Preparation method of lithium titanate negative electrode material

A negative electrode material, lithium titanate technology, used in titanate, alkali metal titanate, chemical instruments and methods, etc., can solve the problems of wide particle size distribution, difficult control of product morphology, incomplete reaction, etc. High tap density, easy to realize industrialization, avoid the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

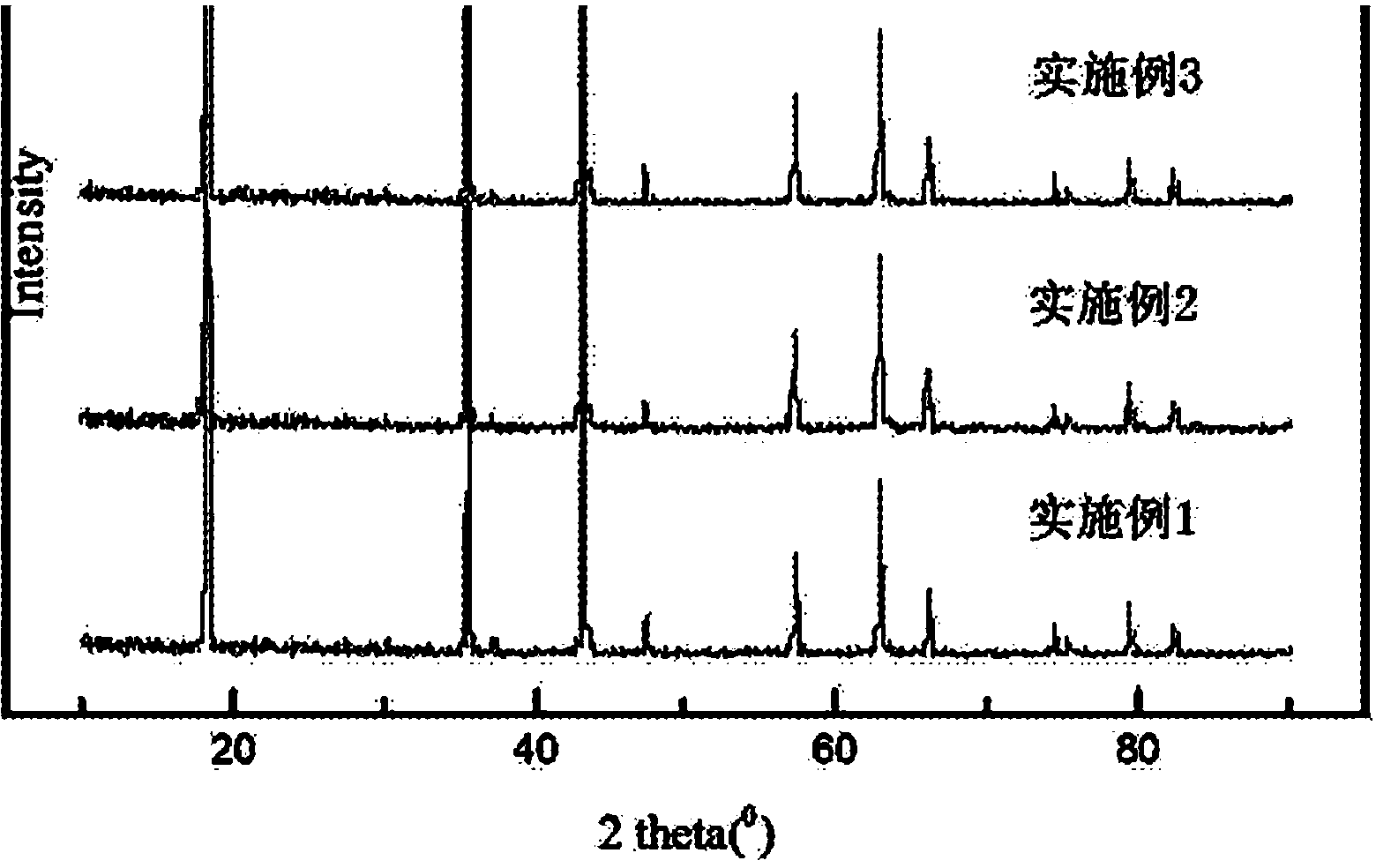

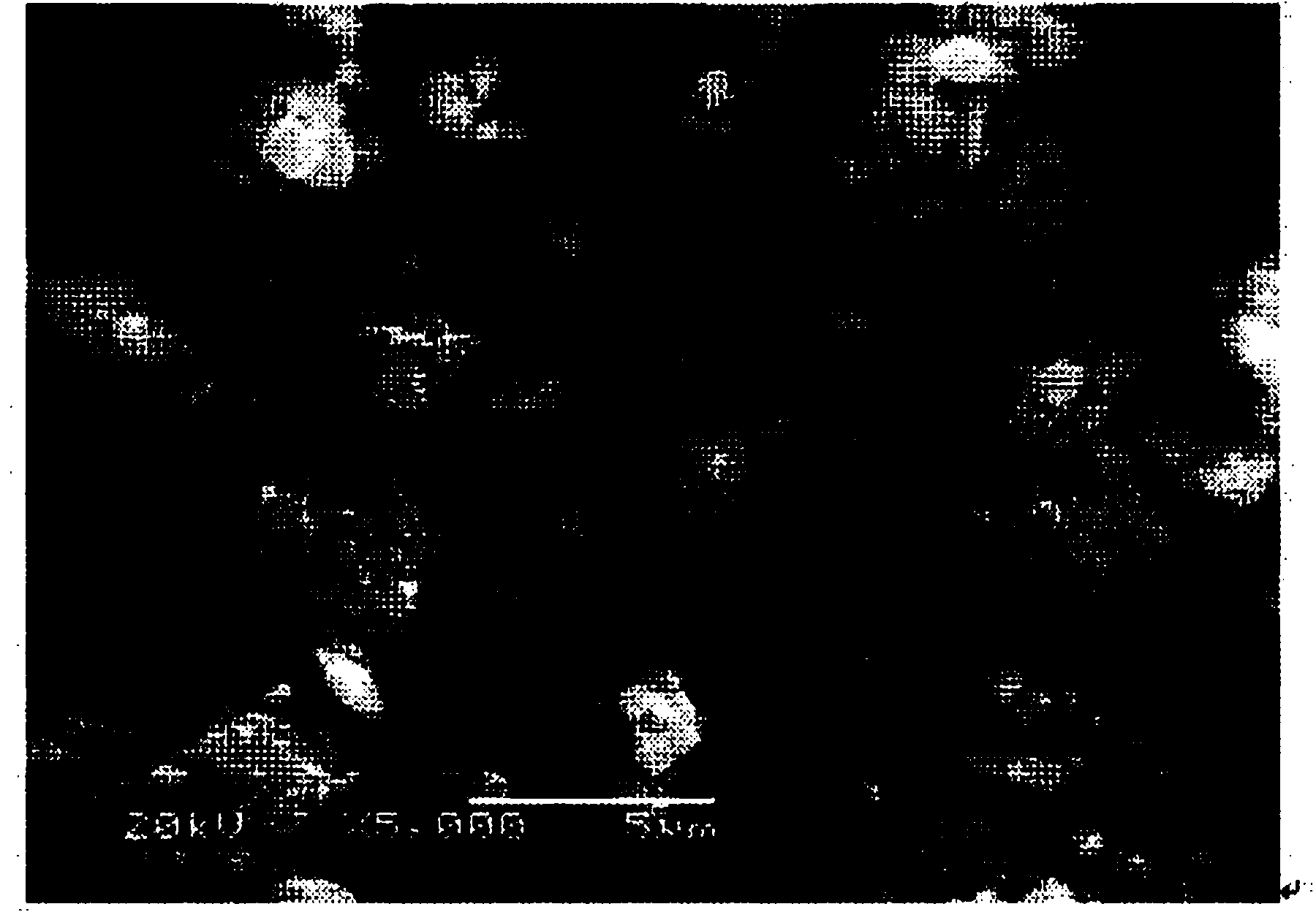

[0025] The present invention as figure 1 , 2 , 3, 4, a preparation method of lithium titanate negative electrode material is characterized in that: the specific preparation steps are as follows: (1) prepare an organic molecule solution, stir for 1-1.5h for use, and then according to the Li:Ti molar ratio (0.80—0.85): 1 Weigh the organic lithium source and titanium source, and add them to the organic molecule solution to be used respectively to obtain a titanium-containing solution and a lithium-containing solution; add the titanium-containing solution and the lithium-containing solution to the bottomed (2) After the precursor liquid is cooled to room temperature, the precipitate is separated by pressure filtration, and the precipitate is separated with ethanol and distilled water respectively. Wash and dry the precipitate in a vacuum oven at 80-120°C for 6-12 hours to obtain a lithium titanate precursor; press this precursor into a 0.5-1.5mm thick sheet in a muffle furnace at...

Embodiment 1

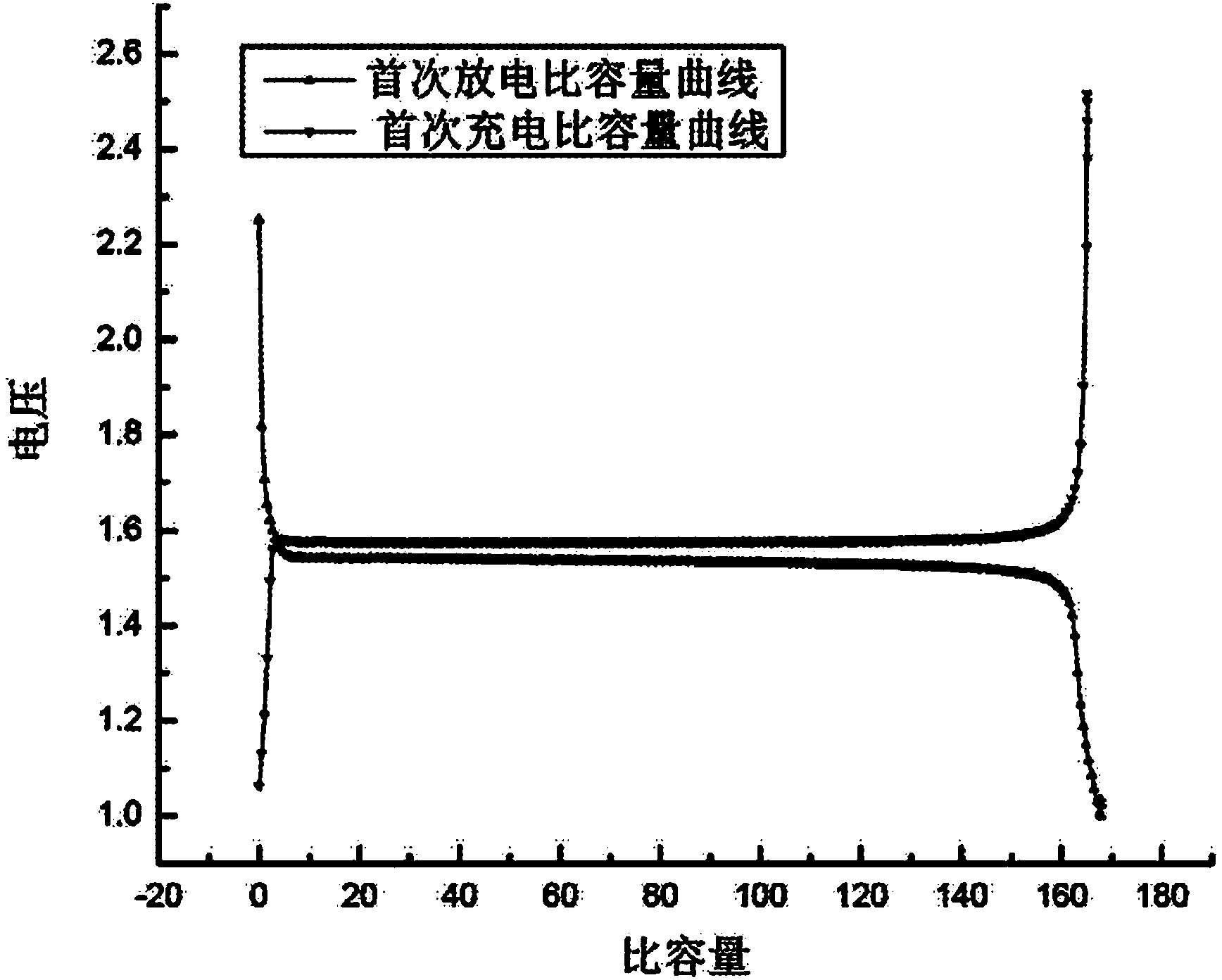

[0027]Example 1: (1) Weigh 0.2g of polyvinylpyrrolidone (PVP) and dissolve it in 35ml of ethanol, stir for 1.5h and set aside (2 parts are prepared at the same time). Then weigh 83.66g of lithium acetate and 340.32g of tetrabutyl titanate according to the Li:Ti molar ratio of 0.82:1, and add them to the previously prepared PVP ethanol solution, and then add the two solutions simultaneously to 60ml of distilled water. (2) After the precursor solution was cooled to room temperature, the precipitate was separated by pressure filtration, and washed with ethanol and distilled water respectively. The precipitate was dried in a vacuum oven at 90°C for 8 hours to obtain a lithium titanate precursor. The precursor was pressed into a 0.5mm-thick sheet and calcined in a muffle furnace at 850°C (introduced with nitrogen) for 12 hours, and then gas powdered after the furnace was cooled to room temperature and passed through a 300-mesh sieve to obtain a lithium titanate negative electrode m...

Embodiment 2

[0028] Example 2: (1) Weigh 0.2g of polyvinylpyrrolidone (PVP) and dissolve it in 35ml of ethanol, stir for 1.5h and set aside (2 parts are prepared at the same time). Then weigh 86.72g of lithium acetate and 340.32g of tetrabutyl titanate according to the molar ratio of Li:Ti of 0.85:1, and add them to the PVP ethanol solution prepared earlier, and then add the two solutions to 60ml of distilled water at the same time. Stirring at 60°C for 420 min in a stainless steel reactor with polytetrafluoroethylene lining to obtain a precursor solution containing flocculent precipitates; (2) After the precursor solution was cooled to room temperature, the precipitate was separated by pressure filtration. Wash with ethanol and distilled water respectively, and dry the precipitate in a vacuum oven at 110° C. for 6 hours to obtain a lithium titanate precursor. The precursor was pressed into a 0.8mm thick sheet and calcined in a muffle furnace at 950°C (introduced with nitrogen) for 10.5h, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com