System and method for inspecting liquid level of buoy

A technology of liquid level monitoring and buoy, which is applied in the direction of liquid/fluid solid measurement, displaying liquid level indicators through pressure measurement, measuring devices, etc. It is easy to be affected by human operation factors and other problems, and achieves the effects of high reliability, improved efficiency and safety, and simple use and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

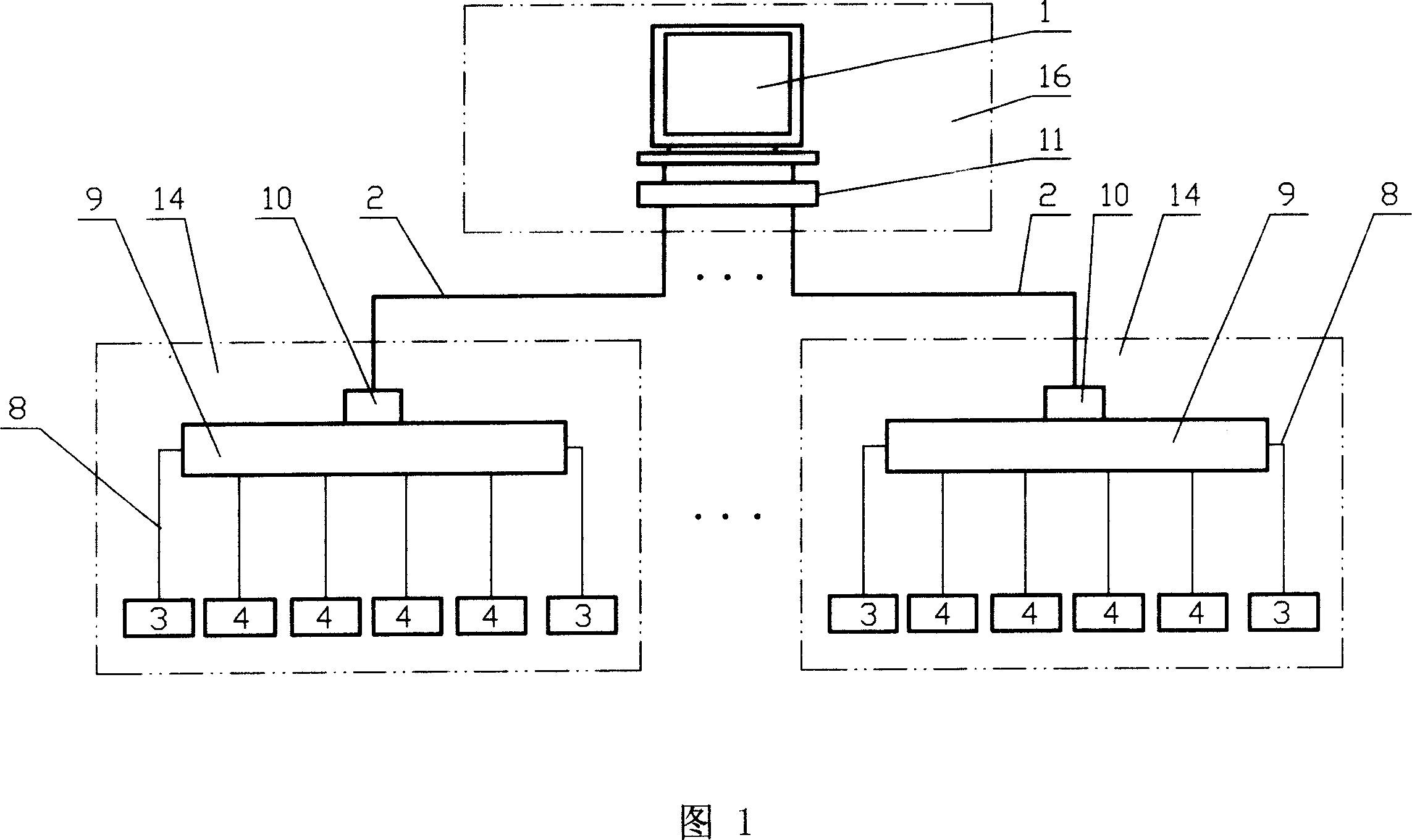

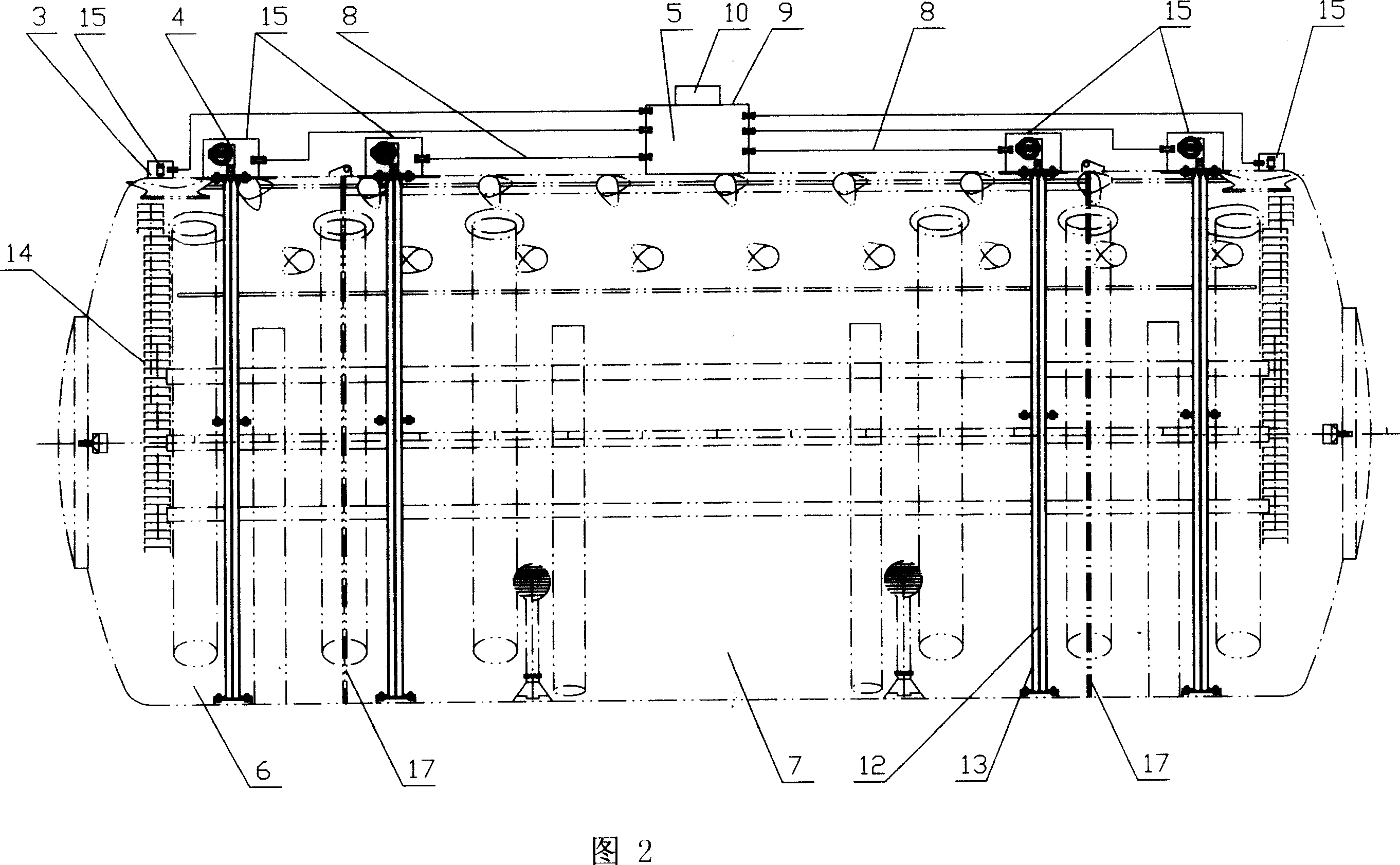

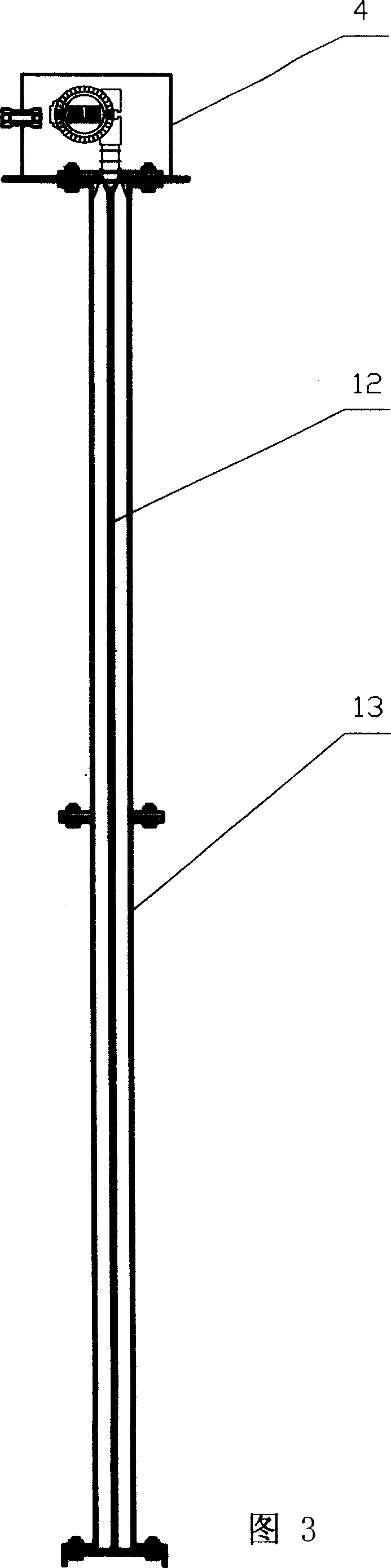

[0020] The present invention comprises buoy 14, sensor, conversion module 5, computer 1, will pay special attention to will liquid level sensor 4 be installed perpendicular to buoy water tank in the process of installing sensor, just can guarantee like this accurate measurement in buoy 14 water tanks For liquid level height, four guided wave radar liquid level sensors 4 with a model of MT5000 are used in this embodiment, and the guided wave radar liquid level sensor 4 and its protective cover 15 are fixed on the buoy water tank by bolts. In addition to installing the sensor 4 vertically to the buoy water tank, attention should also be paid to extending the detection span of the liquid level sensor 4, that is, the probe 12 of the liquid level sensor 4, from the top of the buoy water tank to the bottom of the water tank , otherwise there will be a detection blind zone and the measured data will be inaccurate. A probe protective cover 13 is provided outside the probe 12 of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com