Motor for electrically regulating moving parts in motor vehicles and method for manufacturing motor

A technology for motor vehicles and components, applied in the field of manufacturing the motor, can solve the problem of not getting the prompt of the weight and torque density of the electric motor, and achieve the effects of high torque density, high power density, and power density optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

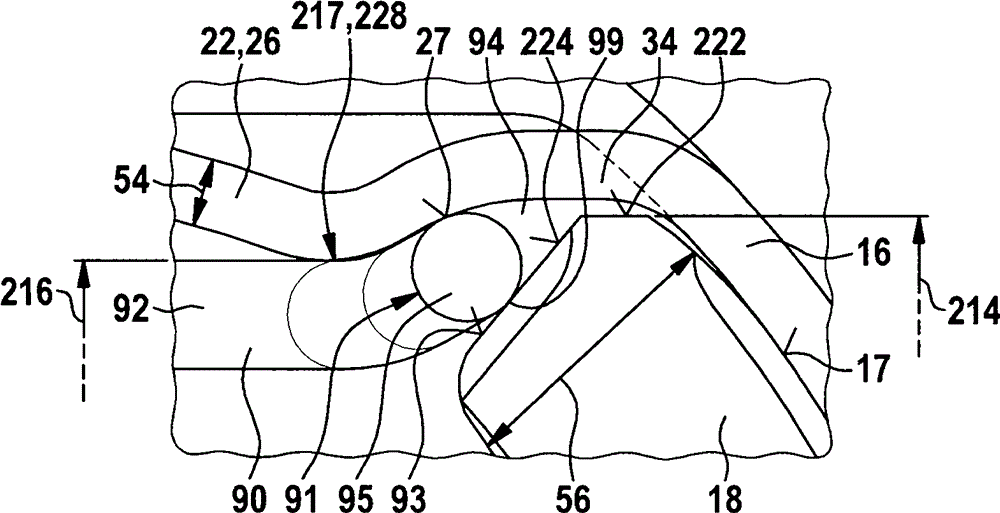

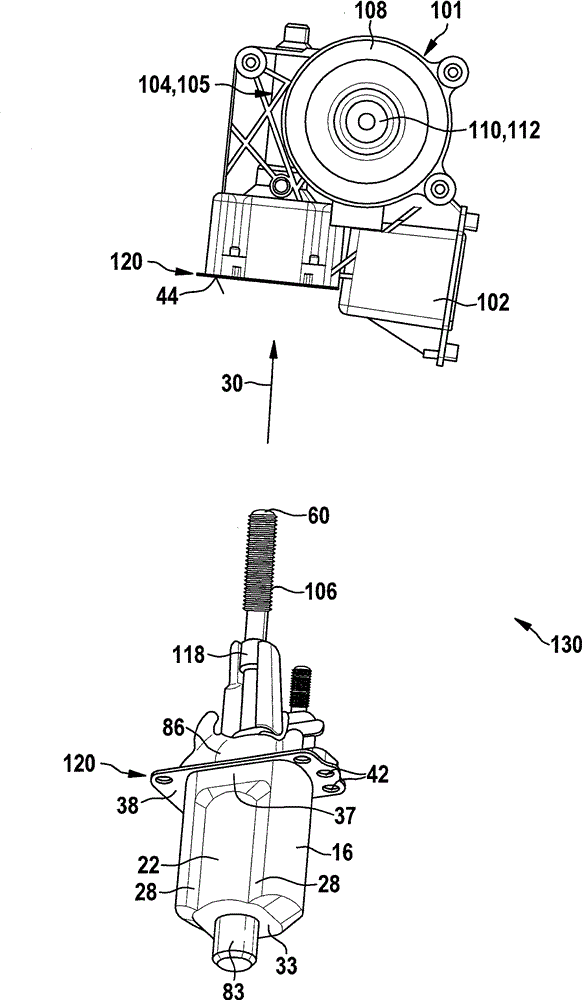

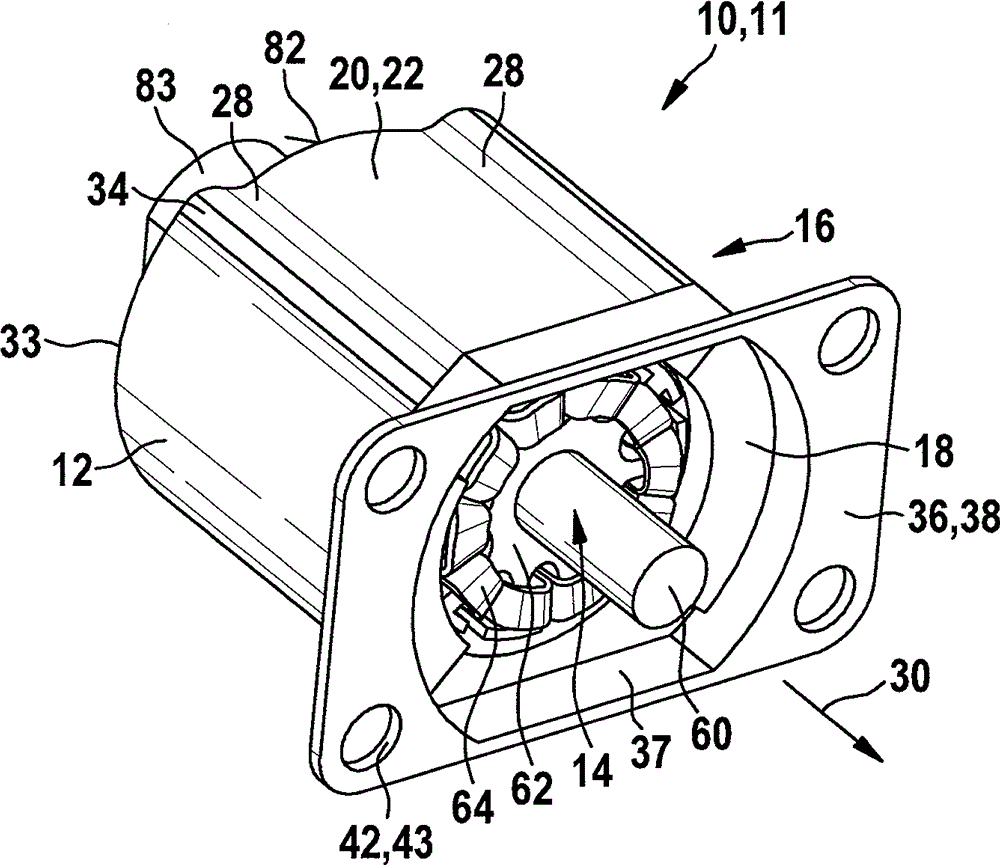

[0022] exist figure 1shows an electric machine 10 according to the invention, which is designed as an electric motor 11 . The electric motor 11 is, for example, a component of a transmission drive unit 130 as it is used to adjust a sliding sunroof, a window pane or a seat part in a motor vehicle. The electric machine 10 has a stator 12 in which two permanent magnets 18 are arranged opposite each other in a pole shoe 16 . The permanent magnet 18 can be designed as a ferromagnetic body, for example. Two opposing series poles 22 are arranged between two opposing permanent magnets 18 , which are formed by the housing wall 26 of the pole shoe 16 . For this purpose, two recesses 28 extending in the axial direction 30 are each formed in the truncated region 20 of the pole piece 16 . The series pole 22 is formed between two concave bends 28 in the circumferential direction 32 as an arcuate pole shoe wall 26 which forms a section of the pole shoe 16 together with the concave curve 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com