Method for producing high-quality ethylbenzene by light hydrocarbon cracking

A high-quality, light hydrocarbon technology, applied in the chemical industry, can solve the problems of high and different reaction temperatures, and achieve the effects of high quality, low production cost and high market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

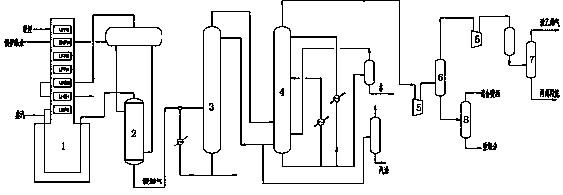

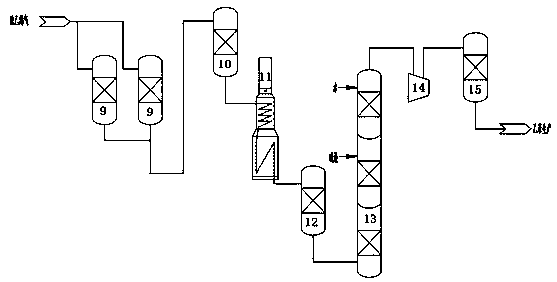

[0027] In order to deepen the understanding of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] Examples such as figure 1 Shown: it is the production process of obtaining concentrated ethylene gas as a raw material by cracking light hydrocarbons, specifically: light hydrocarbons such as ethane, propane, butane are used as raw materials, propane and butane are used as raw materials in this embodiment, after gasification and The superheated steam in the convection section of the cracking furnace 1 is mixed, and then enters the radiation section of the cracking furnace 1. After passing through the radiation section of the cracking furnace 1, the raw material becomes cracked gas containing ethylene, and the cracked gas is cooled to 350 degrees by the quenching heat exchanger 2. The quenching oil tower 3 is cooled to 100 degrees, and after being cooled to 40 degrees by the qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com