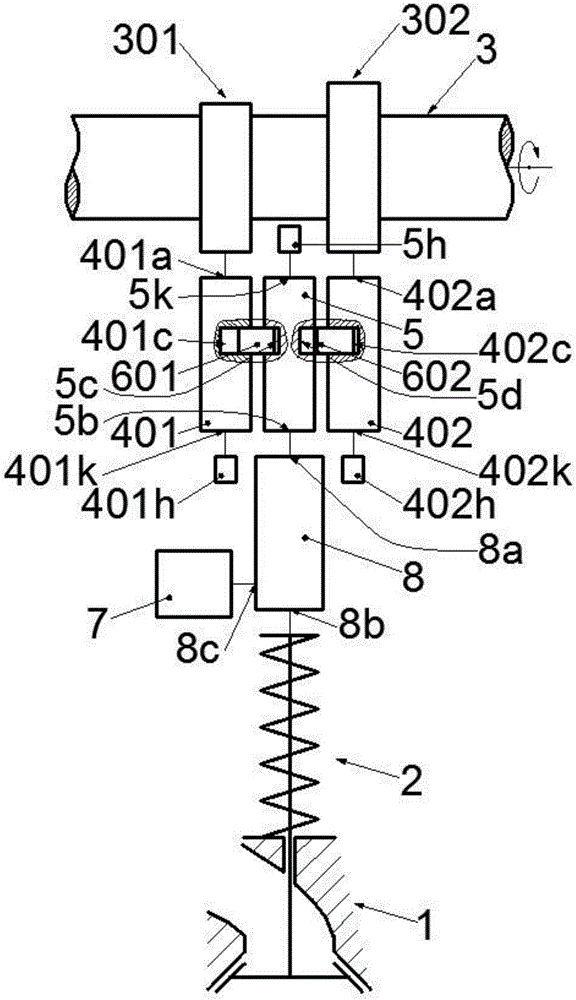

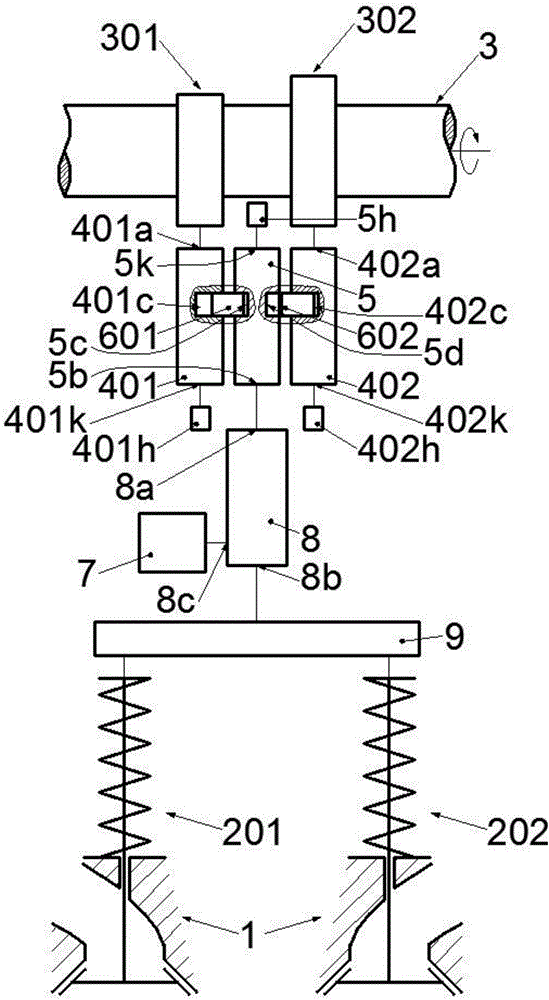

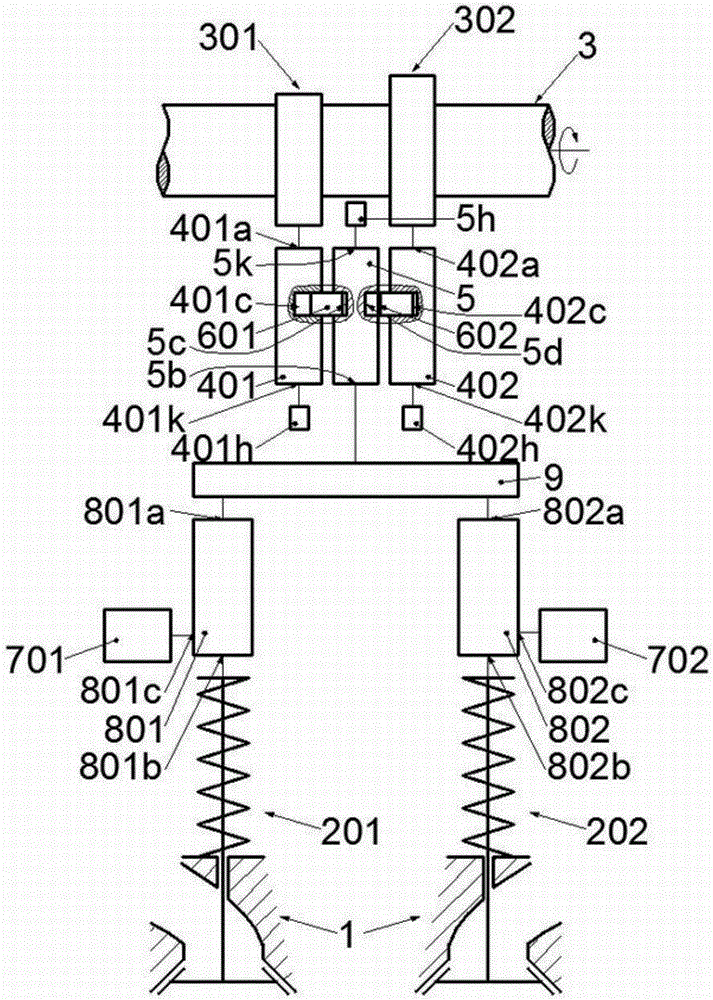

Locking multi-mode lever-type variable valve driving system

A drive system, multi-mode technology, applied in engine components, machine/engine, valve control, etc., to achieve good reliability, high cost performance, and reduced requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The invention relates to a locking multi-mode lever variable valve drive system. The opening timing of the intake / exhaust valves in various modes is very different, which requires a very large angle of phase adjustment when switching between various modes. The current common vane-type VVT mechanism cannot meet the requirements, but can meet the requirements The electric VVT mechanism is expensive and cannot be widely used in the short term; another example is that the opening duration of the intake / exhaust valves varies greatly in various modes. If a mechanical continuously variable valve control mechanism is used alone to achieve a small opening duration Otherwise, the maximum lift of the valve will be very small, and it is difficult to meet the indicators such as inflation efficiency and pumping loss at the same time. If the hydraulic valve control mechanism is used alone to achieve it through oil drainage, the system of the hydraulic valve control mechanism at high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com