Rolling type fiber reinforced plastic pipe and aluminum material press-fitting equipment

A fiber reinforced, pressing equipment technology, applied in the direction of tubular articles, other household appliances, household appliances, etc., can solve the problems that the equipment cannot be pressed, the shape is uneven, and cannot be produced, and the production process is environmentally friendly and clean. , The product is stable and reliable, and the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

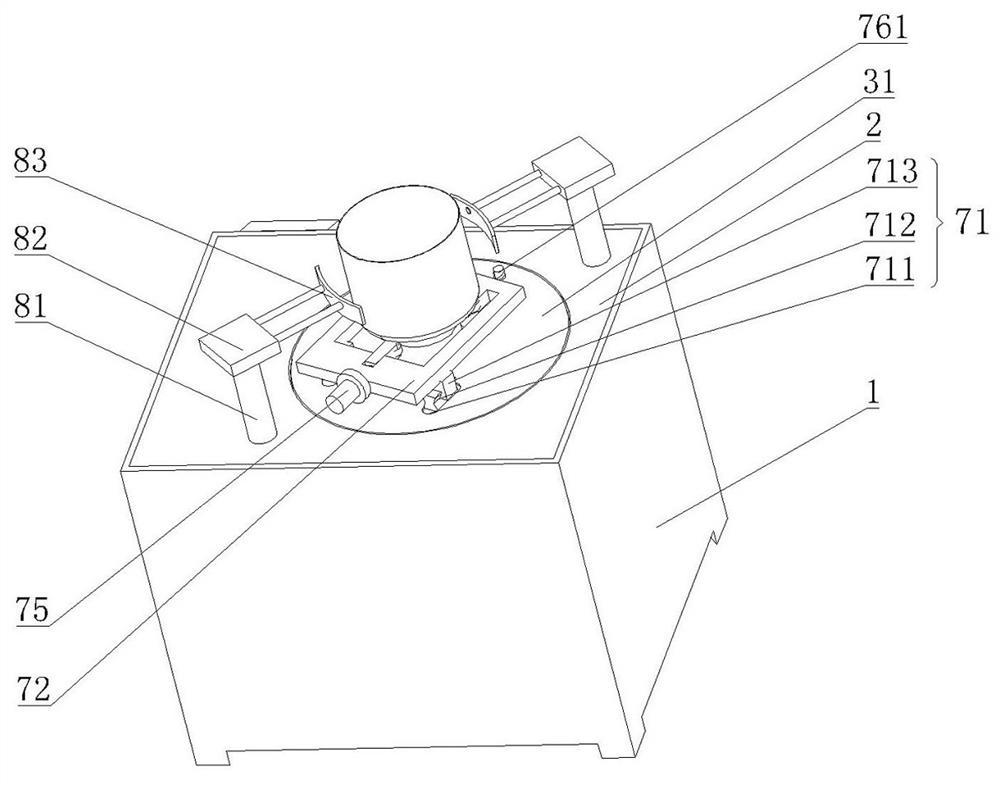

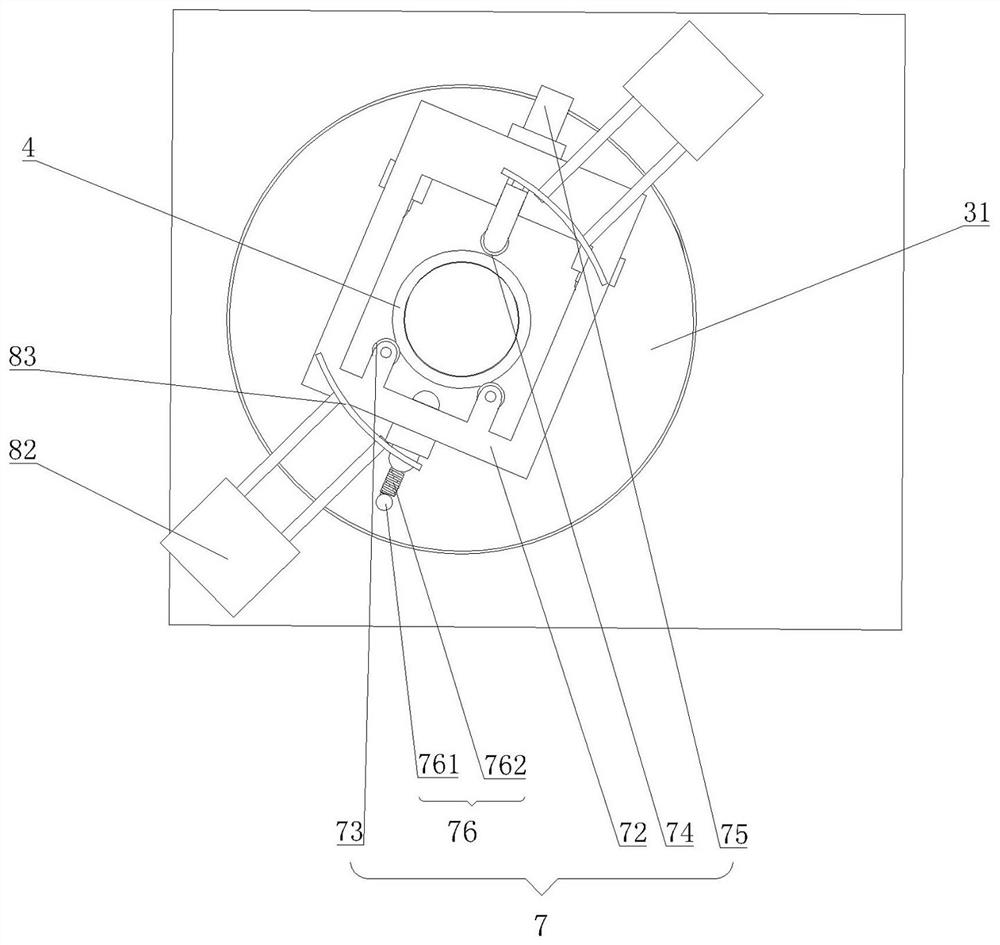

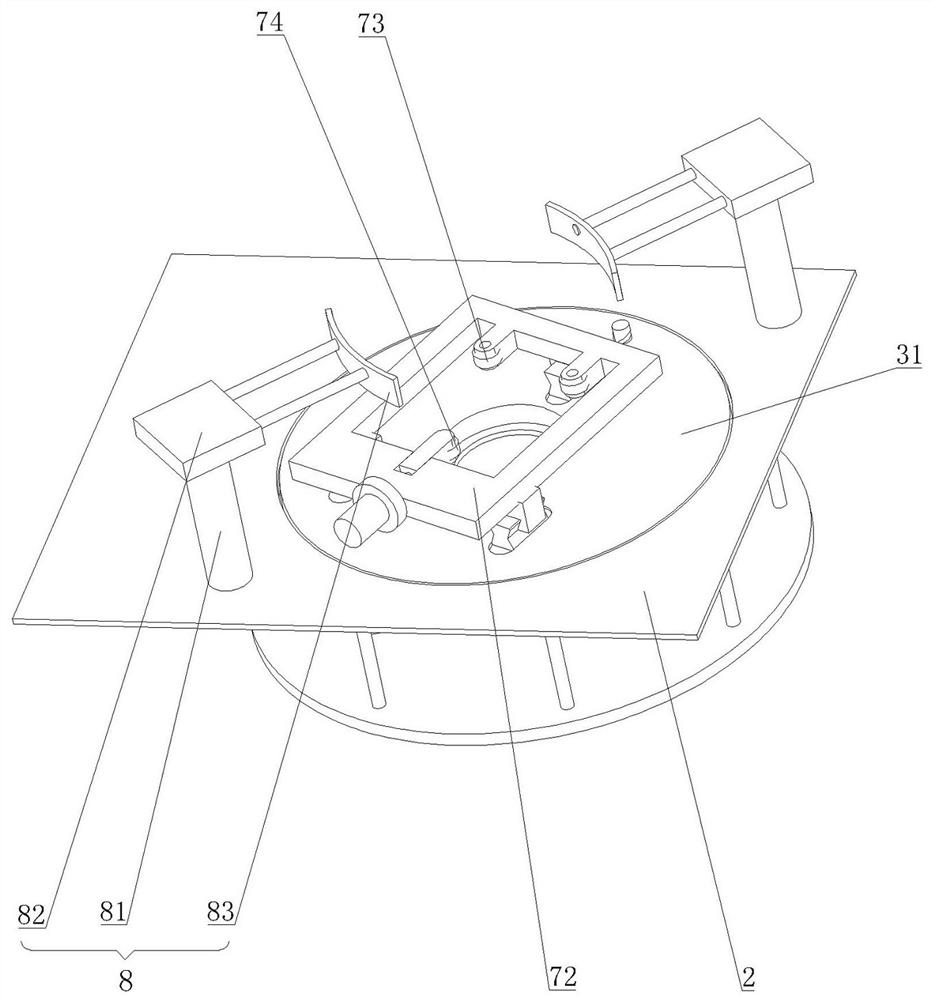

[0036] Example: as attached figure 1 As shown, a rolling type fiber reinforced plastic pipe and aluminum pressing equipment, including a base 1, the base 1 is provided with a hydraulic station for oil supply (not shown in the figure), the base 1 There is also a working platform 2 on the working platform 2, a rotating device 3 is arranged on the working platform 2, a pipe material placing body 4 is arranged on the rotating device 3, and a workpiece positioning block 5 is placed in the pipe material placing body 4. The pipe material 6 to be processed is placed between the placing body 4 and the workpiece positioning block 5 for positioning and preventing excessive extrusion; the rotating device 3 is also provided with a pressing device 7, and the working platform 2 is also A pipe fixing device 8 is provided.

[0037] The rotating device 3 includes a rotating table 31 rotatably disposed on the working platform 2 , the pipe placing body 4 is disposed on the rotating table 31 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com