Self-propelled ground milling machine with integrated maintenance platform

A self-propelled, milling technology, applied in the direction of roads, roads, road repairs, etc., can solve the problems of engine component damage, operator injury, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

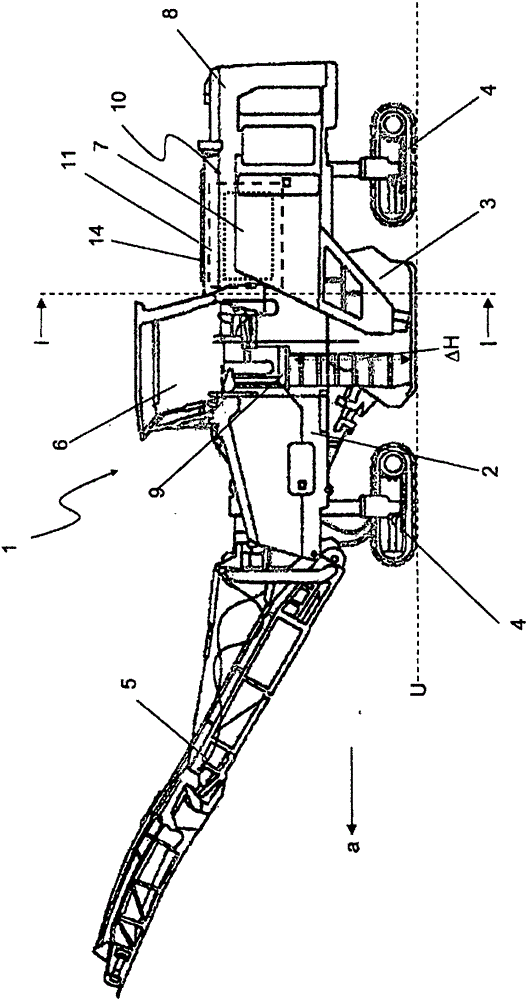

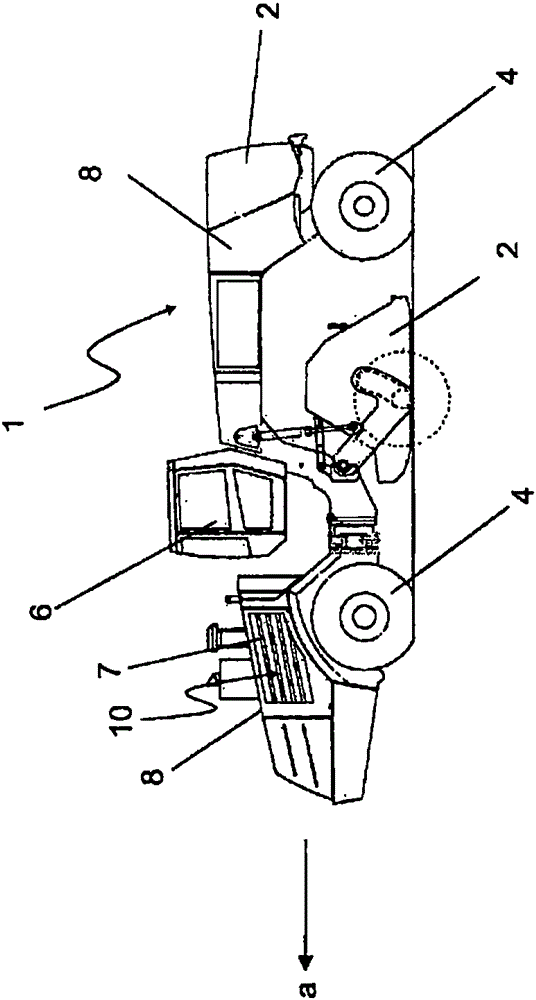

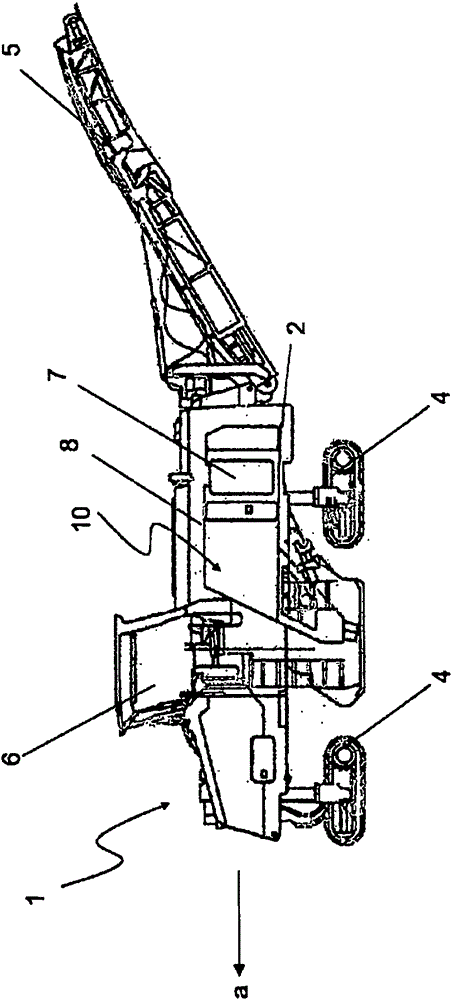

[0044] Identical elements are shown with the same reference numerals in the figures, wherein not every component that is repeated in the figures has to be individually identified in each figure.

[0045] Figure 1a A generic road milling machine 1 is shown in side view. Specifically, the invention relates to a road milling machine of a road cold milling type of a large milling machine. next in Figures 2a to 5b Representatively for such a road milling machine is the road milling machine 1, wherein the formation of the maintenance platform within the scope of the invention can also be used in particular in Figure 1b Stabilized Soil Mixer / Pavement Recycler Neutralizer Figure 1c in surface mining machines.

[0046] Figure 1a , 1b The important elements of the road milling machine 1 of and 1c are the frame 2, the milling rotor (not shown in FIG. Figure 1b Stabilized soil mixer / road surface reclaimer in the stabilized soil mixer / pavement reclaimer), cockpit 6, drive motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com