Equipment and method for producing industrial pure hydrogen by utilizing antibiotic fermentation waste residues

A fermentation waste, industrially pure technology, applied in the petroleum industry, manufacturing combustible gas, granular/powdered fuel gasification, etc., can solve the problems of secondary pollution, serious, equipment corrosion, etc. The effect of good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

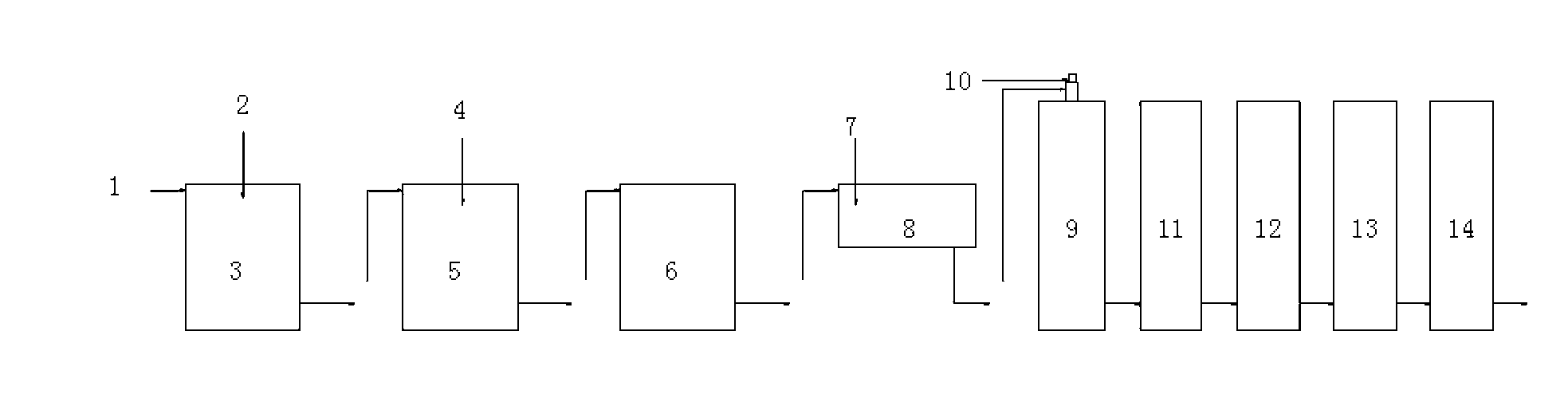

[0013] The present invention will be further described in conjunction with the accompanying drawings.

[0014] Such as figure 1 As shown, the inventive equipment of the present invention includes a preparation tank 3, a pretreatment tank 5, a buffer tank 6, a ball mill 8, a gasification furnace 9, a shift tower 11, a desulfurization tower 12, a decarbonization tower 13, a hydrogen extraction tower 14, and multiple pumps 15; preparation tank 3, pretreatment tank 5, buffer tank 6, ball mill 8, gasifier 9, shift tower 11, desulfurization tower 12, decarbonization tower 13, hydrogen extraction tower 14 are connected in series in sequence, preparation tank 3 and pretreatment tank A pump 15 is respectively installed between the tank 5, the pretreatment tank 5 and the buffer tank 6, and between the buffer tank 6 and the ball mill 8. The disposal process is shown in the attached picture: Put the antibiotic fermentation waste residue (antibiotic fermentation waste residue and activate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com