Novel shielding tool for flywheel housing

A flywheel housing and tooling technology, applied in the direction of injection devices, etc., can solve the problems of easy deformation, contamination of the inner wall of the joint surface, uneven distribution of the fixing force of the cover, and achieve strong vibration and expansion ability, smooth paint surface without bulge, The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

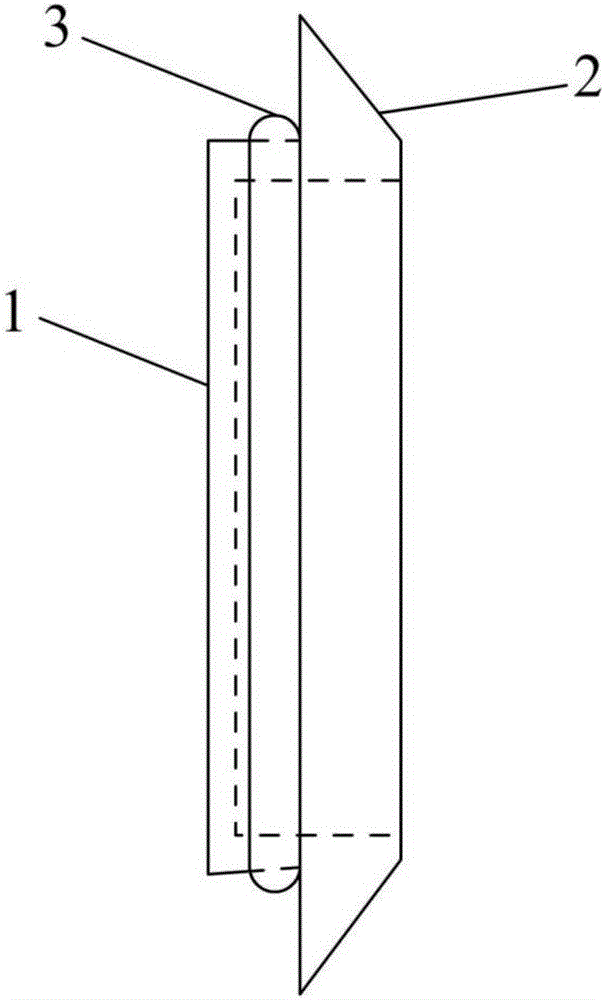

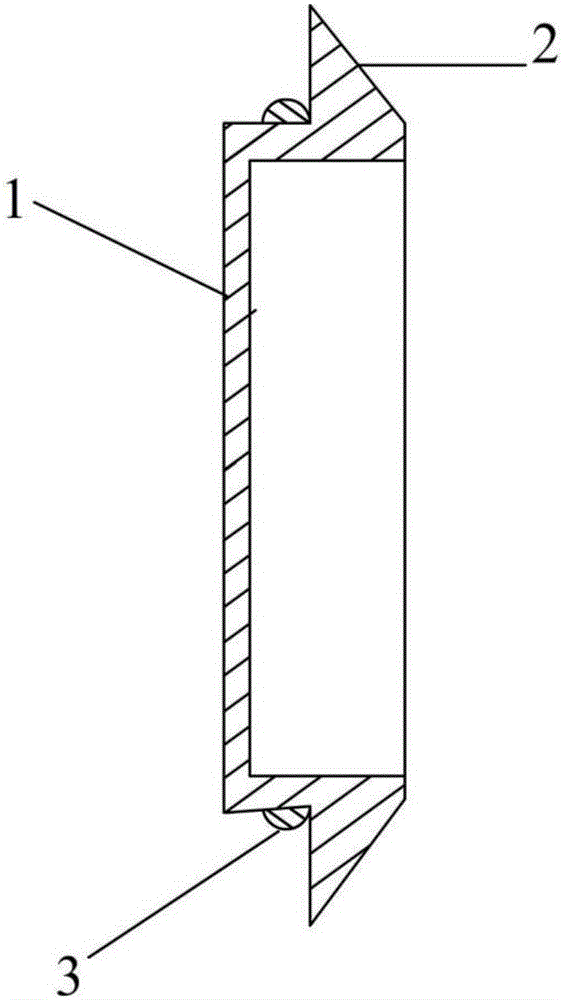

[0017] Such as Figure 1~2 As shown, a new type of flywheel shell shielding tooling includes a cover body, which is made of heat-resistant resin material with low expansion coefficient, and is recessed from the outside to the inside from the middle to form the inner convex body 1 in the middle and the peripheral part 2 structure; the diameter of the inner convex body 1 is 2mm smaller than the shielding cavity of the flywheel housing, which is beneficial to the disassembly and assembly of the cover; the peripheral part 2 is designed with a conical surface, and the conical surface is retracted, and the The tapered surface is smooth, and at the same time, after the cover is put into the flywheel housing, the top end of the peripheral part 2 is flush with the outer body surface of the joint of the flywheel housing. With this design, the diameter of the peripheral part gradually decreases backwards. It is conducive to the flow of paint liquid along the rear, and can effectively pre...

specific Embodiment 2

[0018] Such as Figure 1~2 As shown, a new type of flywheel shell shielding tooling includes a cover body, which is made of heat-resistant resin material with low expansion coefficient, and is recessed from the outside to the inside from the middle to form the inner convex body 1 in the middle and the peripheral part 2 structure; the diameter of the inner convex body 1 is 3mm smaller than the shielding inner cavity of the flywheel housing, which is beneficial to the disassembly and assembly of the cover; the peripheral part 2 is designed with a conical surface, and the conical surface is retracted, The tapered surface is smooth, and at the same time, after the cover is put into the flywheel housing, the top end of the peripheral part 2 is flush with the outer body surface of the joint of the flywheel housing. With this design, the diameter of the peripheral part gradually decreases backwards. It is beneficial for the paint liquid to flow along the rear, and can effectively pre...

specific Embodiment 3

[0019] Such as Figure 1~2 As shown, a new type of flywheel shell shielding tooling includes a cover body, which is made of heat-resistant resin material with low expansion coefficient, and is recessed from the outside to the inside from the middle to form the inner convex body 1 in the middle and the peripheral part 2 structure; the diameter of the inner convex body 1 is 4mm smaller than the shielding inner cavity of the flywheel housing, which is beneficial to the disassembly and assembly of the cover; the peripheral part 2 is designed with a conical surface, and the conical surface is retracted, and the The tapered surface is smooth, and at the same time, after the cover is put into the flywheel housing, the top end of the peripheral part 2 is flush with the outer body surface of the joint of the flywheel housing. With this design, the diameter of the peripheral part gradually decreases backwards. It is conducive to the flow of paint liquid along the rear, and can effective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com