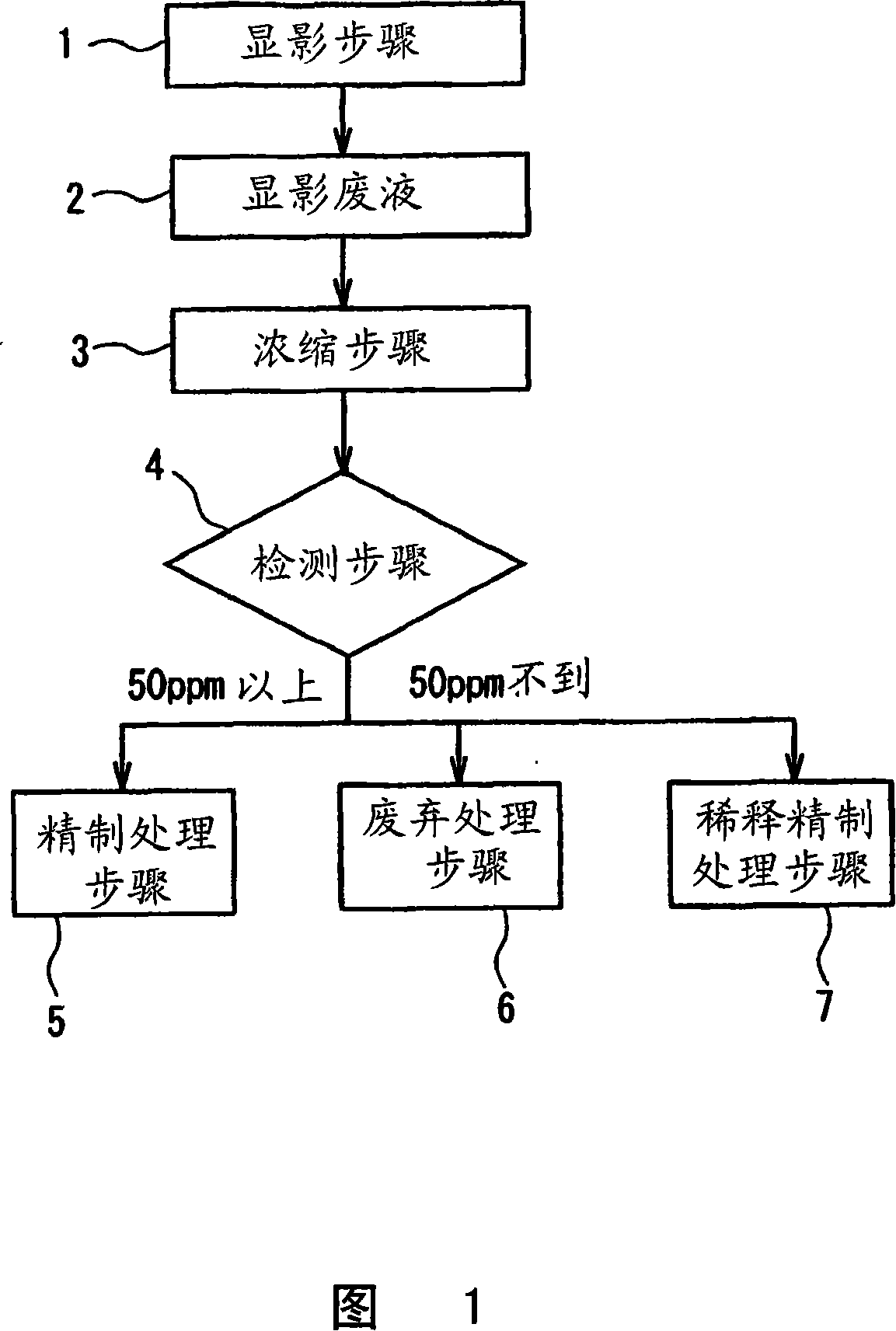

Method for treating development waste liquid

A treatment method and developing solution technology, applied in heating water/sewage treatment, electrochemical water/sewage treatment, photography, etc., can solve problems such as obstacles to long-term stable operation, low purity of TAA hydroxide aqueous solution, and rise in electrolyzer voltage , to achieve the effect of safe and effective disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Using the thin-film concentrator 3, the liquid containing the photoresist and the tetramethylammonium hydroxide (TMAH) solution discharged from the developing step 1 of the liquid crystal display (LCD) factory was concentrated at a liquid temperature of 60° C. under a reduced pressure of 20 kPa. The waste liquid 2 was developed to obtain a brown concentrated liquid (1).

[0077] The various components of the obtained concentrate (1) were analyzed, and the results are shown below.

[0078] TMAH concentration: 20.6wt%

[0079] Concentration of metal impurities:

[0080] Al: 3800ppb (unit TAA is 22.7ppm)

[0081] Na: 40ppb (unit TAA is 0.24ppm)

[0082] Cu: 650ppb (unit TAA is 3.88ppm)

[0083] Fe: 800ppb (unit TAA is 4.78ppm)

[0084] The total content of unit TAA: 31.60ppm

[0085] Total concentration of organic impurities: 3800ppm

[0086] The TMAH concentration was measured by potentiometric titration, the metal concentration was measured by ICP-MS, and the tota...

Embodiment 2

[0128] The concentrate (2) of Comparative Example 1 was diluted by adding a high-purity TMAH aqueous solution. The analysis results of the high-purity TMAH aqueous solution and diluent used are as follows.

[0129] High-purity TMAH aqueous solution

[0130] TMAH concentration: 20.1wt%

[0131] Al: less than 5ppb

[0132] Na: less than 5ppb

[0133] Cu: below 5ppb

[0134] Fe: below 5ppb

[0135] Total concentration of organic impurities: below 10ppm

[0136] Diluent

[0137] TMAH concentration: 20.3wt%

[0138] Al: 6000ppb (unit TAA is 36.3ppm)

[0139] Na: 60ppb (unit TAA is 0.36ppm)

[0140] Cu: 2100ppb (unit TAA is 12.7ppm)

[0141] Fe: 1500ppb (unit TAA is 9.01ppm)

[0142] The total content of unit TAA: 58.37ppm

[0143] Total concentration of organic impurities: 3800ppm

[0144] The content of each metal impurity in this diluted solution is below the reference value (50 ppm) of the present invention.

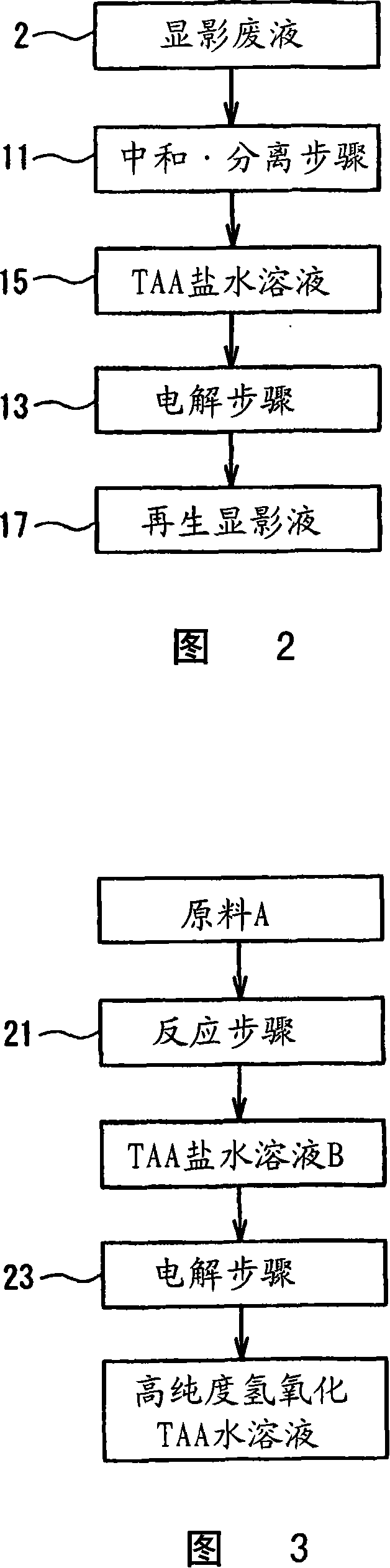

[0145] Using this diluted solution, neutralization, sep...

Embodiment 3

[0156] The concentrated solution (2) (developing waste solution) of Comparative Example 1 was supplied in the form of droplets or mist at the positions shown in Table 1 in the cement manufacturing process (while giving the temperature). In addition, the input amount of developing waste liquid is 10g / Nm relative to the gas flow rate at the input position. 3 Continuous supply from left to right.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com