Nano-composite fracturing fluid as well as preparation method and application thereof

A nano-composite and fracturing fluid technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of inability to achieve oil and gas increase or continuous increase, difficulty in driving residual oil in micro-throat throats, etc., and achieve excellent carrying capacity sand performance, increase oil and gas production, and excellent high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0052] The present embodiments 1-3 provide a nanocomposite fracturing fluid, the preparation method of which comprises the following steps:

[0053] 1. Preparation of nano-inorganic phase

[0054] Using the co-precipitation method, at room temperature (about 25°C), add aluminum nitrate and magnesium nitrate to deionized water, after the dissolution is complete, continue to add sodium hydroxide and 2-acrylamido-2-methylpropanesulfonic acid ( AMPS), and control the molar ratio between aluminum nitrate, magnesium nitrate, sodium hydroxide and AMPS to be about 1:2:1:1. During the continuous stirring process, continuously add 30% mass concentration of sodium hydroxide aqueous solution to adjust the pH value to about 10 to obtain a hydrotalcite slurry;

[0055] Put the industrial layered silicate powder and deionized water into the three-necked flask according to the mass ratio of 1:15, and after natural swelling at a temperature of about 25°C for half an hour, the temperature of t...

Embodiment 1

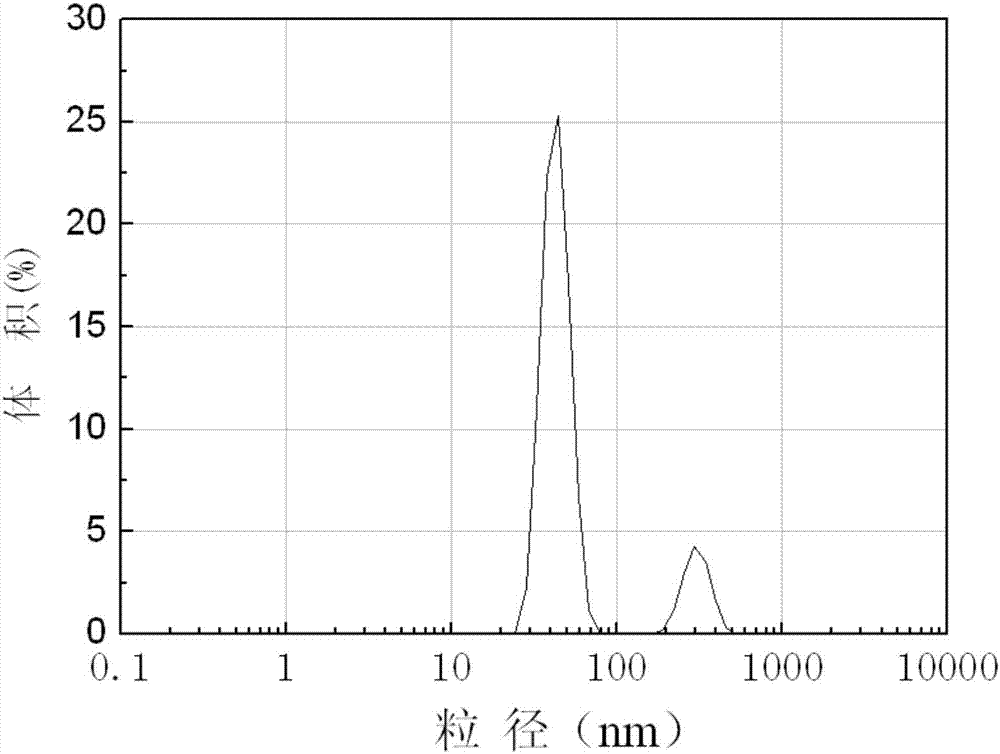

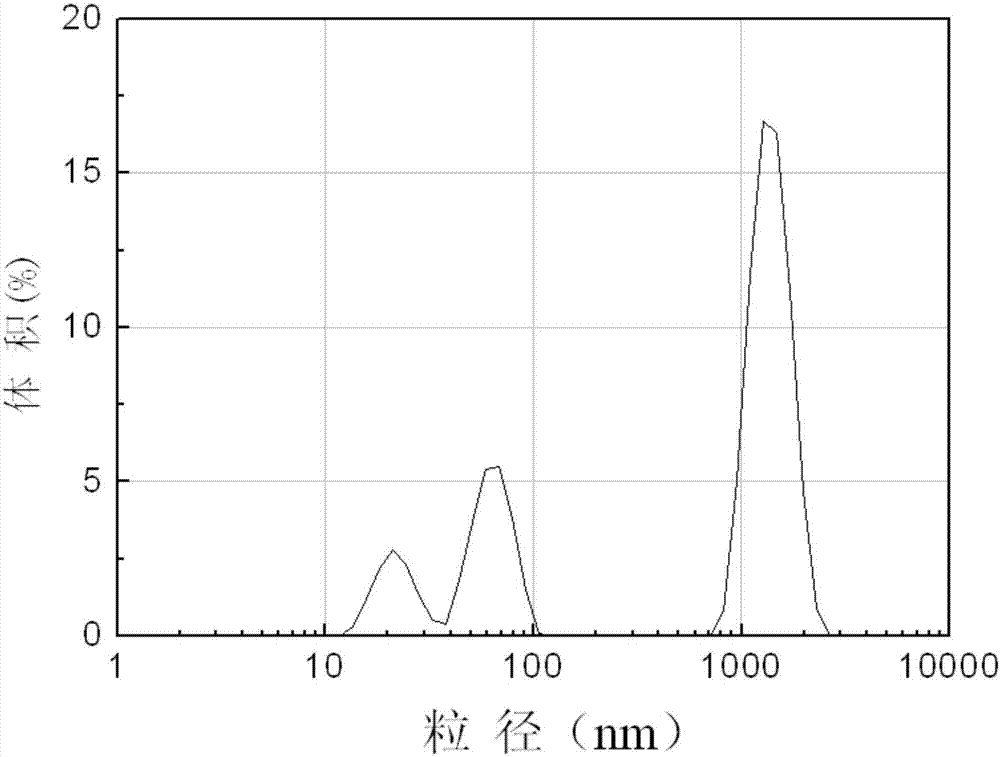

[0082]The particle size distribution curve of embodiment 1 and embodiment 3 and figure 1 Almost consistent, the gel breaking solution contains more than 85% of nanomicelles with a particle size of less than 100nm, and less than 15% of nanomicelles with a particle size ranging from 100nm to 500nm.

[0083] Therefore, the nano-composite fracturing fluids in Examples 1-3 break gel under formation conditions and form multi-scale nano-composite micelles with nucleation and phase separation, so that they can smoothly enter low-permeability, ultra-low-permeability and tight oil and gas and very The micro-channels of regular oil and gas layers are conducive to driving the flow of oil and gas in the "nano-micron pore-throat channels" and the surrounding channels, and form an efficient injection-production system.

experiment example 1

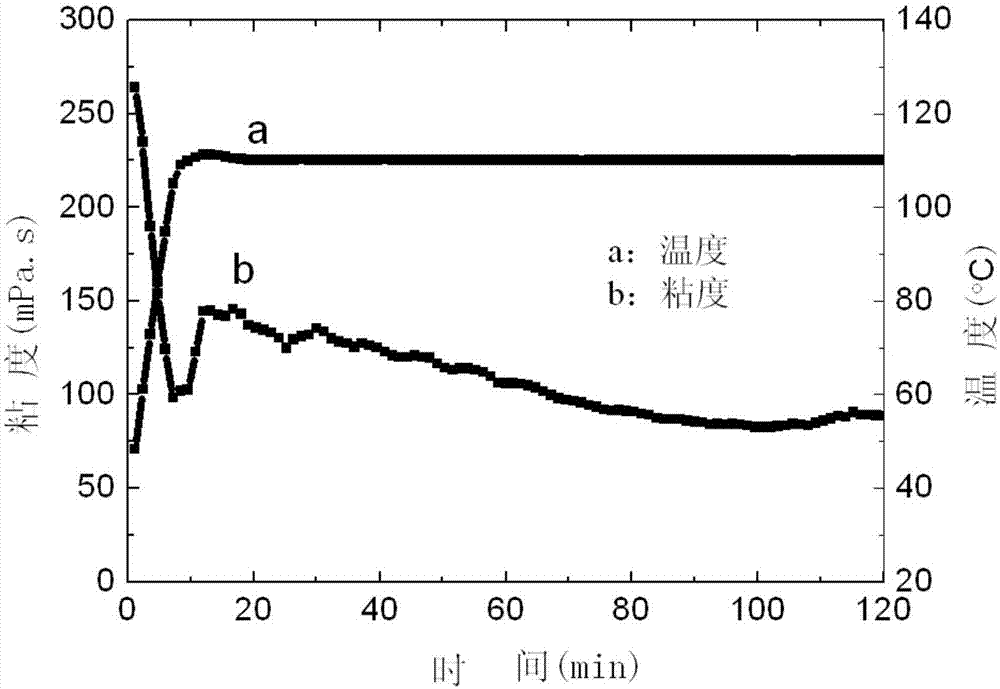

[0089] Firstly, the nano-composite thickener is prepared by the same method as in Examples 1-3, and then the base fluid of the nano-composite fracturing fluid is prepared. The specific steps are:

[0090] Add 350mL of tap water to three beakers respectively, under high-speed stirring, add 0.35g, 0.70g, 1.05g of carboxymethyl cellulose as structure regulator, after the dissolution is complete, then add 2.45g of nanocomposite thickener, dissolve After completion, three groups of nanocomposite fracturing fluid base fluid samples were obtained, which were respectively recorded as samples A1, A2 and A3. The viscosity of samples A1-A3 was measured with a six-speed viscometer, and the results are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com