Patents

Literature

47results about How to "Change handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

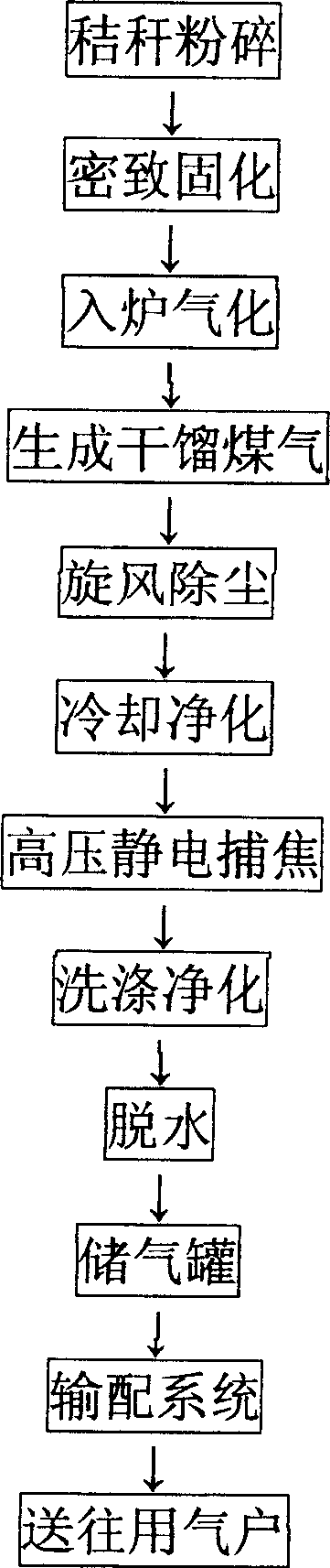

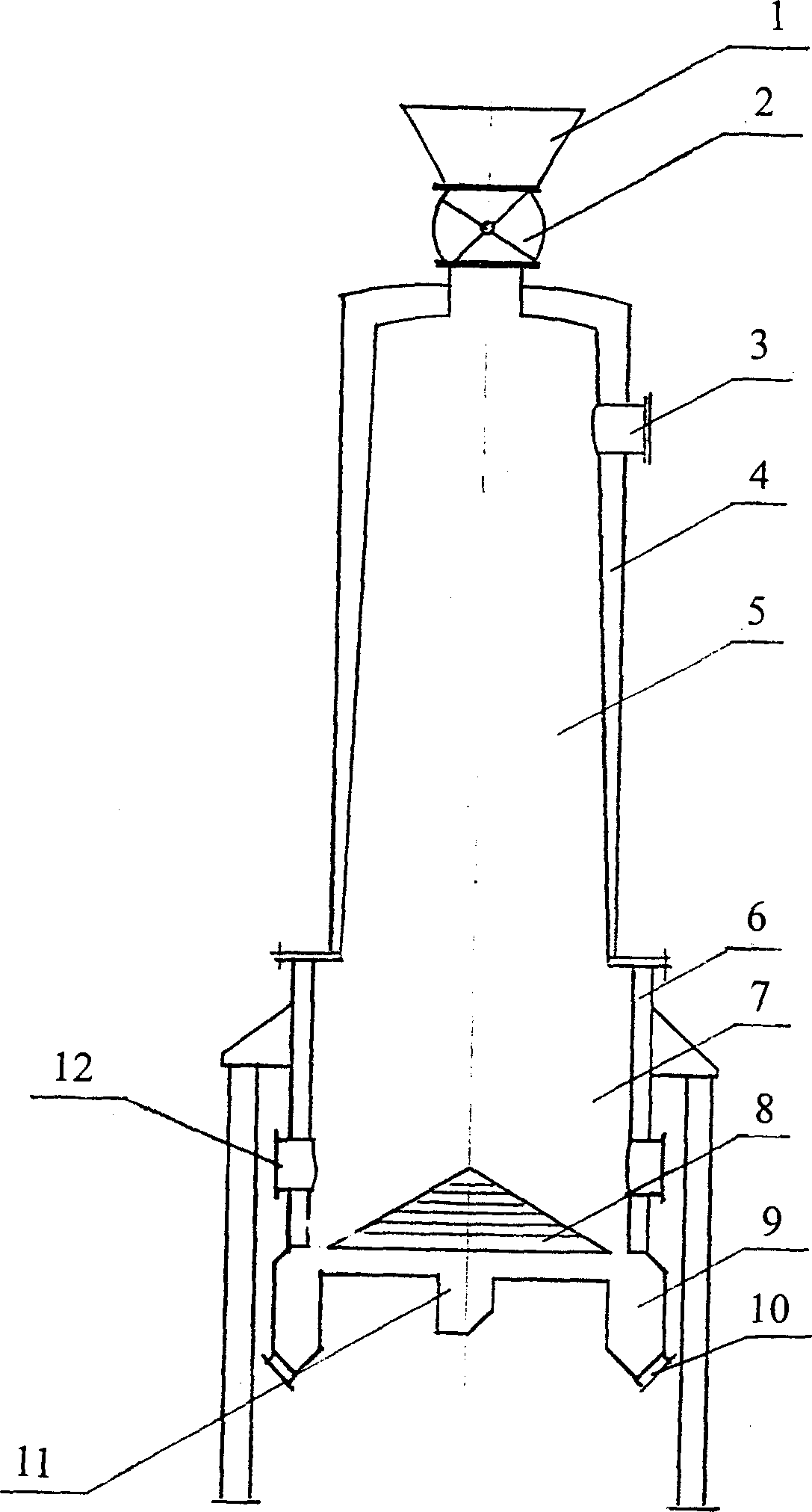

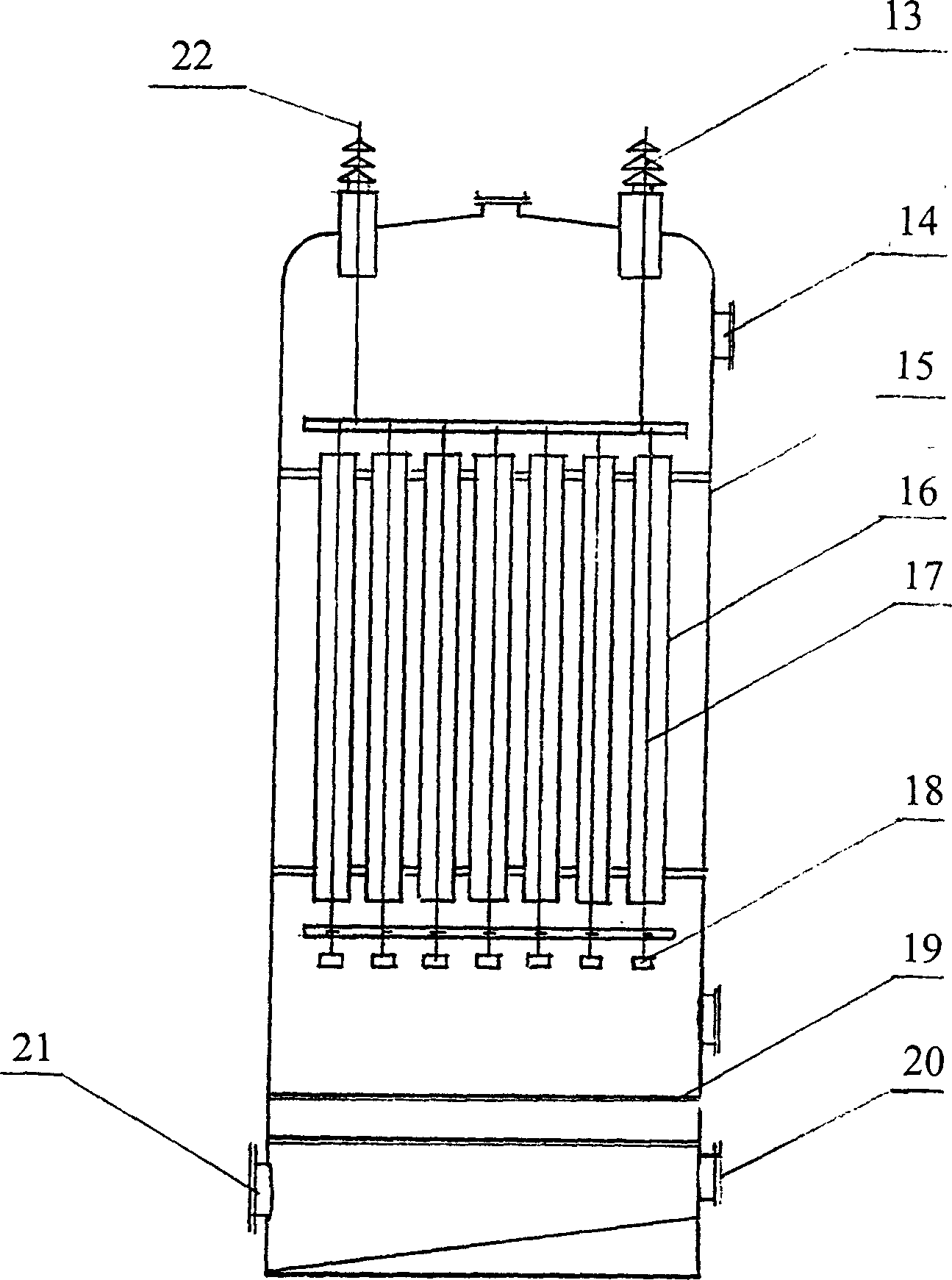

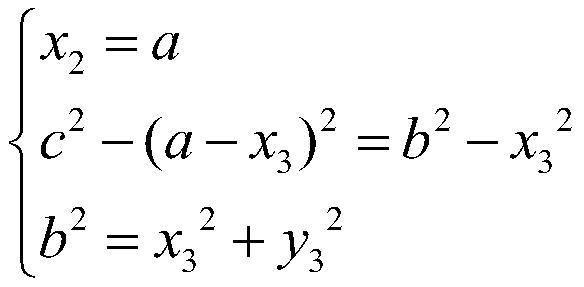

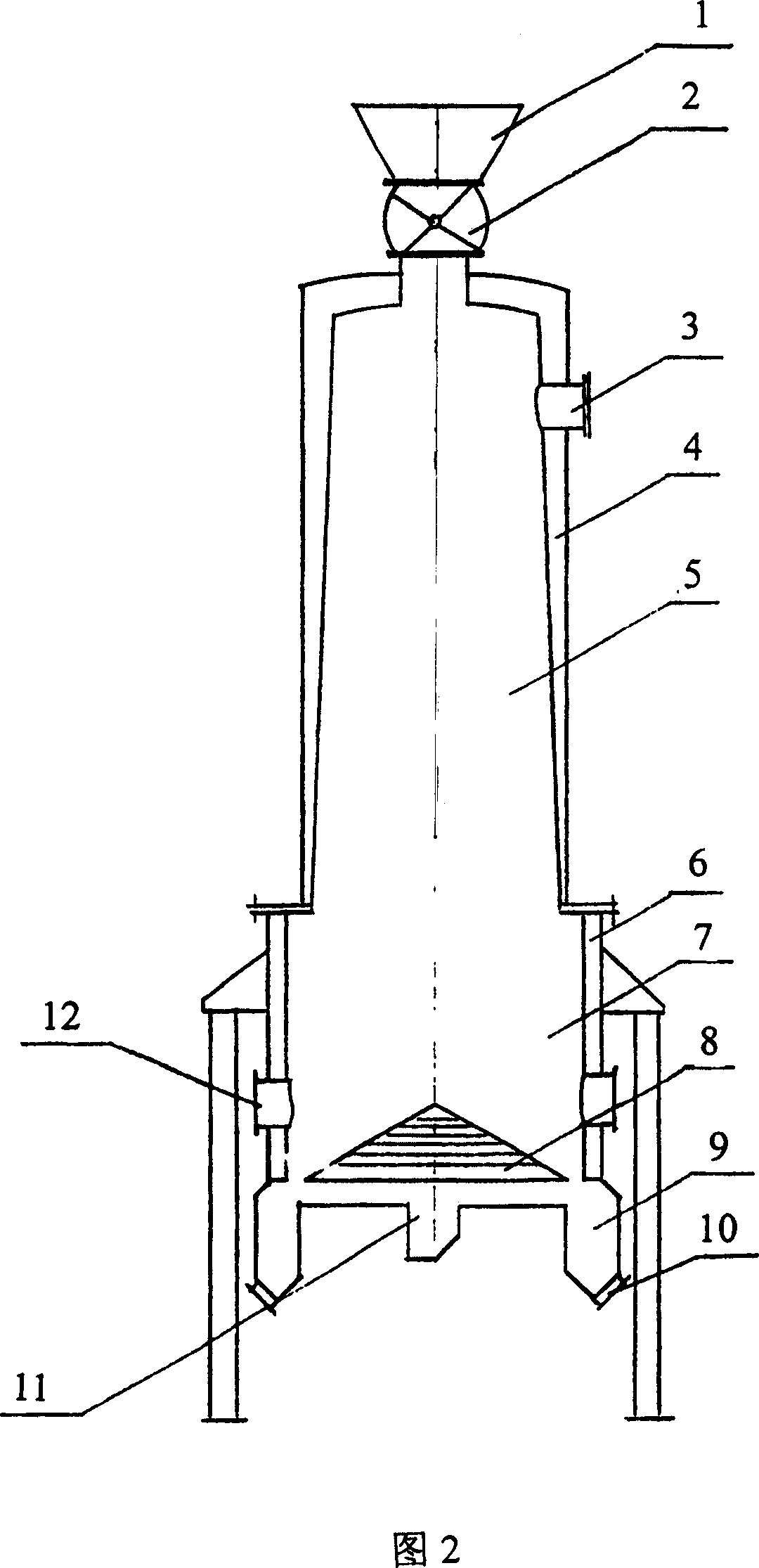

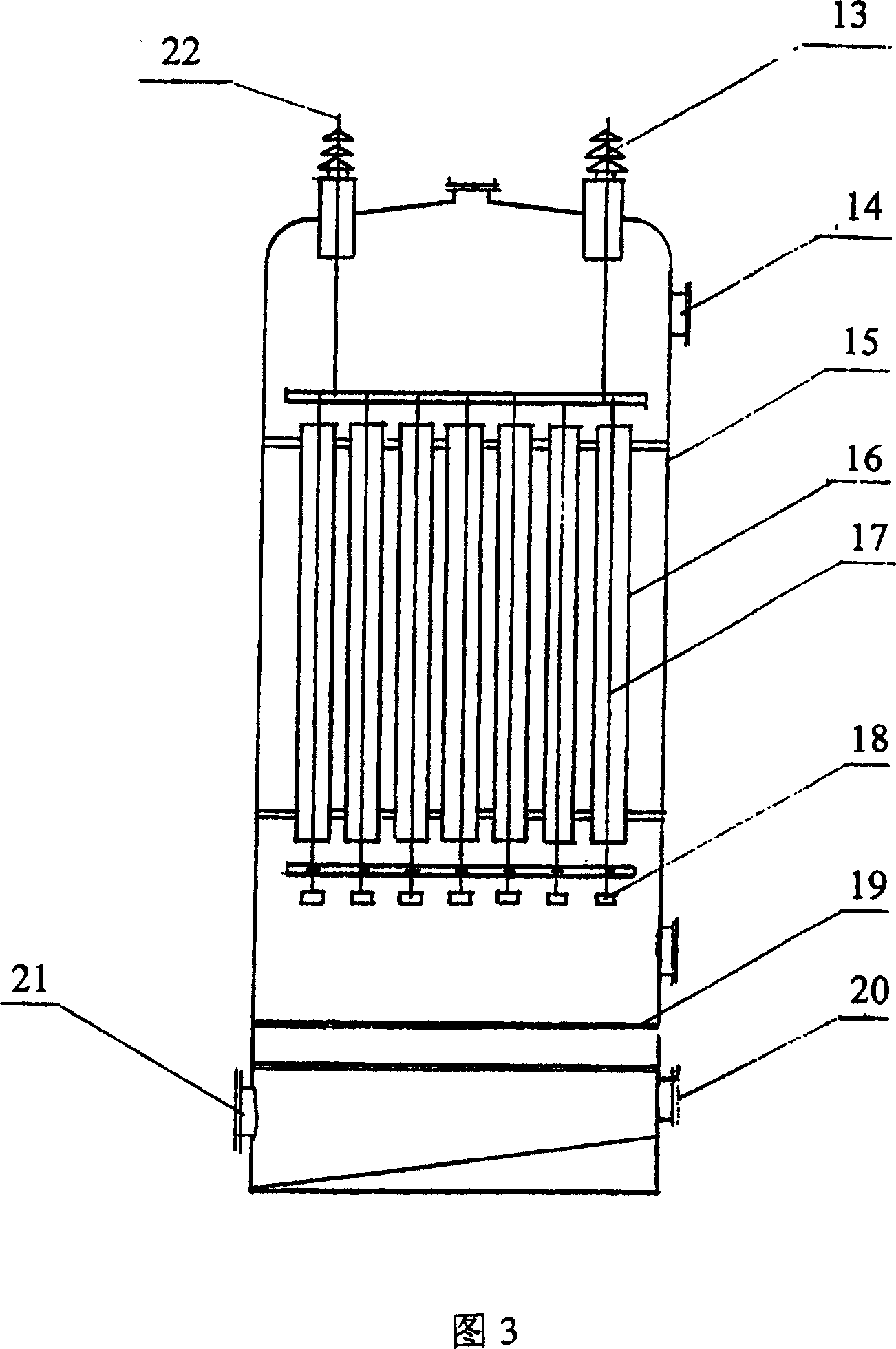

Biomass pyrogenation gasification and purification method

InactiveCN1730609AHigh calorific valueHigh hydrogen contentBiofuelsCombustible gas purificationCyclonePurification methods

The invention provides a biological mass thermal decomposition, gasification and purification method which comprises, disintegrating the biological mass, gasifying in a furnace, obtaining retort gas, cyclone dedusting, cooling down and purifying, high voltage static coke trapping, making the coke tar bubbles and dust in the coal gas deposit onto the coke collection poles, thus purifying the coal gas, finally washing and dewatering.

Owner:MIANYANG TONGMEI ENERGY SCI & TECH CO LTD

Processing technology for smooth and non-shrinkable wool yarns

InactiveCN101812806AGood effectEliminate itchingBiochemical fibre treatmentAnimal fibresEngineeringFatty alcohol

The invention discloses processing technology for smooth and non-shrinkable wool yarns, and belongs to the technical field of performance processing for textile yarns. The processing technology comprises the following steps of: analyzing mechanical and physical properties of wool yarns sold in the market, and humidifying the wool yarns in a yarn processor; performing socking, preprocessing, rinsing, biochemical preparation processing and neutralizing on the wool yarns; and adding a softening and dispersing agent consisting of a silicone softening agent, fatty alcohol-polyoxyethylene ether, amide ether, double-chain esterquat for function processing, drying, and packaging finished products. For the wool yarns processed by the technology, the density and thickness of scales are all reduced, so felt contraction is reduced, and the itchy feeling of the wool is removed on the basis of maintaining the special elasticity and warmness of fibers. Meanwhile, various adverse effects in the spinning process after the wool fibers are subjected to fiber loosening processing in the industry in the prior art are overcome. The wool yarns processed by the technology are smooth, soft, non-shrinkable and non-itchy, and have bright and uniform colors and lasting effect.

Owner:PINDAR INDAL TAIYUAN +1

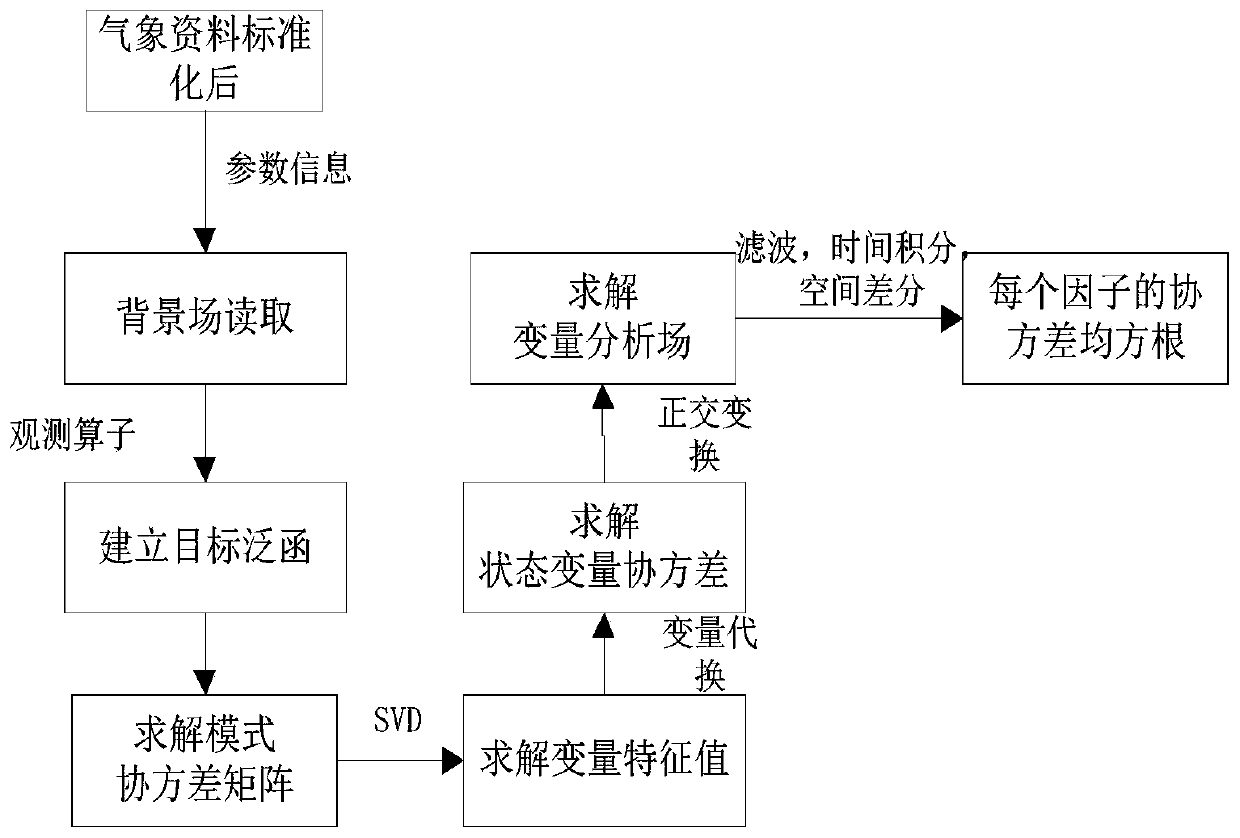

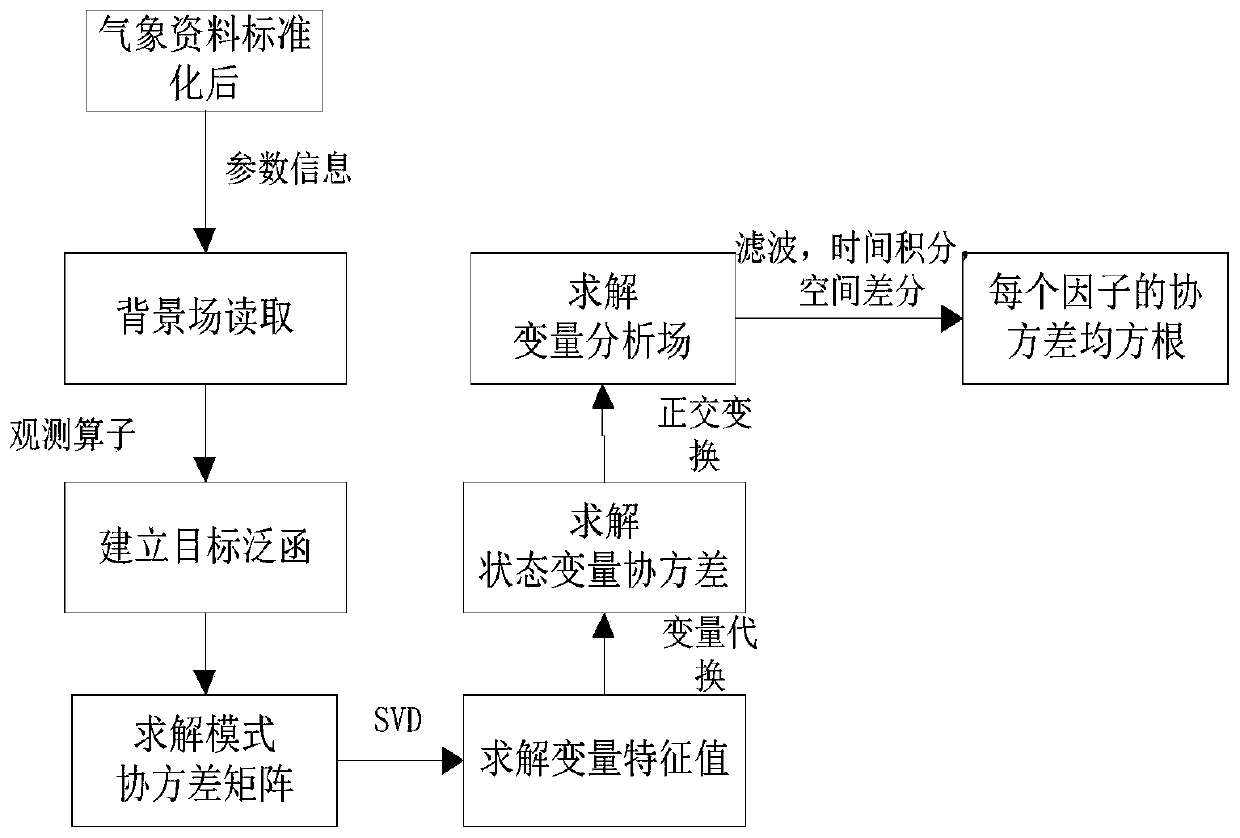

Method for carrying out fusion processing on meteorological data and generating numerical weather forecast

ActiveCN110020462AImprove the accuracy of eigenvaluesImprove accuracyCharacter and pattern recognitionDesign optimisation/simulationNumerical weather predictionData type

The invention discloses a method for carrying out fusion processing on meteorological data and generating a numerical weather forecast, which comprises the following steps: step 1, collecting and receiving various meteorological element data from meteorological observation detection equipment or CCTV to obtain a meteorological element set X1; step 2, performing standardized preprocessing on the acquired meteorological element data to obtain a standardized meteorological element set X; step 3, performing three-dimensional data variation assimilation on the meteorological element set X, performing characteristic error analysis and cross covariance analysis on the data in the meteorological element set X to obtain a covariance error root mean square of each data in the meteorological elementset X, and obtaining an optimal meteorological element data type according to the covariance error root mean square; step 4, performing WRF numerical weather forecast mode compiling according to the optimal meteorological element type; and step 5, performing forecast post-processing on the WRF mode result to generate meteorological element numerical forecast.

Owner:江苏无线电厂有限公司

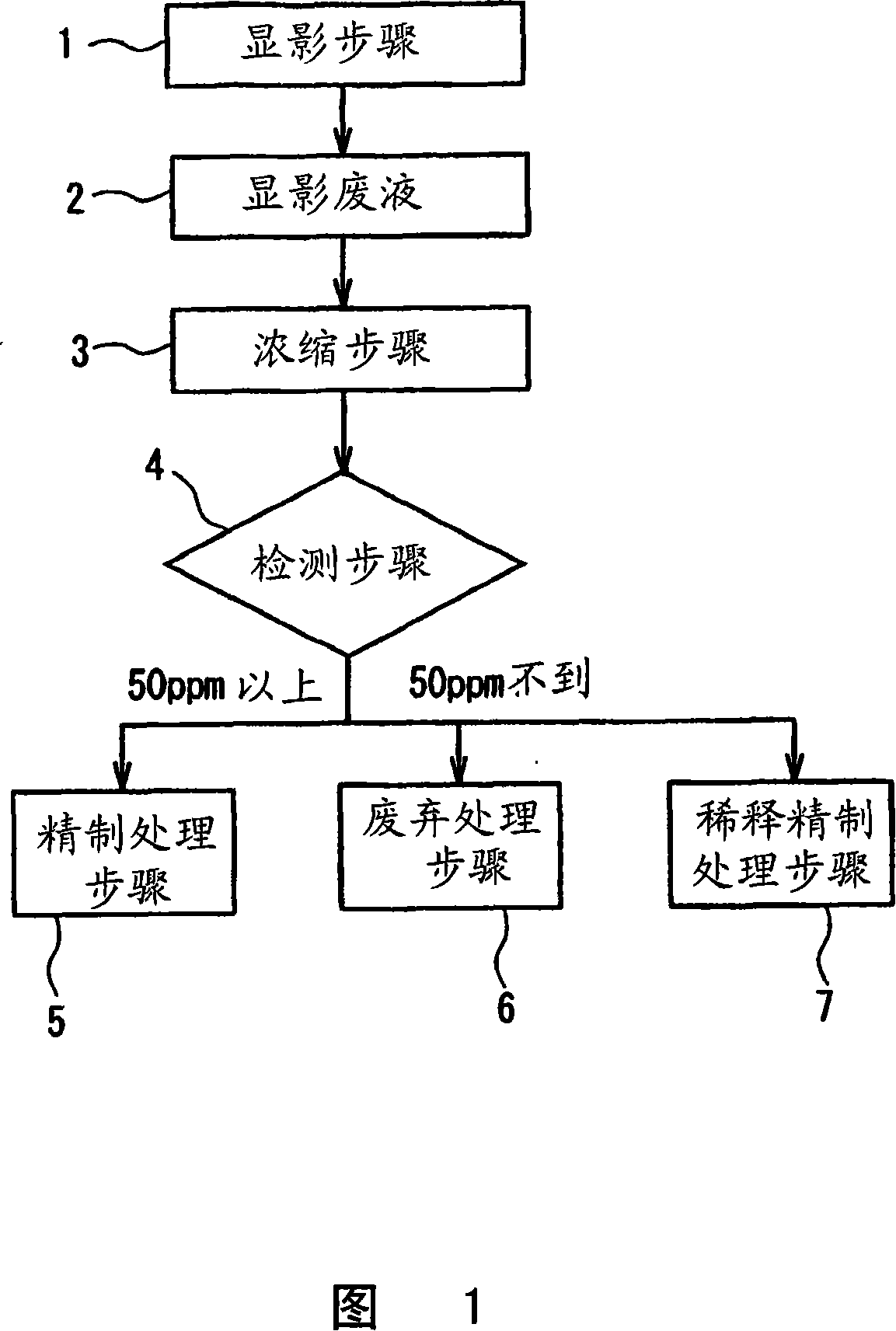

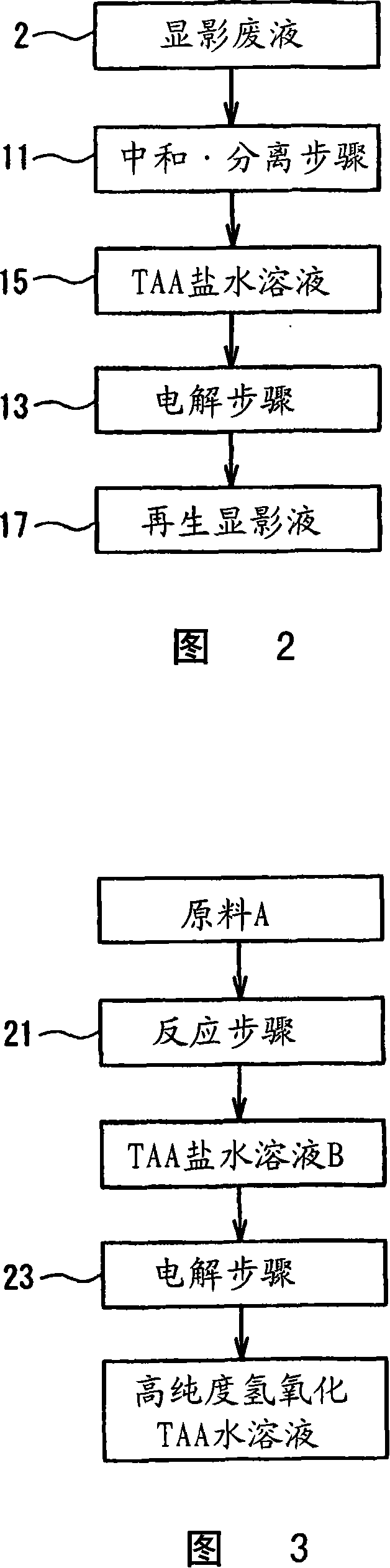

Method for treating development waste liquid

InactiveCN101111804ADisposal is safe and effectiveChange handlingWater/sewage treatment by electrochemical methodsSemiconductor/solid-state device manufacturingLiquid wasteResist

This invention provides a method for treating a development waste liquid comprises selecting one of the step of determining the concentration of a tetraalkylammonium (TAA) and the content of metal impurities in a development waste liquid containing an aqueous tetraalkylammonium hydroxide solution and purifying the development waste liquid depending upon the determined metal impurity content per TAA to generate an aqueous TAA hydroxide solution used as the developing solution, the step of disposing of the development waste liquid, and the step of diluting the development waste liquid with an aqueous TAA hydroxide solution unused as the developing solution and then purifying the diluted development waste liquid to generate the aqueous TAA hydroxide solution used as the developing solution. This method is characterized in that the metal impurity content per TAA as the standard of selection in each step is set to 50 ppm. According to this method, a development waste liquid containing TAA hydroxide discharged from a photoresist development step can be stably purified over a long period of time, and, consequently, a high-purity aqueous TAA hydroxide solution reusable as a developing solution even in the photoresist development step which is required to be highly accurate can be regenerated.

Owner:TOKUYAMA CORP

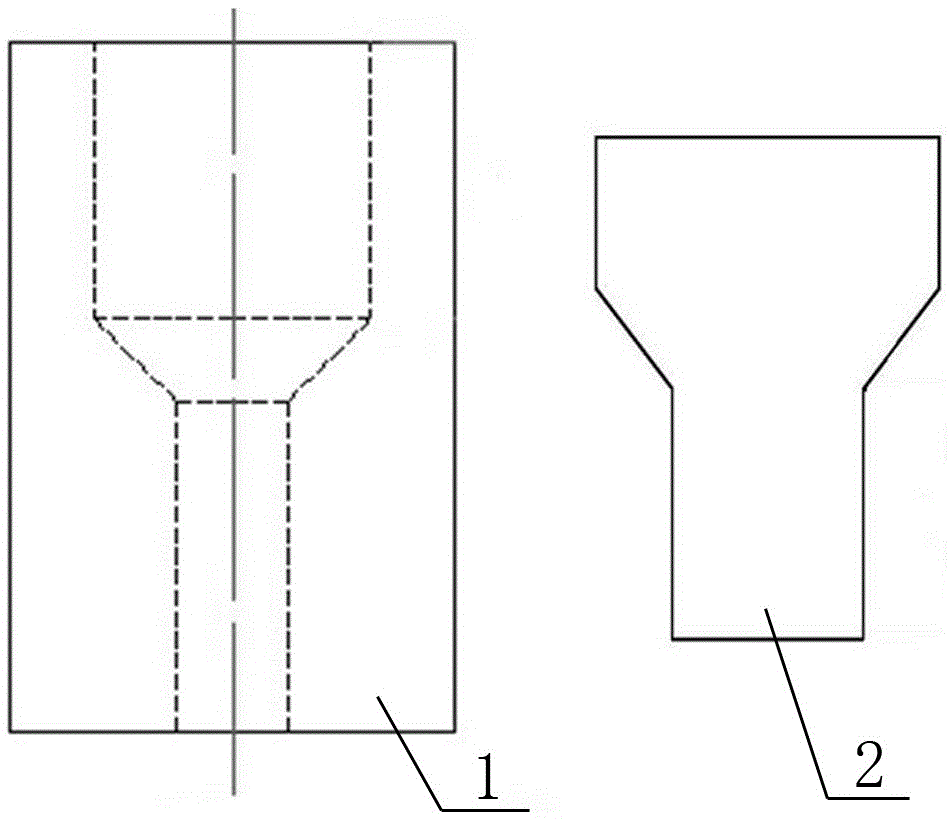

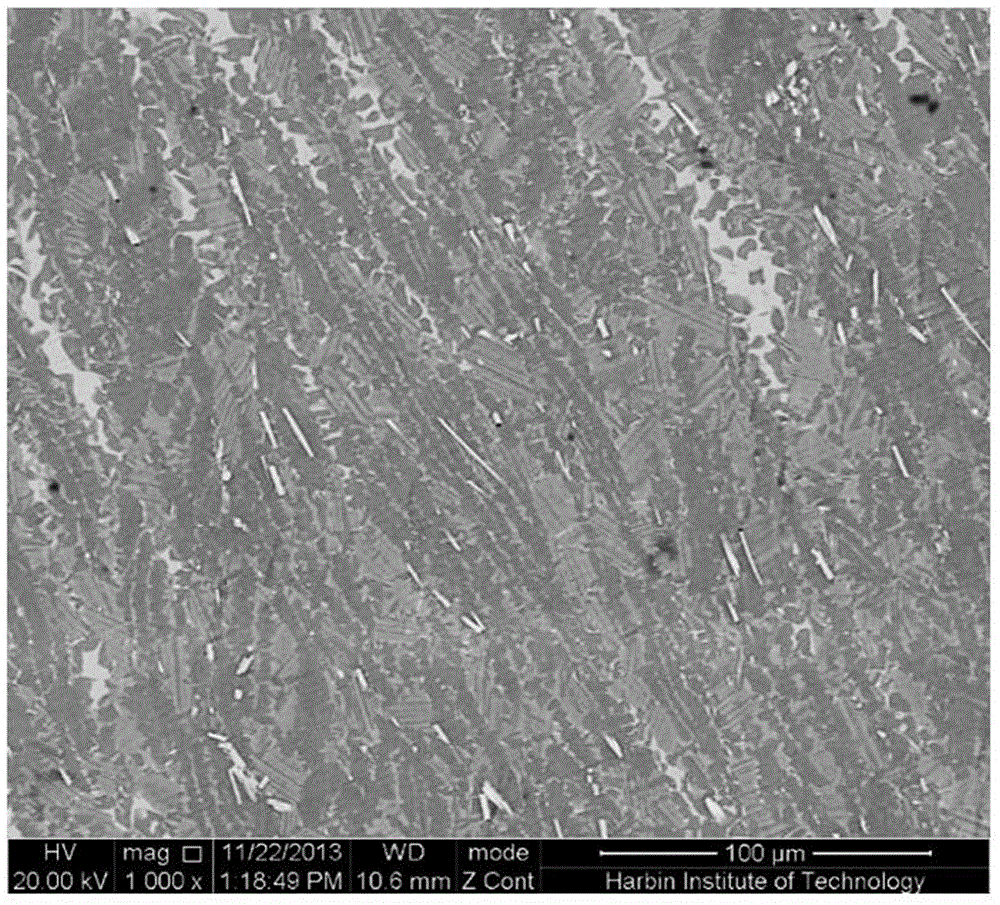

Preparation method for TiAl alloy bar

ActiveCN106636741ASolve the problem of severe segregationPrevent surface oxidationExtrusion diesIngotSkull

The invention discloses a preparation method for a TiAl alloy bar and relates to a preparation method for a bar. The preparation method for the TiAl alloy bar aims at solving the problems that according to a TiAl alloy bar prepared through an existing method, the preparation process is complex, the surface of the bar cracks, the diameter is nonuniform, the bar structure grain size is nonuniform, and TiAl alloy reacts with package materials and is molten when the extrusion temperature is too high. The preparation method for the TiAl alloy bar comprises the specific steps that 1, all raw material components are weighed; 2, a cast ingot is prepared through water cooling copper crucible induction skull melting; 3, pretreatment is conducted on an extrusion blank; and 4, bar extrusion is conducted, and thus the TiAl alloy bar can be obtained. The surface of the TiAl alloy bar obtained through the preparation method is free of cracking, the diameter is uniform, the bar structure grain size is uniform, and the process is simple.

Owner:山西中工重型锻压有限公司

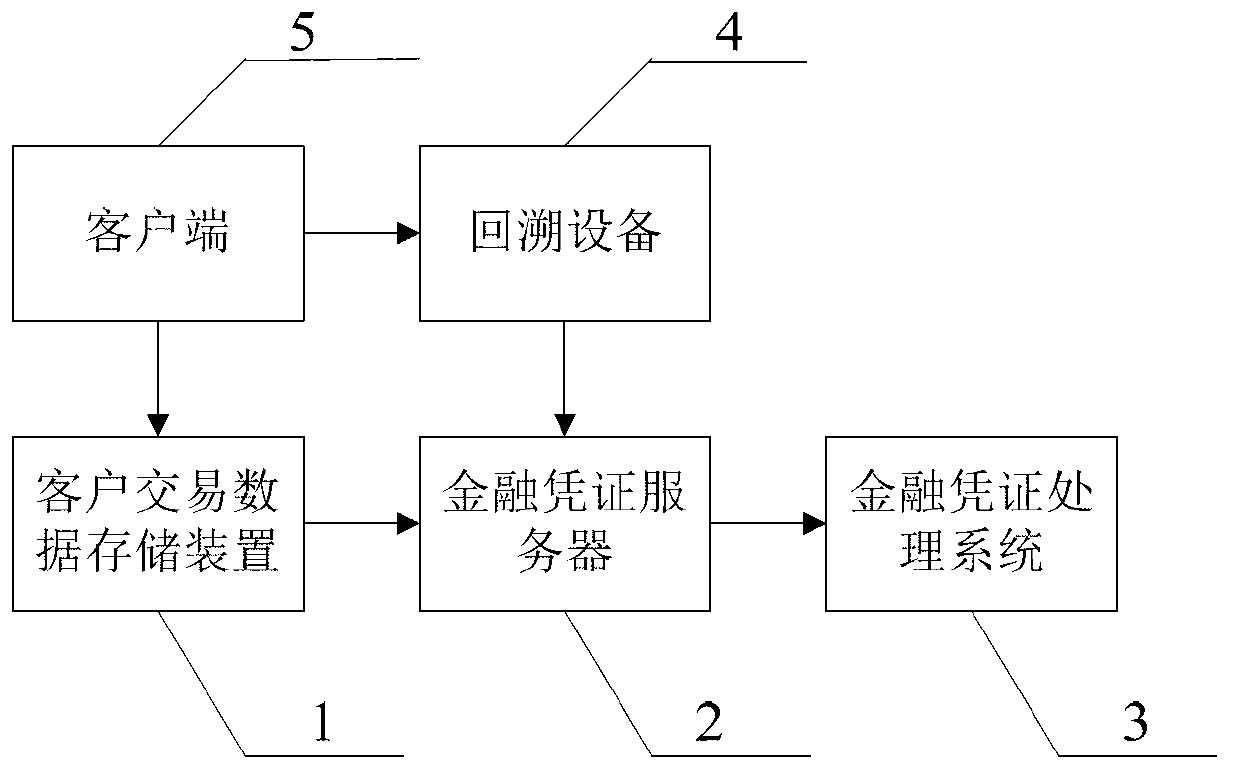

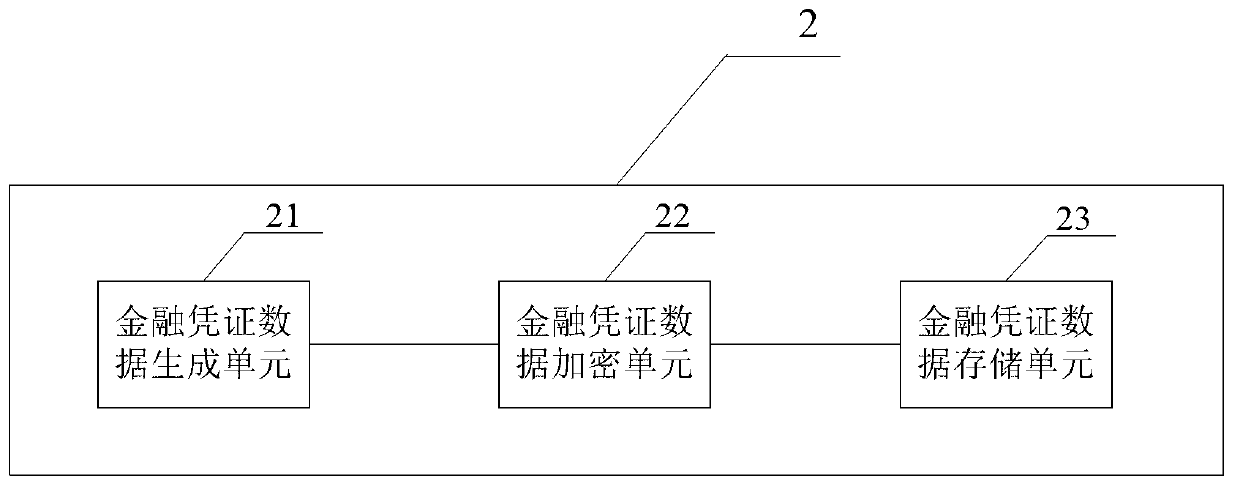

Financial certificate processing system and method thereof

InactiveCN103106607AChange handlingIncrease authenticityUser identity/authority verificationBilling/invoicingTransaction dataSelf-service

The invention discloses a financial certificate processing system and a method thereof. The system comprises a customer transaction data storage device, a financial certificate server and a financial certificate data processing device. According to the financial certificate processing system and the method thereof, a customer can conduct self-service operation and query, and print a needed financial certificate, and the financial certificate processing system ensures authenticity and uniqueness of the financial certificate by means, like backtracing, greatly improves working efficiency, is not limited by business hours of a financial certificate provider, can provide all-day service, and therefore, greatly improves service quality.

Owner:杨磊

Method for producing high-purity sodium sulfite and sodium sulfate by desulfurizing coal-fired flue gas through alkaline method

ActiveCN103961995AReduce desulfurization burdenSimple processDispersed particle separationAlkali metal sulfite preparationSulfite saltFlue gas

The invention discloses a method for producing high-purity sodium sulfite and sodium sulfate by desulfurizing coal-fired flue gas through an alkaline method. A two-stage desulfurization process is adopted; first-stage desulfurization refers to coarse desulfurization in which sulfate is left in first-stage desulfurizing liquid, sodium sulfate is produced, and most of sulfur dioxide in flue gas enters second-stage desulfurization; the second-stage desulfurization refers to main desulfurization in which flue gas can be exhausted up to standard, and the desulfurizing liquid can be directly concentrated and crystalized to produce high-purity sodium sulfite. The method has the advantages of being simple in process and easy to implement; sulfur dioxide in low-concentration flue gas is recycled by adopting the two-stage desulfurization process, so that secondary pollution caused by desulfurization and zero emission are eliminated completely; 95-percent high-purity sodium sulfate and 95-percent high-purity sodium sulfite are produced by using sulfur dioxide flue gas, and sodium sulfite accounts for 90-95 percent, so that the conventional treatment way of pure resource consumption is changed, the desulfurization burdens of enterprises are relieved greatly, and even desulfurization is turned into value-added production, thus remarkable technical and economical effects are achieved.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY +1

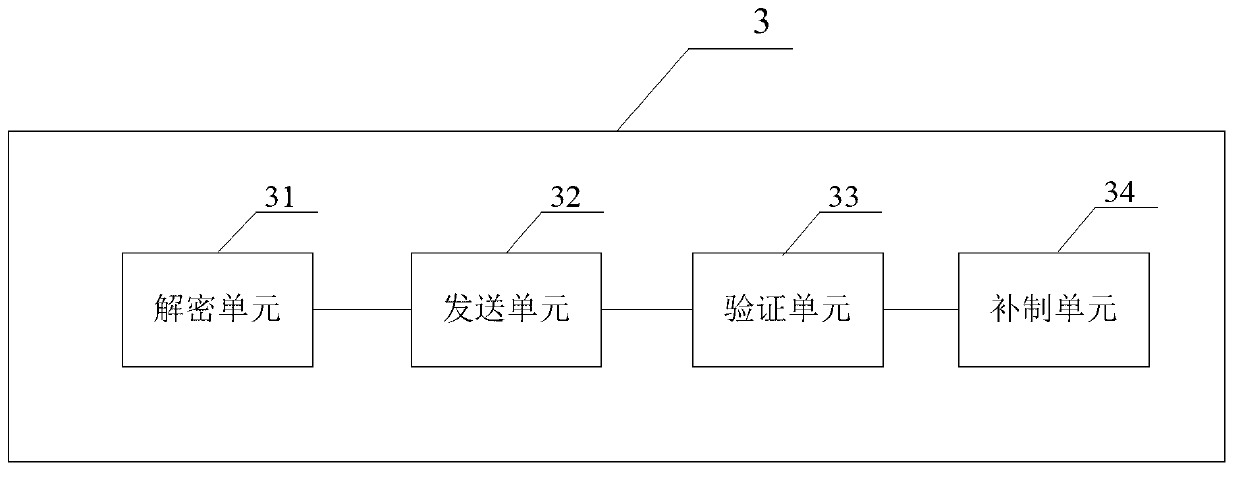

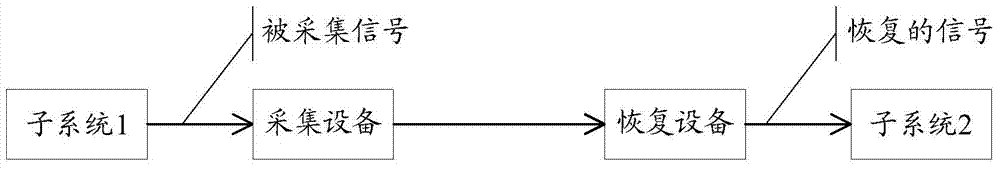

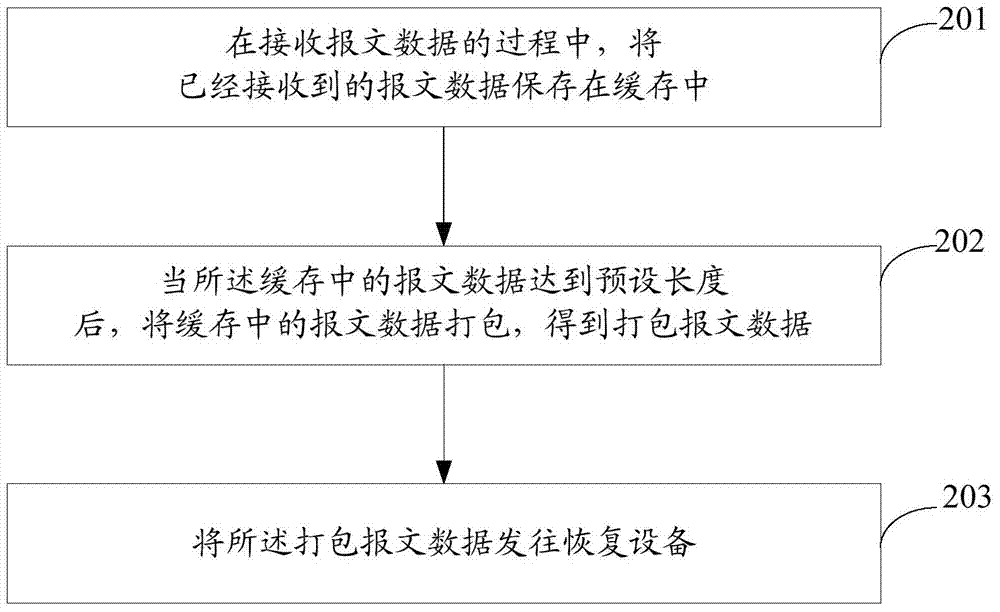

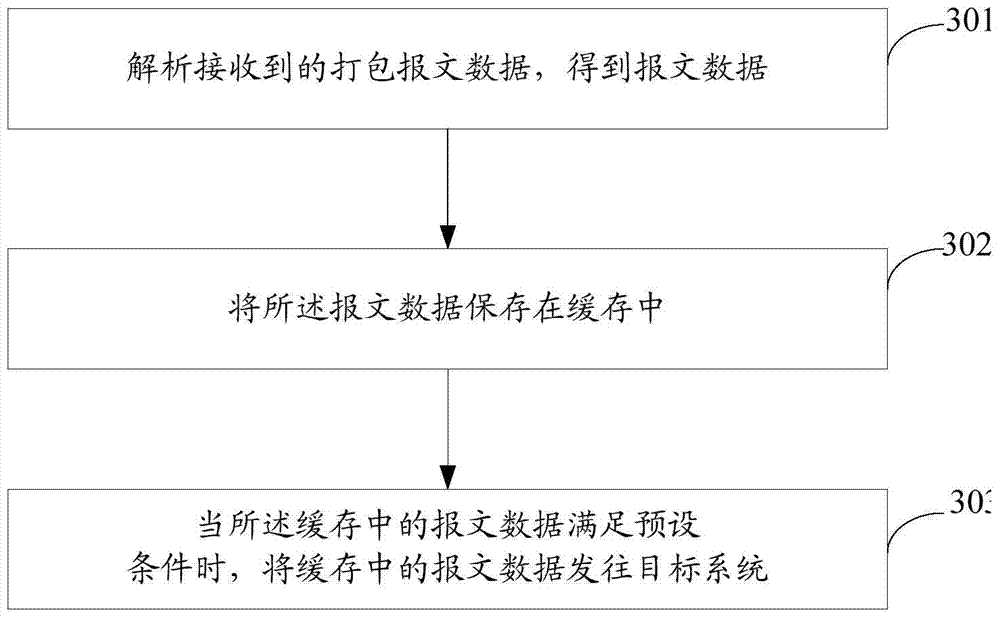

Data relay transmission method, device and system

The invention discloses a data relay transmission method, device and system. The data relay transmission method is characterized in that in acquisition equipment, the received message data are fragmented, packaged and forwarded in the process of receiving the message data, so that the sending operation can be conducted without receiving a complete message, and thus the delay of the acquisition equipment in the communication process is effectively reduced; in a restorer, without receiving a complete message, by a mode of sending the message data after buffering part of message data, the time from receiving data to sending data of the restorer is shortened, and the delay of the restorer in the communication process is reduced. According to the data relay transmission method, device and system provided by the invention, the processing mode of the acquisition equipment and the restorer to communication data can be changed, and the delay time of a communication system into which relay equipment is introduced is greatly reduced.

Owner:BEIJING RUNKE GENERAL TECH

Wicker anti-cracking color-protecting drying method

InactiveCN105500484AChange anti mildewChange softenBiocideWood treatment detailsParaffin waxRootstock

The invention provides a wicker anti-cracking color-protecting drying method, and relates to the technical field of wicker plaiting article production. Before wicker is cut down, anti-cracking color-protecting liquid medicine is injected into the wicker from the rootstock of the wicker or the root of a branch; when the anti-cracking color-protecting liquid medicine is detected at the end of the branch, the wicker can be cut; leaves of the cut-down wicker are removed, and then the wicker is soaked into a solution for 2 h, wherein the solution is prepared on the basis that the ratio of glycerinum to water is 1:10; then, the wicker is taken out and dried, then soaked in molten paraffin wax and taken out, and the surface of the wicker is completely wrapped by paraffin wax; a fine sand and salt mixture is an embedding agent, slow heating is performed, and drying and softening are performed on the wicker. The living wicker processing technology is simple, and a traditional wicker postprocessing method is broken through; after living wicker anti-cracking color-protecting drying processing, the wicker can be directly used for plaiting wicker products, the original color of the wicker can be kept, the wicker is not likely to crack, and the medicine utilization rate is greatly improved compared with a traditional method.

Owner:蚌埠海上明珠农业科技发展有限公司

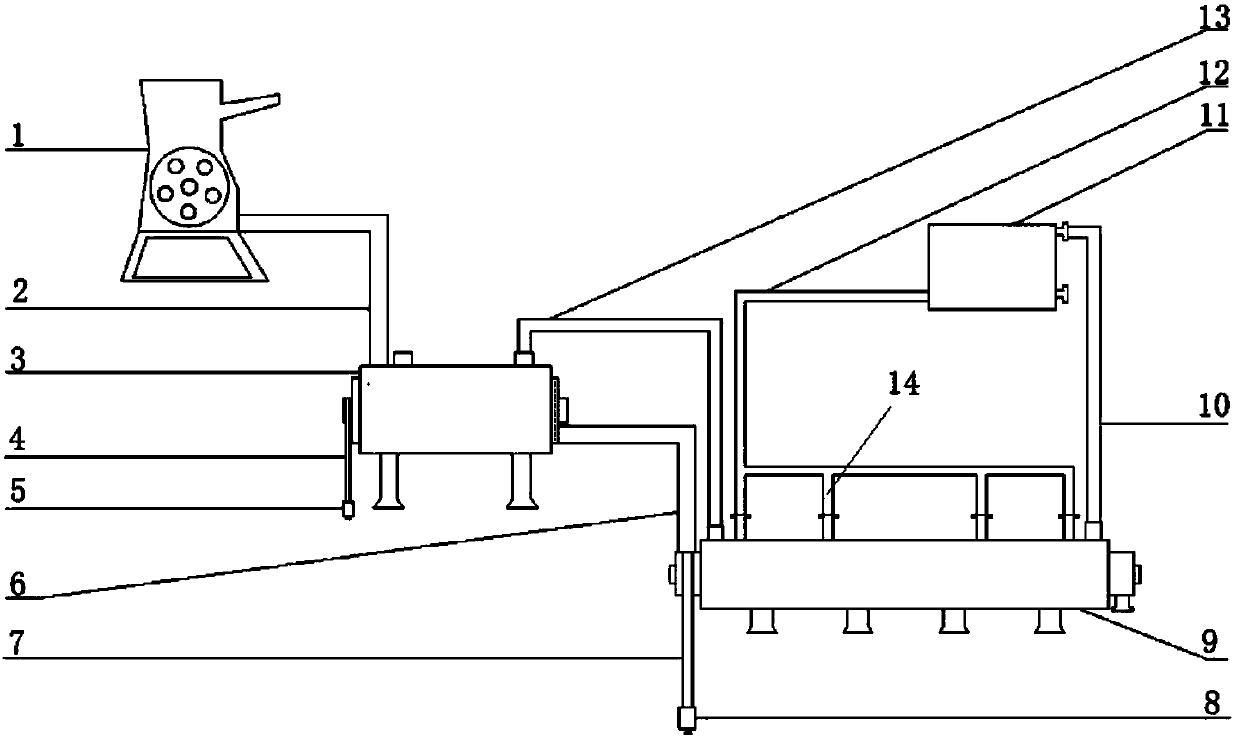

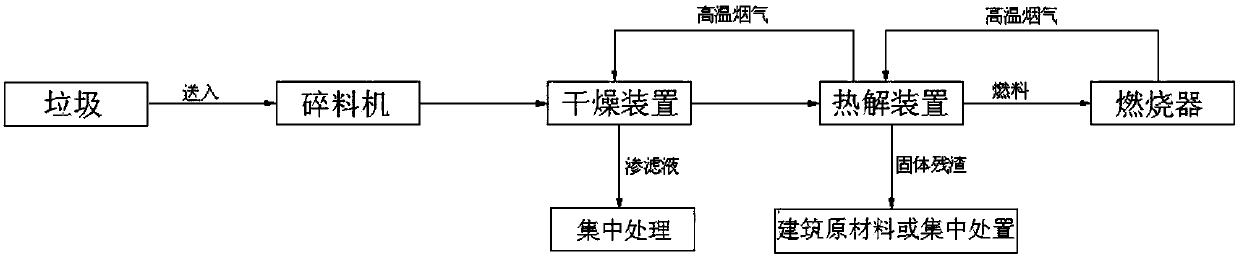

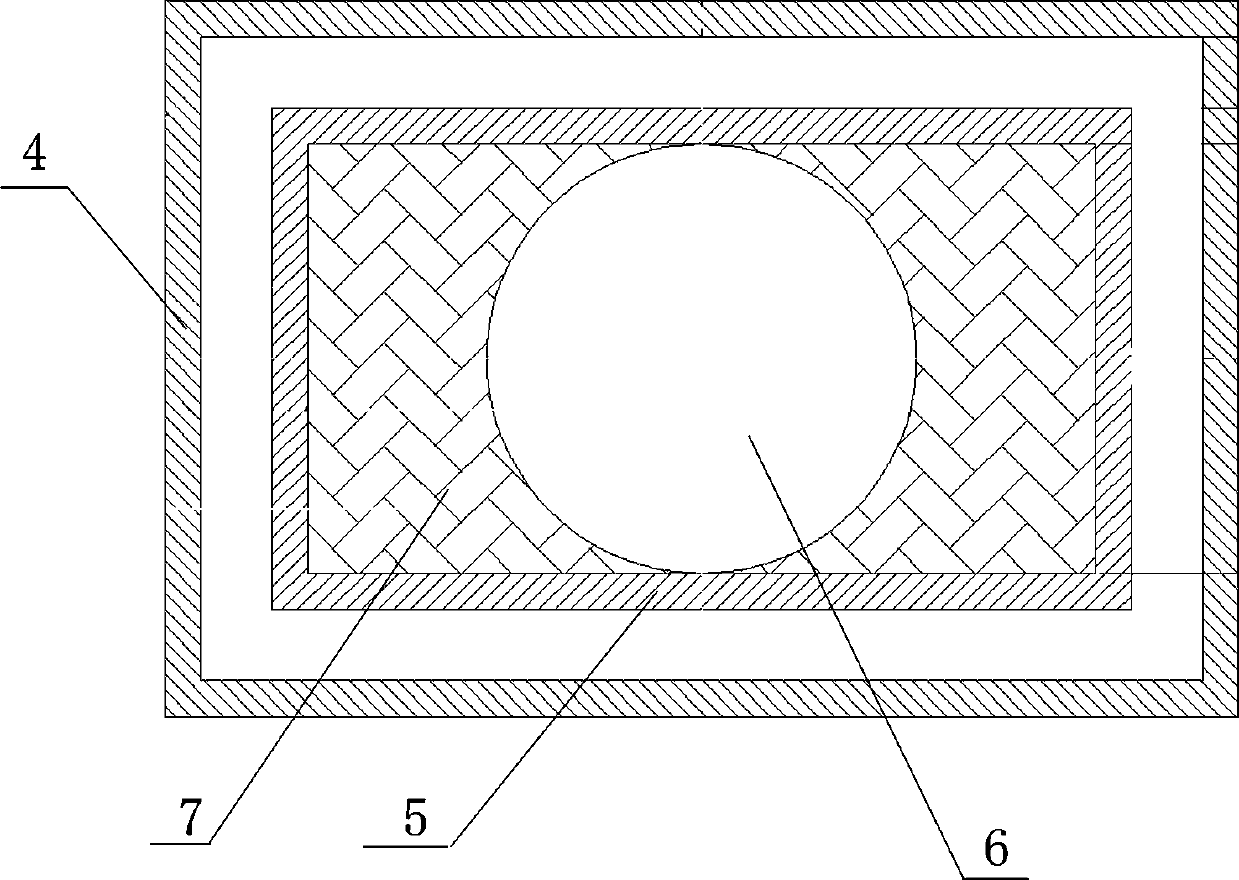

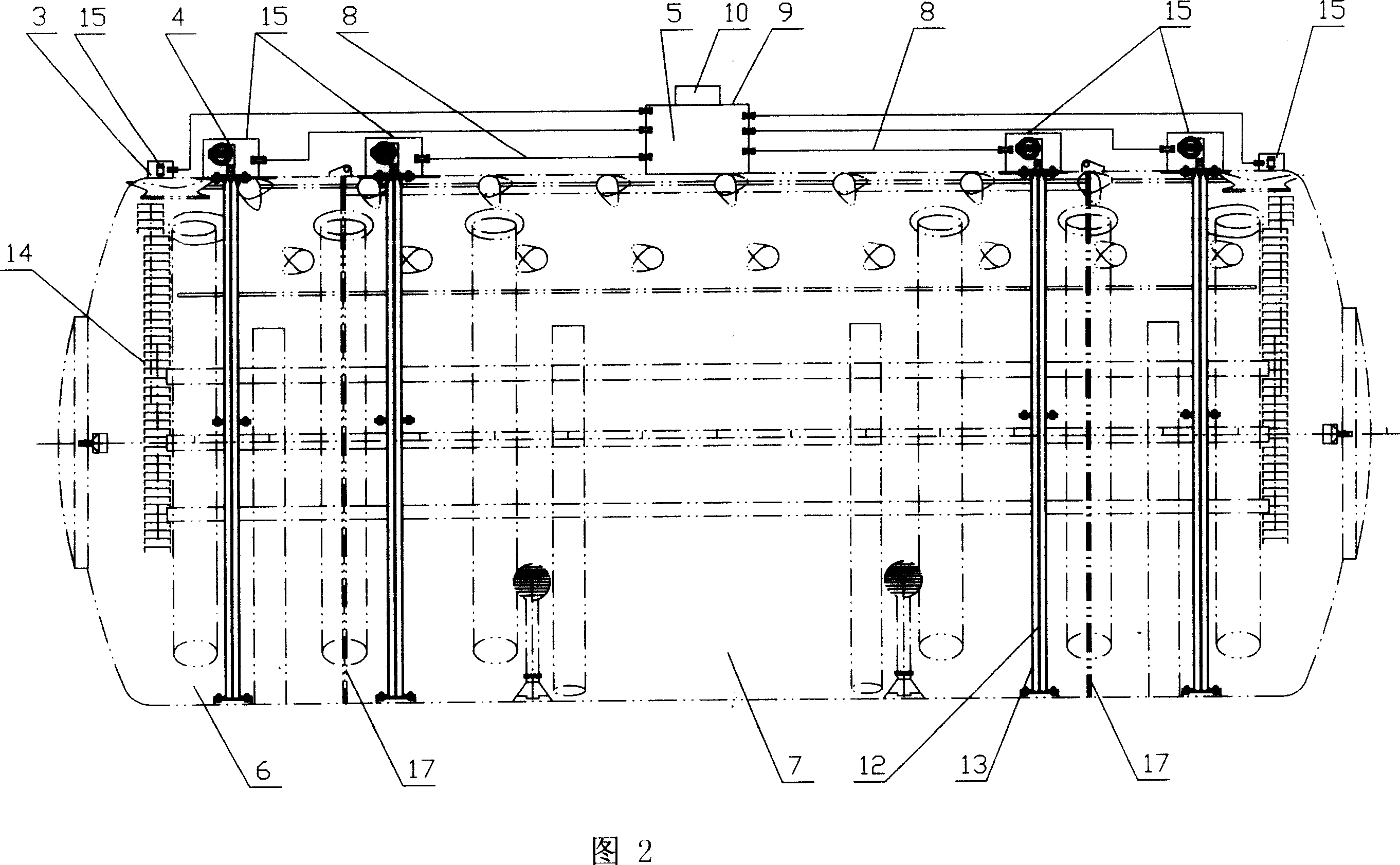

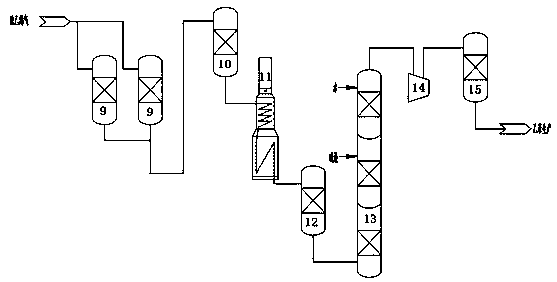

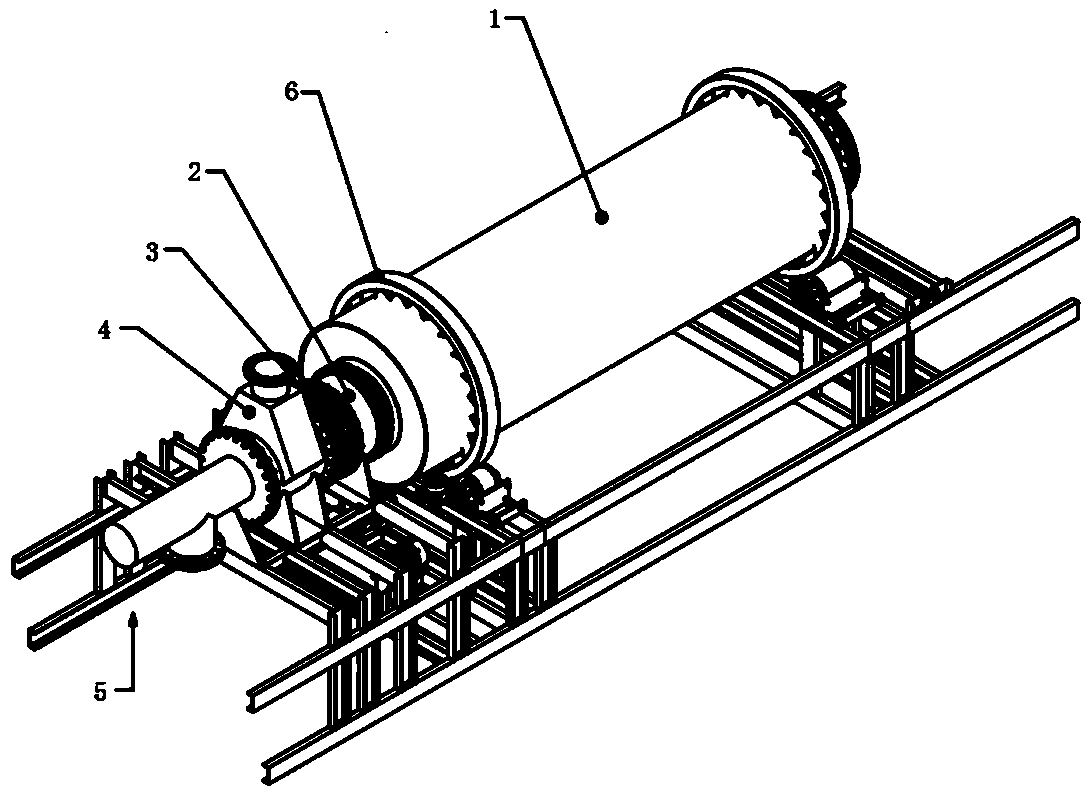

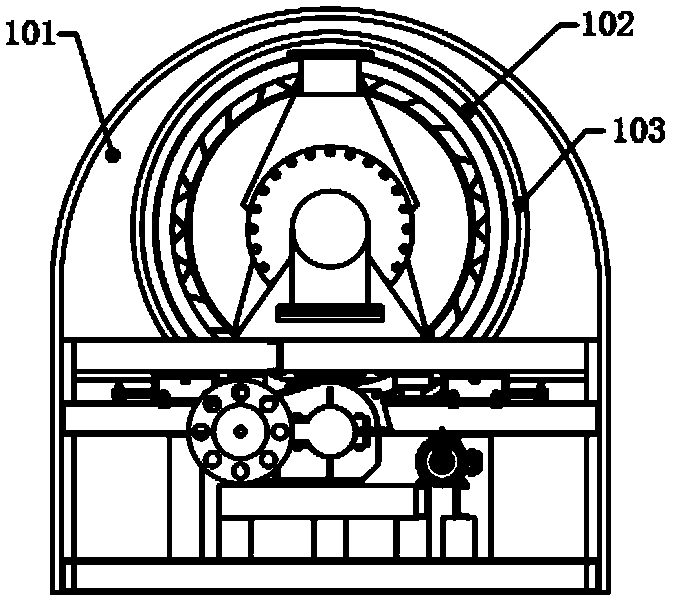

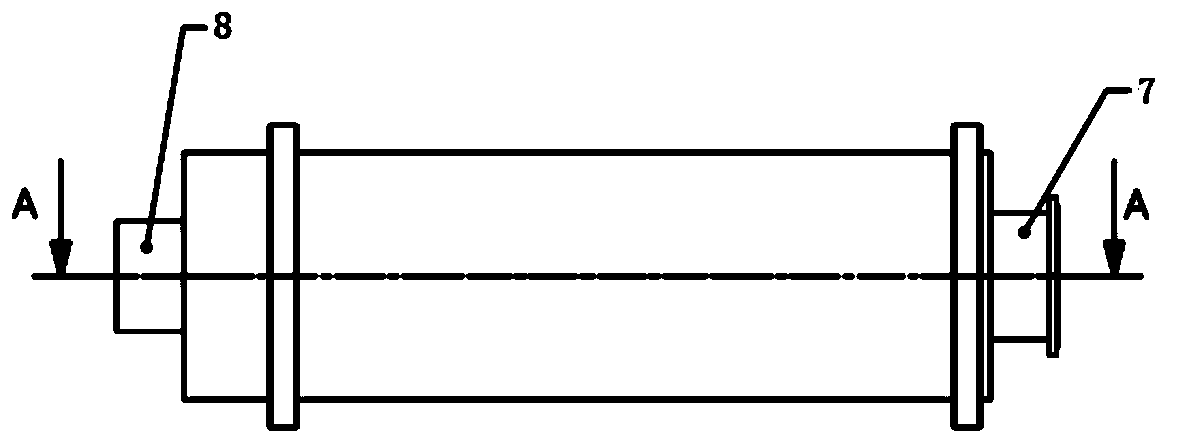

Efficient and low-pollution rural waste pyrolysis method and device

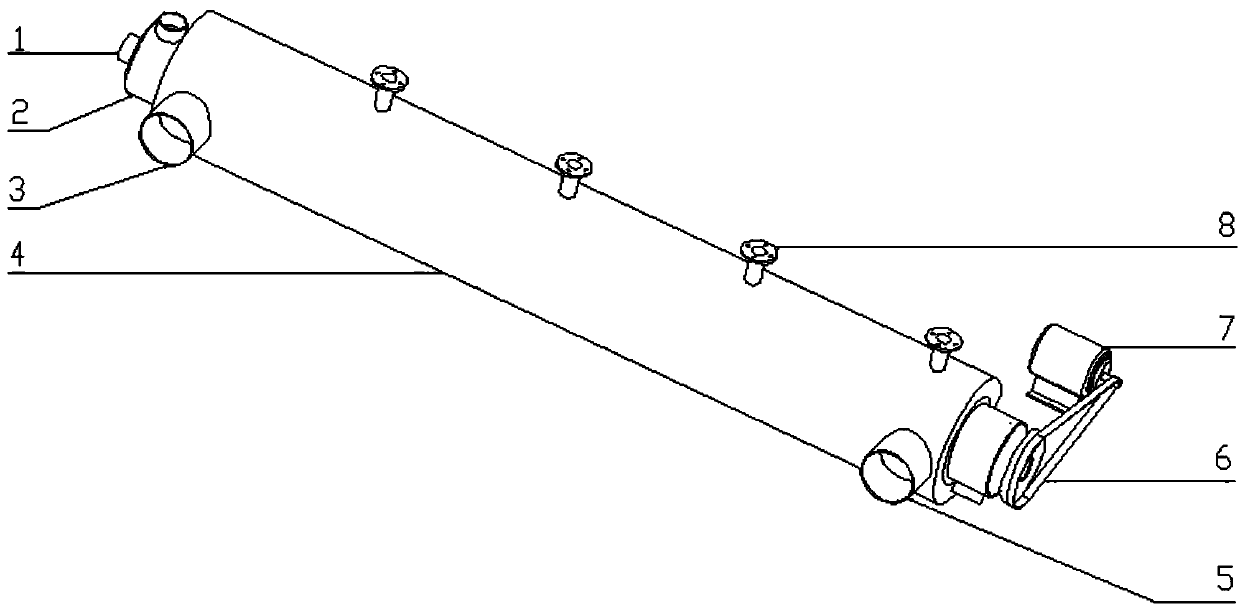

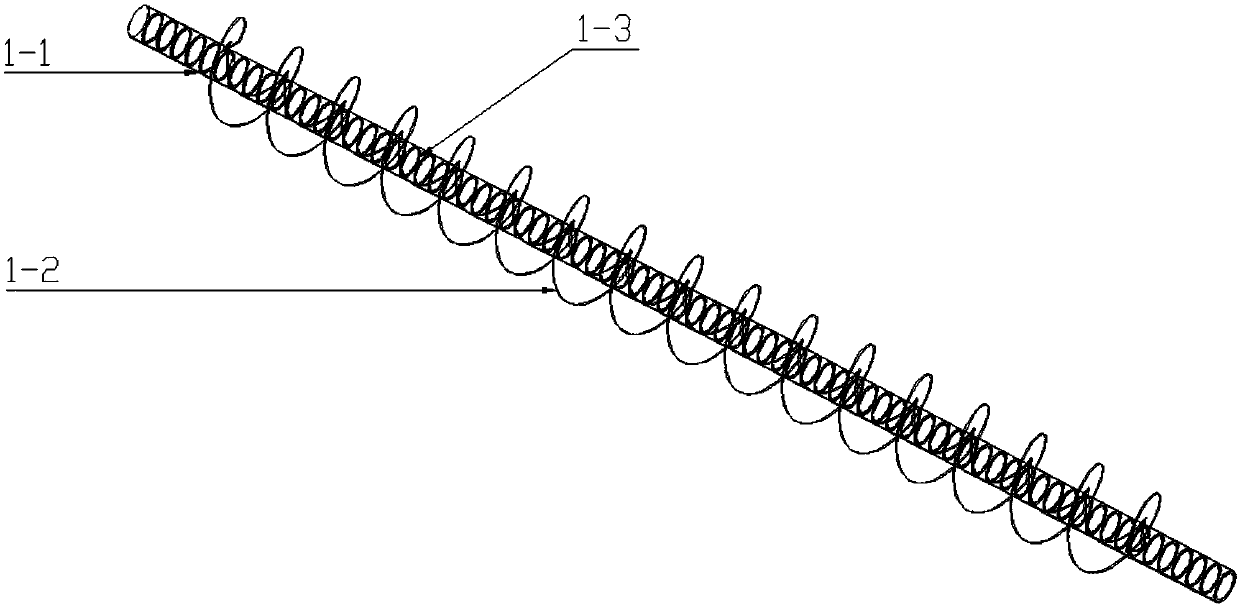

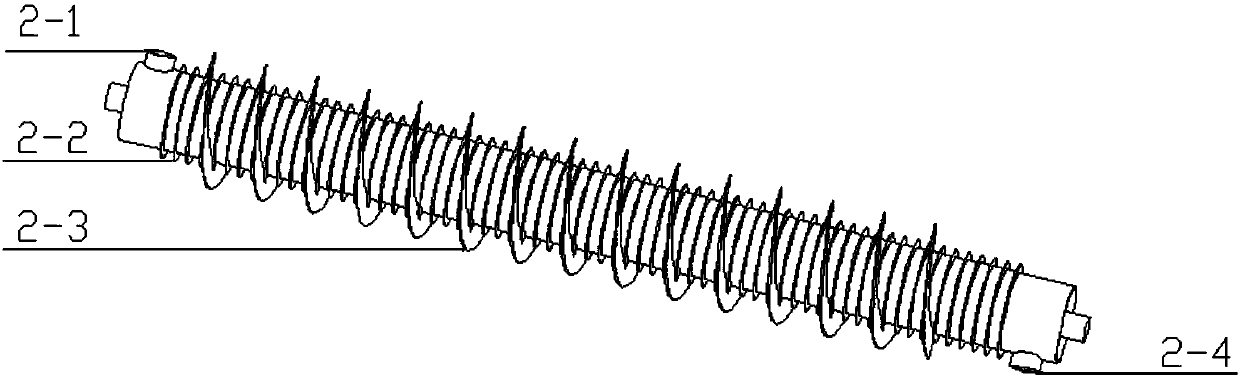

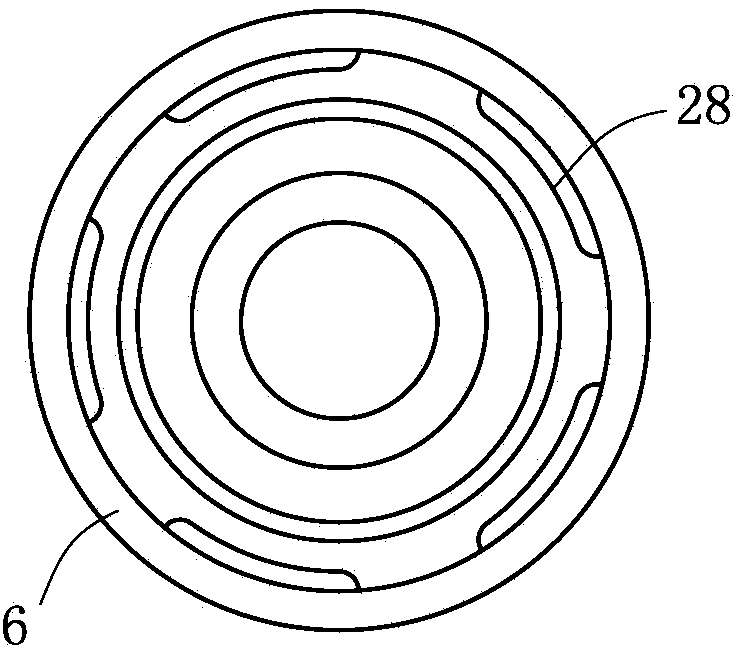

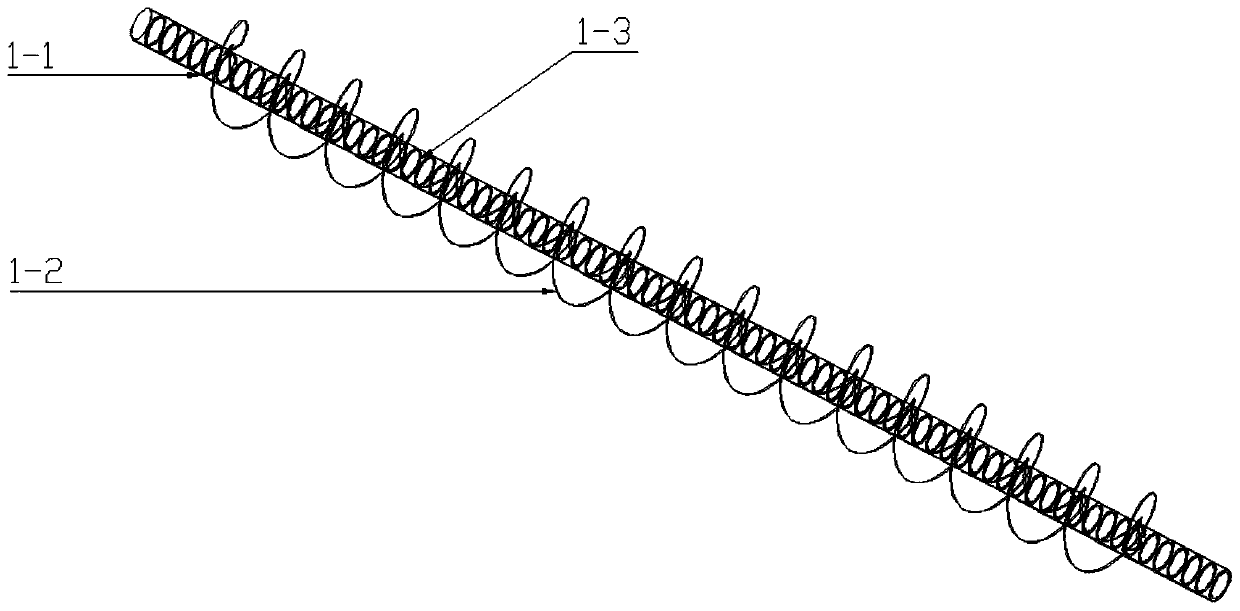

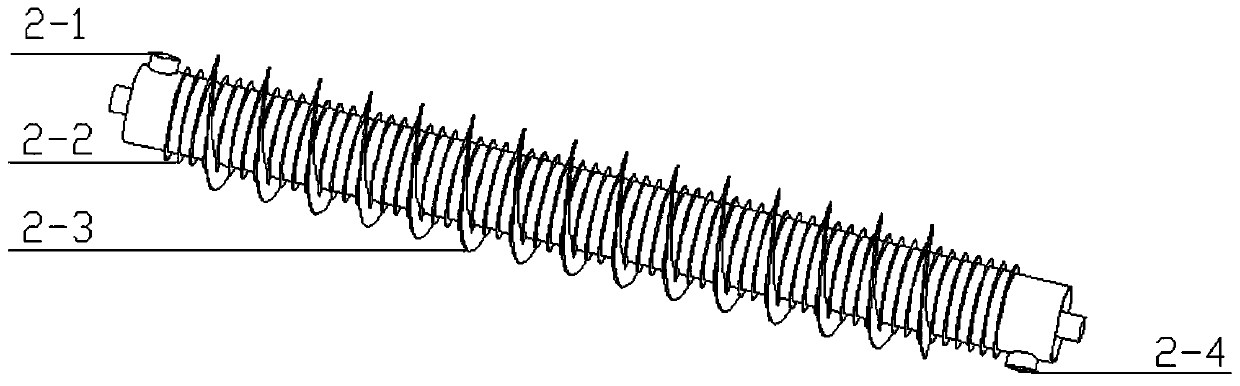

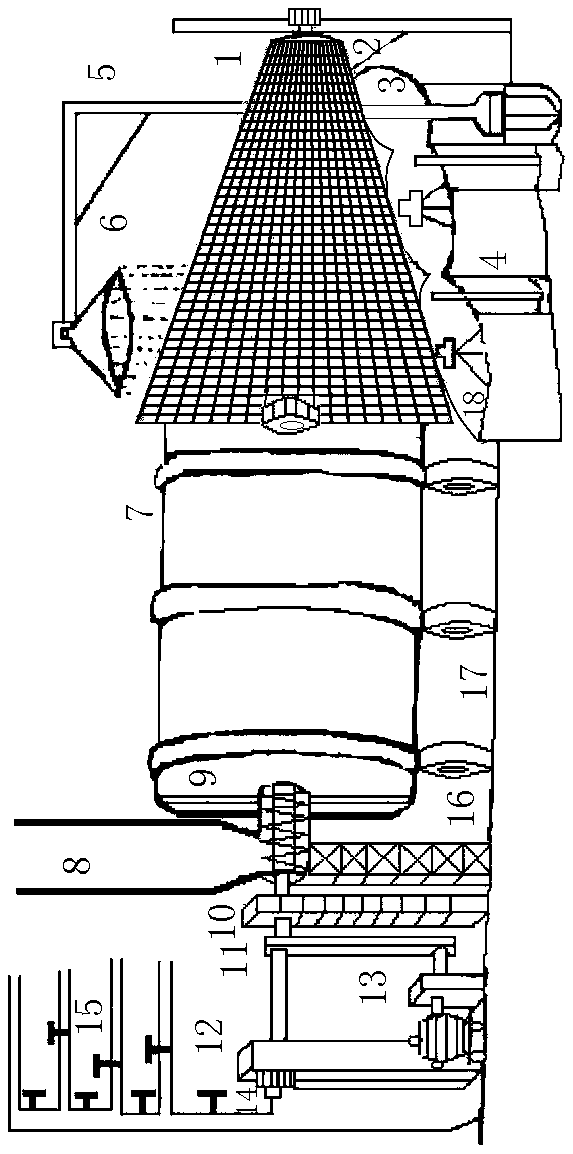

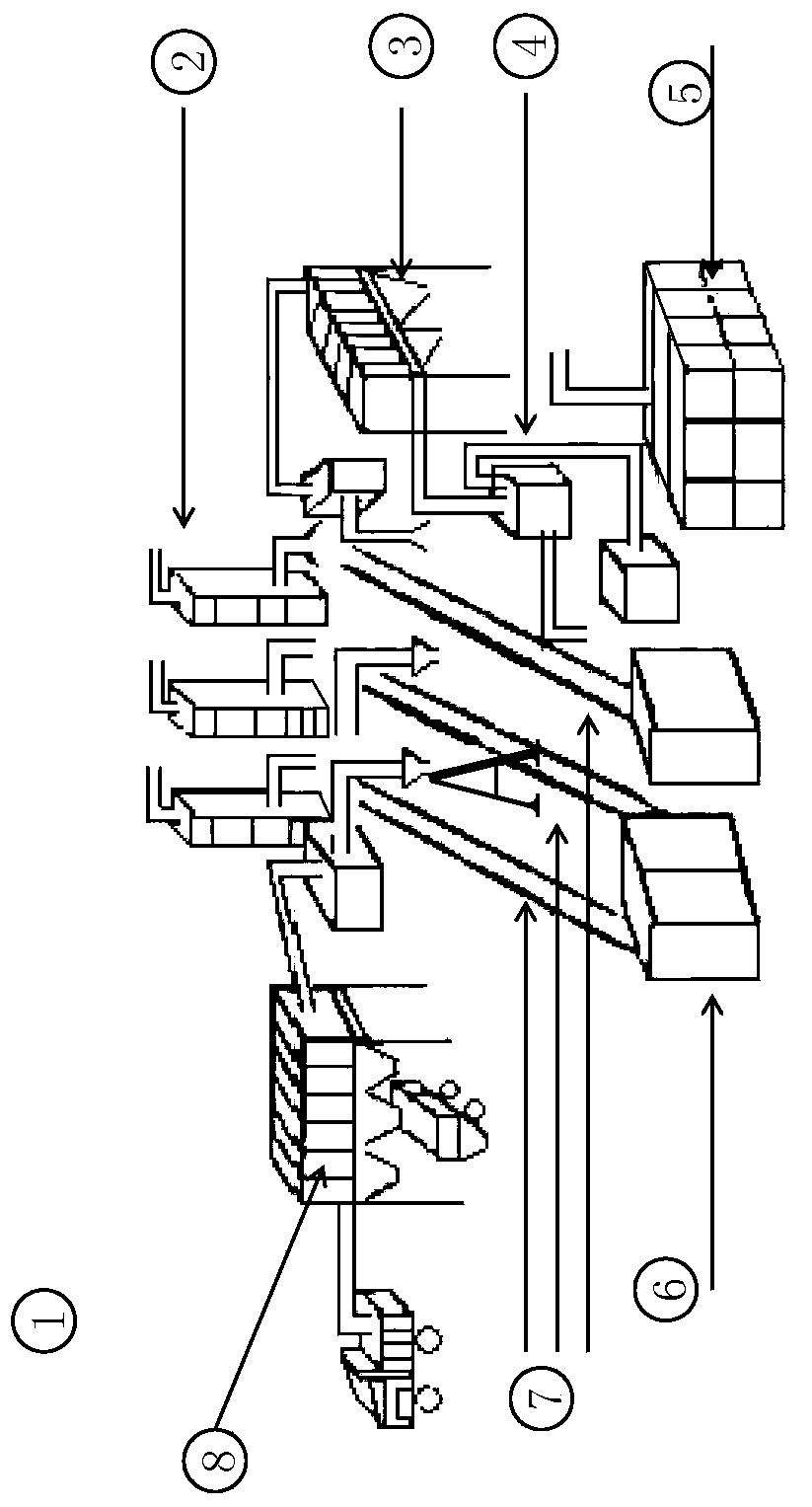

ActiveCN107741017APyrolysis achievedChange handlingBiofuelsIndirect heating destructive distillationFlue gasSpiral blade

The invention discloses an efficient and low-pollution rural waste pyrolysis method and device. The rural waste pyrolysis device comprises an outer cylinder, a middle cylinder and an inner cylinder, wherein the outer cylinder, the middle cylinder and the inner cylinder are sequentially arranged in a sleeving mode from outside to inside; the inner cylinder serves as a first flue gas passage, a cavity formed between the inner cylinder and the middle cylinder serves as a waste pyrolysis cavity, and a cavity formed between the middle cylinder and the outer cylinder serves as a second flue gas passage; spiral blades used for pushing the waste are arranged on the outer circumferential wall surface of the inner cylinder; spiral flow guide blades are arranged on the outer circumferential wall surface of the middle cylinder so that flue gas can flow in the second flue gas passage according to the spiral flow guide track of the spiral flow guide blades; the high-temperature flue gas flows through the two flue gas passages to transfer heat to the waste pyrolysis cavity and heats the waste inside the waste pyrolysis cavity; and the waste is pyrolyzed as the waste moves ahead in the waste pyrolysis cavity under the pushing of the spiral blades. According to the pyrolysis process of the device, products which are generated after the waste is subjected to pyrolysis can be combusted and reused, and on one hand, the products can be used for generating the high-temperature flue gas to provide heat to a waste drying device and a waste pyrolysis device, on the other hand, the products can be used for residential life as well as industrial and agricultural production.

Owner:SOUTH CHINA UNIV OF TECH

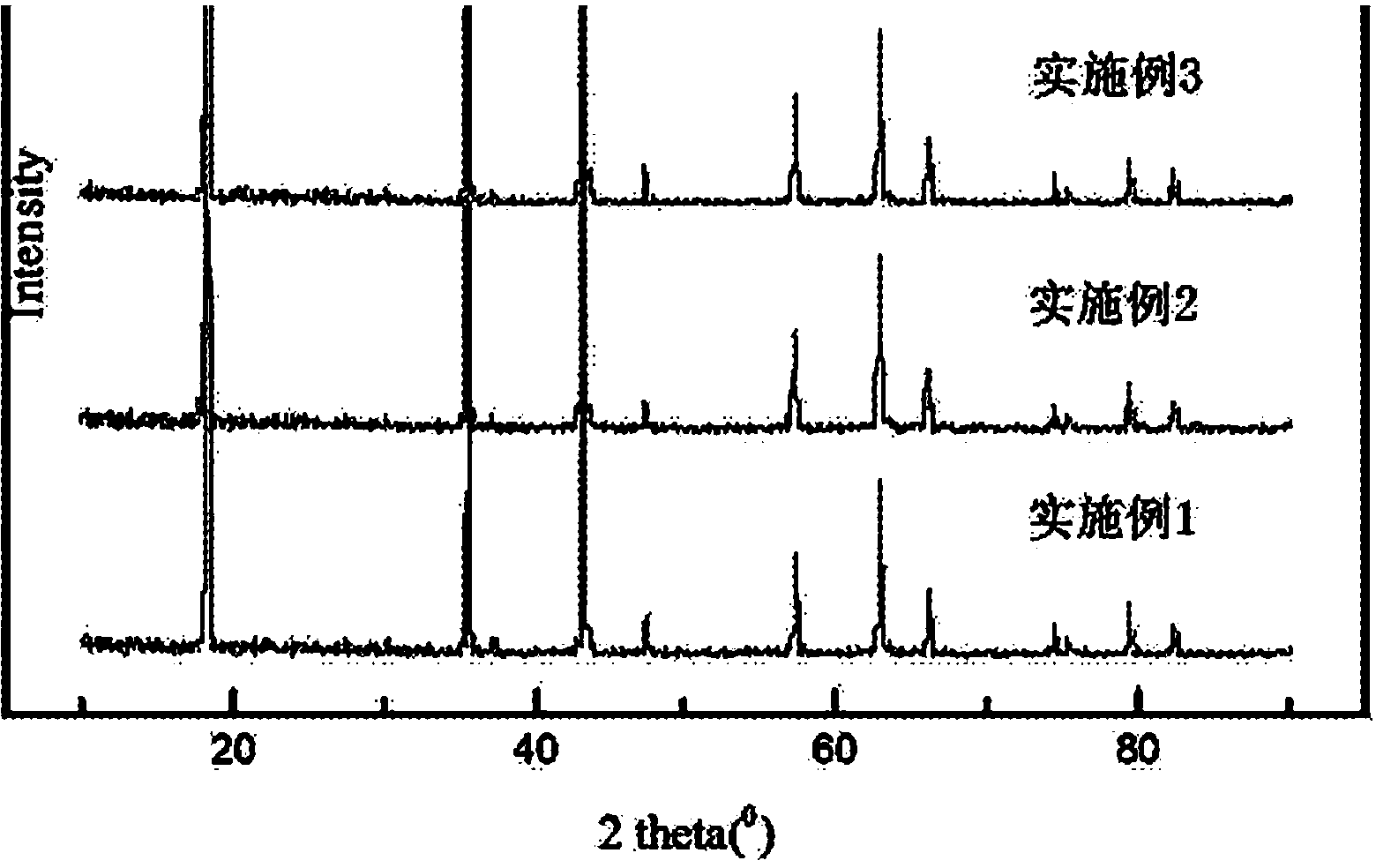

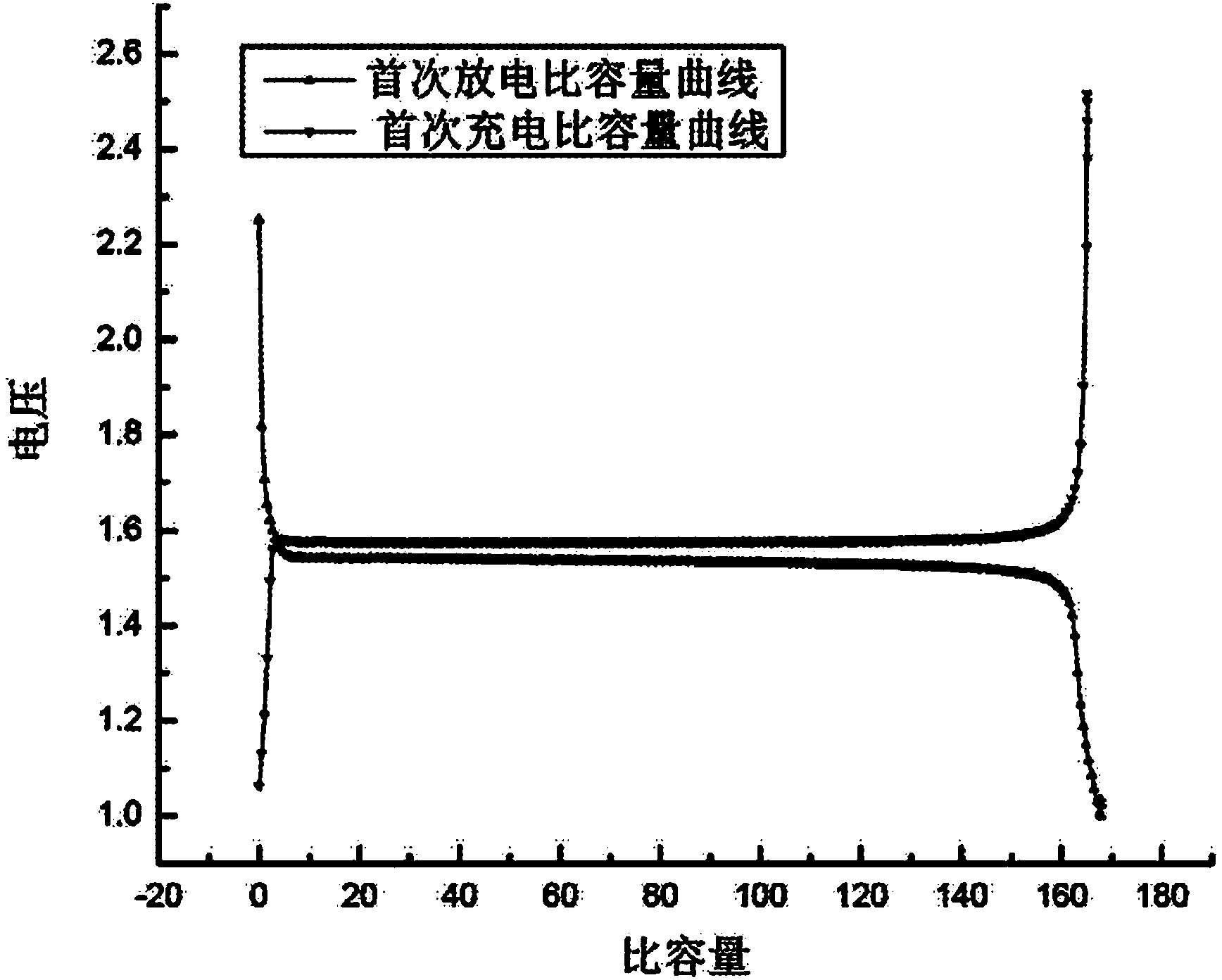

Preparation method of lithium titanate negative electrode material

InactiveCN104393273AGood dispersionImprove complexation effectAlkali titanatesCell electrodesLithiumAlcohol

The invention provides a preparation method of a lithium titanate negative electrode material. The preparation method comprises the specific steps of (1) preparing organic molecular solutions, stirring the solutions for later use, weighing an organic lithium source and a titanium source based on the mol ratio of Li to Ti of (0.80-0.85):1, respectively adding the weighed organic lithium source and titanium source to the organic molecular solutions to obtain a titanium-containing solution and a lithium-containing solution, simultaneously adding the titanium-containing solution and the lithium-containing solution to a reaction kettle containing a base solution, and stirring the solution to obtain a precursor solution containing flocculent precipitates; (2) after cooling the precursor solution to room temperature, separating out the precipitates in a filter pressing manner, washing the precipitates respectively with ethyl alcohol and distilled water, and drying the precipitates in a vacuum drying box to obtain a lithium titanate precursor; pressing the precursor into sheets with the thickness of 0.5-1.5 mm, burning the sheets in a muffle furnace, lowering the temperature of sheets to room temperature along with the temperature reducing of the furnace body, pneumatically pulverizing the sheets, and screening the pulverized sheets with a 300-mesh sieve to obtain the lithium titanate negative electrode materials.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

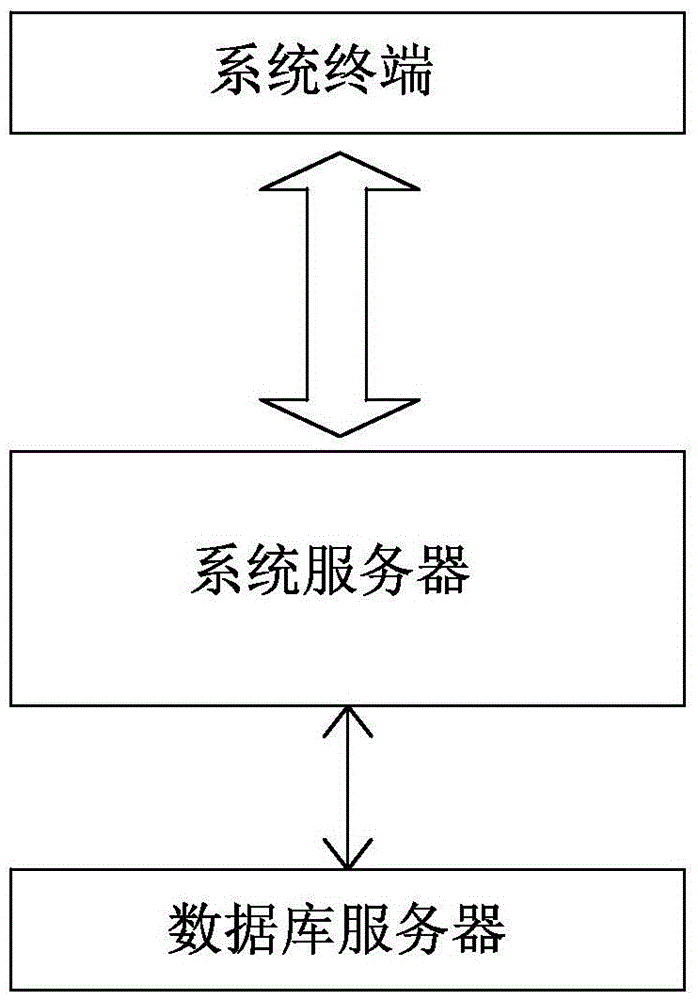

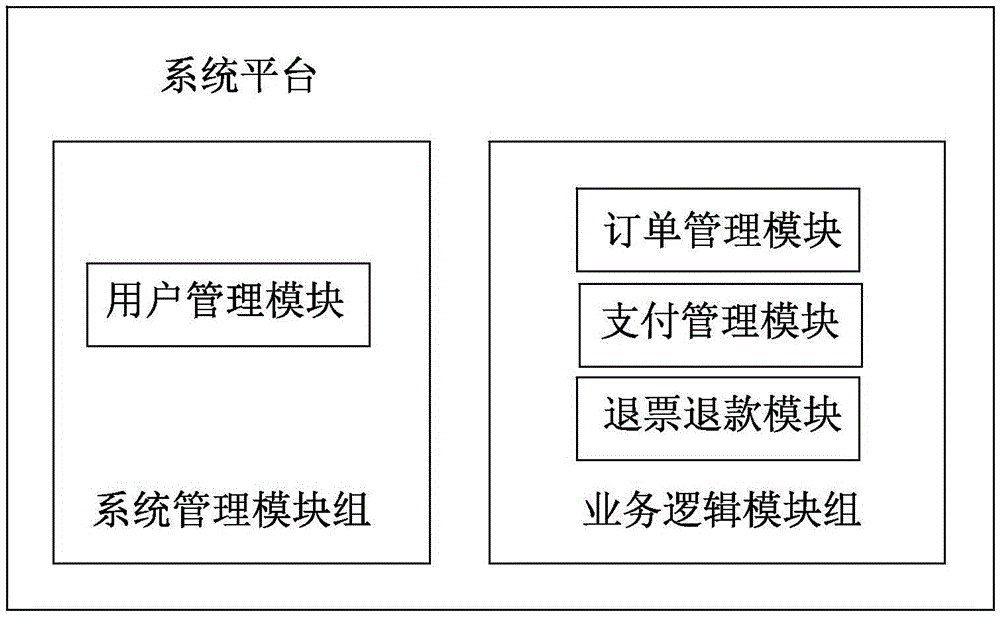

Electronic commerce payment management system in field of civil aviation

InactiveCN105608565ASimple structureImprove efficiencyProtocol authorisationSystems managementStructure of Management Information

The invention relates to an electronic commerce payment management system in the field of civil aviation, and the system comprises a system server and an operation terminal which can visit the system server through web. The system also comprises a database server connected with the system server, and the system server comprises a system management module group and a business logic module group. The system management module group comprises a user management module, and the business logic module group comprises an order management module, a payment management module, and a ticket refunding module. The system is simple and reasonable in structure, is complete in function, is stable and reliable in performance, and improves the efficiency and reliability.

Owner:北京民航信息科技有限公司

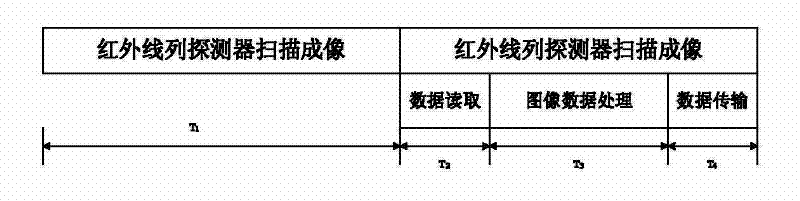

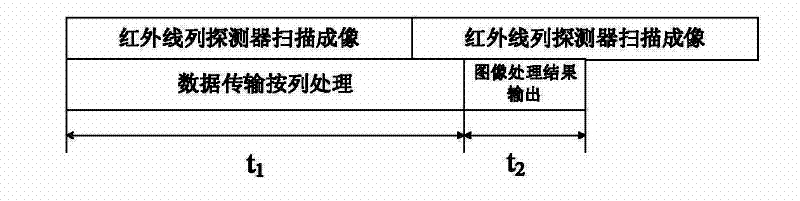

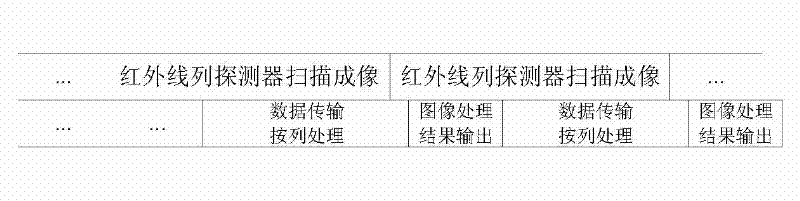

A Method of Image Data Processing Based on Infrared Array Detector

InactiveCN102291521AReduce processing timeImprove real-time performanceRadiation pyrometryPictoral communicationIdle timeImaging processing

The invention relates to an image data processing method based on an infrared linear detector, which comprises the following steps of: immediately transmitting data to a memory of an image processing system after the data collection completion of each line of images in each frame; carrying out data processing by preset image processing program by the detector to complete partial image processing tasks; and calculating and outputting final results through the image processing program. The invention completes the image data processing by utilizing idle time in two-line image data sampling process on the basis of the image data processing method of the infrared ray line detector, the total image data processing time is reduced, the real-time performance of an infrared imaging system is improved, the processing mode of the infrared ray line detector is changed, the image data operation time is reduced, and the real-time performance of the infrared imaging system is improved.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

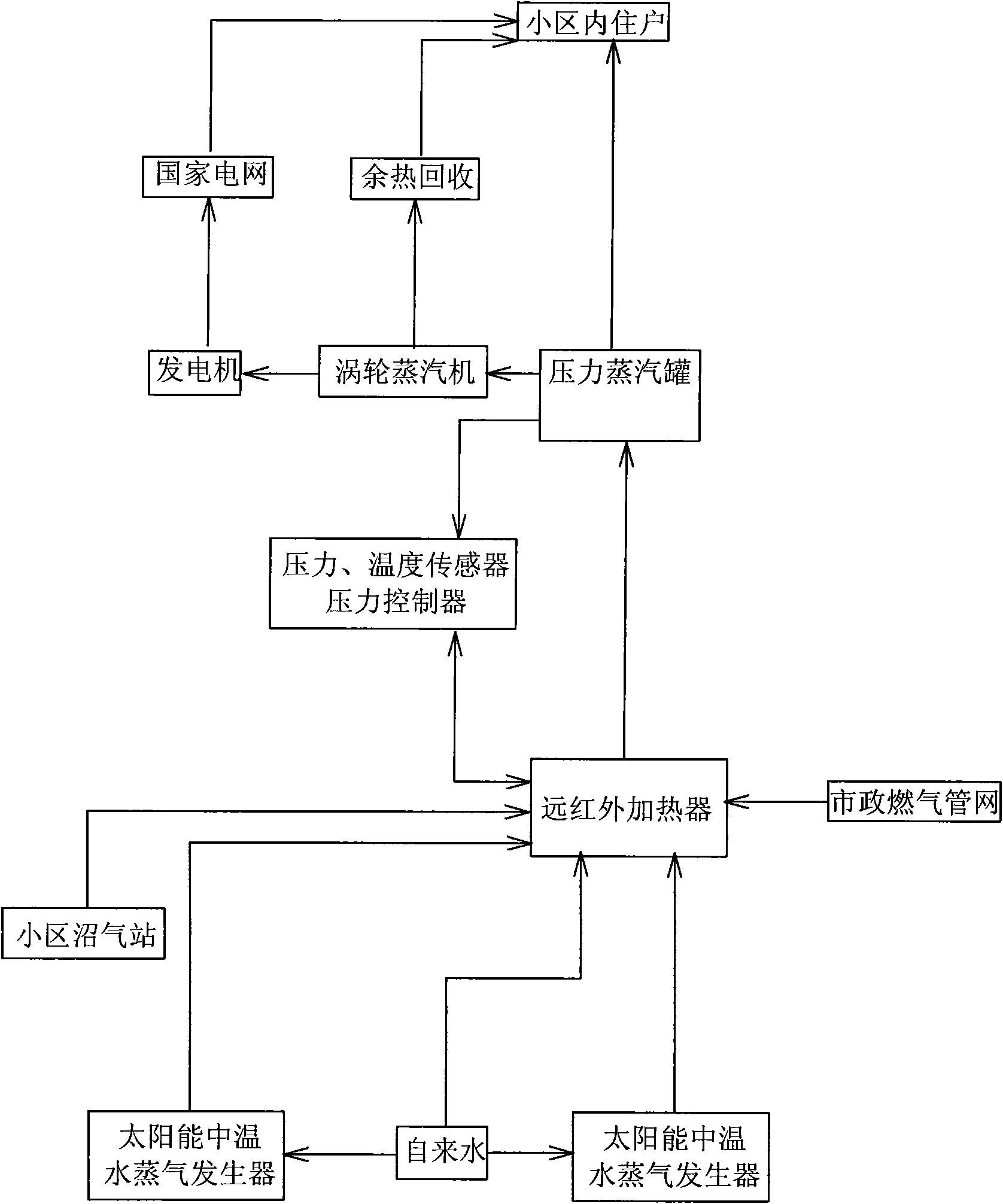

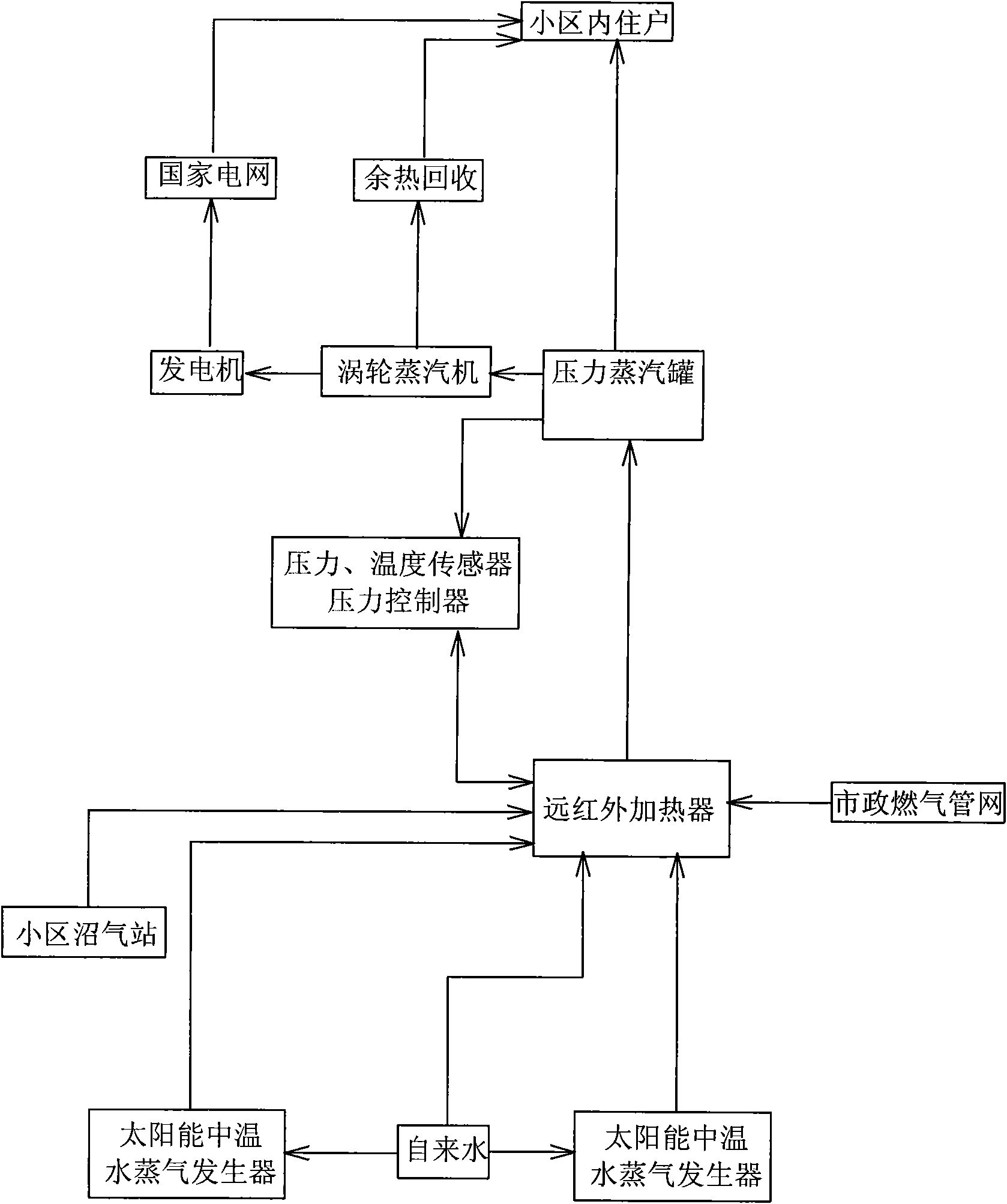

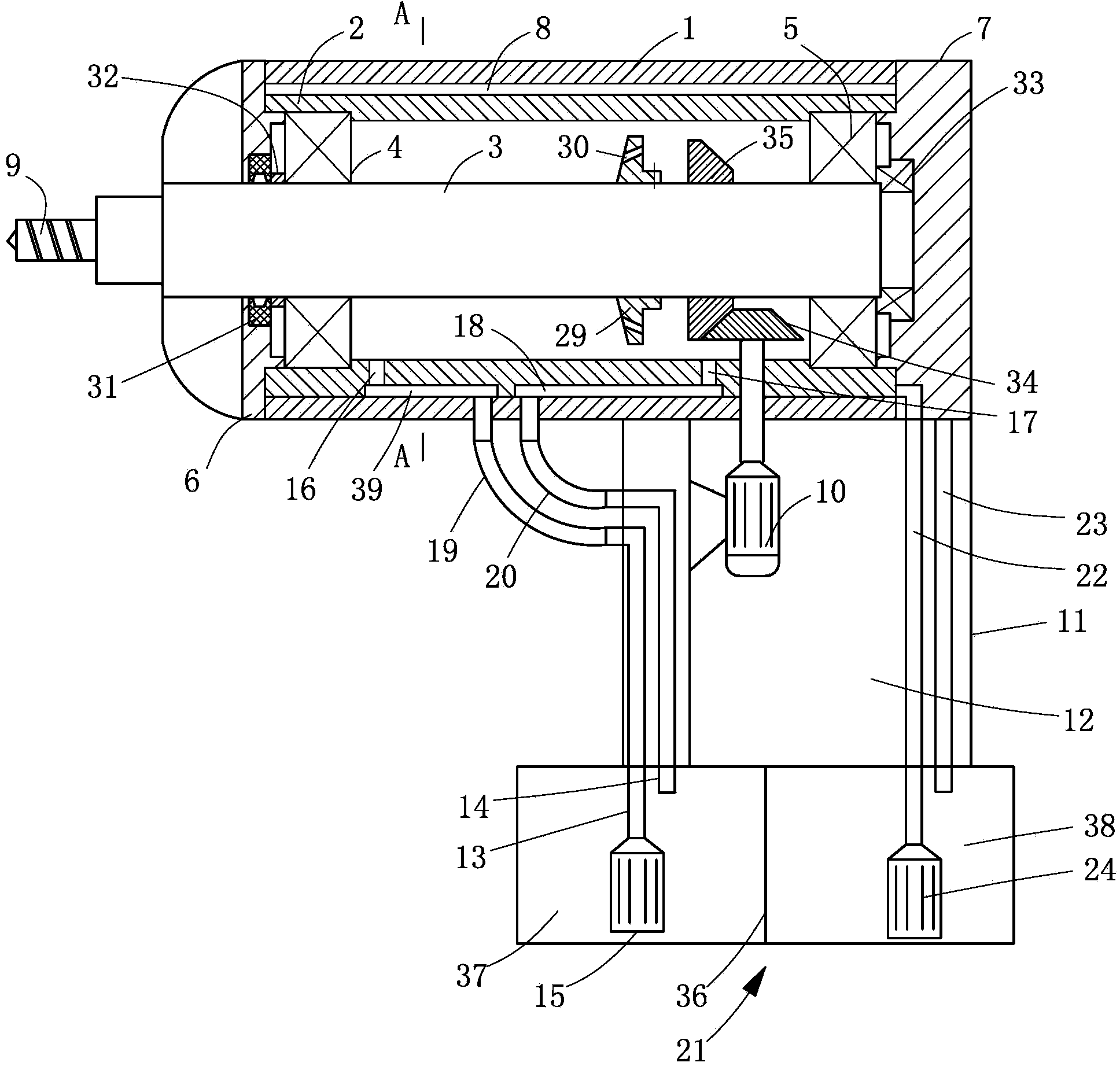

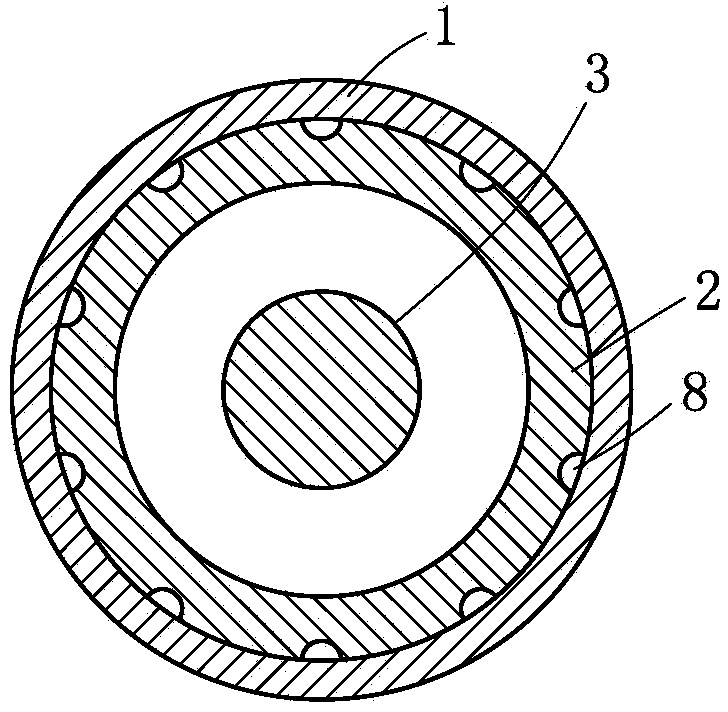

New energy moderate temperate water steam power generating system

InactiveCN101956577AChange emissionsChange handlingBioreactor/fermenter combinationsFrom solar energyNew energyWater vapor

The invention discloses a new energy moderate temperate water steam power generating system which comprises a heating system (1), a pressure steam tank (2) and a steam turbine and a generator (3), wherein the heating system (1) comprises a solar moderate temperature water steam generator, a biogas station and a far infrared heater; the heating system heats tap water for supplying steam for the pressure steam tank (2); and the pressure steam tank supplies steam for the steam turbine, and the steam turbine drives the generator for power generation. The invention adopts advanced technologies of solar energy and biomass energy, comprehensive utilization of straw, production of water steam for driving the steam turbine and power generation by the generator, ensures all-weather uninterrupted power generation, and reutilizes residual heat of power generation for power regeneration and heating of residential plots.

Owner:刘建光 +1

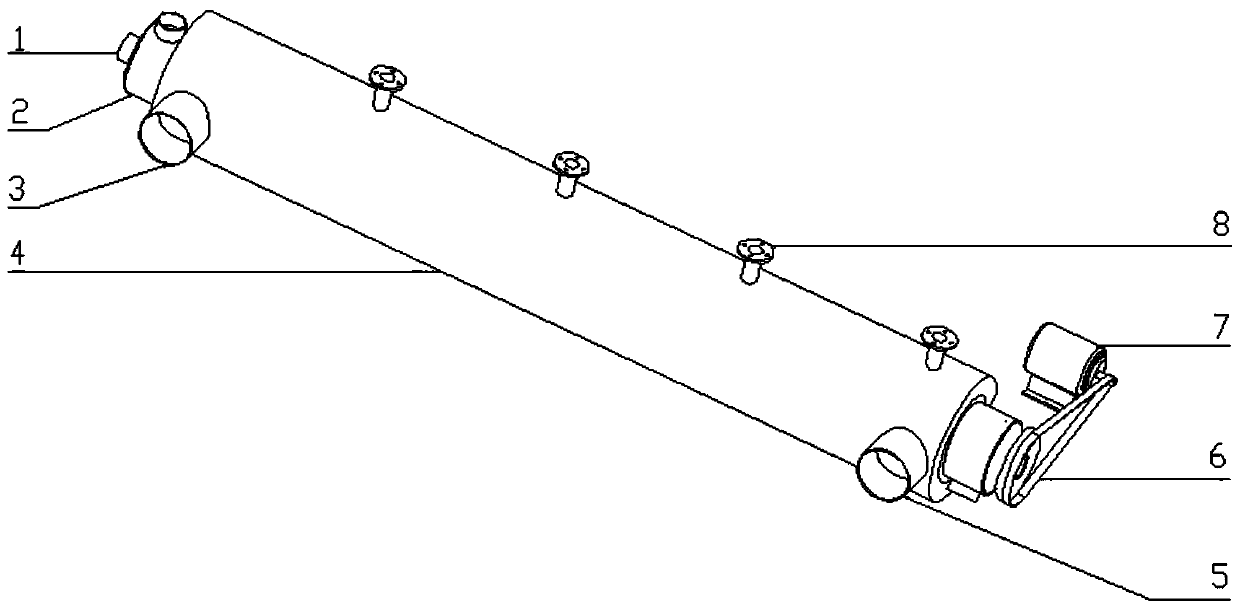

Handheld electric drill

ActiveCN103639473AAchieve lubricationReasonable structurePortable drilling machinesMaintainance and safety accessoriesHand heldFuel tank

The invention discloses a handheld electric drill, and belongs to the technical field of electric tools. The handheld electric drill mainly comprises a shell body, a power shaft is mounted in the shell, the two ends of the shell body are provided with a front bearing end cap and a rear bearing end cap respectively, the space defined by the front bearing end cap, the rear bearing end cap and the shell forms a bearing chamber, and lubricating oil is filled in the bearing chamber. A handheld part is connected to one end, close to the rear bearing end cap, of the shell, the end portion of the handheld part is connected to an oil tank, the oil tank is communicated with the bearing chamber through an oil inlet pipe and an oil return pipe, a first power pump is arranged on the end portion, located inside the oil tank, of the oil inlet pipe, the handheld part is provided with a hollow power source mounting chamber, an electromotor is mounted in the power source mounting chamber, the electromotor is in transmission connection with a power shaft through a bevel gear pair, and the oil inlet pipe and the oil return pipe both penetrate through the power source mounting chamber. According to the handheld electric drill, lubricating oil lubrication is achieved, the service life of the handheld electric drill is prolonged, and the handheld electric drill is widely applied to the processing and manufacturing of electric tools.

Owner:NINGBO HANPU TOOLS

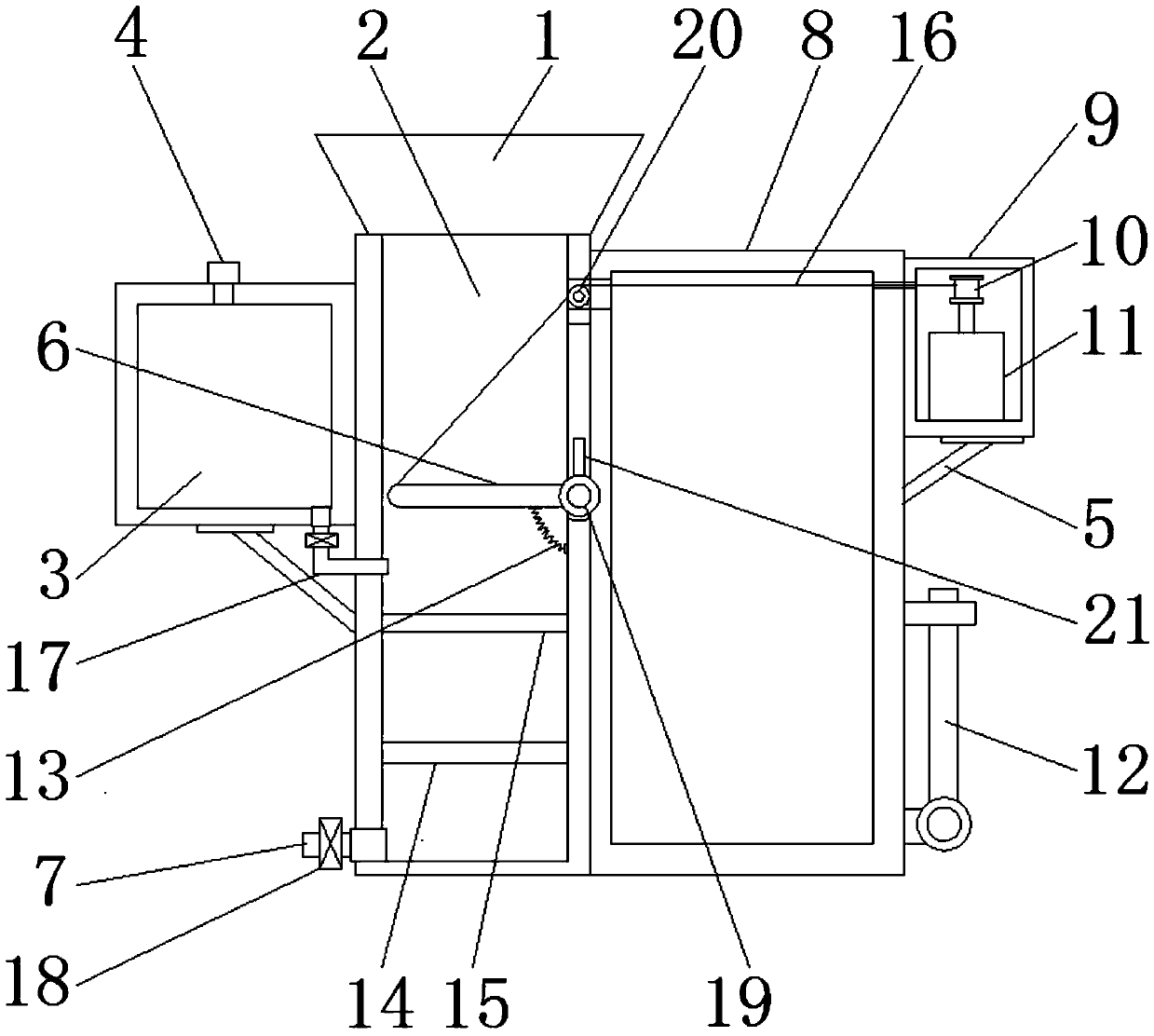

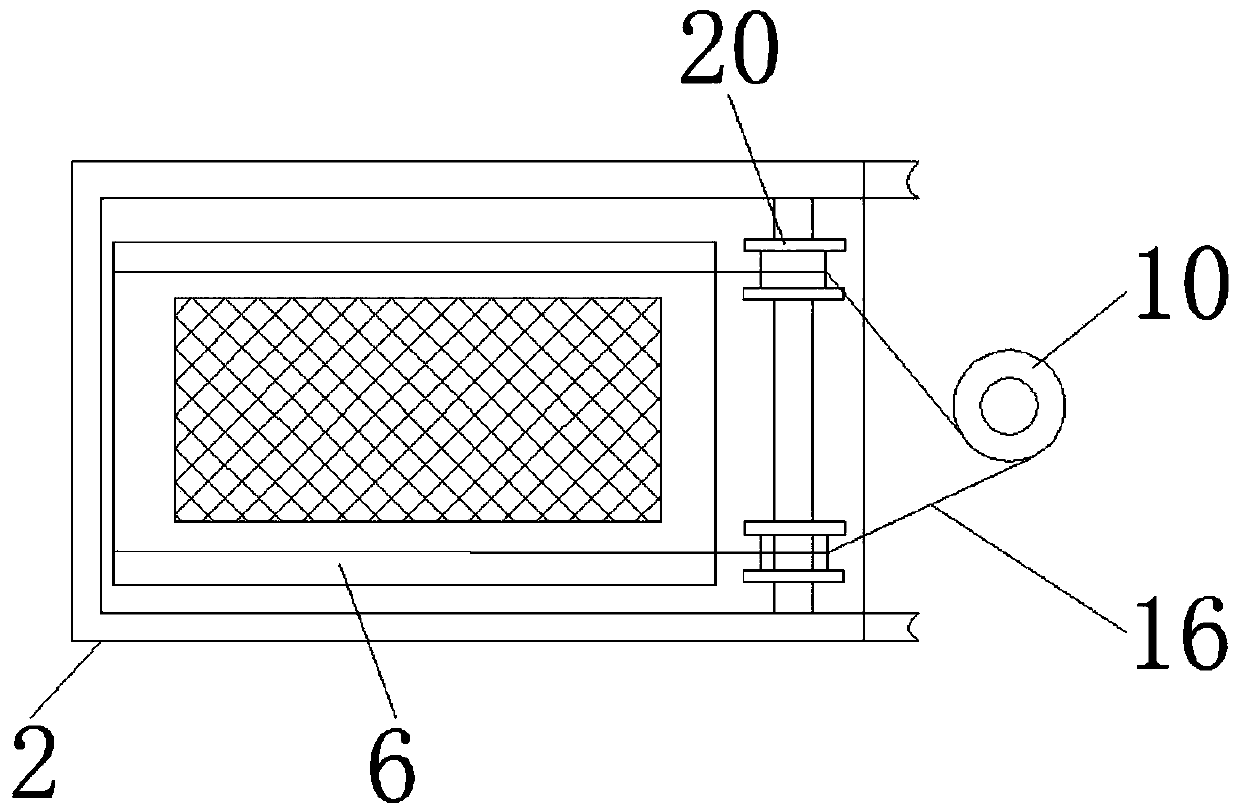

Environmentally friendly equipment for kitchens with high purification efficiency

InactiveCN109534538AImprove purification efficiencyStop the flowSpecific water treatment objectivesTreatment involving filtrationActivated carbonSewage

The invention discloses an environmentally friendly equipment for kitchens with high purification efficiency. The environmentally friendly equipment comprises a sewage treatment tank, a top of the sewage treatment tank is connected with a feeding hopper, a left side of the sewage treatment tank is fixedly connected with a medicine tank, the top of the medicine tank is connected with a feeding tube, an outlet tube is connected to the bottom of the medicament box, a right end of the outlet tube extends through the left wall of the sewage treatment tank and extends to the inside of the sewage treatment tank, the interior of the sewage treatment tank is fixedly connected with a filter plate and an activated carbon board from top to bottom, a rotating plate is connected to the right side of theinner wall of the sewage treatment tank and positioned above the filter plate by a rotating shaft, and an outlet pipe is connected below the left wall of the sewage treatment tank. The environmentally friendly equipment relates to the technical field of water treatment. The environmentally friendly equipment is characterize din that a baffle plate prevents residual sewage from flowing into a garbage bin, and the rotating plate is driven by a drawing rope to dump the garbage into the garbage bin, a traditional garbage disposal mode is changed, and the classification of garbage and sewage is facilitated.

Owner:安徽蓝华科技发展有限公司

Thin-film treatment of high-value glycol and amine solvents to remove contaminants

ActiveUS20160001197A1Minimal additional thermal degradationSimple handlingOrganic compound preparationDispersed particle separationFree formVacuum evaporation

A method cleaning a contaminate solvent used to treat a gas stream, for example a contaminated glycol or a contaminated amine stream, by vacuum evaporation using a mechanically-maintained horizontally-orientated thin film evaporator, where the contaminant material is recovered from the thin film in solvent- free form, as either a heavy organic material or as free flowing salts.

Owner:CHEM GRP MPR SERVICES LLC

Anti-cracking and color-protecting drying method for rattan

The invention provides an anti-cracking and color-protecting drying method for a rattan, and relates to the technical field of production of rattan-woven products. Anti-cracking and color-protecting chemical liquid is injected into the rhizome of the rattan or the root of the twig before the rattan is cut down. When it is detected that the anti-cracking and color-protecting chemical liquid exists at the tail end of the twig, the rattan is cut down. The cut rattan is soaked in a solution prepared from glycerinum and water according to the proportion of 1:10 for two hours after the leaves of the rattan are removed. Then the rattan is taken out, dried, soaked in molten paraffin again and taken out so that the surface of the rattan can be completely wrapped by the paraffin. Fine sand is used as an embedding medium, the rattan is heated slowly, dried and softened. The processing technology for the living rattan is simple and breaks through a traditional rattan post-processing method. After the living rattan is subjected to anti-cracking and color-protecting drying treatment, the rattan can be directly used for weaving rattan-woven products, the original color of the rattan is kept, the rattan is not prone to cracking, and the chemical utilization rate is greatly improved compared with the traditional method.

Owner:蚌埠海上明珠农业科技发展有限公司

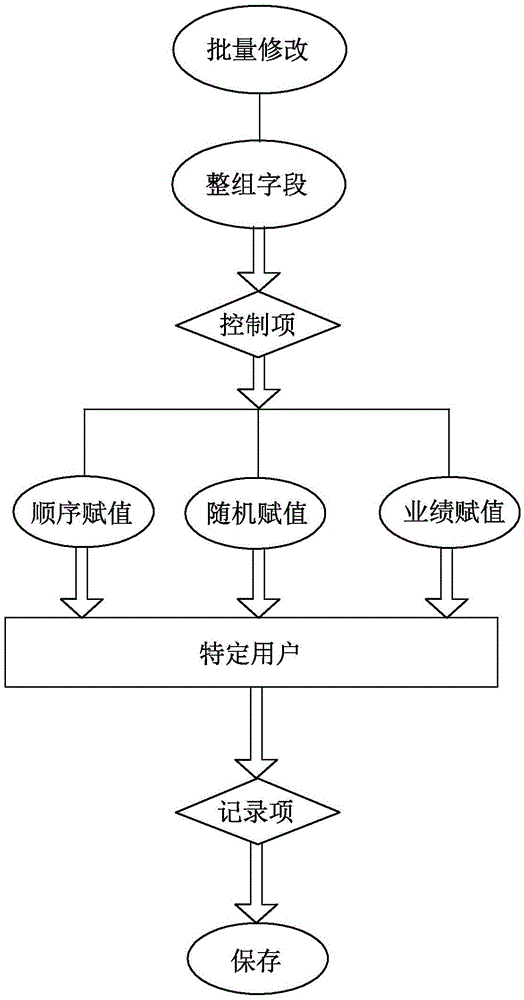

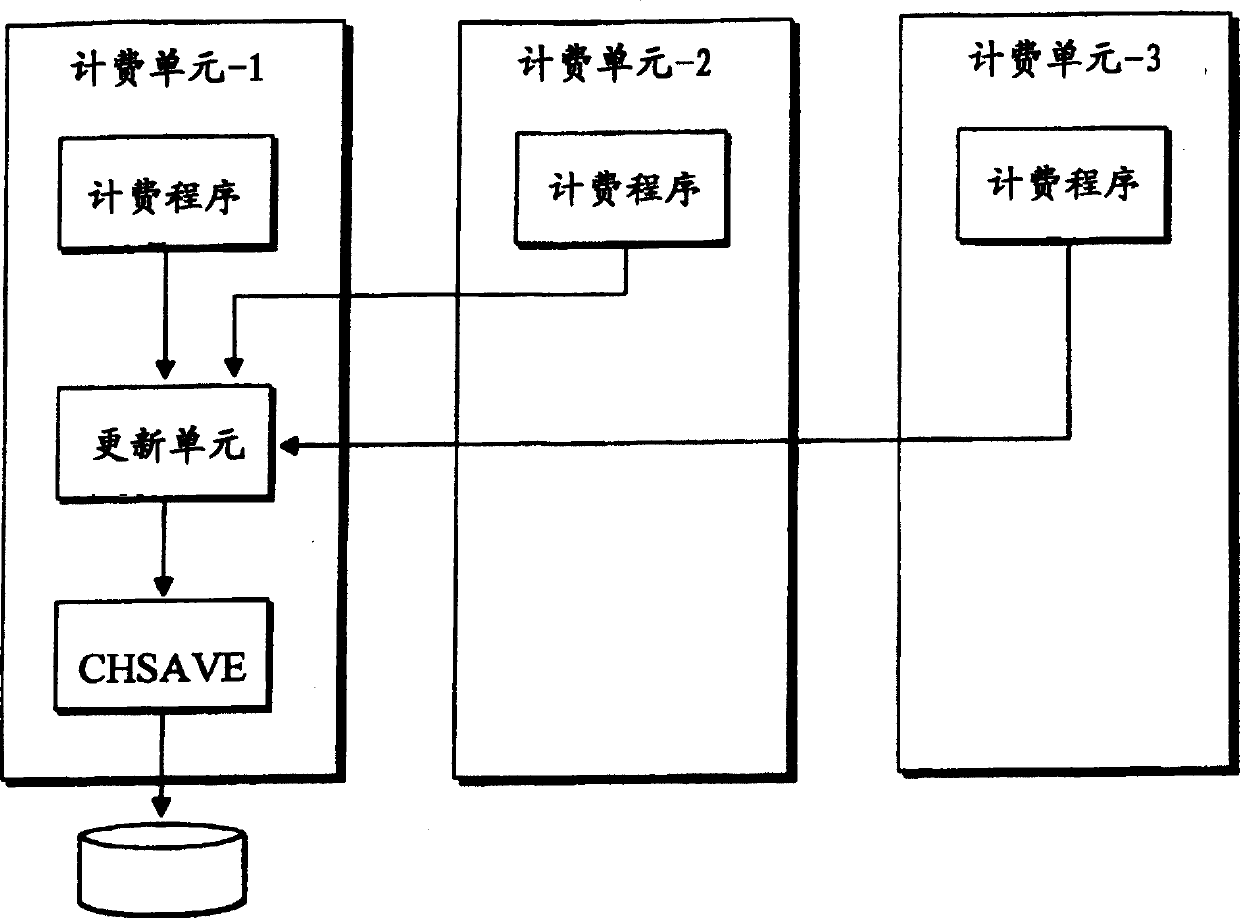

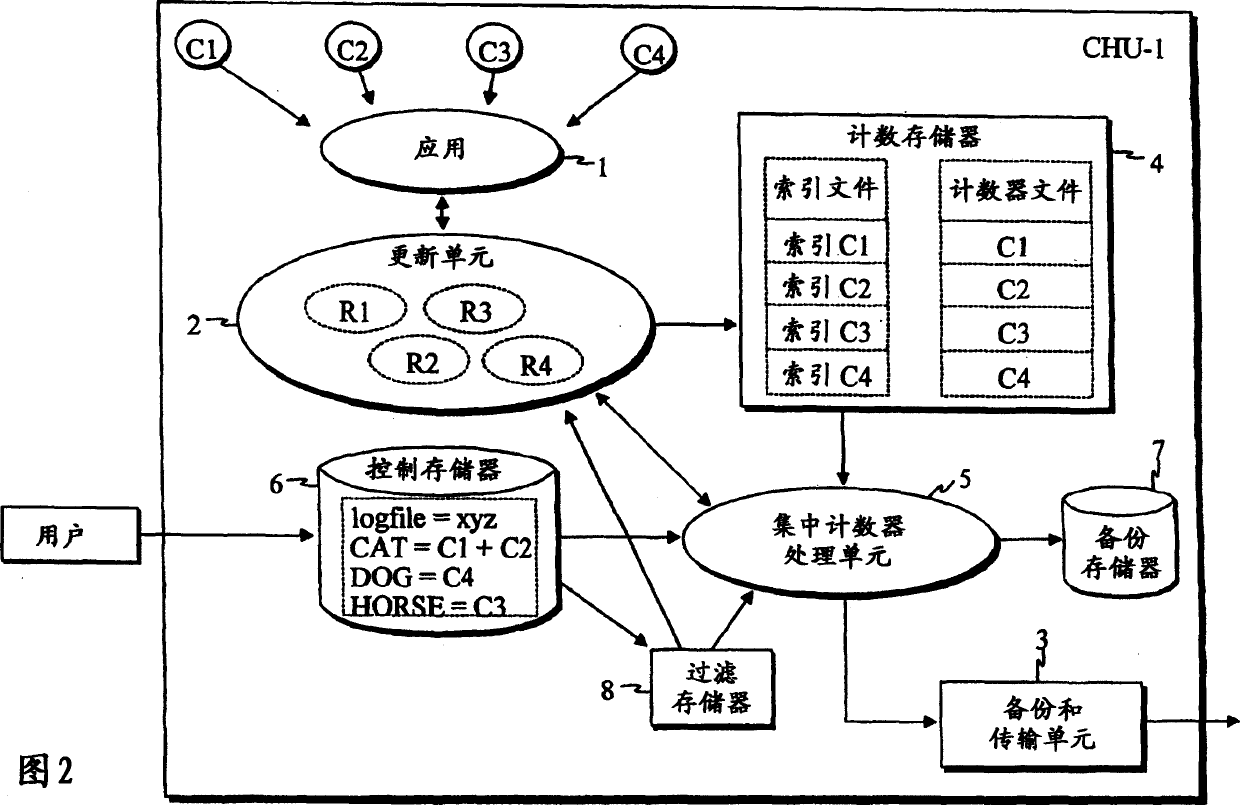

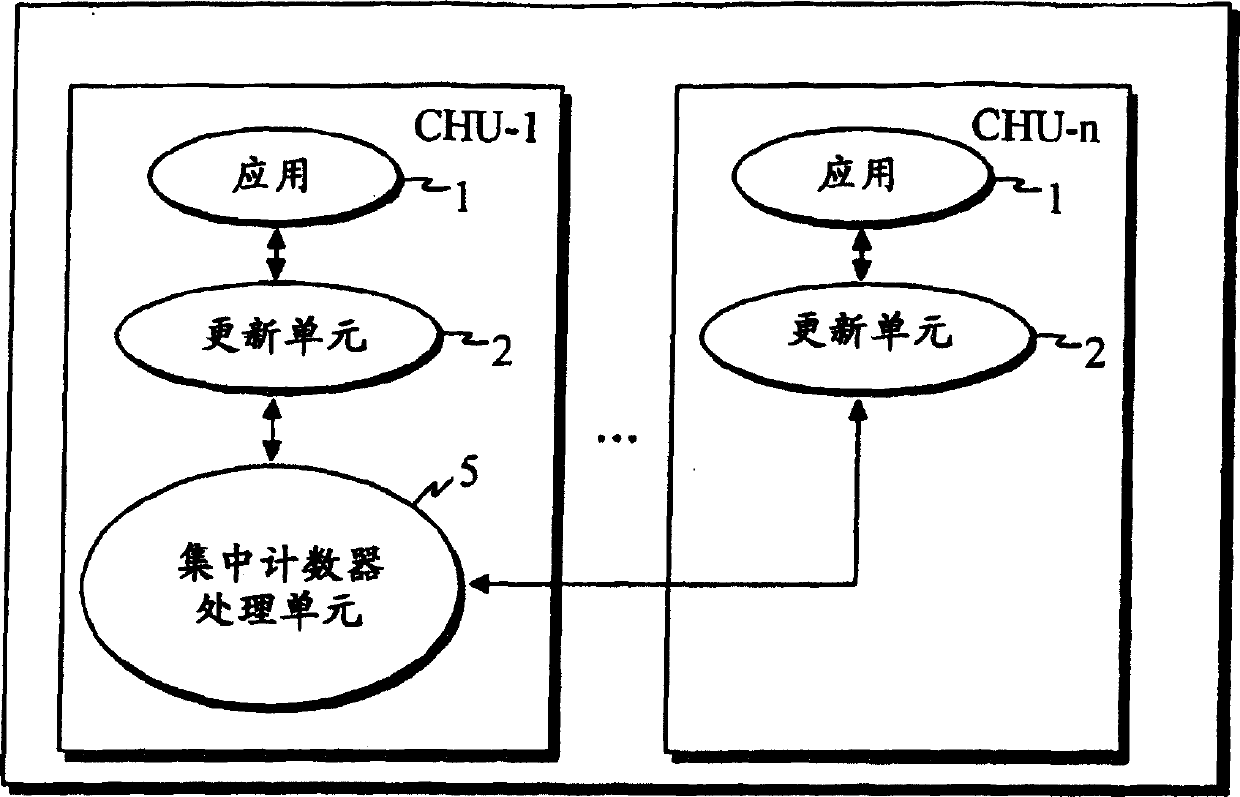

Method and system for collecting counter data in a network element

InactiveCN1602618AEasy to collectChange handlingMetering/charging/biilling arrangementsSupervisory/monitoring/testing arrangementsControl dataDatabase

The present invention relates to a method and system for collecting counter data from a set of counters in a network element. According to the present invention, the update unit updates the count file, and the centralized counter processing unit collects changed counter data from the count file to write into the transmission file. The collection of said counter data is controlled using collection information from a control file, wherein specific counters are taken into account by changing said information in said control file. The information in the control file also specifies the supported interface by specifying the format of the counter data to be written to the transport file.

Owner:NOKIA CORP

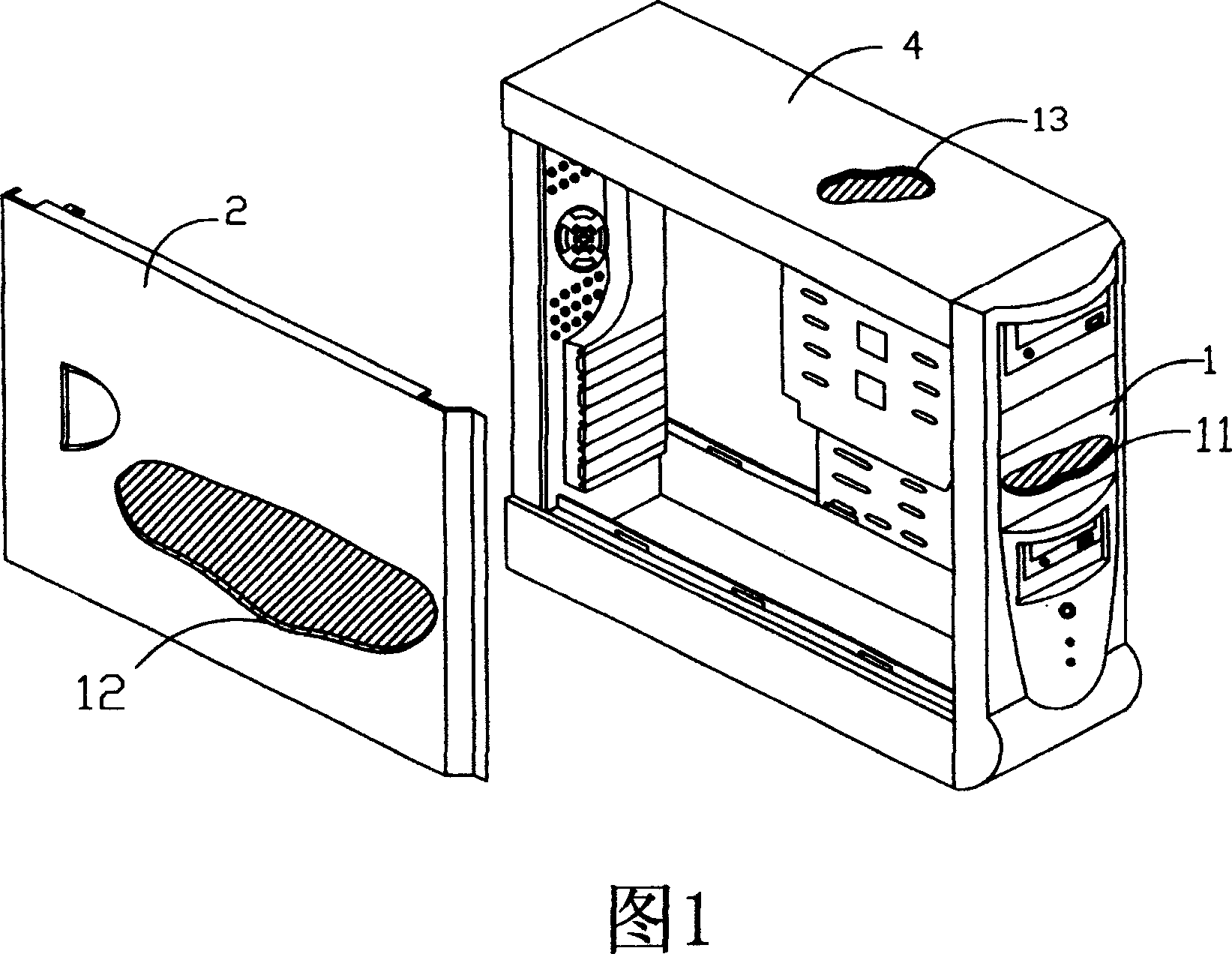

Plastic impregnated case

InactiveCN101034302AMeet high-grade market demandChange handlingLiquid surface applicatorsDigital processing power distributionEngineeringCoating

The invention relates to a plastic-coated machine box, having decorating function, changing the traditional cold sense and having human features, improving market attraction and having a certain elasticity, and comprising panel and the actively linked left and right side plates, as well as cover plate, and characterized in that: the panel is equipped with plastic coating, and the plastic coating is of plastic coating liquor or powder and comprises PVC plastic coating liquor or PE plastic coating powder, and the left side plate, right side plate or cover plate is separately equipped with plastic coating and in use, it has better handle and plasticity. And it has features of long service life, safe and reliable, extremely good protection and decoration effects, and novel structure.

Owner:李伟高

Efficient low-pollution treatment method and apparatus of rural waste

The invention discloses an efficient low-pollution treatment method and apparatus of rural waste. The apparatus comprises a waste crusher, a waste dryer, a waste pyrolysis device and a combustor; thewaste crusher is connected to a waste entry of the waste dryer through a waste conveying pipe; a waste discharge pipe of the waste dryer is connected with a waste pyrolysis entry of the waste pyrolysis device; a fuel discharge pipe of the waste pyrolysis device is connected with a fuel entry of the combustor, and a flue gas pipe of the combustor is connected with a flue gas inlet of the waste pyrolysis device; a flue gas outlet of the waste pyrolysis device is connected with a high-temperature flue gas inlet of the waste dryer through a flue gas return pipe. The apparatus has the advantages that the apparatus targets at efficient low-pollution pyrolysis of waste and clean use of energy, and the original waste treatment mode is changed; waste pyrolysis is performed under low oxygen or zerooxygen condition, less oxides of heavy metals are produced, and fewer toxic organic matters are generated and emitted.

Owner:SOUTH CHINA UNIV OF TECH

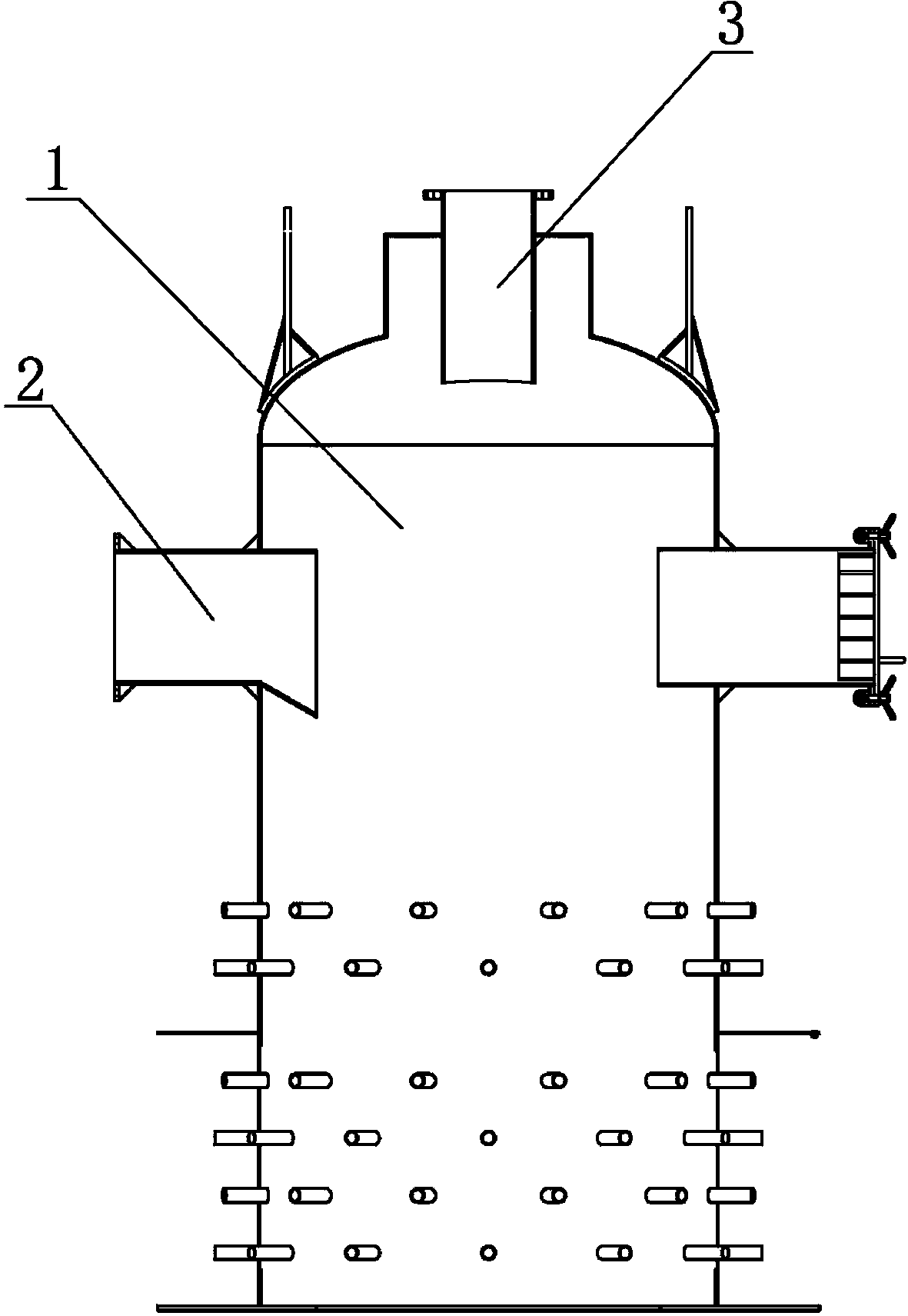

Novel efficient household garbage environmental protection magnetization incinerator device

InactiveCN108105775ASave energyImprove pyrolysis efficiencyIncinerator apparatusHollow cylinderFlue gas

The invention relates to a garbage incinerator, in particular to a novel efficient household garbage environmental protection magnetization incinerator device which magnetizes garbage by the aid of amagnetic field, improves pyrolysis efficiency, reduces incineration temperature and improves environmental protection. The device comprises a base, an incinerator body, a feed port, a flue gas port, acentral magnetic receiving device and a magnetizer, the incinerator body is a hollow cylinder, the base is mounted on the lower portion of the incinerator body, the feed port is formed in the upper portion of the side wall of the incinerator body, the flue gas port is formed in the top of the incinerator body, the central magnetic receiving device is vertically arranged at the internal perpendicular bisector of the incinerator body, and the magnetizer is mounted inside the side wall of the incinerator body. A small amount of magnetized air is led into the incinerator body, parts of combustibles in treated solid waste and combustible products generated by pyrolysis are combusted, and organic substances in the solid waste are subjected to continuous pyrolysis by generated heat. As the magnetized air is indirectly magnetized by treated substances, energy needed by pyrolysis is reduced, and pyrolysis efficiency is improved.

Owner:KUNMING BOYIN SCIANDTECH CO LTD

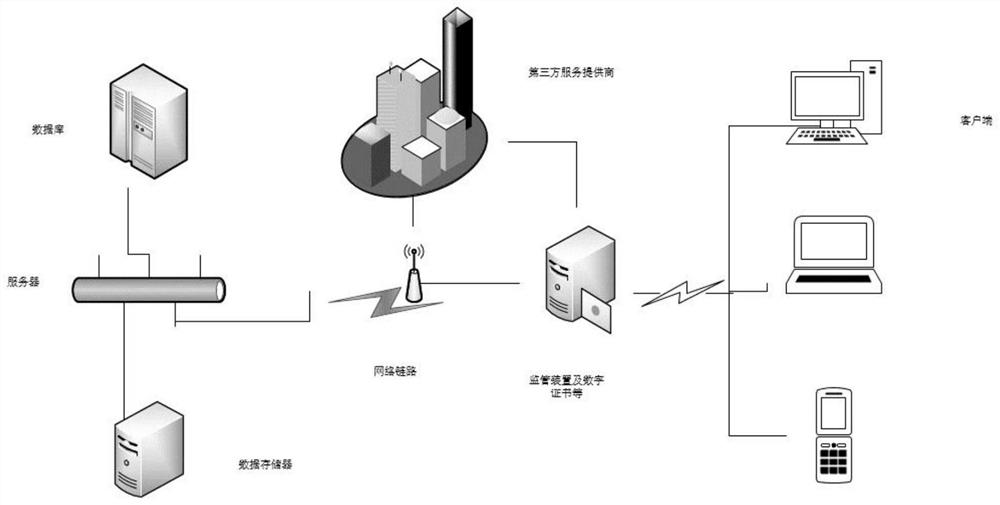

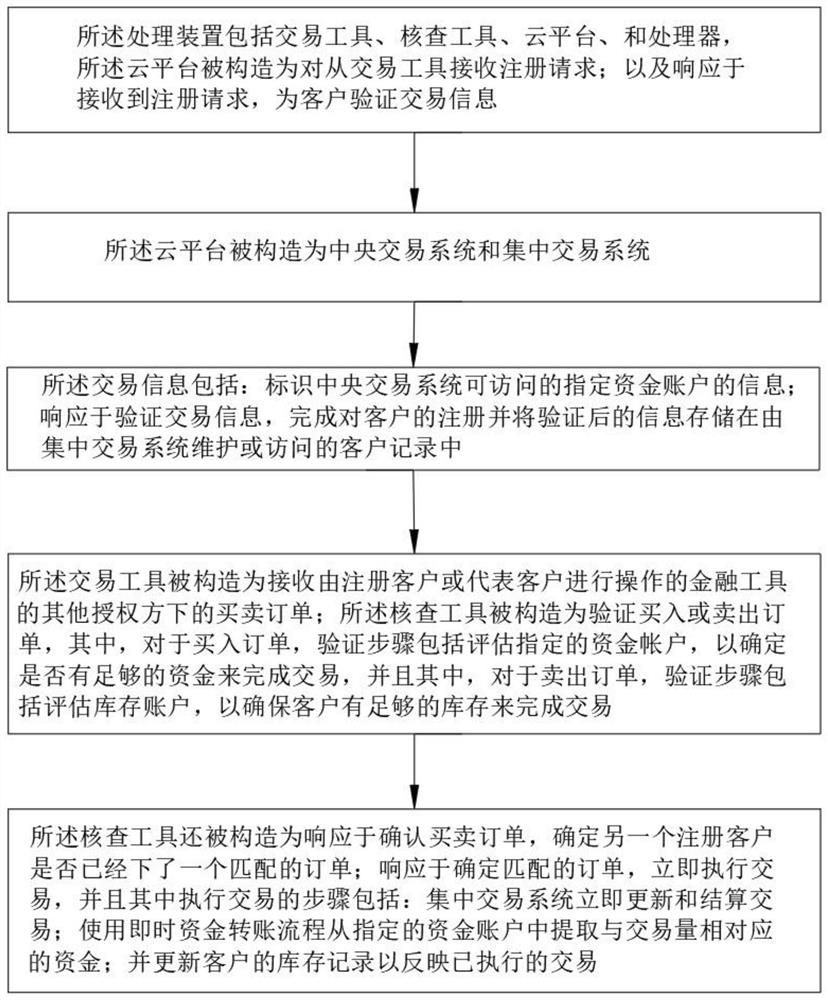

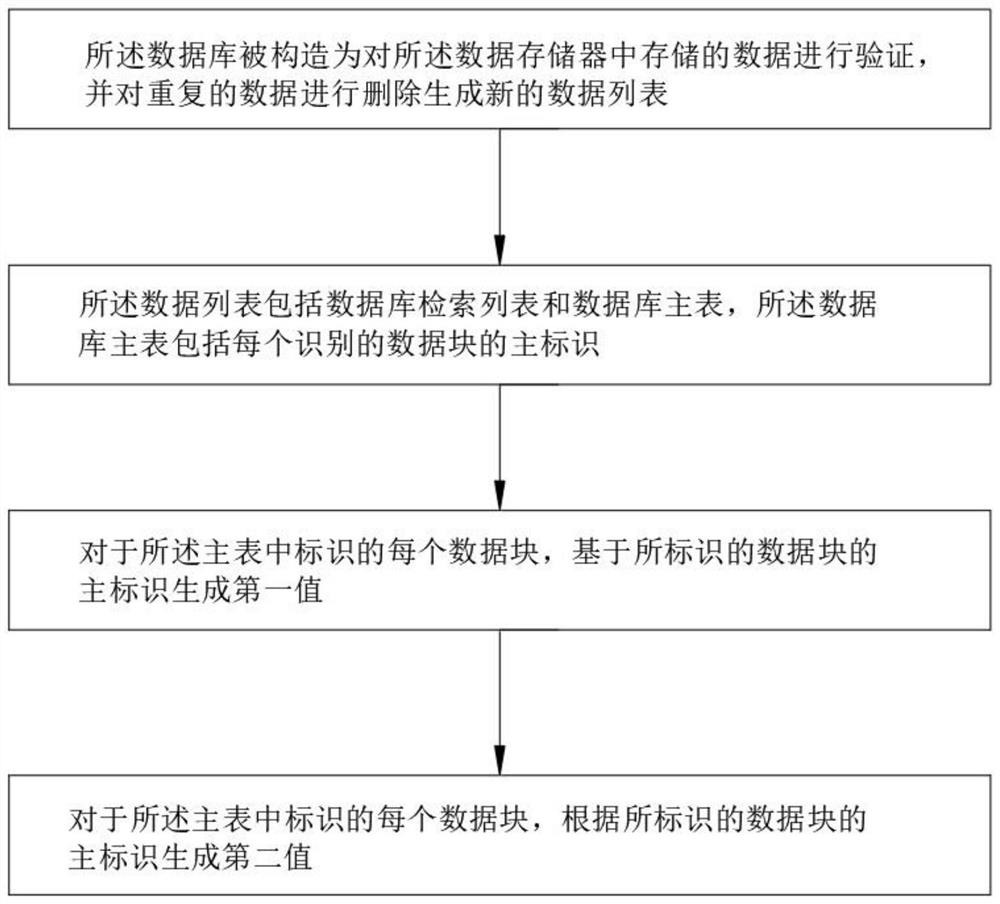

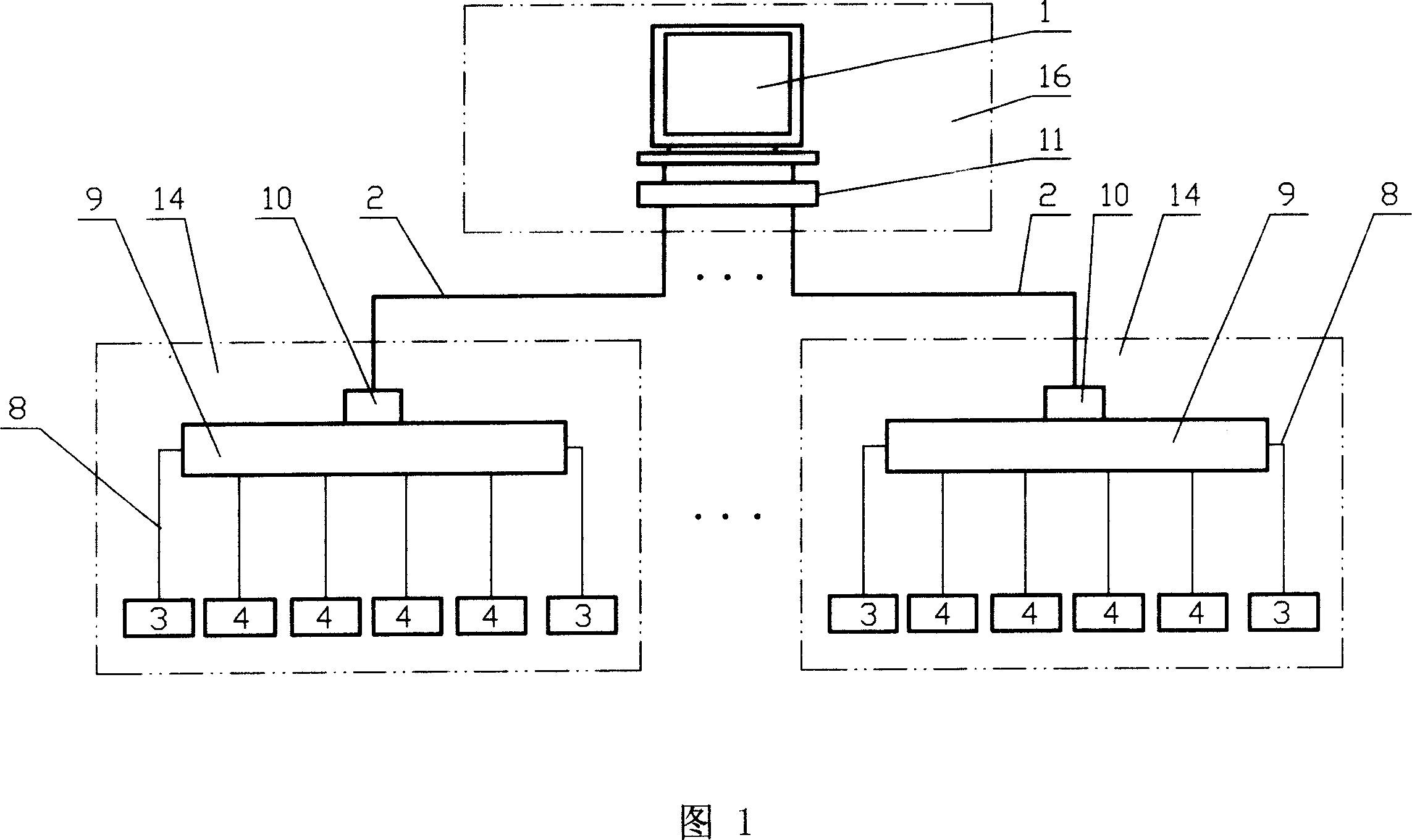

Collective asset production clearing and asset checking system

PendingCN111898886AEnsure safetyImprove securityDigital data protectionBuying/selling/leasing transactionsTransaction dataData memory

The invention provides a collective asset production clearing and asset checking system, which comprises a supervision device, a database, a data memory, a server and a processing device, and is characterized in that the supervision device is configured to supervise check operation in the database; the data memory is configured to check transaction data stored in the memory; the database is used for accessing a data link for communication among a plurality of clients and accessing the transaction data based on the supervision device; and the processing device is configured to check and clear the stored transaction data and verify the transaction information through the server and the response of the server. According to the invention, all transaction information is stored in the data memory, and in the process of verifying each transaction, an order on the data memory needs to be called or data needs to be checked, so that the transaction can be carried out safely.

Owner:广东金宇恒软件科技有限公司

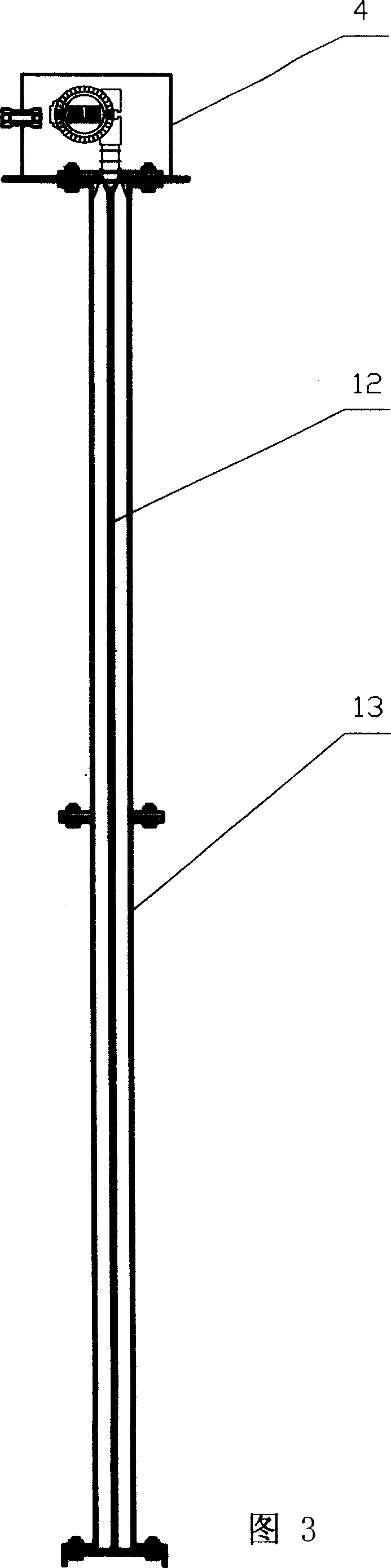

System and method for inspecting liquid level of buoy

ActiveCN1963416ARealize real-time automatic monitoringImprove efficiencyMachines/enginesLubrication indication devicesComputer moduleEngineering

This invention relates to float cylinder liquid level monitor system and its method for liquid level status, deepness, position and remaining float force, wherein, the invention comprises computer, sensor, conversion module; the sensor is connected to conversion input end and output end of conversion module is connected to computer. The invention can realize float cylinder liquid level real time monitoring to alter regular human or single device low accuracy and non-scientific data process status.

Owner:WUHAN WUCHUAN MEASUREMENT & TEST

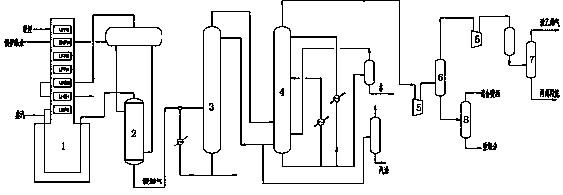

Method for producing high-quality ethylbenzene by light hydrocarbon cracking

ActiveCN110218140AMeet operational requirementsQuality improvementHydrocarbon purification/separationHydrocarbonsCarbonyl sulfideAlkyne

The invention relates to a method for producing high-quality ethylbenzene by light hydrocarbon cracking. The method comprises the following steps: (1) preparing a concentrated ethylene gas: performingtreatment on a light hydrocarbon raw material in a cracking gas to form an ethylene-containing cracked gas, performing cooling on the cracked gas, performing compression, allowing the compressed gasto enter a depropanizing tower, allowing a material separated from the top of the depropanizing tower to enter a deethanizing tower, and performing separation to obtain the concentrated ethylene gas;(2) performing pretreatment on the concentrated ethylene gas: removing impurity chlorine of the concentrated ethylene gas, removing impurity arsenic, removing diolefin, removing alkyne, removing oxygen, removing carbon monoxide and nitrogen oxides, removing carbonyl sulfide, removing impurity sulfur, and removing alkaline impurities to obtain a concentrated ethylene dry gas; and (3) producing theethylbenzene in a large scale by utilizing the concentrated ethylene dry gas through a liquid phase process. The method provided by the invention adopts the low-cost light hydrocarbon as the ethyleneraw material, realizes the purpose of large-scale production of the ethylbenzene by adopting the liquid phase process, and has low production costs, high quality of the produced ethylbenzene, and higher market value.

Owner:常州瑞凯化工装备有限公司

A high-efficiency and low-pollution pyrolysis method and device for rural garbage

ActiveCN107741017BFast heatingEvenly heatedBiofuelsIndirect heating destructive distillationThermodynamicsFlue gas

Owner:SOUTH CHINA UNIV OF TECH

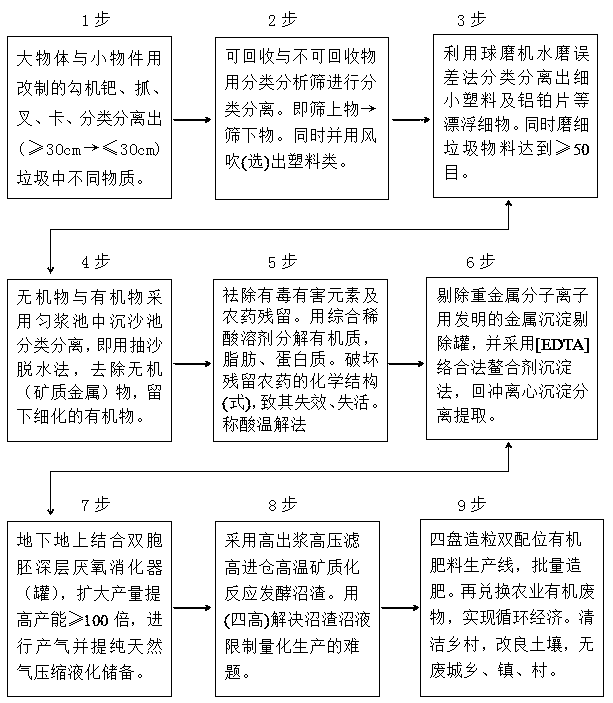

Block chain factory method for producing gas and preparing fertilizer by twice application of solid-liquid organic wastes of household garbage

InactiveCN111269045AEliminate pollutionNo secondary pollutionBio-organic fraction processingWaste based fuelLiquid wasteEcological environment

The invention relates to the fields of agricultural organic waste treatment, environmental protection and energy, and particularly relates to a block chain factory method for producing gas and preparing a fertilizer by twice application of solid-liquid organic wastes of household garbage. According to the method, a blockchain environment protection technology is adopted, household garbage, agricultural organic waste and solid waste and liquid waste are subjected to gas production and fertilizer production with the same machine in the same factory, and liquefied natural gas capable of being putinto market profit is produced firstly; and then a high-quality water-soluble organic fertilizer generated by high-temperature mineralization reaction is produced and put into agriculture, to improvesoil and improve quality of crops, so that the living ecological environment of human beings is improved. Peasants are enriched by using exchange measures, so that the aim of benefiting human beingsby using ecology is fulfilled.

Owner:熊汉夫

Medium-frequency induction heating pyrolysis type garbage treatment device and garbage treatment system

PendingCN110303032AChange handlingFocus on recyclingSolid waste disposalTransportation and packagingWaste treatmentHigh pressure

The invention discloses a medium-frequency induction heating pyrolysis type garbage treatment device, and relates to a waste solid garbage treatment system. The medium-frequency induction heating pyrolysis type garbage treatment device comprises a pyrolyzing furnace body, a feeding mechanism and a discharging mechanism, a high-temperature pyrolyzing chamber is arranged in the pyrolyzing furnace body, a medium-frequency induction heating layer is arranged in the high-temperature pyrolyzing chamber and is used for performing medium-frequency induction heating on garbage, and the pyrolyzing furnace body is connected with the feeding mechanism and the discharging mechanism which are used for achieving the feeding action and the discharging action respectively. The medium-frequency induction heating pyrolysis type garbage treatment device has the beneficial effects that the treatment mode of the waste solid garbage can be perfectly changed, the transportation cost and the secondary pollution in the transportation process can be reduced, the medium-frequency induction heating pyrolysis type garbage treatment device is used for resourceful treatment of solid wastes and manufacturing regenerated fuel, and then undoubtedly becomes a quite promising solid waste treatment method, the high-pressure high-temperature pyrolyzing device is not simply adopted for treating and eliminating the garbage, and also is aimed at regeneration and reuse of energy and other resources in the urban garbage at the same time, and then the comprehensive effects of environmental protection, energy conservation and resource regeneration circulation application are achieved.

Owner:周翠红

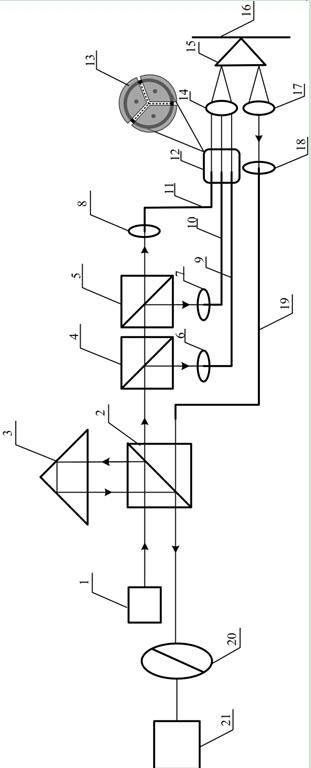

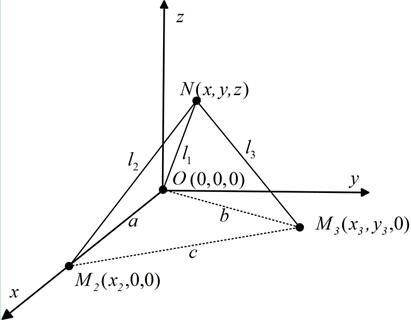

A three-dimensional coordinate measuring device and measuring method based on laser continuous frequency sweep

ActiveCN110375643BRealize measurementChange handlingUsing optical meansElectromagnetic wave reradiationFirst lightData acquisition

The invention discloses a three-dimensional coordinate measuring device and a measuring method based on laser continuous frequency sweep, comprising: a light source, which generates polarized initial light to a first light splitting module; the first light splitting module divides the polarized initial light into reference light and second light The initial light; the second light splitting module divides the second initial light into several beams of detection light and sends them to the detection module; the detection module produces measurement light after the detection light is reflected by the object to be measured and enters the first light splitting module; the processing module receives the first beam of light A reference light and a measurement light of the spectroscopic module are processed. The method includes: establishing a coordinate system according to the measuring device; turning on the light source to obtain measurement data; and calculating the three-dimensional coordinates of the measured object according to the data. The substantive effects of the present invention are: simple structure, no need to collect the entire interference signal, and insensitive to external interference, the measurement of the beat frequency signal can be realized only by weak laser, and the long-distance three-dimensional coordinate measurement and position.

Owner:CHINA JILIANG UNIV

Biomass pyrogenation gasification and purification method

InactiveCN100335593CHigh calorific valueHigh hydrogen contentBiofuelsCombustible gas purificationCyclonePurification methods

The invention provides a biological mass thermal decomposition, gasification and purification method which comprises, disintegrating the biological mass, gasifying in a furnace, obtaining retort gas, cyclone dedusting, cooling down and purifying, high voltage static coke trapping, making the coke tar bubbles and dust in the coal gas deposit onto the coke collection poles, thus purifying the coal gas, finally washing and dewatering.

Owner:MIANYANG TONGMEI ENERGY SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com