Sewage treatment method in garment production process

A sewage treatment method and production process technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem that sewage cannot meet discharge standards, harmful organic substances cannot be degraded, and can be degraded. Biochemical treatment effect is poor and other problems, to achieve the effect of convenient management, small maintenance workload, strong operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

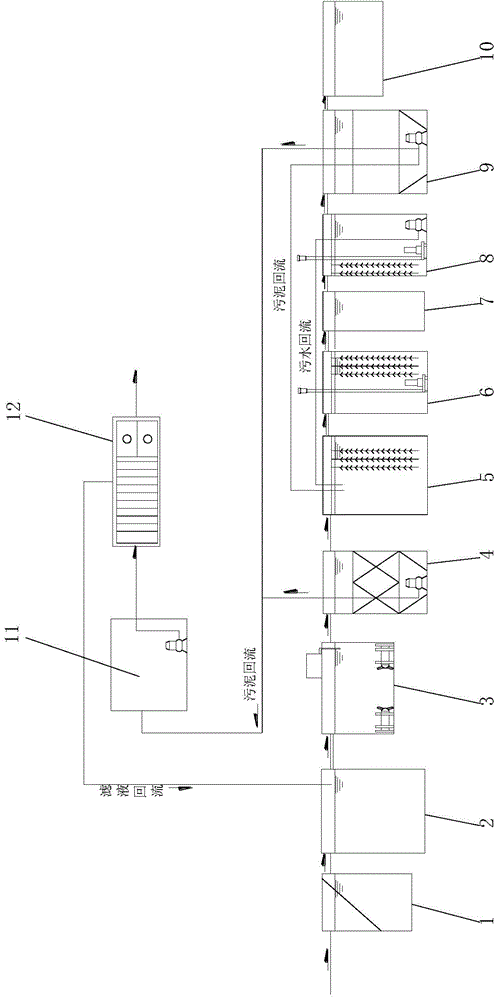

[0028] Such as figure 1 Shown, the sewage treatment method in the clothing production process of the present invention specifically comprises the following steps:

[0029] 1) Filtration: Sewage enters the grid well 1, and the grid in the grid well 1 is filtered to remove large solid impurities and part of solid suspended matter in the sewage;

[0030] 2) Adjustment of water quality and water quantity: the above-mentioned sewage that removes large solid debris and part of solid suspended matter enters the regulating tank 2, and the regulating pond 2 adjusts the water quality and water quantity to be uniform;

[0031] 3) Flocculation reaction: The adjusted sewage enters the flocculation reaction tank 3, and the colloidal substances and suspended solids in the sewage are fully mixed with the coagulant and flocculant in the flocculation reaction tank 3 under the agitation of the agitator. , forming solid flocs;

[0032] 4) Solid-liquid separation: the above-mentioned sewage cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com