Toning method for PET bottle-grade polyester chip

A polyester chip and color oil technology, which is applied in the field of color matching in the preparation process, can solve the problems of stable influence of dosage production process, high yellow index, large hue fluctuation, etc., and achieves uniform and beautiful appearance, good gloss, The effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

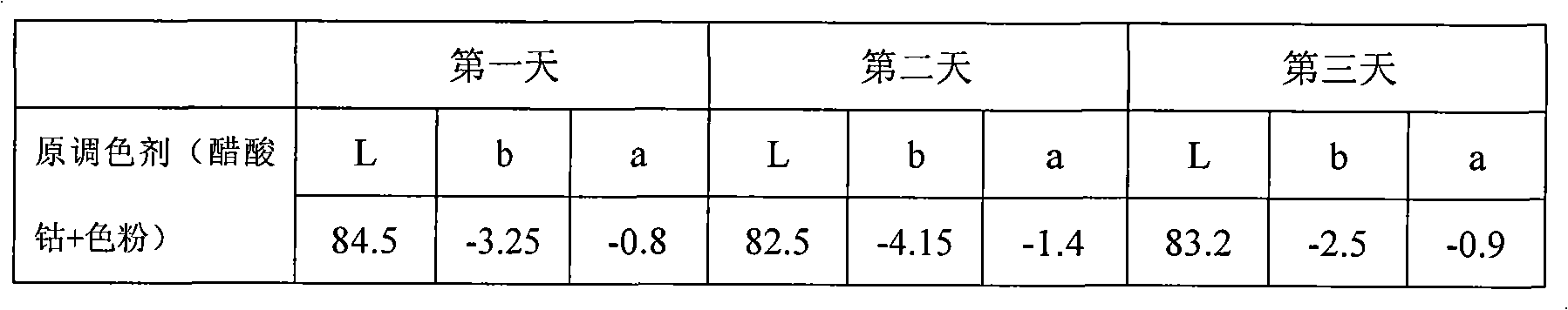

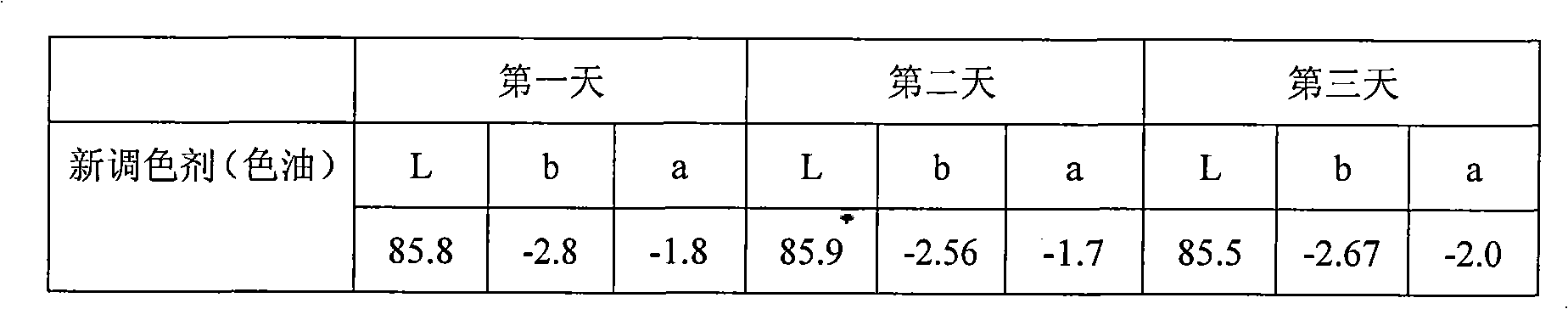

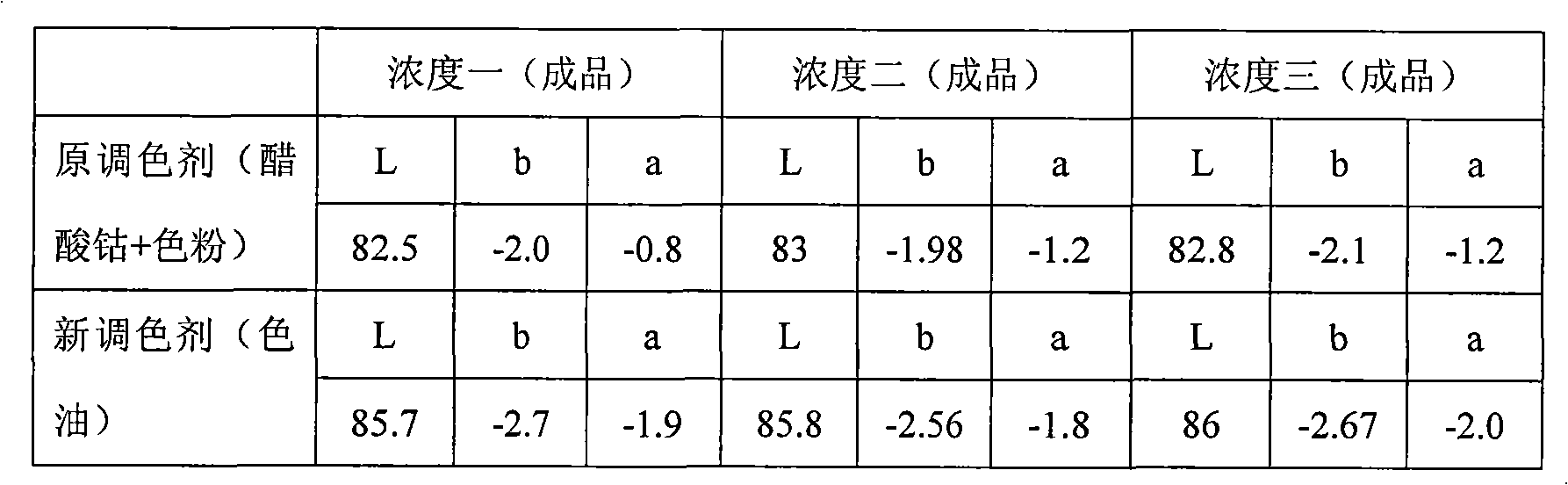

Examples

Embodiment 1

[0021] During the preparation of PET bottle-grade polyester chips, ethylene glycol is added to the blending tank, and ethylene glycol is used as a carrier. Purple oil and blue oil are added to ethylene glycol at a temperature of 65°C, and mixed evenly , with a concentration of 0.03‰ and 0.08‰, respectively, and then transported to the supply tank for storage, and continuously added from the pipeline to the production of bottle flake polyester.

Embodiment 2

[0023] During the preparation of PET bottle-grade polyester chips, ethylene glycol is added to the blending tank, and ethylene glycol is used as a carrier. Purple oil and blue oil are added to ethylene glycol at a temperature of 70°C and mixed evenly , with a concentration of 0.08‰ and 0.05‰, respectively, and then transported to the supply tank for storage, and continuously added from the pipeline to the production of bottle flake polyester.

Embodiment 3

[0025] In the preparation process of PET bottle-grade polyester chips, ethylene glycol is added to the blending tank, and ethylene glycol is used as a carrier, and purple oil and blue oil are added to ethylene glycol at a temperature of 80 ° C, and mixed evenly , with a concentration of 1.3‰ and 1.5‰, respectively, and then transported to the supply tank for storage, and continuously added from the pipeline to the production of bottle flake polyester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com