Suction nozzle for a vacuum cleaner

A technology of vacuum cleaners and sensors, applied in the direction of vacuum cleaners, suction nozzles, applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

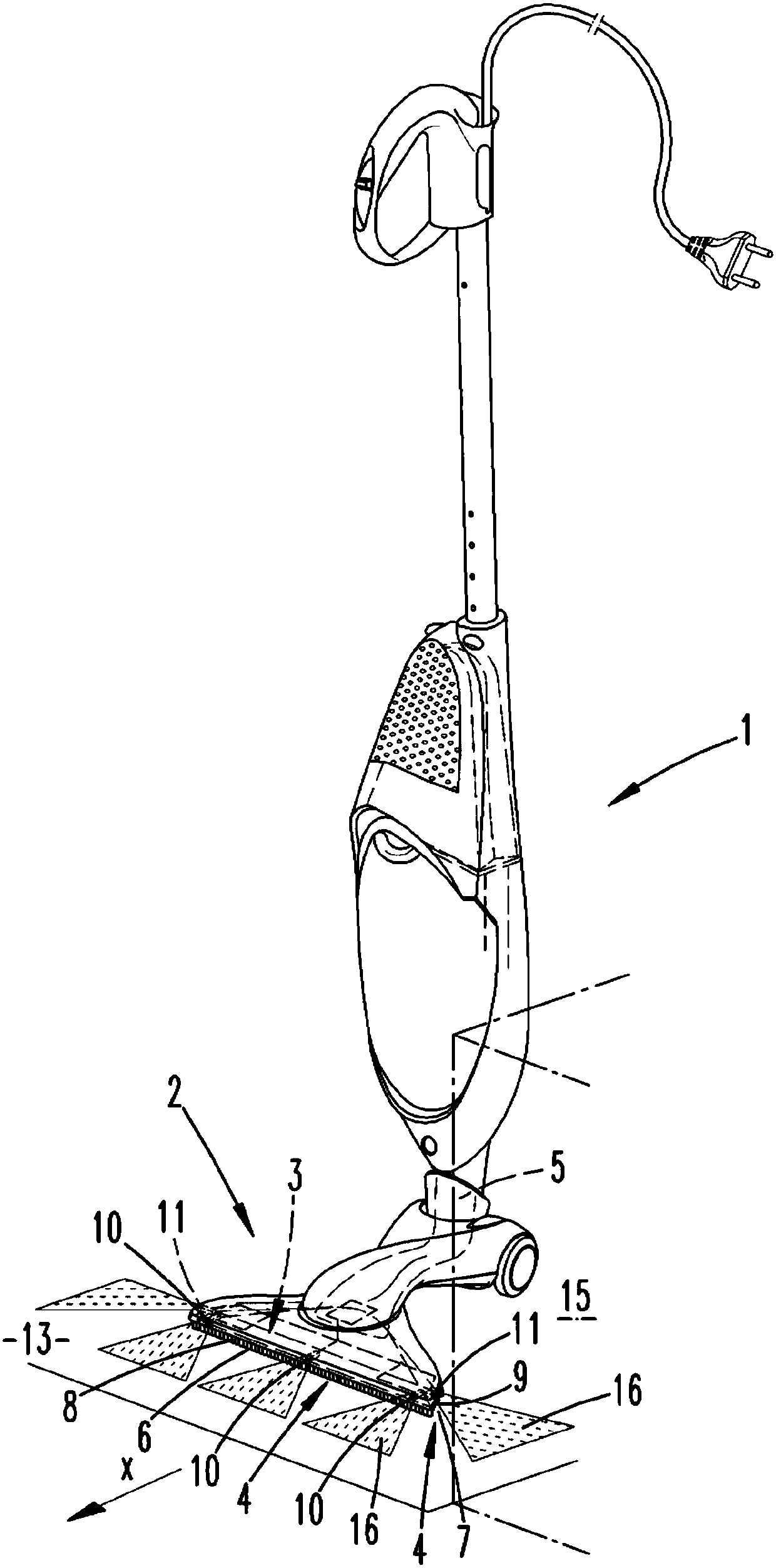

[0025] exist figure 1 The vacuum cleaner 1 shown in is a conventional hand-held floor vacuum cleaner with a suction nozzle 2 according to the invention. The suction nozzle 2 has a suction opening 3 , the suction air flow outlet 5 of which is fluidically connected to the fan of the vacuum cleaner 1 via a corresponding channel connection. Suction material sucked in through the suction opening 3 of the suction nozzle 2 thus passes through the suction air flow outlet 5 into the filter chamber of the vacuum cleaner 1 , which is provided in a conventional manner, for example with a dust filter bag.

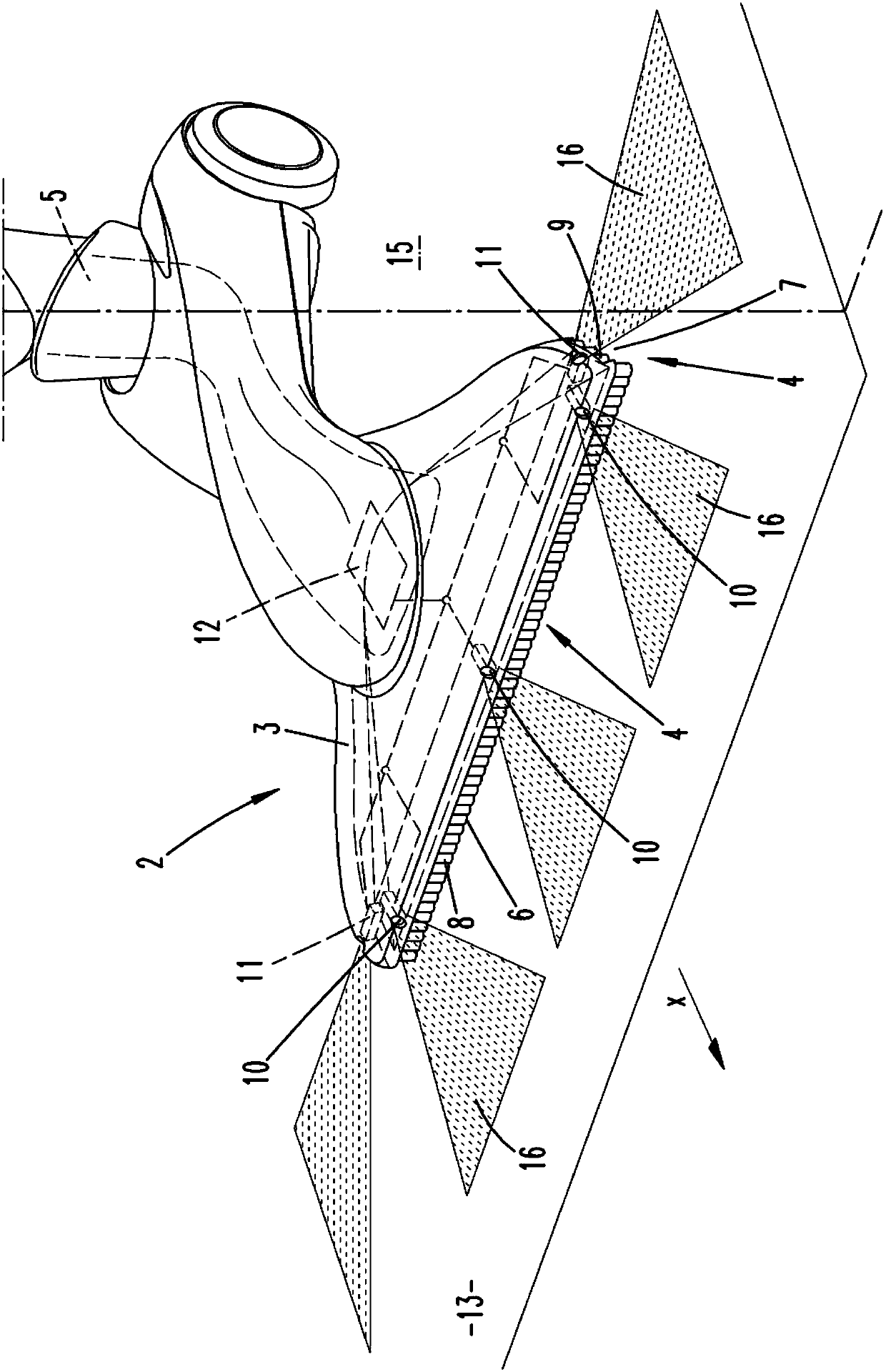

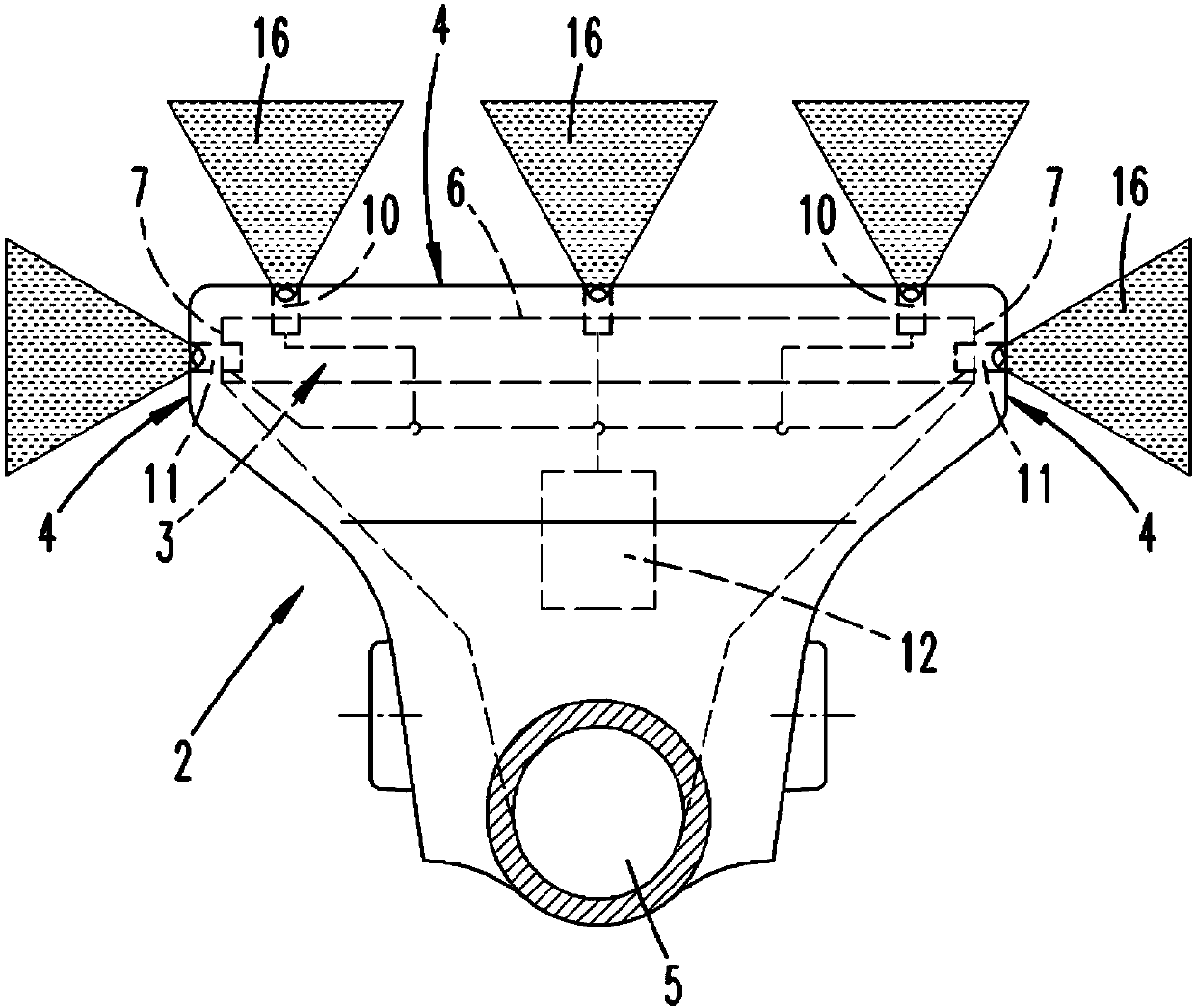

[0026] Such as figure 2 As shown in detail, the suction nozzle 2 has a suction opening 3 , the suction edge 4 of which defines the partial area of the surface 13 to be cleaned to which the negative pressure is applied. The suction edge 4 has a plurality of suction edge sections 6 , 7 , of which a first suction edge section 6 is oriented substantially perpendicularly to the general ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com