Implementation method for bidirectional reversible feeding and discharging of annealing furnace

A realization method and technology of annealing furnace, applied in the direction of furnace, furnace type, heat treatment furnace, etc., can solve the problem that the material on the left side of the preparation table cannot be sent to the right annealing furnace, etc., so as to improve the efficiency of equipment installation and ensure Stability, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

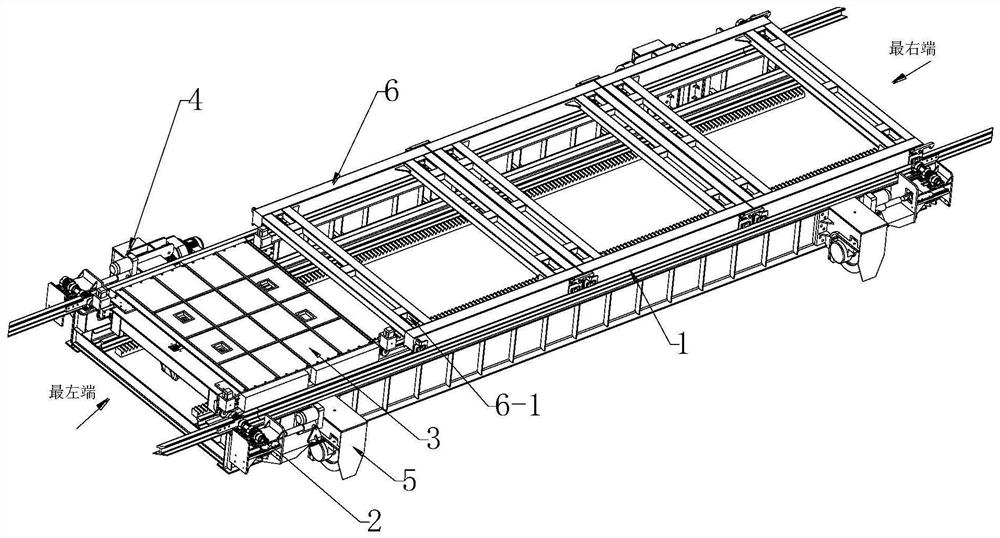

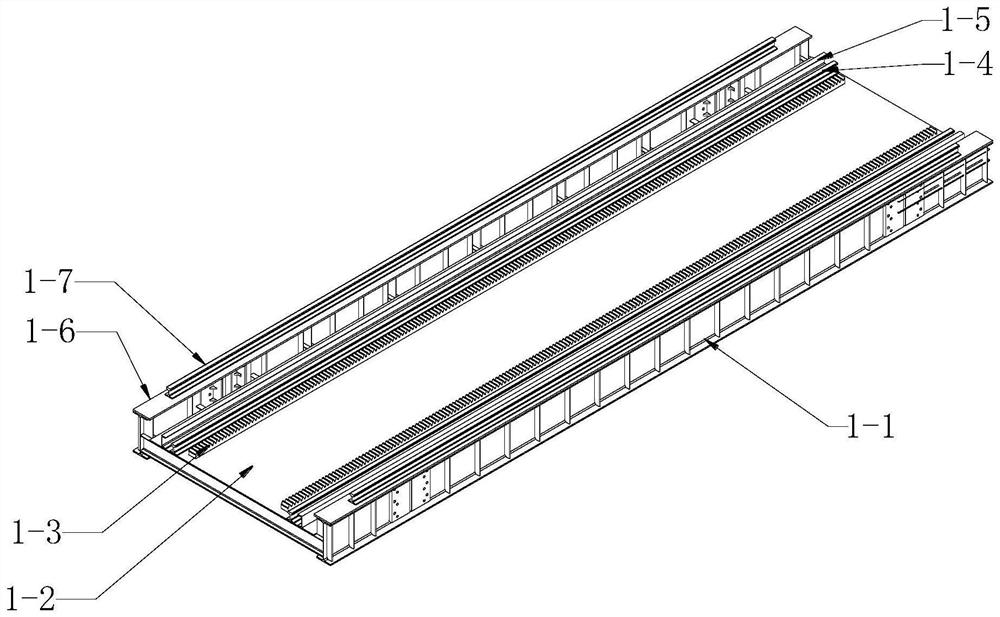

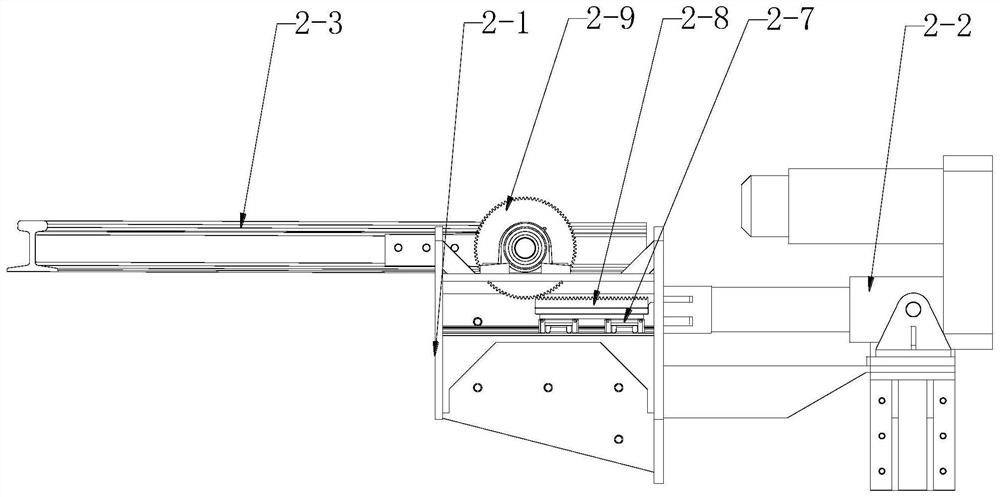

[0052] as attached figure 1 As shown, the method for realizing the two-way reversible feeding and discharging of the annealing furnace of the present invention, the method is to install the rail mechanism 2 at the two ends of the large material truck support frame 1 respectively, so as to realize the large material vehicle support frame 1 and the withdrawal. Lap jointing of the guide rails in the furnace; then install the pusher assembly 3 that can reciprocate and reversibly push the material rack tray 6 on the large material cart support frame 1, and the height of the pusher assembly 3 is lower than the lower edge of the material rack tray 6 to realize The two-way reversible material in and out of the annealing furnace. The pusher assembly 3 includes a pusher trolley mechanism and a guide rail layer walking mechanism. The pusher trolley mechanism reciprocates along the large material trolley support frame 1 and can change directions, and the pusher trolley mechanism is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com