Medium-frequency induction heating pyrolysis type garbage treatment device and garbage treatment system

A waste treatment device and induction heating technology, which are applied in transportation and packaging, chemical instruments and methods, solid waste removal, etc., can solve problems such as damage to incineration equipment, difficulty in controlling the combustion process, secondary pollution, etc., and reduce transportation costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

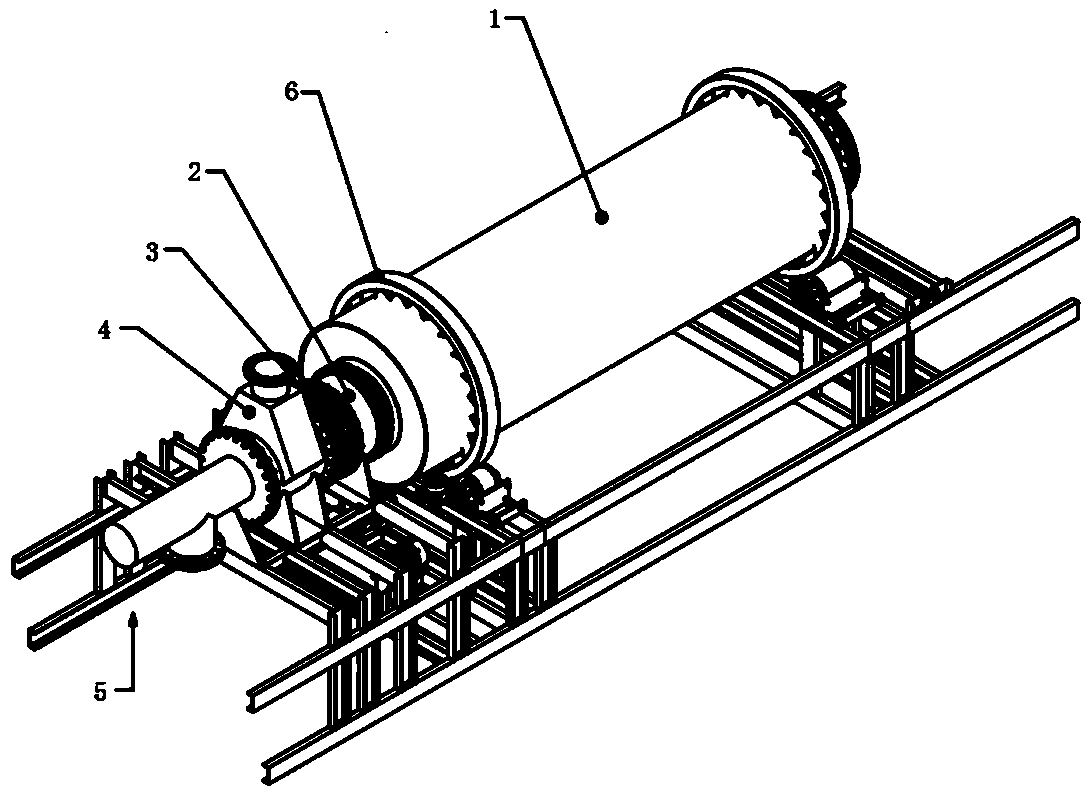

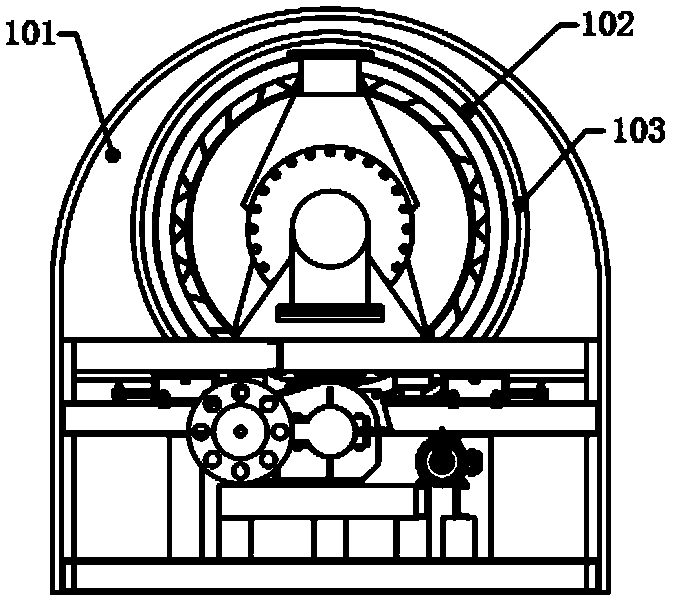

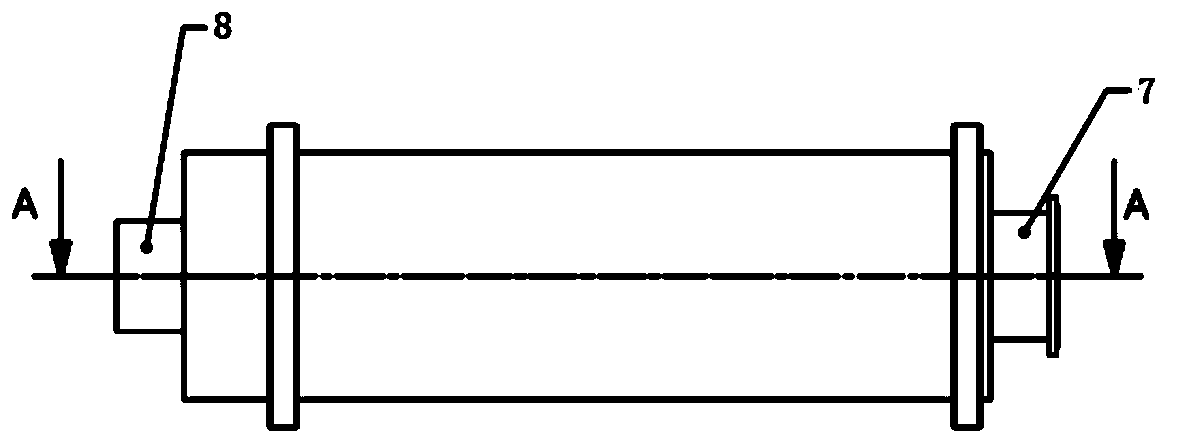

[0024] see Figure 1~4 , in the embodiment of the present invention, a kind of medium-frequency induction heating cracking garbage processing device, comprises cracking furnace body 1, feeding mechanism 7 and discharging mechanism 8, in this embodiment, described cracking furnace body 1 is equipped with high-temperature cracking Chamber 104, a medium frequency induction heating layer 103 is installed in the high temperature cracking chamber 104, and the outside of the medium frequency induction heating layer 103 is provided with an insulation layer 102 and a shell protection layer 101 in sequence, for carrying out medium frequency induction heating to garbage. In the scheme, the AC power rail with a power frequency of 50 Hz becomes a source device with an intermediate frequency (300 Hz to 20 kHz), and the three-phase power frequency AC is rectified and then converted into a direct current, and then the direct current is converted into an adjustable intermediate frequency curren...

Embodiment 2

[0033] A garbage treatment system, which includes the intermediate frequency induction heating cracking garbage treatment device as described in the above embodiments, for example: the combustible oil and gas produced by it can be used to generate electricity, and the remaining heat in the combustible oil and gas and intermediate frequency heating process is used to generate electricity;

[0034] Another example: combustible oil and gas burn and pyrolyze the organic harmful substances in them through sufficient combustion, pyrolyze and gasify them, and discharge them from the flue into the harmless gas that passes through the high-temperature plasma area and instantly completely pyrolyzes and gasifies the residual harmful substances, and finally discharges them. The carbon dioxide is purified and recovered through the carbon dioxide purification and recovery device to make carbon dioxide gas, which not only reduces the emission of carbon dioxide, but also creates good economic b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com