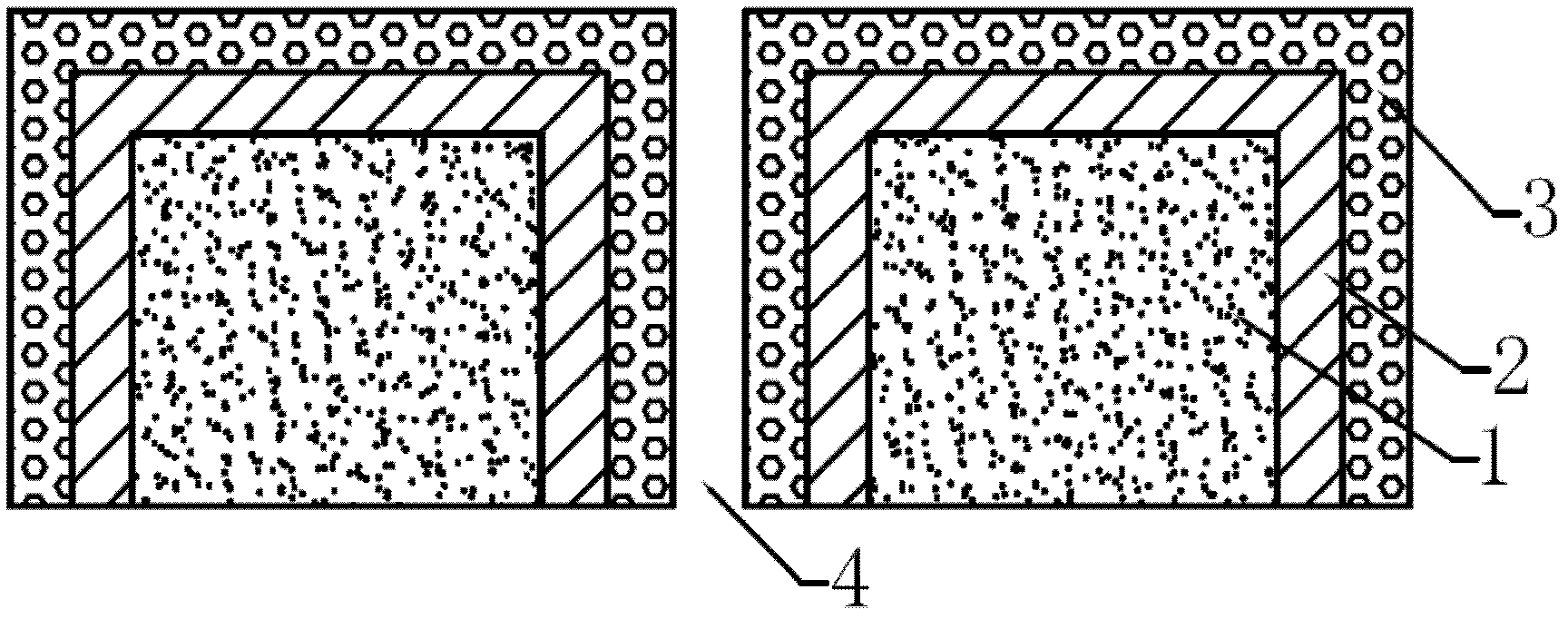

Light refractory brick and production method thereof

InactiveCN107500791AGreat economic and social benefitsUniform and beautiful appearanceCeramic materials productionClaywaresPerliteEnvironmentally friendly

The invention discloses a light refractory brick and a production method thereof. The light refractory brick is characterized by comprising the following raw materials in parts by weight: 60-90 parts of fly ash, 5-10 parts of perlite, 2-4 parts of sawdust, 5-10 parts of silica, 5-10 parts of floating beads, and 4-6 parts of a binder. Compared with the prior art, the light refractory brick has the advantages of being environmentally friendly, and fully utilizing the fly ash for developing a brick body, thus not only providing a new way for comprehensive utilization of the fly ash, but also being a compensation for increasingly rare raw materials for producing bricks, with great economic and social benefits. The product disclosed by the invention has uniform and beautiful appearance and color, neat edges and corners, and uniform cross-section tissue, without a phenomenon of cracks or collapsing, and exceeds the national standard of clay light bricks in terms of heat conductivity coefficient and strength.

Owner:宿州市埇桥区三八街道九里村兴农服务有限公司

Special effect paint containing rainbow effect pigment paste and preparation method thereof

InactiveCN106675263AWill not affect whitenessGood dispersionReflecting/signal paintsState of artMasterbatch

The invention relates to special effect paint containing rainbow effect pigment paste and a preparation method thereof. The special effect paint containing rainbow effect pigment paste is prepared by the following steps: 0.2-6 parts of pigment of a rainbow effect pigment paste, 15-28 parts of base-material resin, 0.1-0.6 part of a dispersion auxiliary agent, and 60-85 parts of a solvent are weighed and added into a reaction kettle in order; dispersion is uniform, and a homogeneous silvery white mixture which is a target product is obtained. Compared with the prior art, the special effect paint color masterbatch containing rainbow effect pigment paste has the advantages of simple preparation method, good pigment dispersibility, good storage stability, and the like, after construction, the product shows rainbow effects under the sun, the color is cool and full, and glossiness is high; in addition, the raw materials have low price, compared with products of competitors, the manufacture cost is dominated, cost performance is high, variety is relatively complete, and customized demands of clients for colors are satisfied.

Owner:DONGLAI COATING TECH SHANGHAI

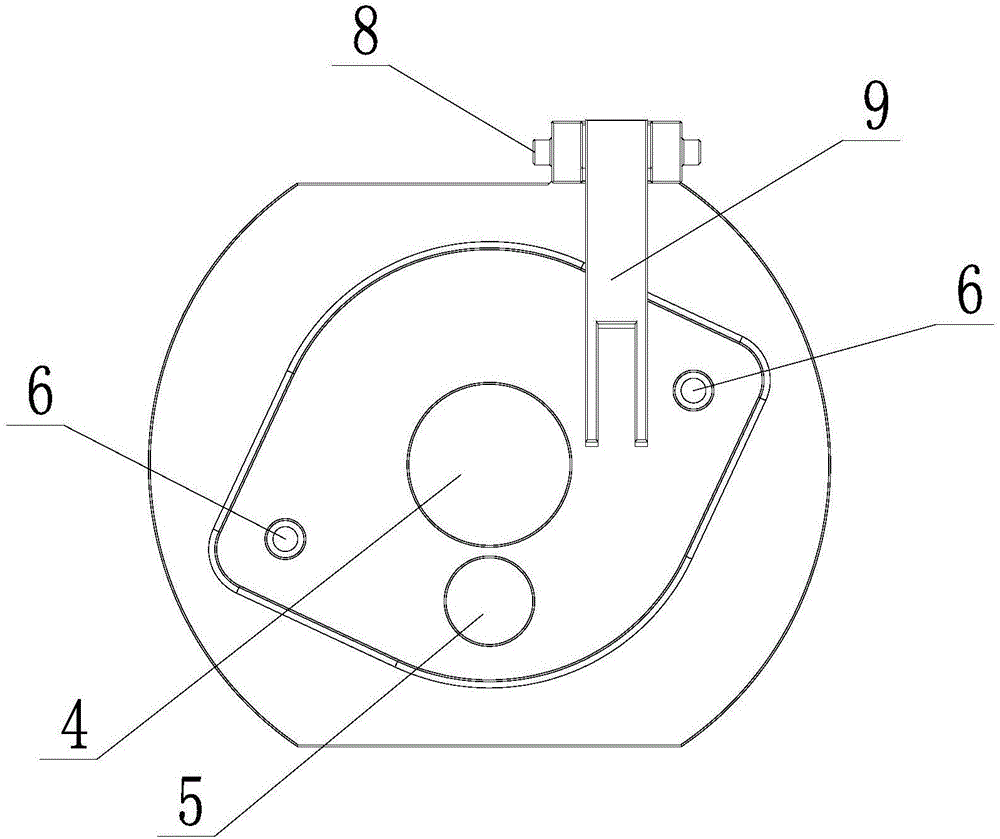

Novel shielding tool for flywheel housing

The invention discloses a novel shielding tool for a flywheel housing. The novel shielding tool for the flywheel housing comprises a cover body, and the cover body is sunken from the middle to the exterior and forms an inner convex body in the middle and a periphery part; the size of the inner convex body corresponds to the size of a shielding cavity of the flywheel housing; the periphery part is designed to be of a conical surface, and the conical surface is of a retraction mode; after the flywheel housing is covered by the cover body, the top end of the periphery part is flush with the outer surface of the fit part of the flywheel housing. The novel shielding tool for the flywheel housing further comprises an elastic fastening ring, and the elastic fastening ring is combined at the intersection part of the inner convex body and the periphery part. The novel shielding tool for the flywheel housing has the advantages that the machining cost is low, the shielding effect is good in the paint spraying process, the operation is simple, the consumed time of processes is short, and the clearing workload and the painting make-up workload caused by missed painting can be greatly lowered.

Owner:GUANGXI YUCHAI MASCH CO LTD

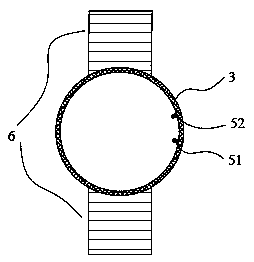

Machining method for heat conducting pipe

InactiveCN104708292AReduce eccentricityUniform and beautiful appearanceHeat conductingMolding machine

The invention discloses a machining method for a heat conducting pipe. The method comprises the following steps of 1, conducting fin forming, wherein a cut plate forms fins through a fin forming machine or fin forming is directly performed on the plate and then splitting cutting is conducted, and the fins can be formed on the upper surface and the lower surface of the plate or on one surface of the plate; 2, conducting pipe forming, wherein forming is conducted on the finished plate through a pipe forming machine so that a round pipe with a seam can be formed; 3, conducting welding, wherein after the round pipe is formed through the pipe forming machine, welding is conducted on the seam of the round pipe; 4, processing a welding joint, wherein the unevenly welded portion of the seam of the pipe is ground and polished through a welding joint processing machine; 5, conducting annealing. By the adoption of the machining method for the heat conducting pipe, the heat conducting pipe is formed in a one-off mode from a plate band, and the machining process is shortened; because the technology that the fins are rolled on the plate band and then welding is conducted is adopted, destructive machining is not needed after welding, and the phenomenon that the weld joint may be damaged after rolling in the prior art is avoided.

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP

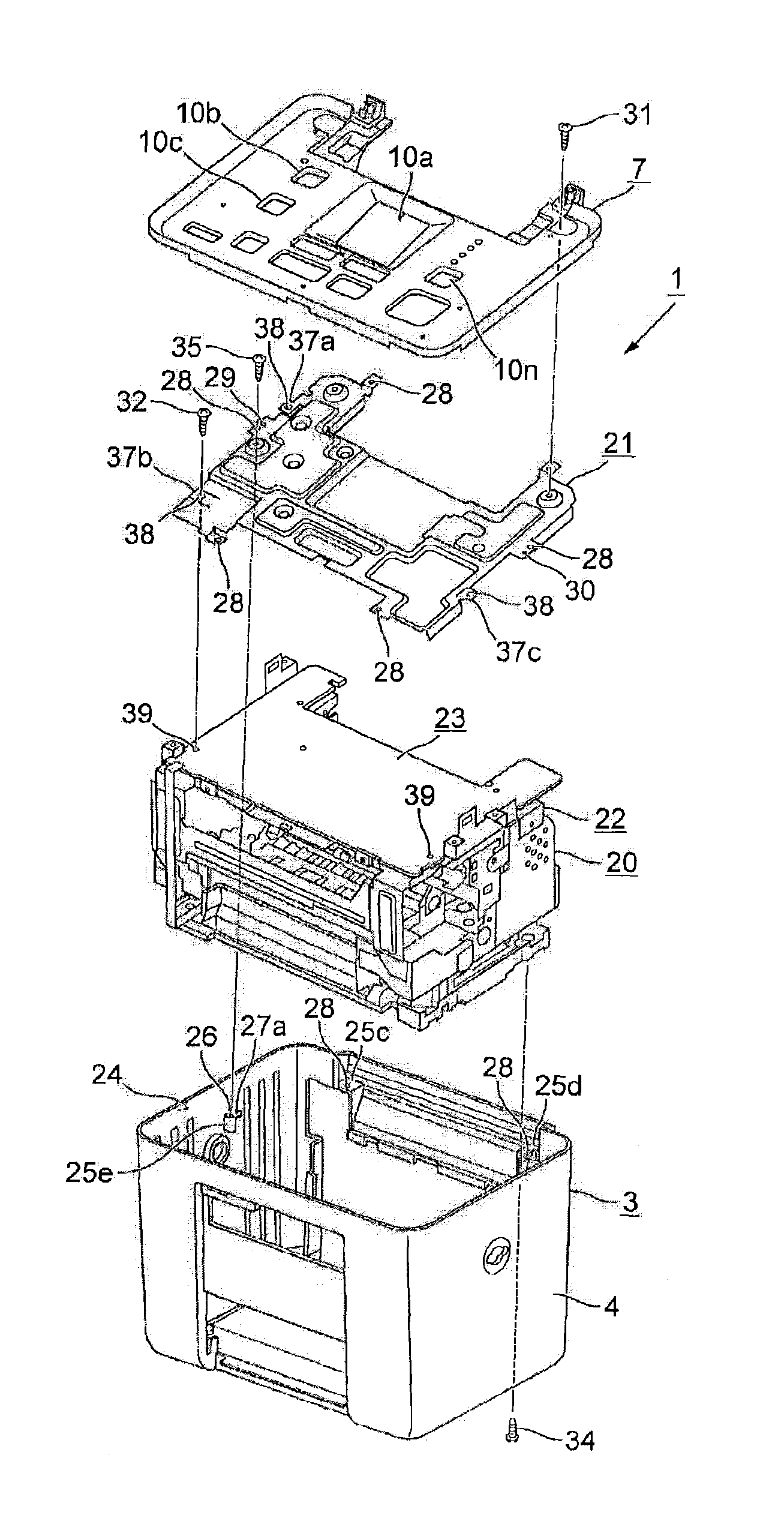

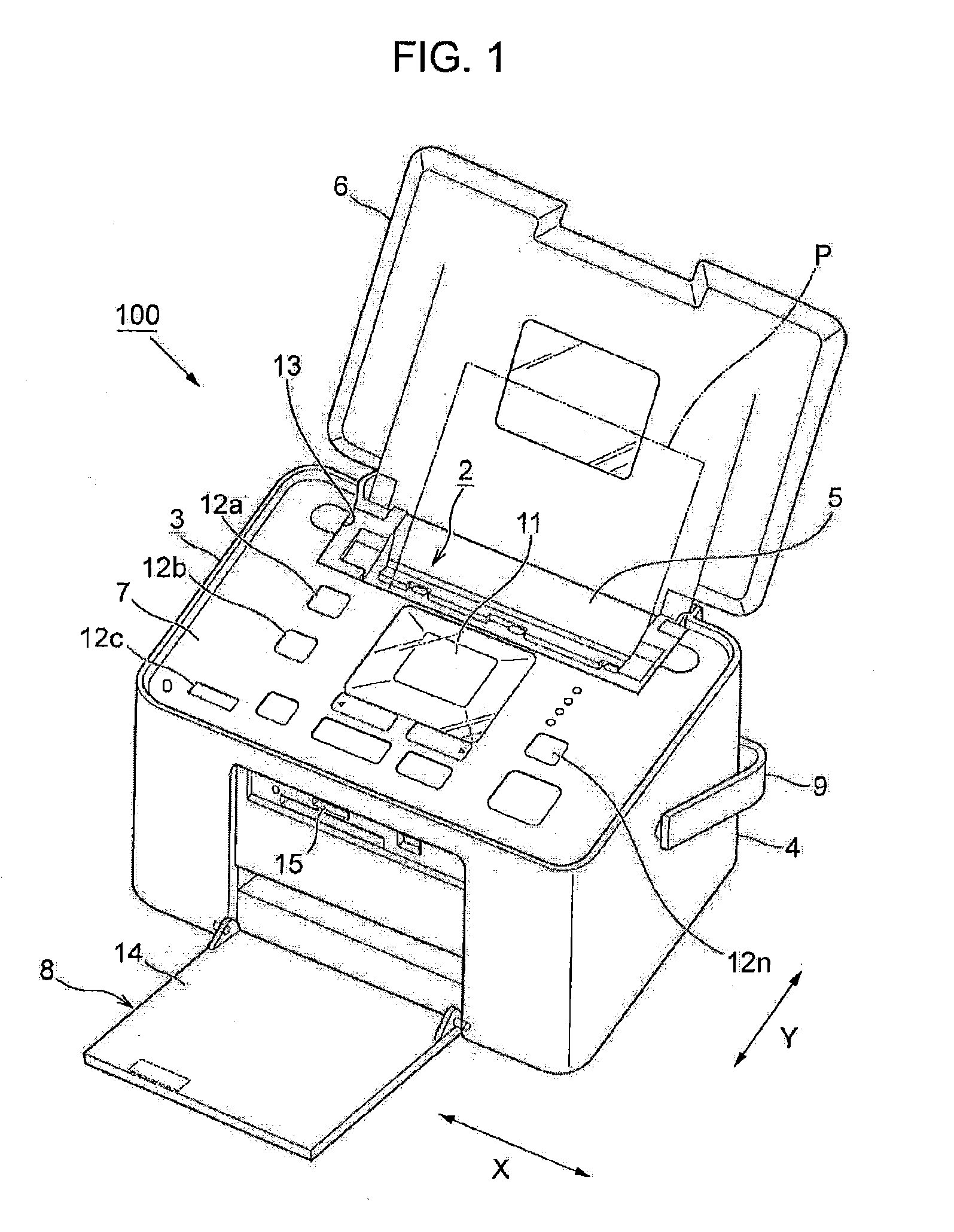

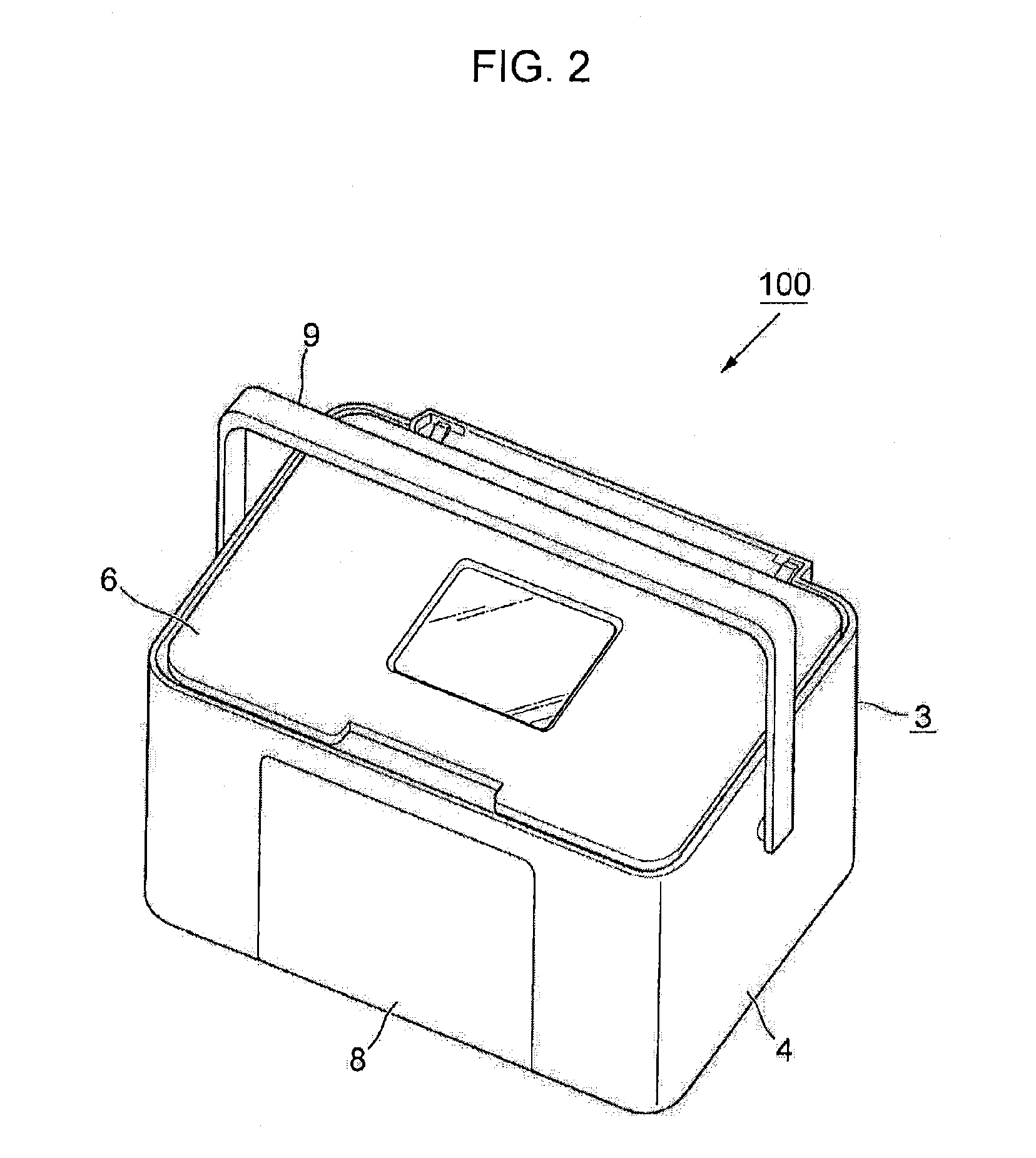

Fixing device of shield plate, recording apparatus and liquid ejecting apparatus

InactiveUS7922319B2Reduce variationEasy to adjustTypewritersOther printing apparatusElectrical and Electronics engineering

Owner:SEIKO EPSON CORP

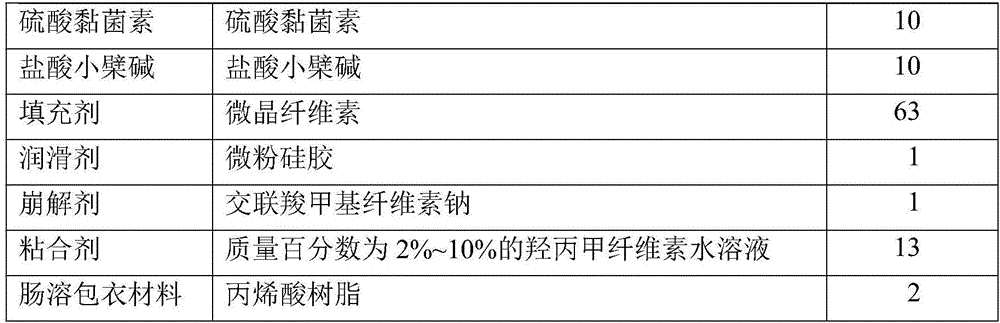

Colistin sulfate and berberine hydrochloride composition and preparation method of pellets of colistin sulfate and berberine hydrochloride composition

InactiveCN106310222AImprove bioavailabilityImprove liquidityAntibacterial agentsOrganic active ingredientsEscherichia coliColistin Sulfate

The invention relates to a colistin sulfate and berberine hydrochloride composition and a preparation method of pellets of the colistin sulfate and berberine hydrochloride composition and aims to solve the problems that the effect of treating escherichia coli and salmonella infection by using the colistin sulfate is poor due to poor intestinal absorption in the prior art, and the use dosage is required to be increased for reaching an ideal treatment effect. The preparation method comprises the following steps: firstly, mixing the colistin sulfate, the berberine hydrochloride, a filling agent, a lubricating agent and a disintegrating agent; secondly, crushing to obtain mixture powder; adding a binding agent to obtain pellets; coating to obtain the pellets of the colistin sulfate and berberine hydrochloride composition. The pellets of the colistin sulfate and berberine hydrochloride composition, obtained by the preparation method disclosed by the invention, are prepared by adopting conventional equipment such as a granulating device and a coating device in the pharmaceutical industry; the preparation method can realize continuous production and is suitable for industrial production; high yield is realized.

Owner:LESHAN RUIHEXIANG ANIMAL HEALTH PHARMA CO LTD

Manufacturing method of nitrogen phosphorus potassium composite fertilizer rich in nitrogen and potassium

ActiveCN1255362CExpand the range of raw materialsEasy process adjustmentGranulation by liquid drop formationFertiliser formsCooling towerEffective height

The invention relates to a method for manufacturing high-nitrogen, high-potassium, nitrogen, phosphorus, and potassium compound fertilizers. The molten liquid or solid urea produced in an ammonia plant is heated to 125-135°C, and the powdered potassium-containing raw material with a particle size of less than 1 mm is heated to 110-100°C. 135°C or heated to 90-110°C, phosphorus-containing raw materials with a particle size of less than 1 mm are added to calcium powder, placed in a mixer and stirred for 2-10 minutes, and the formation temperature is 110-135°C, viscosity is 1500-2500cPa.s, The mixed slurry with good fluidity is co-melted, and then the melted slurry is sprayed into an air cooling tower with an effective height greater than 50 meters or 65 meters and a diameter of 6-20 meters by using a rotary spray granulator, and solidified by air cooling It is powdery or granular high-nitrogen and high-potassium compound fertilizer. It can adapt to various phosphorus and potassium-containing raw materials, and can produce various high-nitrogen and high-potassium NPK compound fertilizers with low production costs.

Owner:山东新天新肥业有限公司

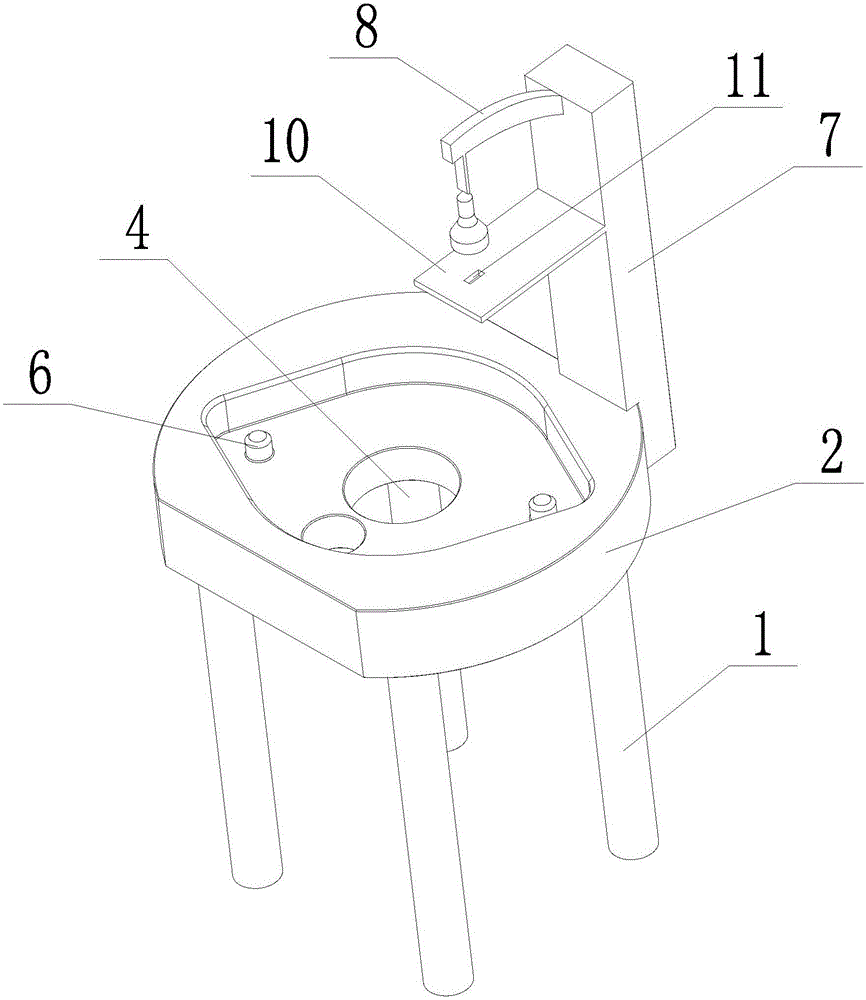

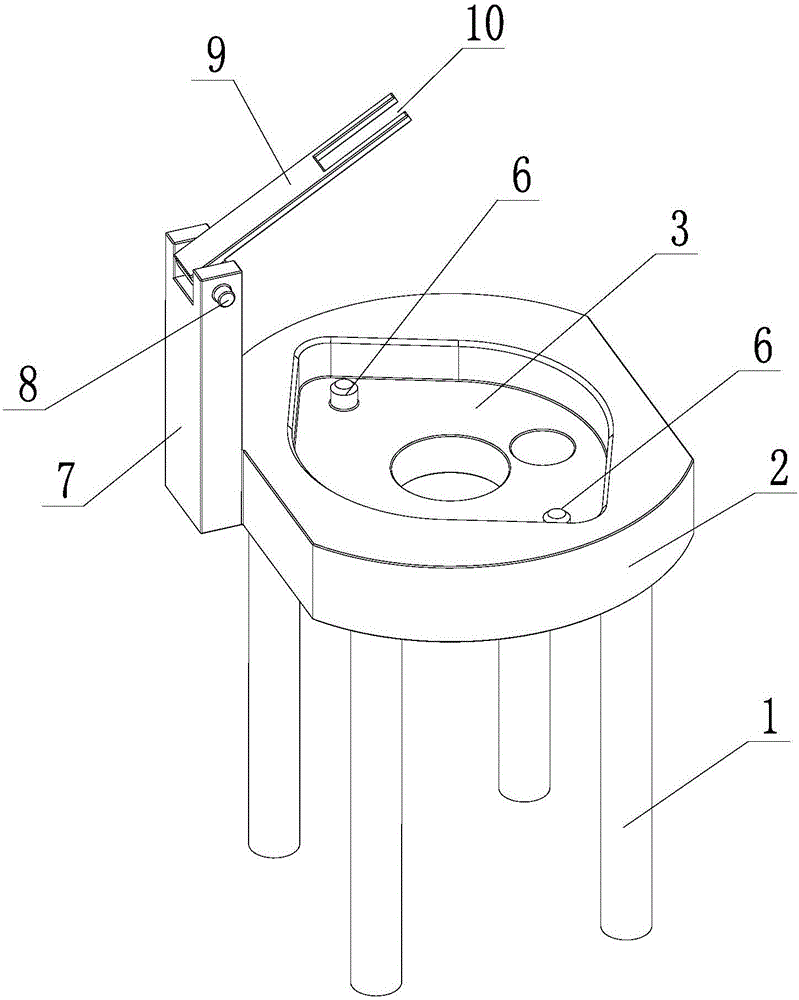

Motor shell bar code positioning and pasting device

InactiveCN106628466APrecise positioningAccurate positioning and pastingLabelling machinesDaily operationMechanical equipment

The invention relates to the technical field of mechanical equipment, in particular to a motor shell bar code positioning and pasting device. The motor shell bar code positioning and pasting device comprises supporting legs, a motor shell storage table, a direct illuminating lamp and a bar code positioning plate. According to the motor shell bar code positioning and pasting device, a motor rotary shaft storage hole, an terminal storage hole and positioning studs are arranged in a motor shell storage tank, so that a motor shell is accurately positioned; and the direct illuminating lamp irradiates a bar code positioning groove in the bar code positioning plate, then a light ray of the bar code pasting position can be left, a worker just needs to paste a bar code on the light ray which penetrates through the bar code positioning groove, in this way, the defect that bar code pasting of a motor shell bar code fixing device is not orderly or attractive enough during daily operation is overcome, labor consumption is reduced, and motor products are uniform and attractive in appearance. Besides, the motor shell bar code positioning and pasting device is simple and reasonable in structural design, convenient and fast to use and install and suitable for being applied and popularized.

Owner:ZHIDE MOTOR SUZHOU CO LTD

Preparation method for back contact type silicon solar cell

ActiveCN102403406BReduce holesAvoid shading lossFinal product manufactureSemiconductor devicesMetallic electrodeElectrical battery

The invention discloses a preparation method for back contact type silicon solar cell, which comprises the following steps of: (1) etching texture on the illuminated surface of silicon chips, and setting holes; (2) coating, diffusing and forming junctions on the illuminated surface of the silicon chips; forming PN junctions on the illuminated surface and in the holes; (3) setting transparent heat conducting film on the PN junctions on the illuminated surface and in the holes; (4) etching the circumference; plating antireflection films on the transparent heat conducting film on the illuminated surface of silicon chips; and (5) preparing through hole electrode, back metal electrode and back passivation field on the non-plating film surface of the silicon chips to obtain the back contact type silicon solar cell; and the through hole electrode is electrically communicated with the transparent conducting film. The illuminated surface of the back contact type silicon solar cell is not covered by electrode, so shading loss is avoided and the photoelectric conversion efficiency is greatly improved. The quantity of to-be-opened holes is greatly reduced so as to dramatically reduce the fragmentation rate and simplify the preparation processes.

Owner:CSI CELLS CO LTD +1

Wearables with Near Field Communication

ActiveCN105446127BConducive to thin and light designUniform and beautiful appearanceElectronic time-piece structural detailsAntenna supports/mountingsCommunication circuitsEmbedded system

Owner:HUIZHOU SPEED WIRELESS TECH CO LTD

Manufacturing method for back contact type silicon solar cell

ActiveCN102403405BReduce holesAvoid shading lossFinal product manufactureSemiconductor devicesFragmentation rateContact type

The invention relates to a manufacturing method for a back contact silicon solar cell, which comprises the following steps of: (1) setting holes on the surface of silicon wafers, and etching textures on the light receiving surfaces of the silicon wafers; (2) diffusing on the light receiving surfaces of the silicon wafers to make junctions, and forming PN junctions in the light receiving surfaces, the peripheries and holes of the silicon wafers; (3) setting transparent conductive films on the PN junctions in the light receiving surfaces, the peripheries and holes of the silicon wafers; (4) etching the peripheries of the silicon wafers to remove the transparent conductive films and the PN junctions on the peripheries of the silicon wafers, and coating antireflection films on the transparent conductive films in the light receiving surfaces of the silicon wafers; and (5) preparing through hole electrodes, back metal electrodes and back passivation fields on the non film coated surfaces of the silicon wafers to obtain the back contact silicon solar cells. The light receiving surfaces of the back contact silicon solar cells are not covered with electrodes, so that the shading loss is avoided, and the photoelectric conversion efficiency is remarkably improved; holes to be arranged are also greatly reduced, so that the fragmentation rate is greatly reduced; and the manufacturing process is simplified.

Owner:CSI CELLS CO LTD +1

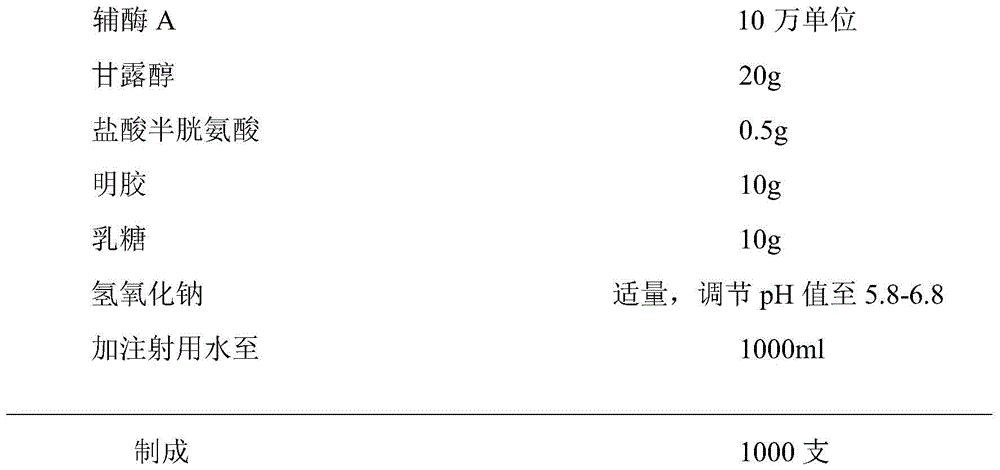

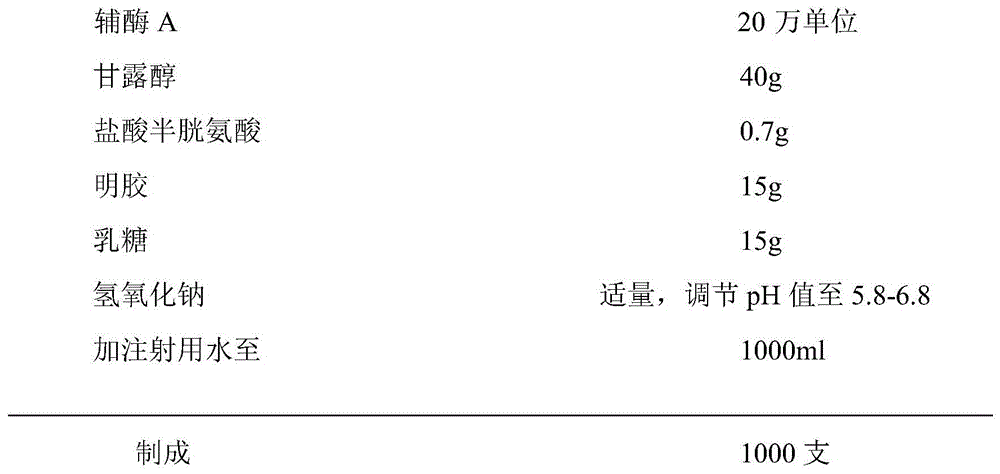

A kind of freeze-dried preparation of coenzyme A and preparation method thereof

InactiveCN105055344BReduce loss on dryingSimple preparation processPowder deliveryOrganic active ingredientsMANNITOL/SORBITOLFiltration

The invention discloses a coenzyme A freeze drying agent and a preparation method thereof, which comprise product prescription, stable liquid preparation, injection preparation, aseptic filtration, filling, freeze drying, capping, leakage detecting and lamp detection packing, and uses coenzyme A as main effective components, and uses optimized skeleton agent mannitol, reductant cysteine hydrochloride, stabilizer gelatin and lactose and the like as pharmaceutic adjuvants to improve stability of drugs. The coenzyme A freeze drying agent and the preparation method thereof reduce water content of finished products below 0.6% by optimizing freeze drying process, and enables coenzyme A for injection to be steadier. The coenzyme A freeze drying agent and the preparation method thereof solve the stability problem of the coenzyme A, improve product yield of the coenzyme A, and have the advantage of simple process, steady quality and high product yield compared with existing freeze drying agents.

Owner:武陟维尔康生化制药有限公司

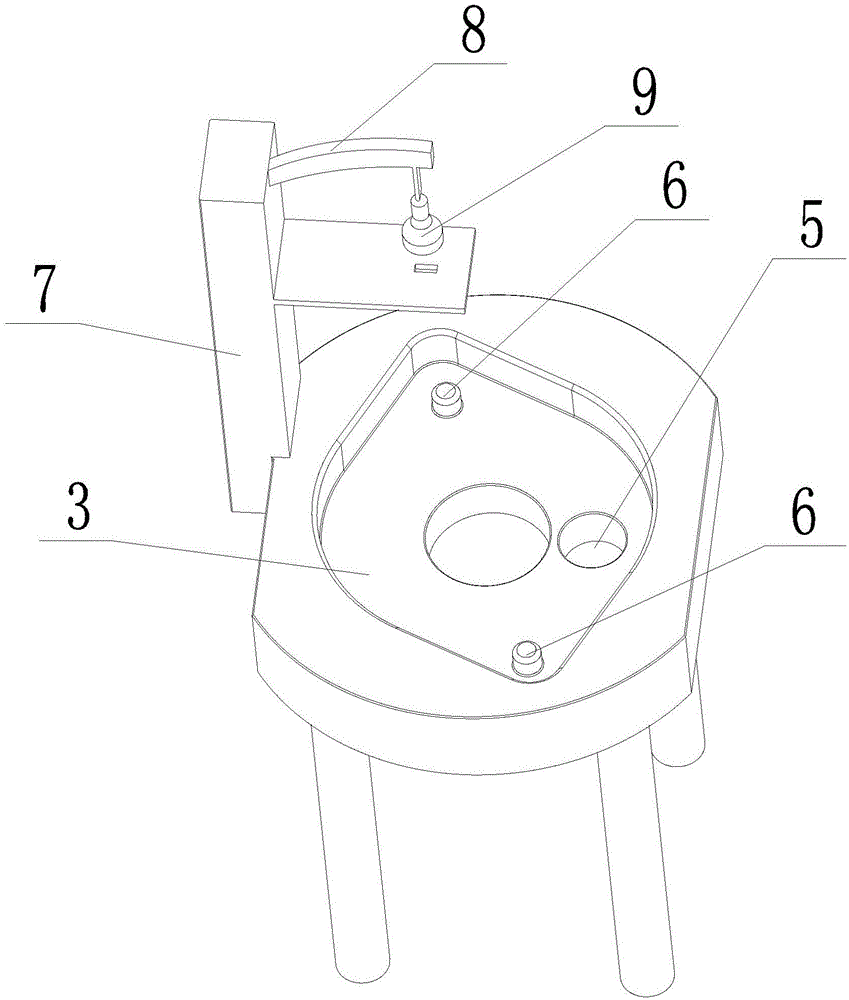

Motor shell barcode positioning pasting device

InactiveCN106742468APrecise positioningAccurate positioning and pastingLabelling machinesElectric machineryBarcode

The invention relates to the technical field of mechanical equipment and devices, in particular to a motor shell barcode positioning pasting device. The motor shell barcode positioning pasting device comprises supporting legs, a motor shell holding table and a barcode positioning plate. A motor shell holding groove of the motor shell barcode positioning pasting device is internally provided with a motor rotating shaft holding hole, a terminal holding hole and positioning posts, and a motor shell can be accurately positioned. One end of the barcode positioning plate is movably connected with the top end of a fixing post through a rotary shaft, and the other end of the barcode positioning plate is provided with a barcode positioning groove. The defect that barcode pasting conducted by a motor shell barcode fixing device in daily work is not orderly or attractive enough is overcome, manpower consumption is reduced, and the appearances of motor products are unified and attractively. In addition, the motor shell barcode positioning pasting device is simple and reasonable in structural design, convenient and fast to use and install and suitable for use and popularization.

Owner:ZHIDE MOTOR SUZHOU CO LTD

Toning method for PET bottle-grade polyester chip

The invention discloses a toning method of PET bottle class polyester chip. During preparing the PET bottle class polyester chip, the ethylene glycol as carrier is added into blending jar and then the oil is added into ethylene glycol and the mixture is uniformly blended and then conveyed to a supplying jar to store, and the mixture is continuously added to the production of bottle class polyester by tube, so that the purple agent content of the product is 1-5ppm, the purple agent content is 1-5ppm. The technological process is simple and oil blending temperature is low, suitable for reducingthe energy consumption, and the cost is saves, therefore the brightness of the product is good and the appearance color is more uniform, beautiful and stable.

Owner:海南盛之业高新技术有限公司

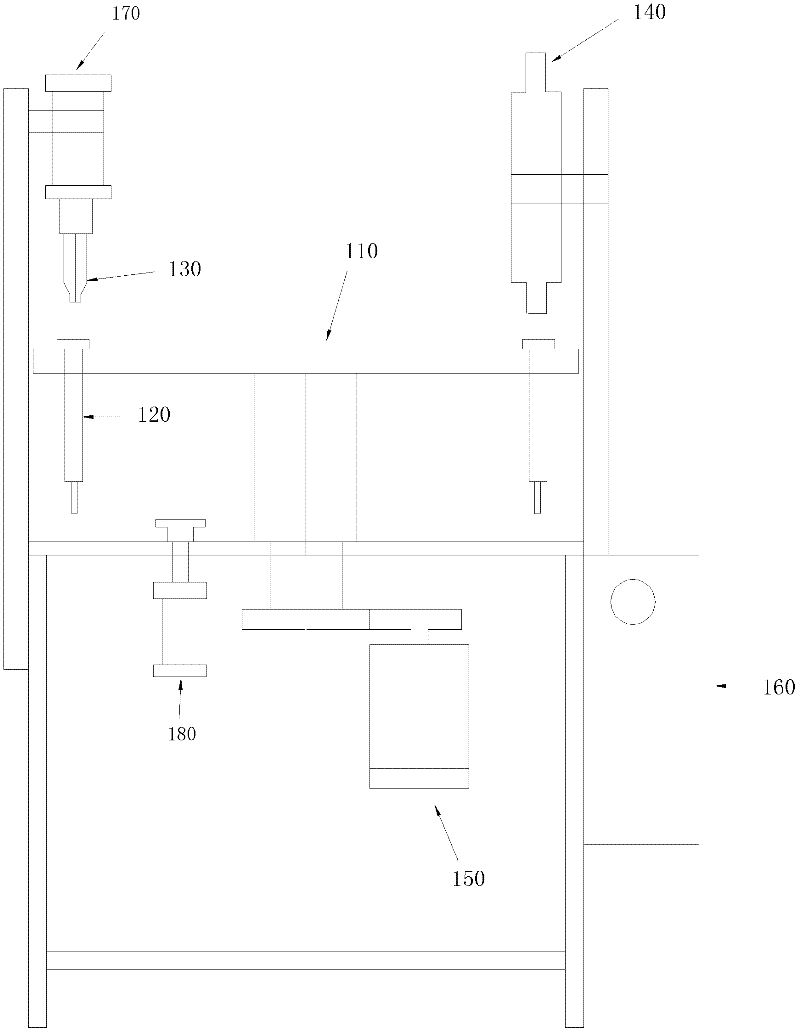

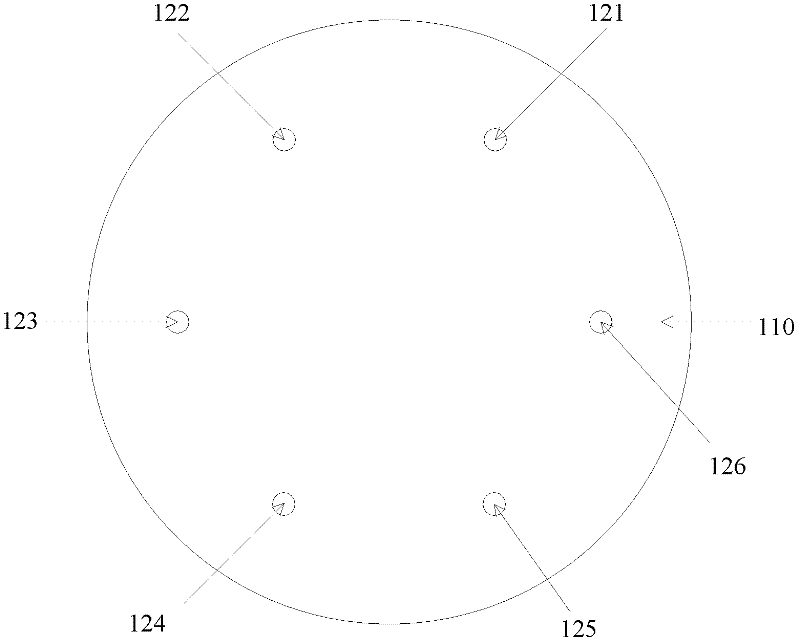

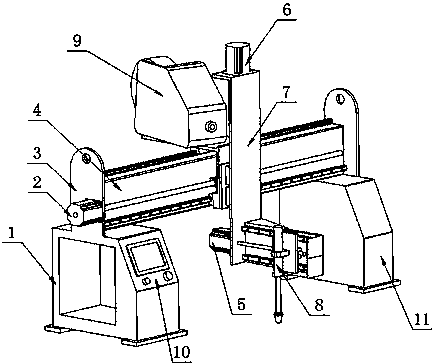

Rolling type fiber reinforced plastic pipe and aluminum material press-fitting equipment

PendingCN113306162AReliable productReduce manufacturing costTubular articlesMaterial resourcesManufacturing engineering

The invention provides rolling type fiber reinforced plastic pipe and aluminum material pressing equipment. The rolling type fiber reinforced plastic pipe and aluminum material press-fitting equipment comprises a base, a working platform is arranged on the base, a rotating device is arranged on the working platform, a pipe containing body is arranged on the rotating device, a press-fitting device is further arranged on the rotating device, and a pipe fixing device is further arranged on the working platform. Due to the arrangement of the press-fitting device, perfect press-fitting of aluminum parts and glass fiber reinforced plastic is achieved; according to the equipment, the qualified rate of a produced press-fit product reaches 99%, the product is stable and reliable, and the production cost is reduced; the production speed is 20 s / piece, which is far higher than the efficiency of using one piece of glue in 3 min in a traditional manual mode, so that manpower and material resources are saved; press-fit workpieces are uniform and attractive in appearance; and the production process is environmentally friendly and clean, and no waste is generated.

Owner:山东永丰液压机械有限公司

Tire breaking roller special welding machine

PendingCN110732811AEasy to operateCompact structureWelding/cutting auxillary devicesAuxillary welding devicesWall plateSoldering gun

The invention discloses a tire breaking roller special welding machine. The tire breaking roller special welding machine comprises a first welding seat, an X-axis transmission assembly, fixing wall plates, a movable frame, a Y-axis transmission assembly, a Z-axis transmission assembly, a displacement assembly, a water cooling welding gun, a wire feeder, a control box and a second welding seat. Thefixing wall plates are fixedly mounted on the top end faces of the first welding seat and the second welding seat through bolts, the X-axis transmission assembly is arranged on one side of the end face of the fixing wall plate on the top of the first welding seat, the movable frame is fixedly mounted on the end faces of the inner sides of the fixing wall plates through bolts, the displacement assembly is arranged on the outer side of the movable frame, and the Z-axis transmission assembly and the wire feeder are arranged on the top of the displacement assembly. The tire breaking roller special welding machine is easy to operate, different positions of a breaking roller can be welded by adjusting the position of the water cooling welding gun, the appearance of the welded breaking roller isuniform and attractive, and the welding quality is high; and meanwhile the labor intensity of workers can be greatly reduced, and the operating time is shortened.

Owner:山东金兴自动焊接设备有限公司

Vacuum auxiliary molding technique produced by high-facade composite material for ship

ActiveCN101352925BThe mechanical properties of the parts are stableStable mechanical propertiesHigh elevationEngineering

The invention discloses a vacuum assistant resin infused method for molding a high elevation part of composite materials used on ship and comprises the working procedures of raw material preparation, forming process, etc. The invention is characterized in that in the forming process, the direction of a resin channel is the same as the height direction of the product; a plurality of glue-injectionpipes or exhaust pipes parallel to the width direction of the product are arranged in the height direction of the product; the product is divided into a plurality of forming units by the glue-injection pipes or exhaust pipes in the height direction; the distance between the edge of permeable medium and the glue-injection pipes or exhaust pipes is controlled and each unit comprises a flood protection material system of stream guidance, glue injection and gas exhaust, and the like; in the forming process, each unit is immersed successively from bottom to top in a relay style. The invention is used for molding the high elevation part of composite materials used on ship, increases the penetration degree and uniformity of the resin, raises the product quality, and gives good mechanical and sea-water proof property to the product with greatly reduced weight, thereby improving the loading capacity and ample stability of the operation platform on water surface and under water.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com