Safe and energy-saving gas stove

A gas furnace, safe technology, applied in the direction of burner, combustion method, heating fuel, etc., can solve the problems of energy consumption, low combustion rate, low combustion rate, etc., and achieve improved combustion efficiency, improved mixing effect, and improved combustion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

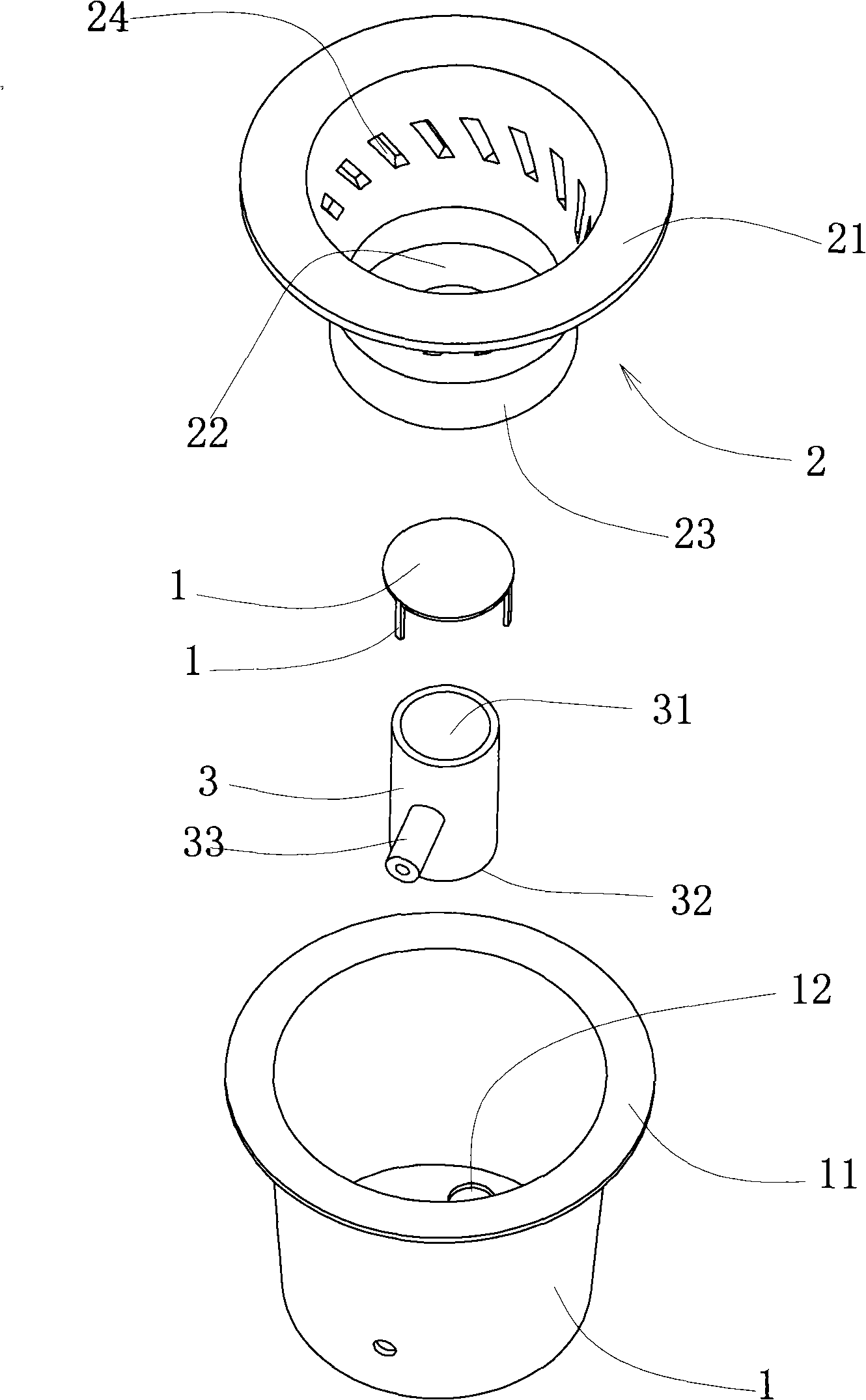

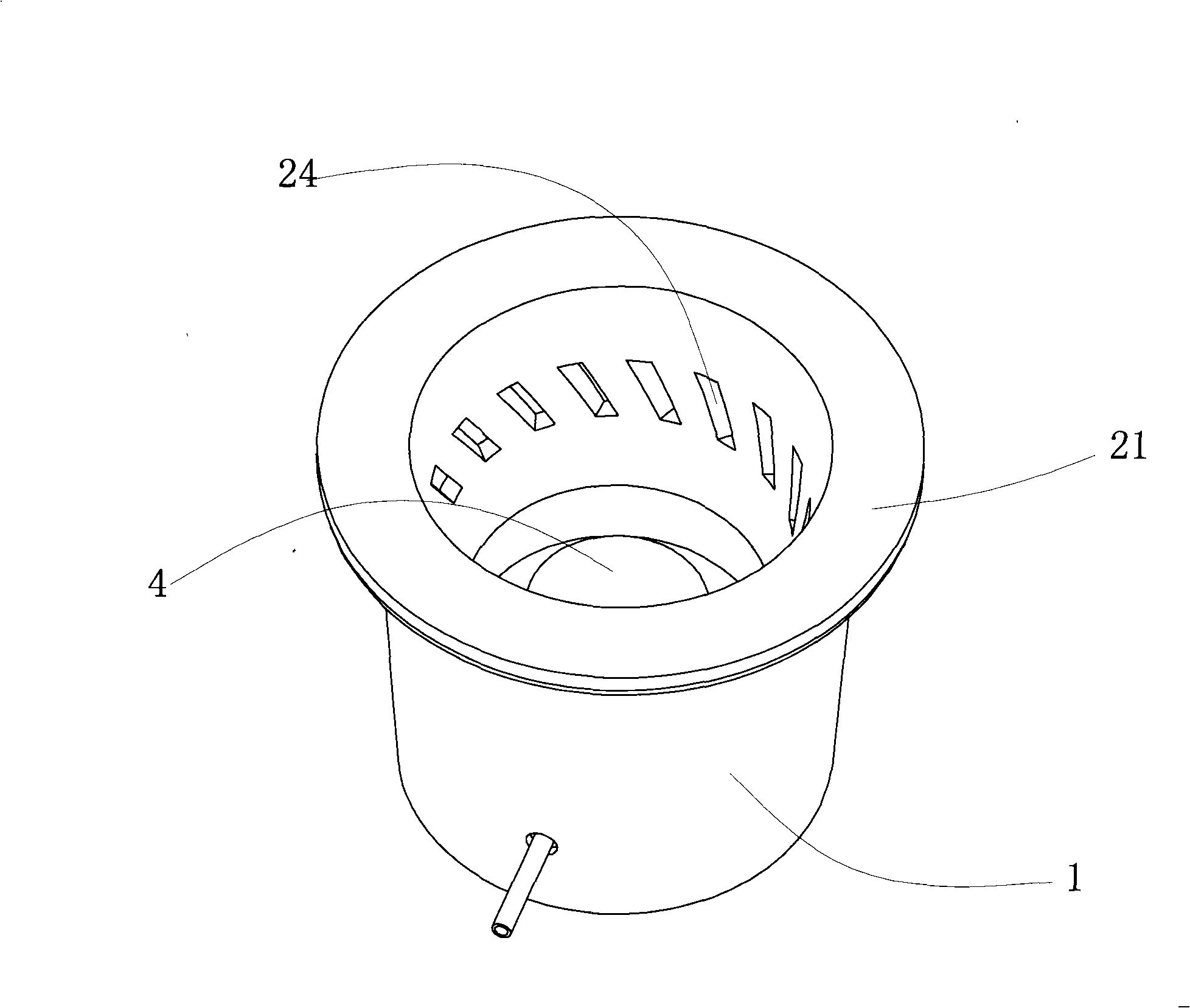

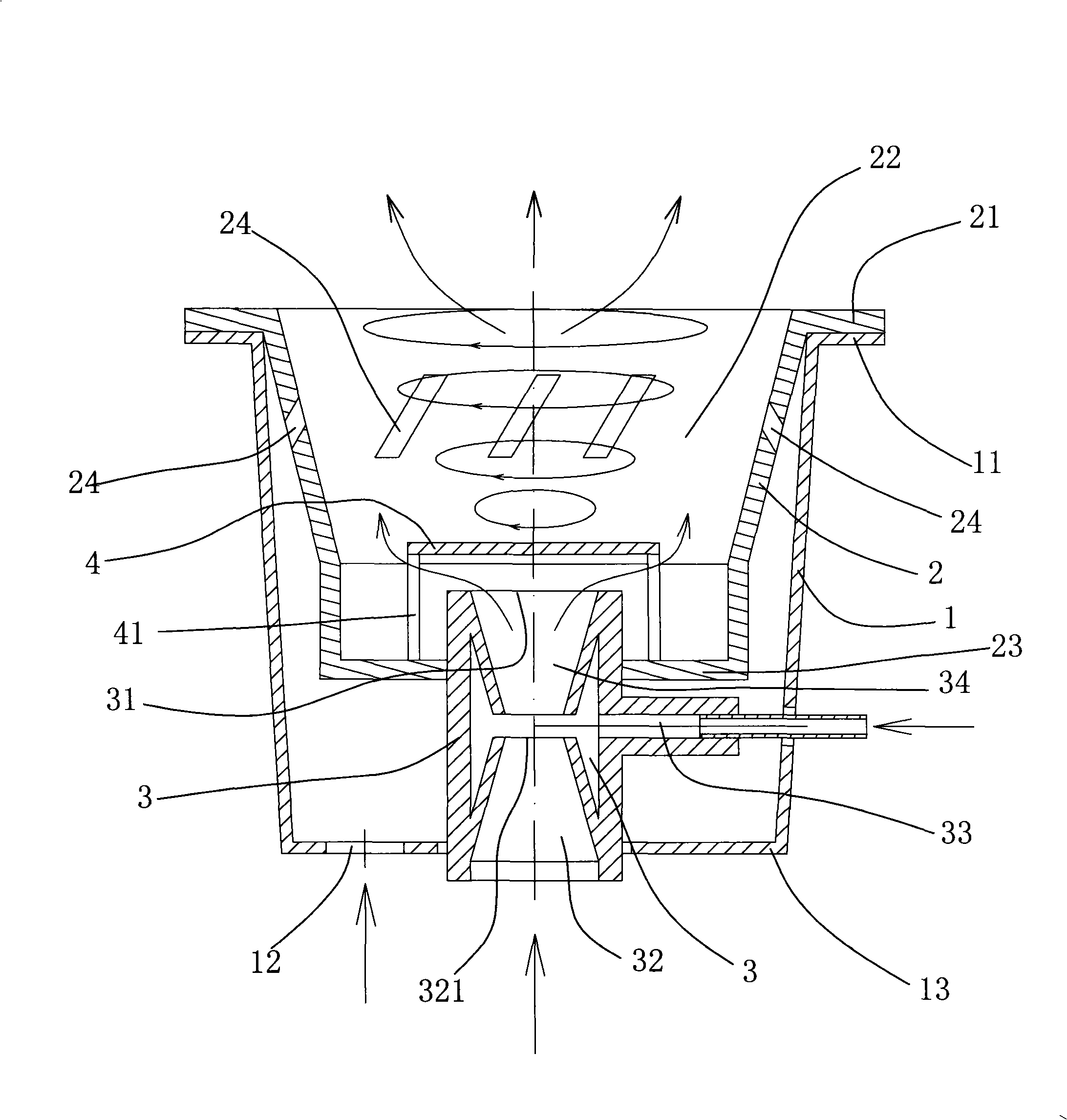

[0021] See Figure 1 to Figure 3 , Figure 1 to Figure 3 Disclosed is a safe and energy-saving gas stove, comprising a casing 1 and a combustion cavity 2, the combustion cavity 2 is located above the casing 2, the casing 1 is in an inverted conical shape, and the upper end of the casing 1 is curled outwards to form a An annular plane 11, the combustion chamber 2 is conical, and its upper end is an outwardly curled annular plane 21, the annular plane 21 of the combustion chamber 2 is placed on the annular plane 11 of the shell 1, The two are fixedly connected by screws (not shown); the combustion chamber 22 of the combustion chamber 2 extends downwards into the housing 1, and in the housing 1, a jet mixer is provided at the bottom of the combustion chamber 2 3. The outlet end 31 of the jet mixer 3 is connected to the bottom surface 23 of the combustion chamber 2 and communicates with the combustion chamber 22 of the combustion chamber 2, above the outlet end 31 of the jet mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com