A kind of freeze-dried preparation of coenzyme A and preparation method thereof

A technology of freeze-dried preparations and coenzyme, which is applied in the direction of freeze-dried transportation, medical preparations containing active ingredients, anti-toxins, etc., which can solve the problems of unstable product quality, reduced potency content, high drying weight loss, etc., and achieve the appearance of finished products Good, stable finished product quality, simple prescription effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

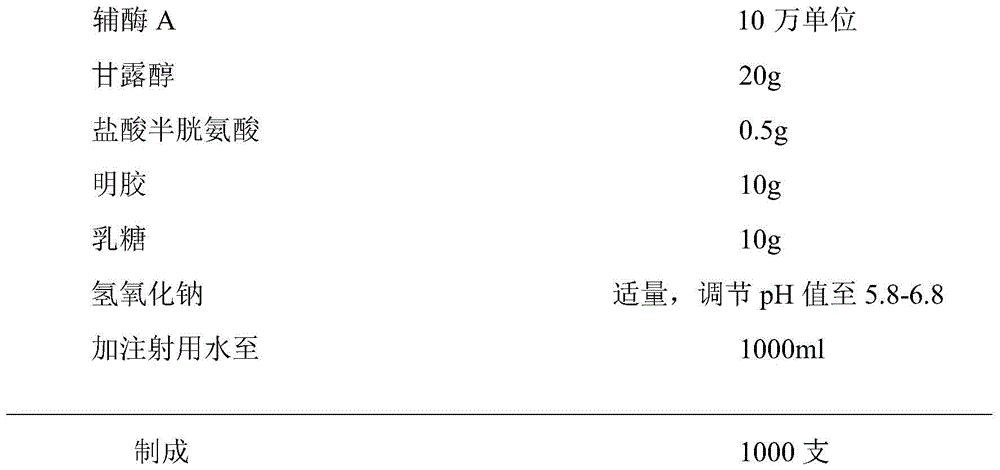

Embodiment 1

[0026]

[0027] Preparation

[0028] (1) Take by weighing the stabilizer gelatin, lactose, and coenzyme A of the prescribed amount, first add the stabilizer to prepare water for injection with 50% volume, stir and heat to 40°C for dissolution, add medicinal charcoal with a volume of 0.1% (g / ml), Stir and adsorb for 25 minutes, filter and decarbonize, add sodium hydroxide to adjust the pH value to 5.8-6.8, cool to room temperature, then add weighed coenzyme A to disperse it, and stir to form a stable solution.

[0029] (2) Take by weighing the skeleton agent mannitol and the reducing agent cysteine hydrochloride of the prescription amount, add 30% water for injection of the preparation volume, stir to make it dissolve completely, add medicinal charcoal with a volume of 0.1% (g / ml), stir Adsorbed for 20 minutes, decarbonized by filtration, adjusted the pH value to 5.8-6.8 by adding sodium hydroxide, and cooled to room temperature.

[0030] (3) Combine the above two liquids...

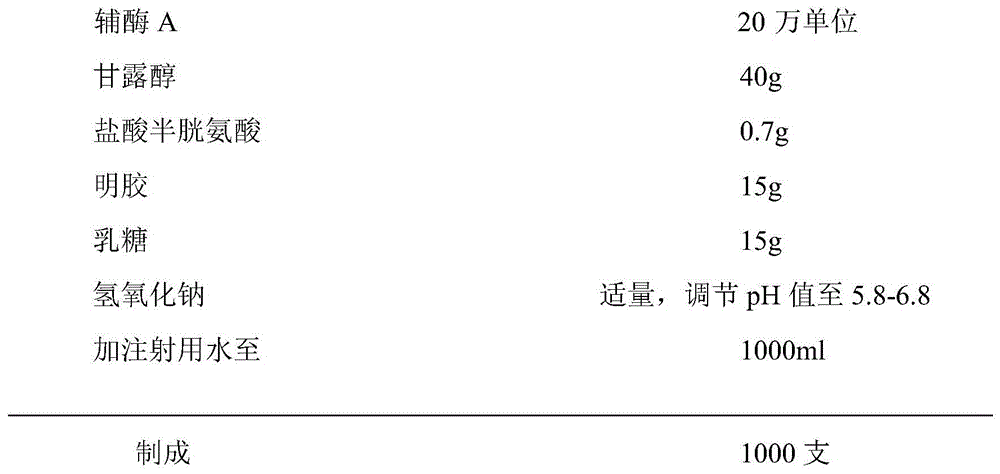

Embodiment 2

[0036]

[0037] Preparation

[0038] (1) Take by weighing the stabilizer gelatin, lactose, and coenzyme A of the prescribed amount, first add the stabilizer to prepare water for injection with 50% volume, stir and heat to 40°C for dissolution, add medicinal charcoal with a volume of 0.5% (g / ml), Stir and adsorb for 30 minutes, filter and decarbonize, add sodium hydroxide to adjust the pH value to 5.8-6.8, cool to room temperature, then add weighed coenzyme A to disperse it, and stir to form a stable solution.

[0039] (2) take by weighing the skeleton agent mannitol of recipe quantity, reducing agent cysteine hydrochloride, then add preparation volume 30% water for injection, stir and make it dissolve completely, add the medicinal charcoal of volume 0.5% (g / ml), Stir and adsorb for 30 minutes, filter to remove carbon, add sodium hydroxide to adjust the pH value to 5.8-6.8, and cool to room temperature.

[0040] (3) Combine the above two liquids, add water for injection t...

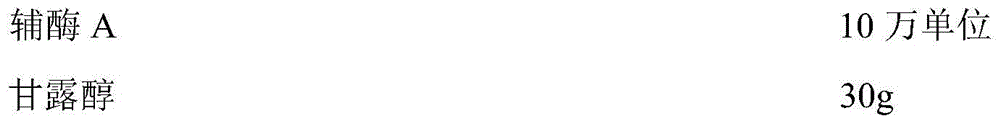

Embodiment 3

[0046]

[0047]

[0048] Preparation

[0049] (1) Take by weighing the stabilizer gelatin, lactose, and coenzyme A of the prescribed amount, first add the stabilizer to prepare water for injection with 50% volume, stir and heat to 40°C for dissolution, add medicinal charcoal with a volume of 0.1% (g / ml), Stir and adsorb for 25 minutes, filter and decarbonize, add sodium hydroxide to adjust the pH value to 5.8-6.8, cool to room temperature, then add weighed coenzyme A to disperse it, and stir to form a stable solution.

[0050] (2) Take by weighing the skeleton agent mannitol and the reducing agent cysteine hydrochloride of the prescription amount, add 30% water for injection of the preparation volume, stir to make it dissolve completely, add medicinal charcoal with a volume of 0.1% (g / ml), stir Adsorbed for 25 minutes, filtered to remove carbon, added sodium hydroxide to adjust the pH value to 5.8-6.8, and cooled to room temperature.

[0051] (3) Combine the above two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com