Gaseous flow separator with device for thermal-bridge defrosting

An air flow separator and air separation technology, applied in jet propulsion, climate sustainability, gas turbine installations, etc., can solve problems such as failure, lubricant leakage, technical complexity, etc., and achieve simple components, rapid assembly, and simple assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

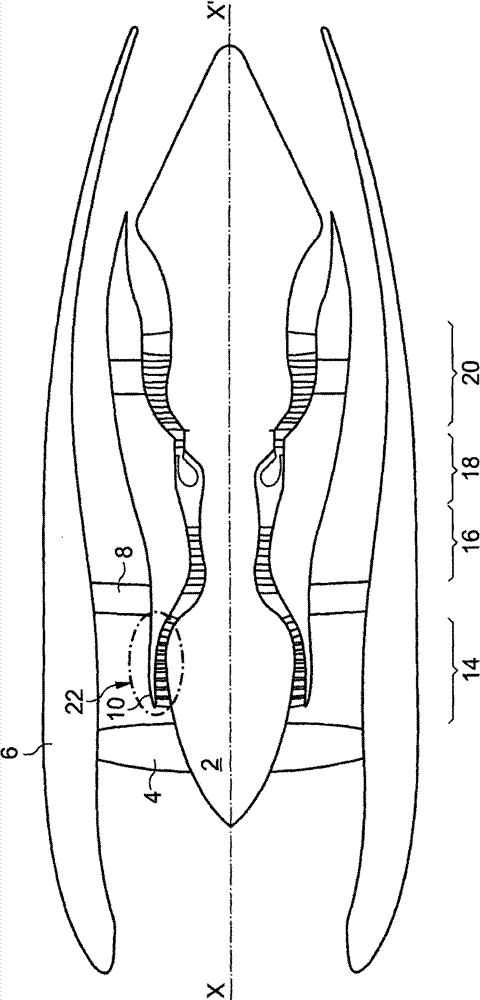

[0032] exist figure 1 A twin-flow turbojet engine is schematically shown in . It shows the main elements, namely the nacelle 6 acting as an external casing around the components, the rotor 2 rotating about the axis X-X' of the machine and the fan 4 supported by the rotor 2 .

[0033] In the following description, the terms "upstream" and "downstream" refer to an axial position along the axis X-X' in the direction of the air flow through the jet engine. The term "front" is equivalent to "upstream" and "rear" is equivalent to "downstream".

[0034] The terms "inner" or "inner", and "outer" or "outer" refer to a radial position relative to the axis XX' of the turbine, "outer" or "outer" meaning a position away from said axis and "Inner" or "inner" means a position near the axis.

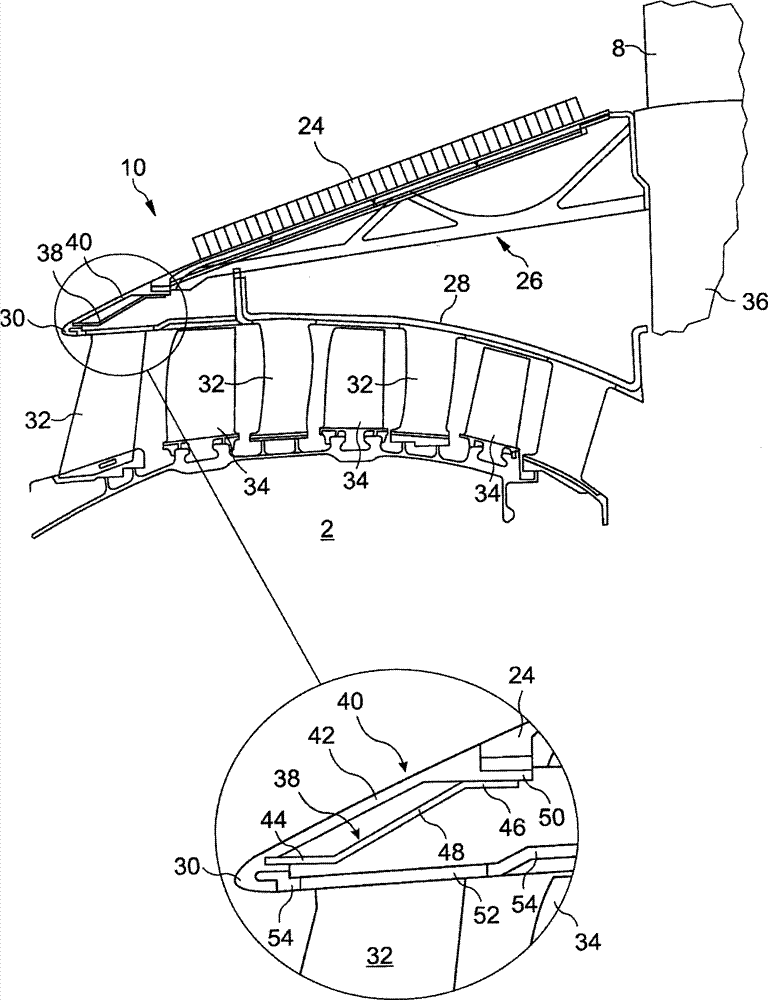

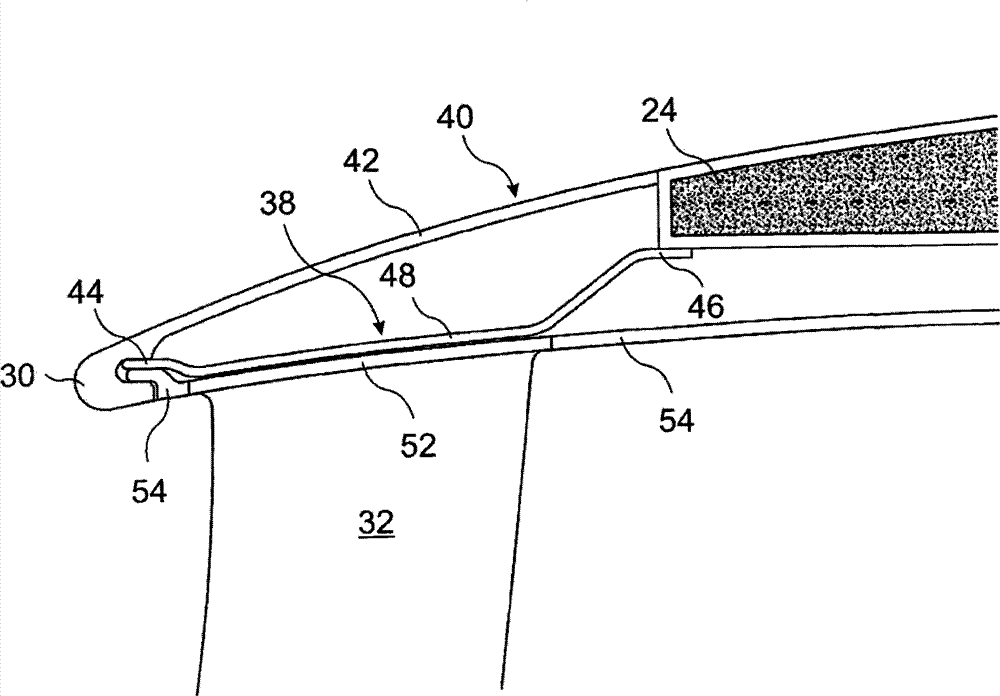

[0035] Downstream of the fan 4, the airflow is divided by a splitter tip 10 into a primary and a secondary airflow. The main air flow passes through the inner annular main duct or main flow path to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com