Patents

Literature

54results about How to "Low equipment investment cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

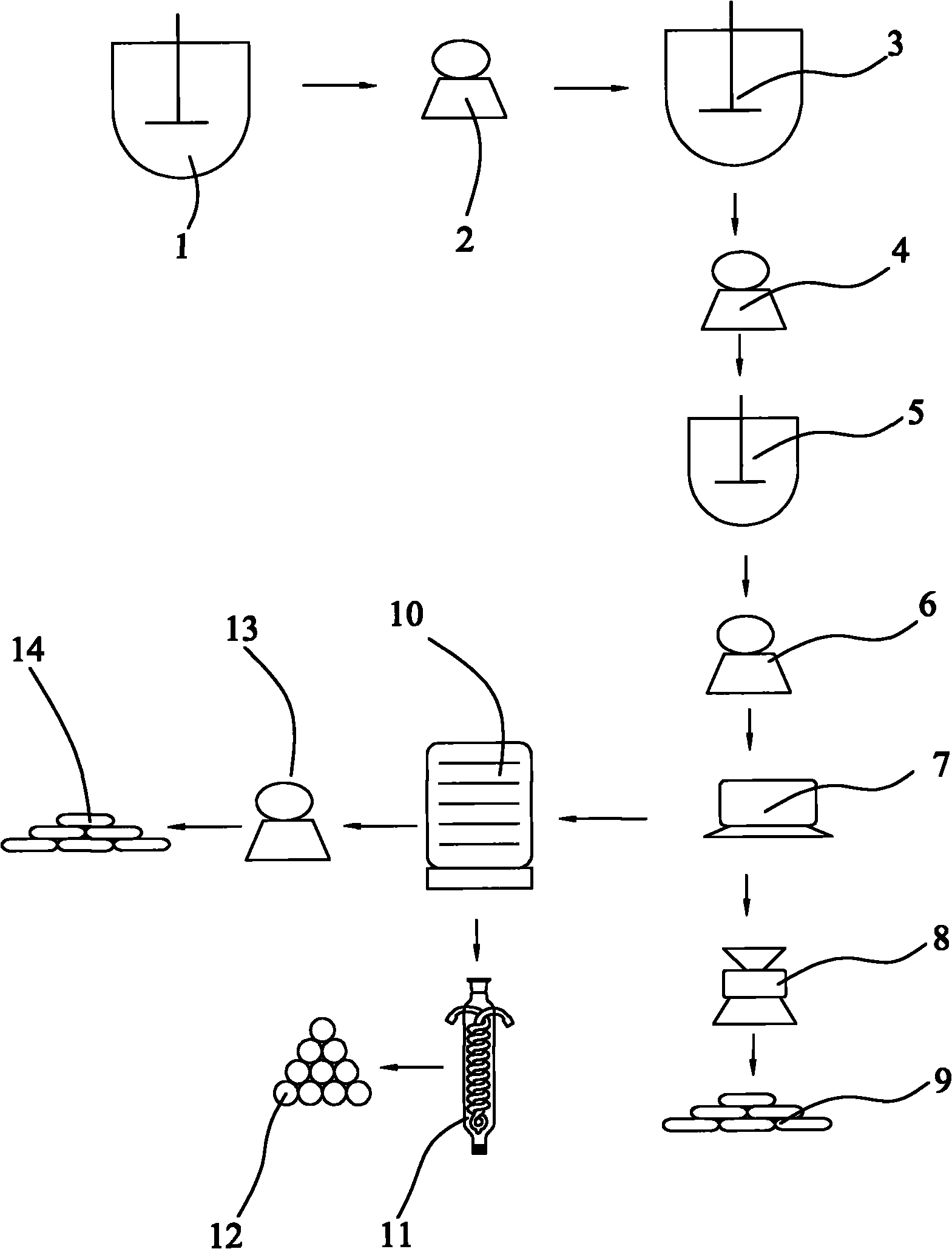

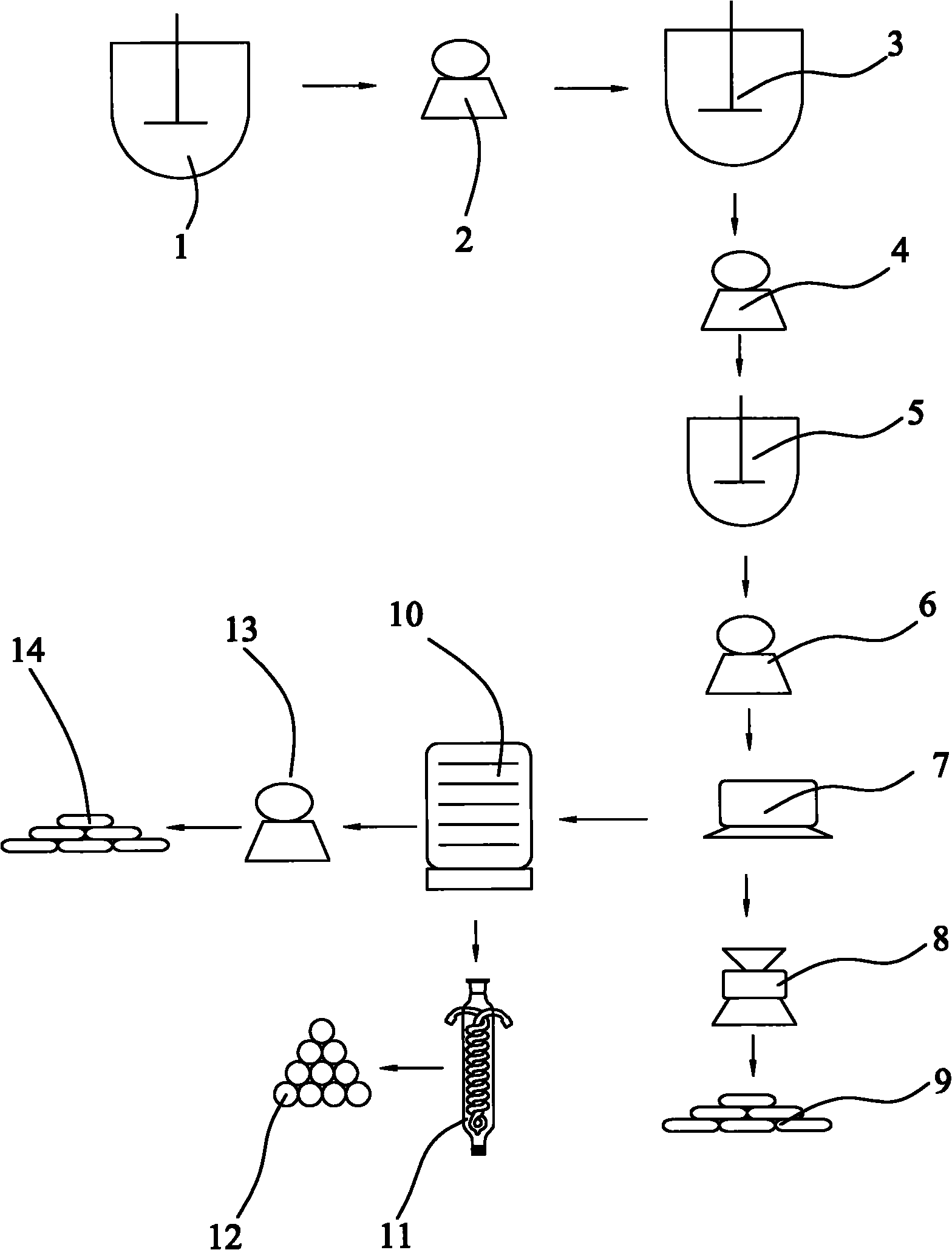

Processing method for reducing and recycling organic waste water and processing system

InactiveCN105540967AReduce foulingReduce the risk of contaminationFatty/oily/floating substances removal devicesWater contaminantsReverse osmosisWastewater

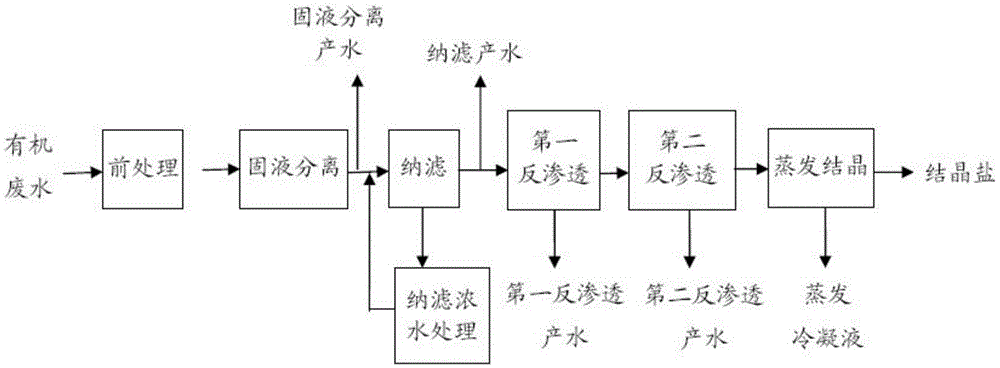

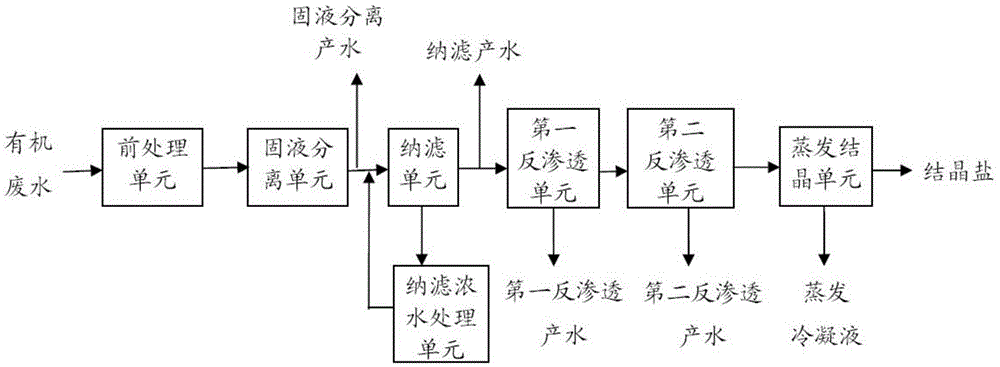

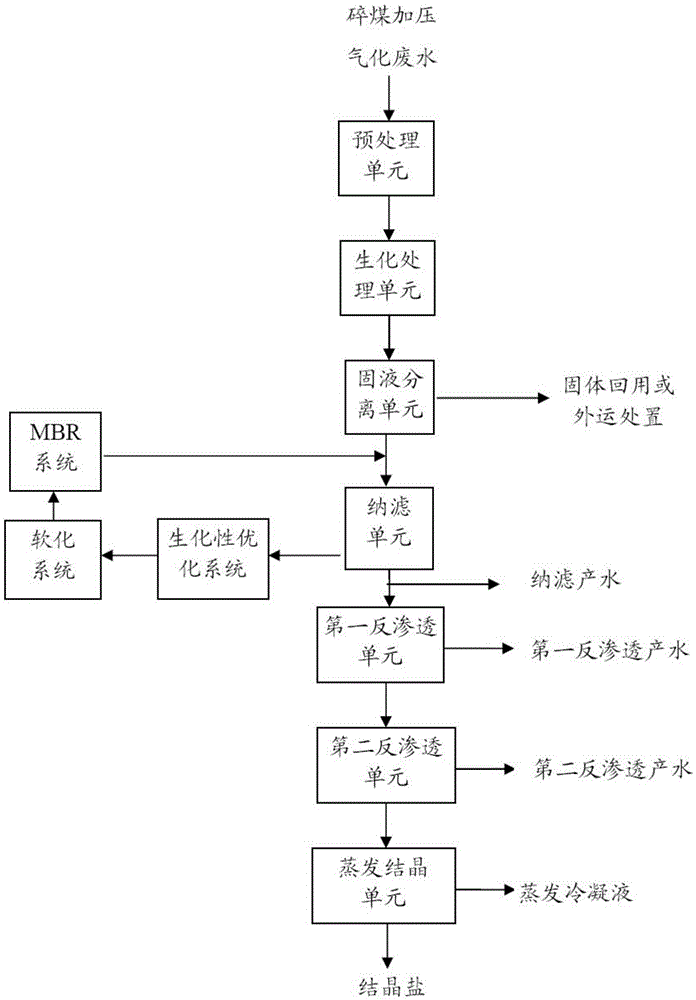

The invention provides a processing method for reducing and recycling organic waste water. The method comprises steps: (1) pre-treating waste water to obtain pre-treated out-water; (2) treating the out-water obtained from the step (1) through solid-liquid separation; (3) nano-filtering the out-water obtained from step (2); (4) treating nano-filtered concentrated water obtained from the step (3) to obtain out-water subjected concentrated water nano-filtering, returning to the step (3) for mixing the out-water subjected to concentrated water nano-filtering with the out-water subjected to solid-liquid separation, and performing nano-filtering; (5) performing first reverse osmosis treatment on out-water obtained from the step (3) through nano-filtering; (6) performing second reverse osmosis treatment on concentrated water obtained from the step (5) through first reverse osmosis treatment; and (7) evaporating and crystallizing a concentrated liquid obtained from the step (6) through second reverse osmosis treatment in order to obtain crystallized salt and evaporated concentrated water. The invention further provides a processing system of the method. Through the method and system, waste water is truly reduced and recycled.

Owner:DATANG INT CHEM TECH RESINST

Hydrogenation method for improving cetane number of secondary processing diesel oil

ActiveCN101760234AControl the mixing ratioReduce the impactHydrocarbon oil crackingOil and greasePolycyclic aromatic hydrocarbon

The invention relates to a hydrogenation method for improving the cetane number of secondary processing diesel oil, which comprises the following steps: mixing secondary processing diesel oil and vegetable oil and / or animal fat; carrying out hydrogenation reaction by mixed ingredients and hydrogenation refining catalysts through contact in the existence of hydrogen; and cooling, separating and fractionating reaction outflow materials to obtain diesel oil products with mixed ingredients as the reference. The method provided by the invention can process low-quality diesel oil distillate with high sulfur content, high nitrogen content and small cetane number. The clean diesel oil products with low sulfur content, high polycyclic aromatic hydrocarbon and large cetane number can be obtained. Because the addition proportion of the vegetable oil is controlled, the influence on the hydrogenation catalysts by water generated in the reaction is reduced, the device operation period is prolonged, and in addition, the yield of obtained diesel oil products is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Desulfurizer with high sulfur capacity for eliminating sulfur alcohol, sulphide and hydrogen sulfide through catalytic oxidation, and preparation

ActiveCN101049551ASimple processLow equipment investment costDispersed particle separationCatalyst activation/preparationChemistryActivated carbon

A desulfurizing with high sulfur capacity for removing thiols, thioether and hydrogen sulfide from natural gas, petroleum gas, and other industrial gases is composed of carrier (activated carbon) and catalyzing component prepared from metallic oxide or salt (0.1-5 Wt%), modifier (2-10) and promoter (0.01-0.5). Its preparing process includes such steps as pre-treating activated carbon, impregnating the catalytic component, and drying.

Owner:DALIAN CATALYTIC ENG TECH

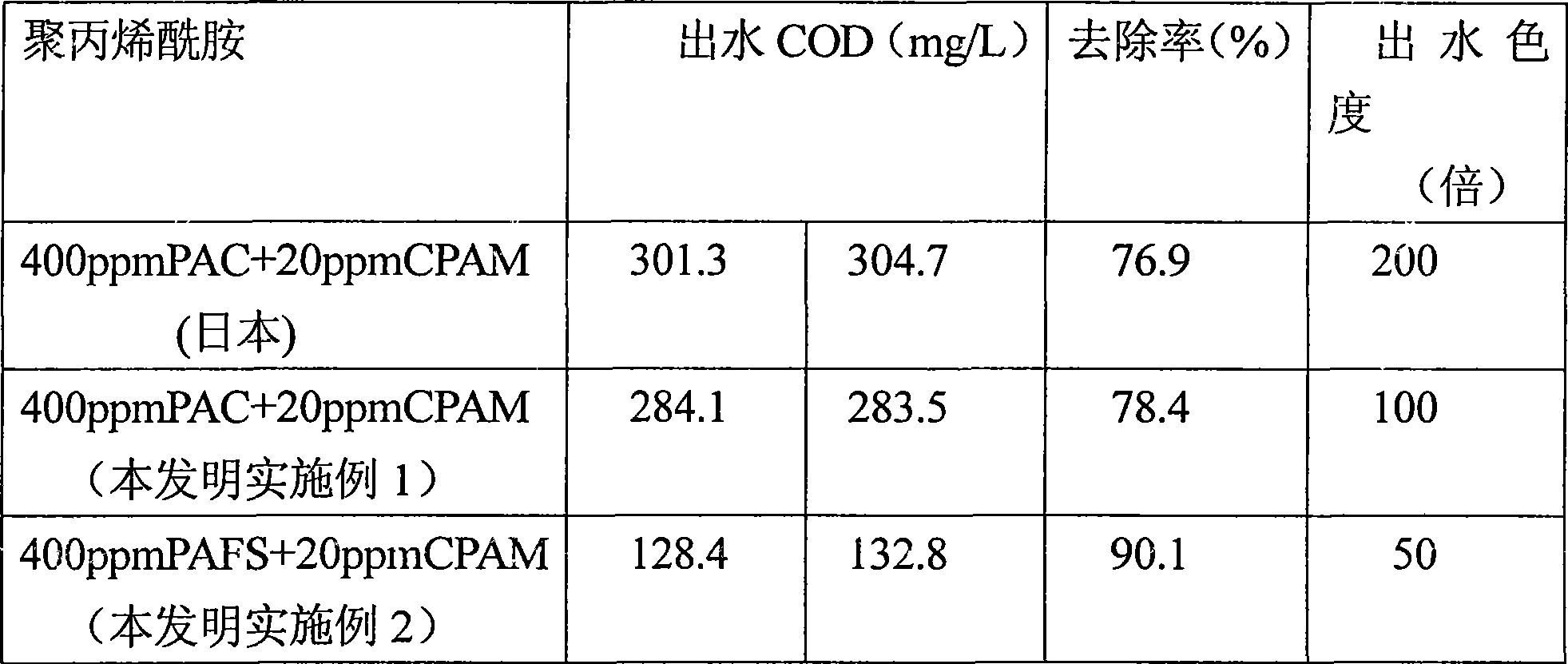

Process for producing cation polyacrylamide

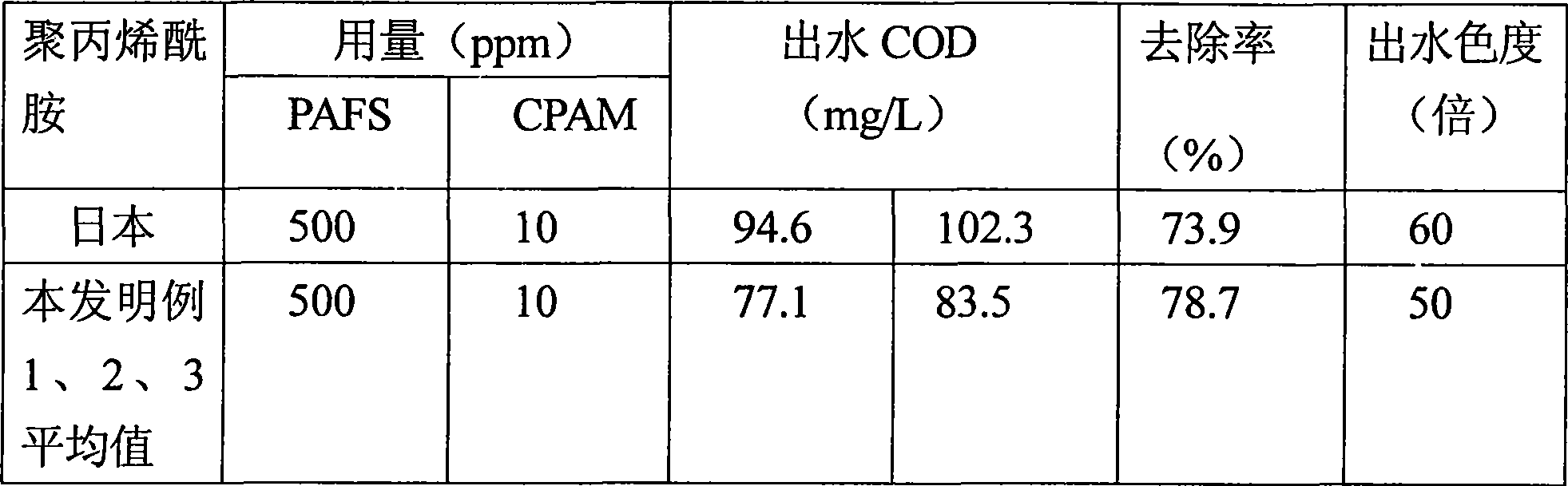

The invention provides a technique for producing cationic polyacrylamide, and comprises the raw materials by mass percent: 10.0 to 25.0% of acrylamide, 5.0 to 10.0% of acryloxyethyl trimethylammonium chloride, 0.02-0.04% of redox, 0.03-0.015% of azo compound, 0.5 to 5.0 of urea, 0.02 to 0.15% of fatty acid salt, and 65.5-84% of deionized water; the raw materials are put into a reactor and added with the redox to have induced polymerization reaction under nitrogen protection at the room temperature, and then added with the azo compound to have secondary induced polymerization reaction; finally, the products of the invention are obtained after granulation and dryness. The technique is stable, slow in induction, even in reaction, mild and ordered, and easy in the control of operation process; the obtained products are rapid in dissolution rate, little in usage, large in water yield, big and dense in floccules, and not easy in fragmentation. The technique is mainly used for various environment-friendly fields such as sewage disposal, sludge dewatering, etc.

Owner:SICHUAN TONGFENG TECH

Preparation method of multielement composite scale inhibitor

InactiveCN102464409AExcellent anti-scaling performanceLow equipment investment costScale removal and water softeningReverse osmosisRoom temperature

The invention discloses a preparation method of a multielement composite scale inhibitor. The method is characterized by comprising the following steps: adding 1 part of melamine, 1-3 parts of 30-40% hydrolyzed maleic anhydride, 1-3 parts of ammonium chloride and 1-3 parts of formaldehyde into a container; stirring, dissolving and reacting at 80+ / -5 DEG C for 0.5-2 h; adding 1-3 parts of urea, 1-3 parts of ammonium chloride and 1-3 parts of formaldehyde, and reacting at 90 + / -5 DEG C for 2-4 h; adding 1-3 parts of 15-30% polyacrylic acid and 1-3 parts of 0.5-2% cation polyacrylamide, reacting at 70 + / -5 DEG C for 0.5-1 h; cooling to room temperature to obtain a finished product. The method reduces equipment investment and cost of a reverse osmosis system, and reverse osmosis scale inhibitor has high scale inhibition performance.

Owner:HUBEI ZHONGBI ENVIRONMENTAL PROTECTION TECHCO

Method for preparing adiponitrile

ActiveCN103664691AHigh purityQuality improvementPreparation by hydrogen cyanide additionIsomerizationPhosphine

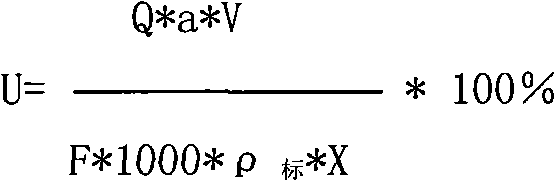

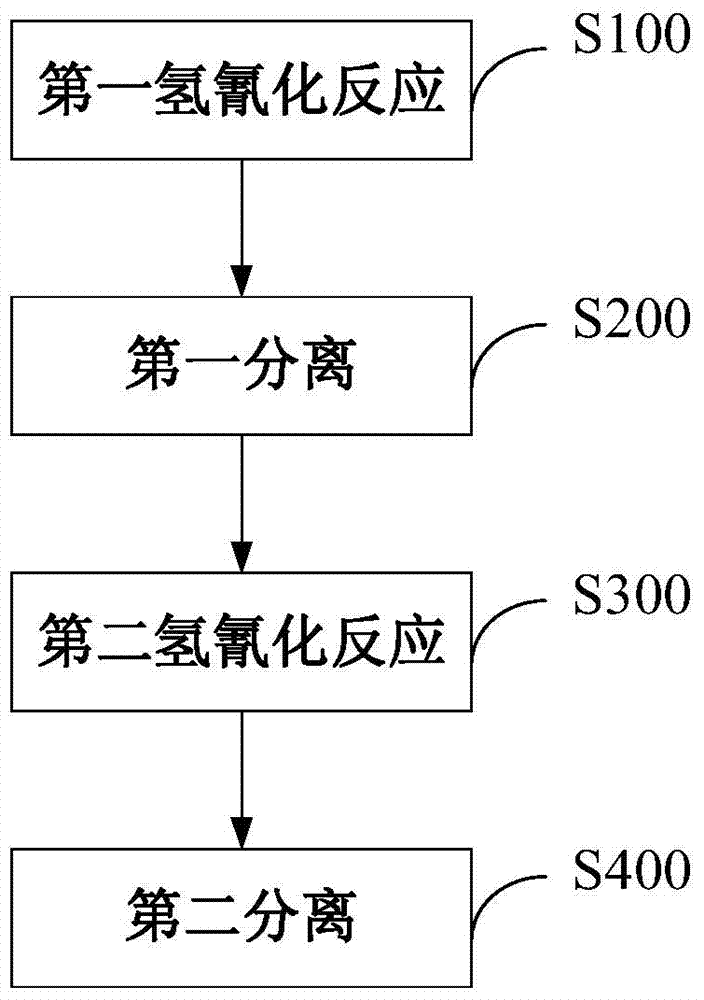

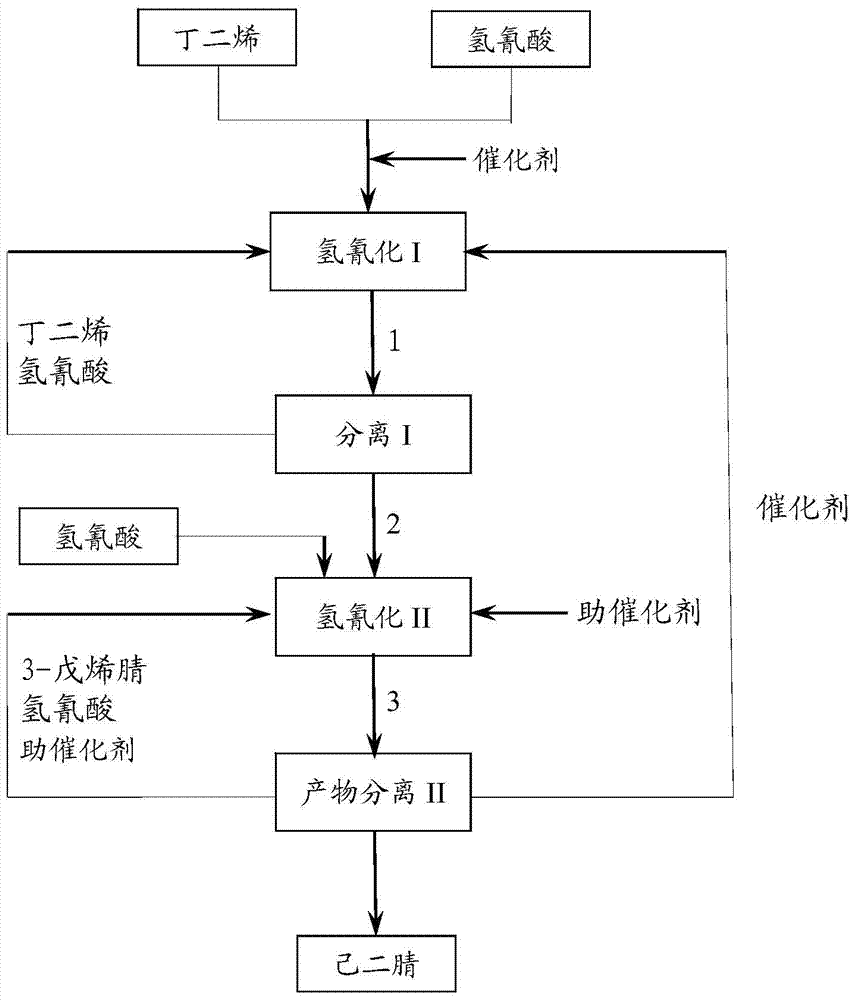

The invention discloses a method for preparing adiponitrile. The method comprises the following steps: performing a first hydrocyanation reaction on butadiene and first hydrocyanic acid under the action of a catalyst to obtain a first mixture; performing primary separation on each component in the first mixture to obtain a second mixture, residual butadiene and residual first hydrocyanic acid respectively; adding a co-catalyst into the second mixture, and introducing second hydrocyanic acid to obtain a third mixture containing the adiponitrile; performing secondary separation on the third mixture to obtain the adiponitrile, residual 3-pentenenitrile, residual second hydrocyanic acid, the reacted catalyst and the reacted co-catalyst, wherein the catalyst is a coordination compound consisting of a monodentate phosphine ligand, a bidentate phosphine ligand and zerovalent nickel, and the co-catalyst is Lewis acid. The method for preparing the adiponitrile has the advantages of small quantity of side products, no need of performing a 2M3BN isomerization reaction, simple process, low cost, high yield, good product quality, economical efficiency and environmental friendliness.

Owner:ANHUI ANQING SHUGUANG CHEM GRP +1

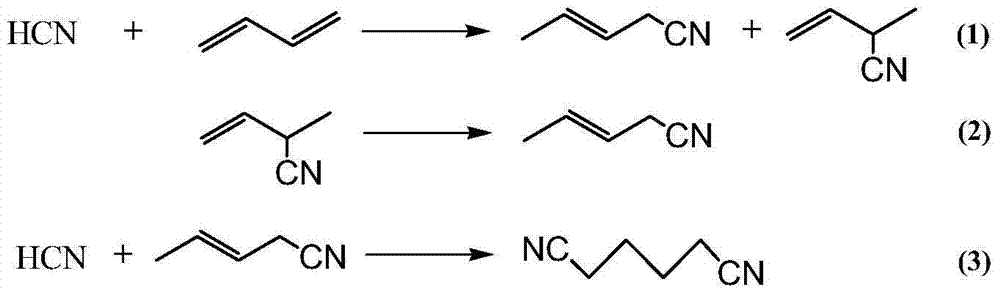

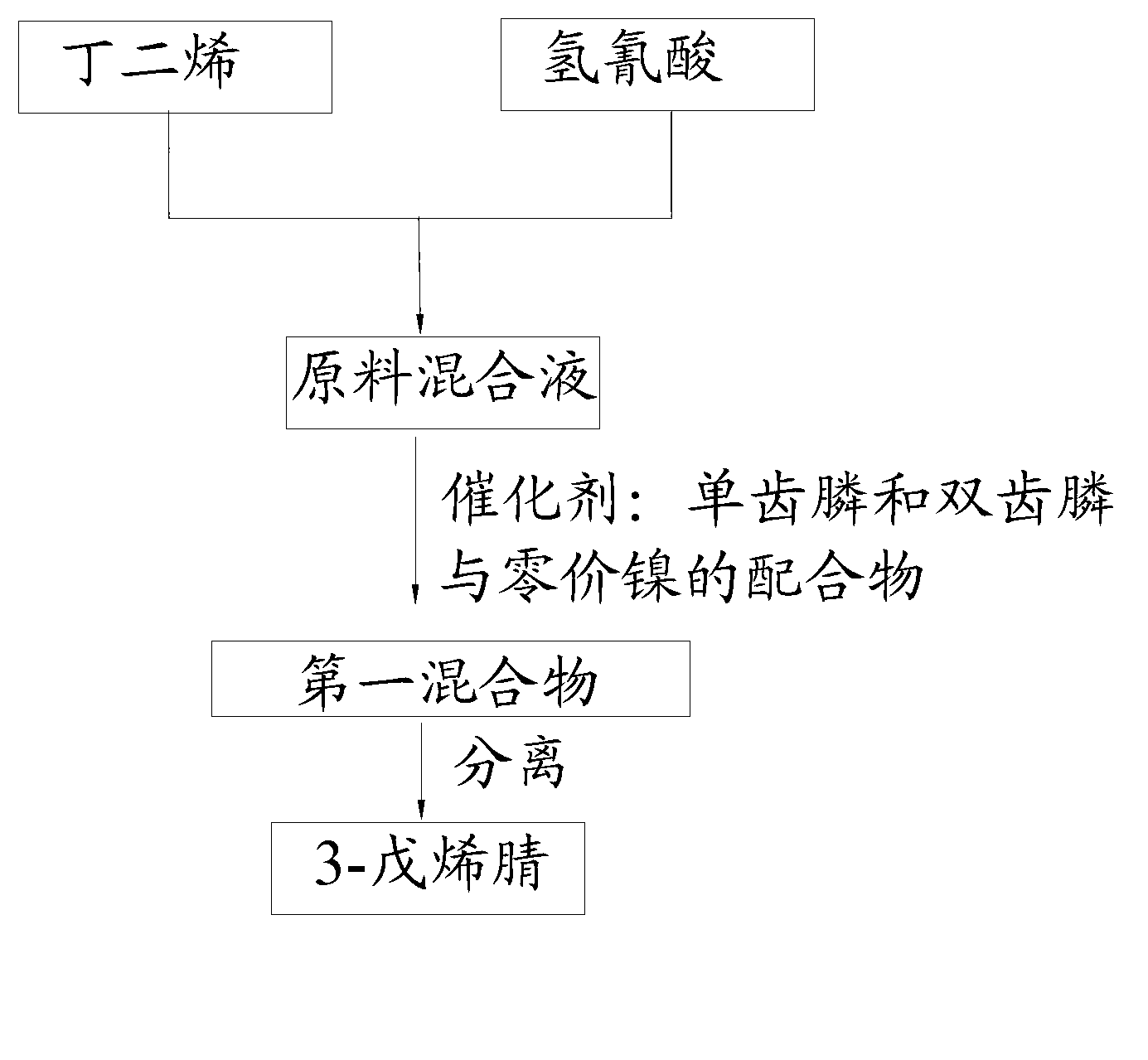

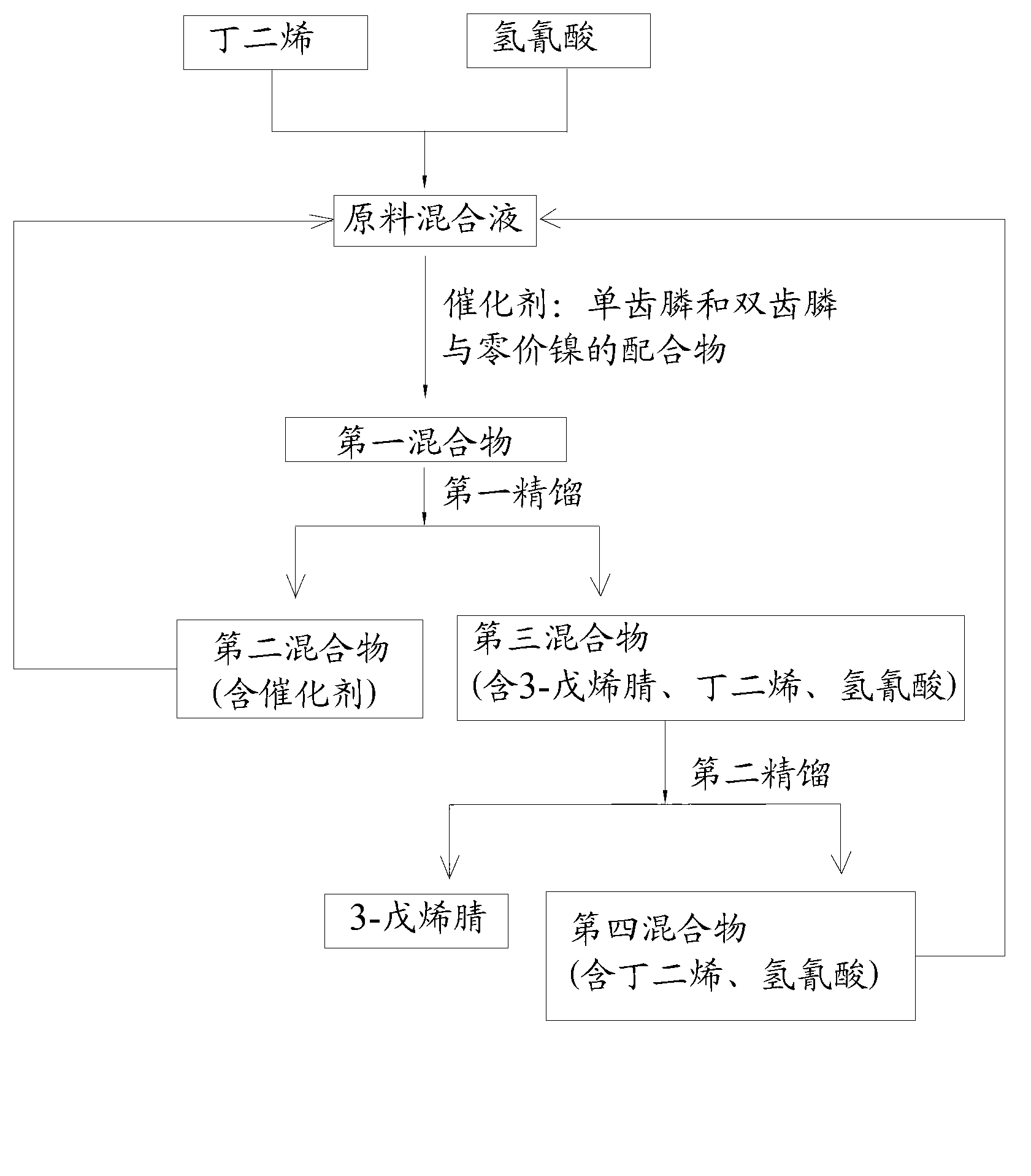

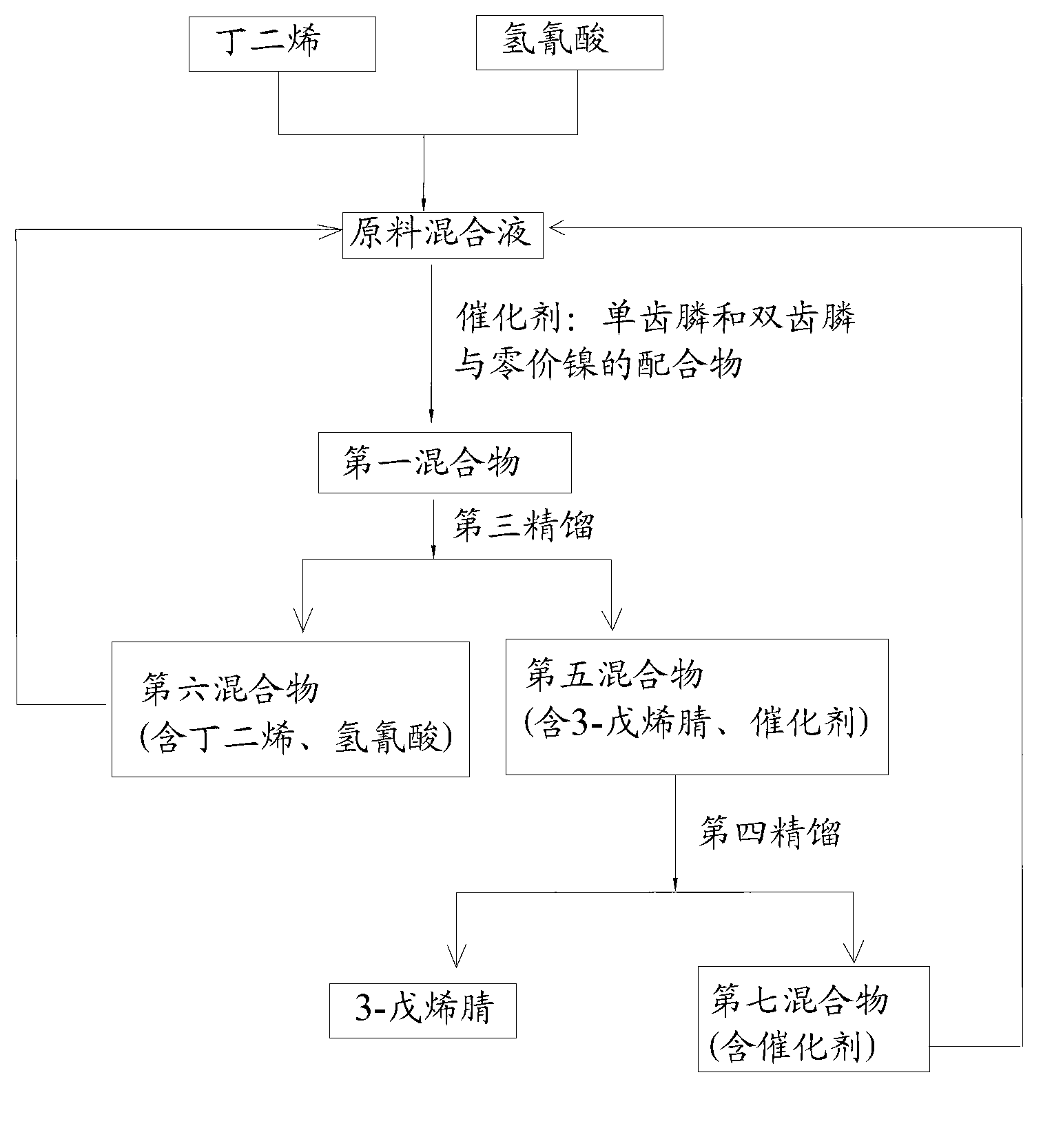

Preparation method of 3-pentenenitrile and preparation method of adiponitrile

ActiveCN103012197AEfficient preparationCheap manufacturingPreparation by hydrogen cyanide additionButadiene DioxidePhosphine

The invention provides a preparation method of 3-pentenenitrile and a preparation method of adiponitrile. The preparation method of 3-pentenenitrile comprises the following steps: 1, performing the hydrocyanation reaction on raw material mixed solution of butadiene and hydrocyanic acid under the action of a catalyst so as to obtain a first mixture containing the 3-pentenenitrile; and 2, carrying out separation on the first mixture to obtain the 3-pentenenitrile, wherein the catalyst is a coordination complex consisting of monodentate phosphine, bidentate phosphine and zero-valent nickel. By adopting the method, the 3-pentenenitrile can be effectively, efficiently and economically prepared by using the butadiene and the hydrocyanic acid as the raw materials; the integral process is safe and reliable; the flow is simple; and moreover, production cost and equipment investment can be obviously reduced.

Owner:ANHUI ANQING SHUGUANG CHEM GRP +1

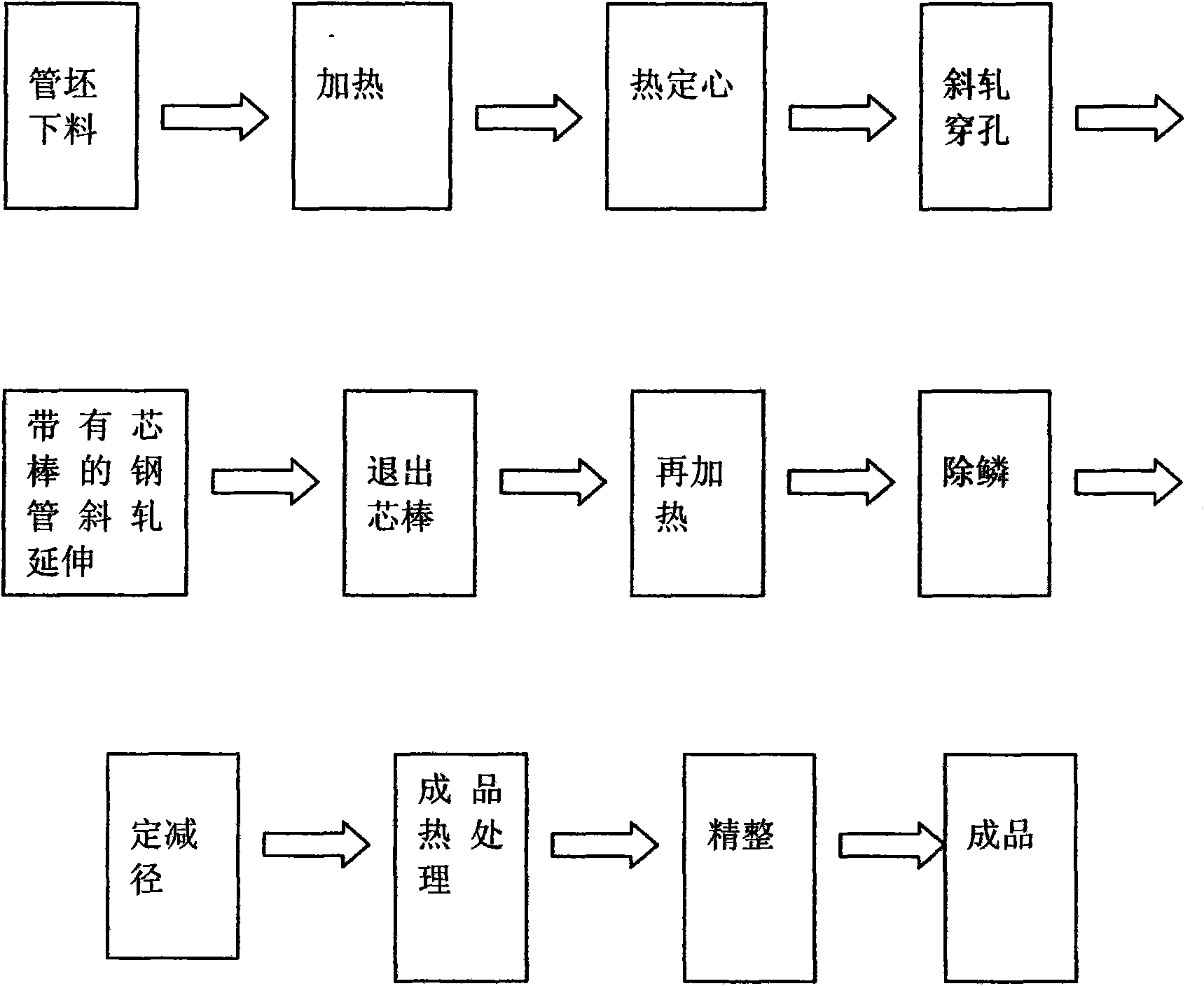

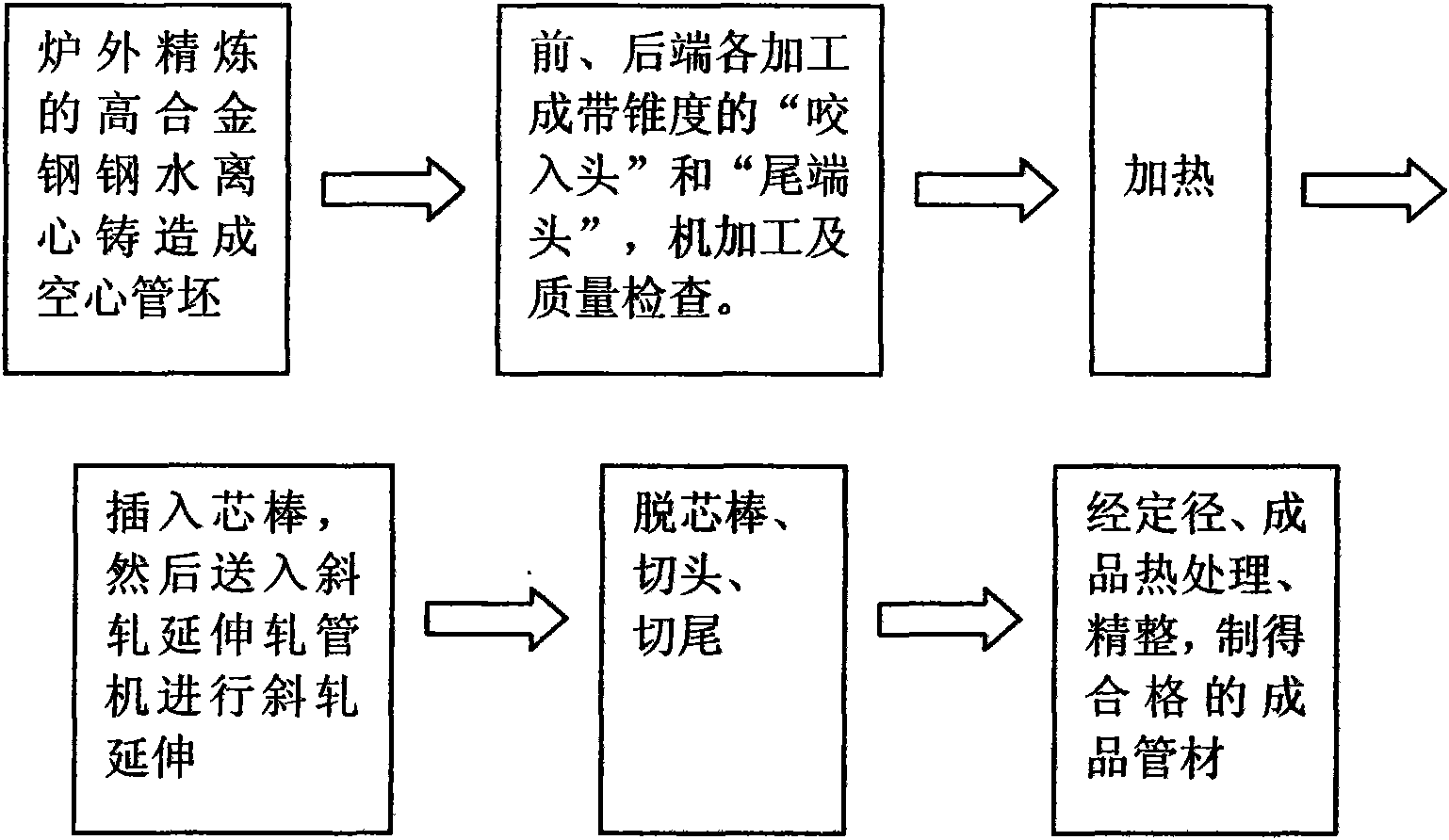

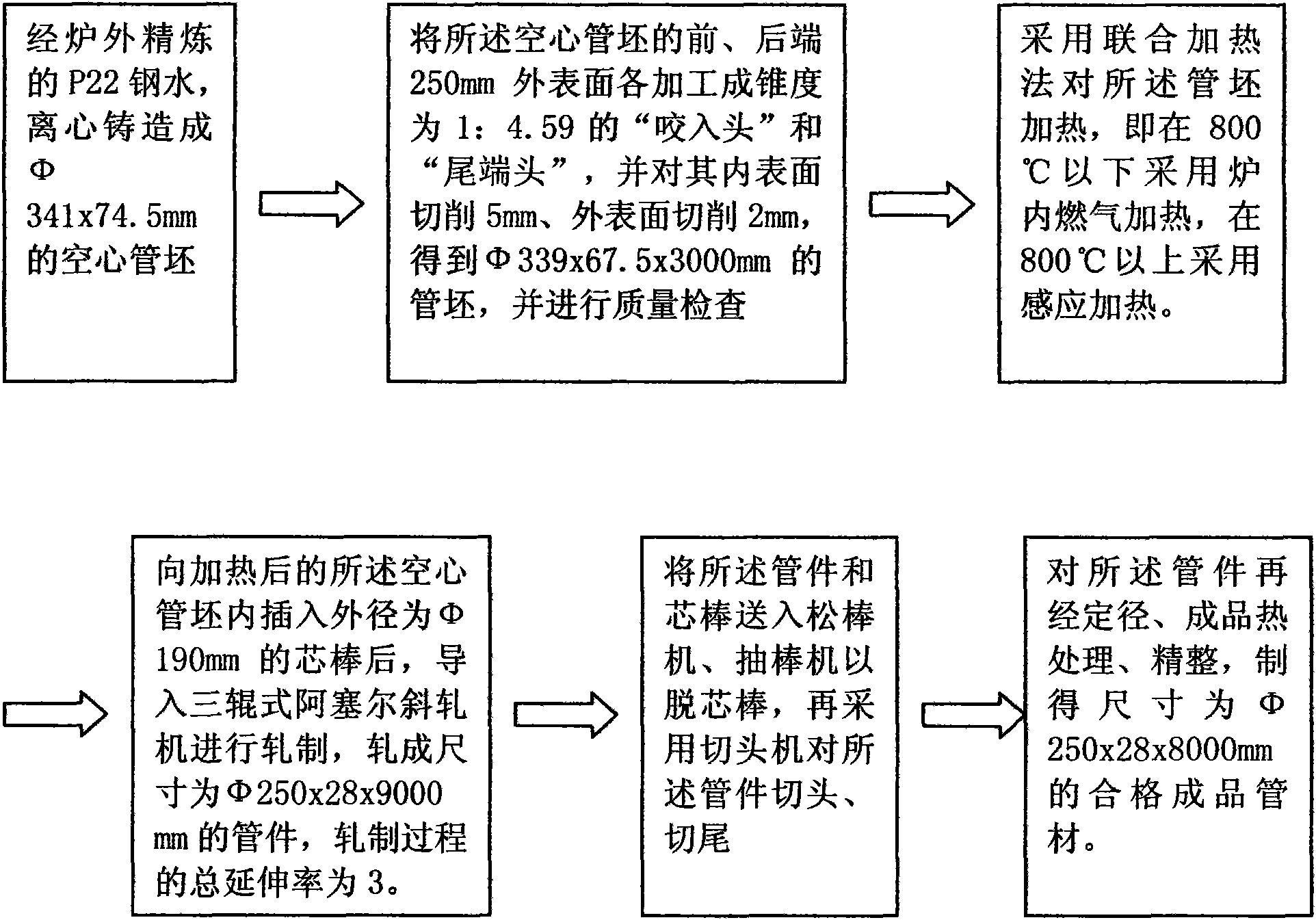

New technique for producing high alloy steel high-end pipe by adopting cross rolling elongation technology

InactiveCN101579702ALow equipment investment costLow running costMandrel separation arrangementsMetal rolling arrangementsPipe fittingMaterial Perforation

The invention relates to a new technique for producing a high alloy steel high-end seamless pipe by adopting cross rolling elongation technology without perforation, comprising: molten high alloy steel which is externally refined is made into a hollow shell by centrifugal casting; the outside surfaces of the front and the rear ends of the hollow shell are respectively processed to be a 'gripping head' and a 'tail end head' with conicity, and machining and quality inspection are carried out on the inside and the outside surfaces as well as the 'gripping head' and the 'tail end head' of the hollow shell; heating is carried out; a mandril is inserted into the heated hollow shell, and then the hollow shell is sent into a cross rolling elongating mill for cross rolling, so that the pipe fittings having the wall thickness, the diameter and the length being in accordance with the requirements can be produced; the mandril is removed, and the head and the tail are cut off; finally, the qualified finished pipes can be obtained after sizing, heat treatment for finished product and finishing operation. The technique has short process flow and does not need cross rolling perforation, thus reducing the cost and improving the quality; due to small tapered treatment for the front and the rear ends, 'tail triangle' is avoided when the medium-thick walled pipes are produced, and the performance of secondary gripping is improved, thus improving the quality of the product and the production efficiency.

Owner:北京蓝海科融新技术有限公司

Prepn of solid phosphoric acid catalyst for oligomerization of propylene

InactiveCN1398833AStrong resistance to polyphosphoric acid corrosionLow equipment investment costHydrocarbonsBulk chemical productionPhosphoric acidTungsten

A preparation process of solid phosphoric acid catalyst for oligomerization of propylene includes preparing polyphosphate in 72-88 wt% at 120-180 deg.C in a copper reactor, preparing phosphate at 150-230 deg.C, mixing with diatomite, extruding into strips, drying by roasting, and activating. The molar ratio expression of the catalyst is SiAaBb(P2O5)c.(H2O)d. where A is at least one selected from B, Al and In; B is at least one selected from Ti, Zr, V, Nb, Cr, Mn, Mg and W; a=0.2-1.5; b=0.01-0.2; c=1.0-2.0; and d=0.6-1.2. The reactor is strongly resistant to corrosion of polyphosphate, the method has low production cost and the catalyst has high activity and high crushing strength.

Owner:CHINA PETROLEUM & CHEM CORP +1

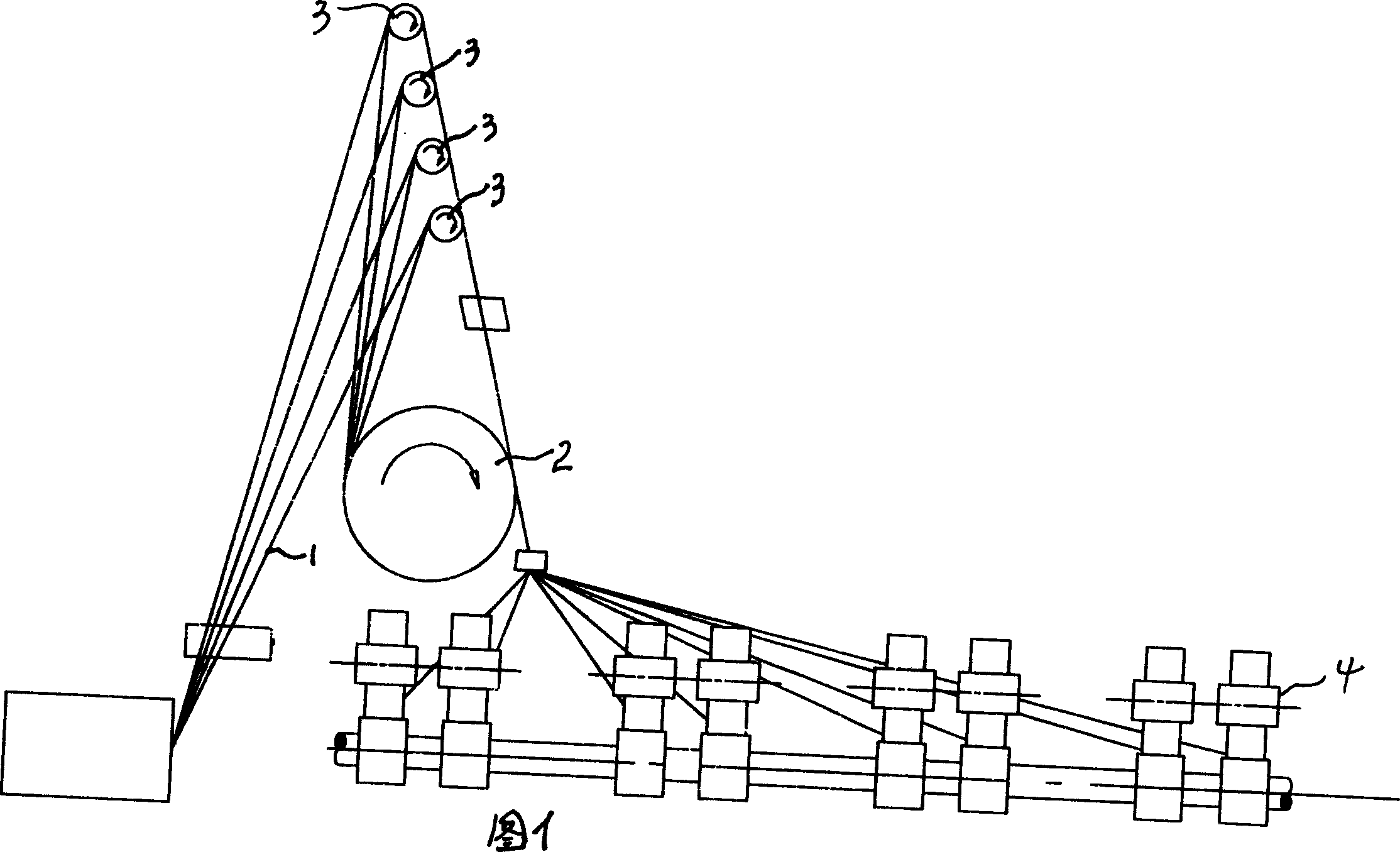

Spining technology for viscose rayon continuous spinning machine

InactiveCN1434154AIncrease productivityReduce production costs and equipment investment costsWet spinning methodsYarnEngineering

The spinning process for viscose rayon continuous spinning machine includes the following steps: making the viscose pass through viscose tube, metering pump, filter, spinneret seat and spinneret and jet from die-spinning nozzle, solidifying in setting bath to obtain thread-line, after formed, spirally window said thread-line along its axis from one end of paired rollers formed from common roller and small diameter roller which have a certain included angle from axis, and winding out from another end, and making it pass through yarn guide and wind around bobbin to form bobbin, then making the three-line undergo the processes of continuous setting, washing unit water, oiling and drying. The described paired rollers are formed from one common roller and at least two small diameter rollers which are respectively two-by-two combined.

Owner:张天兴

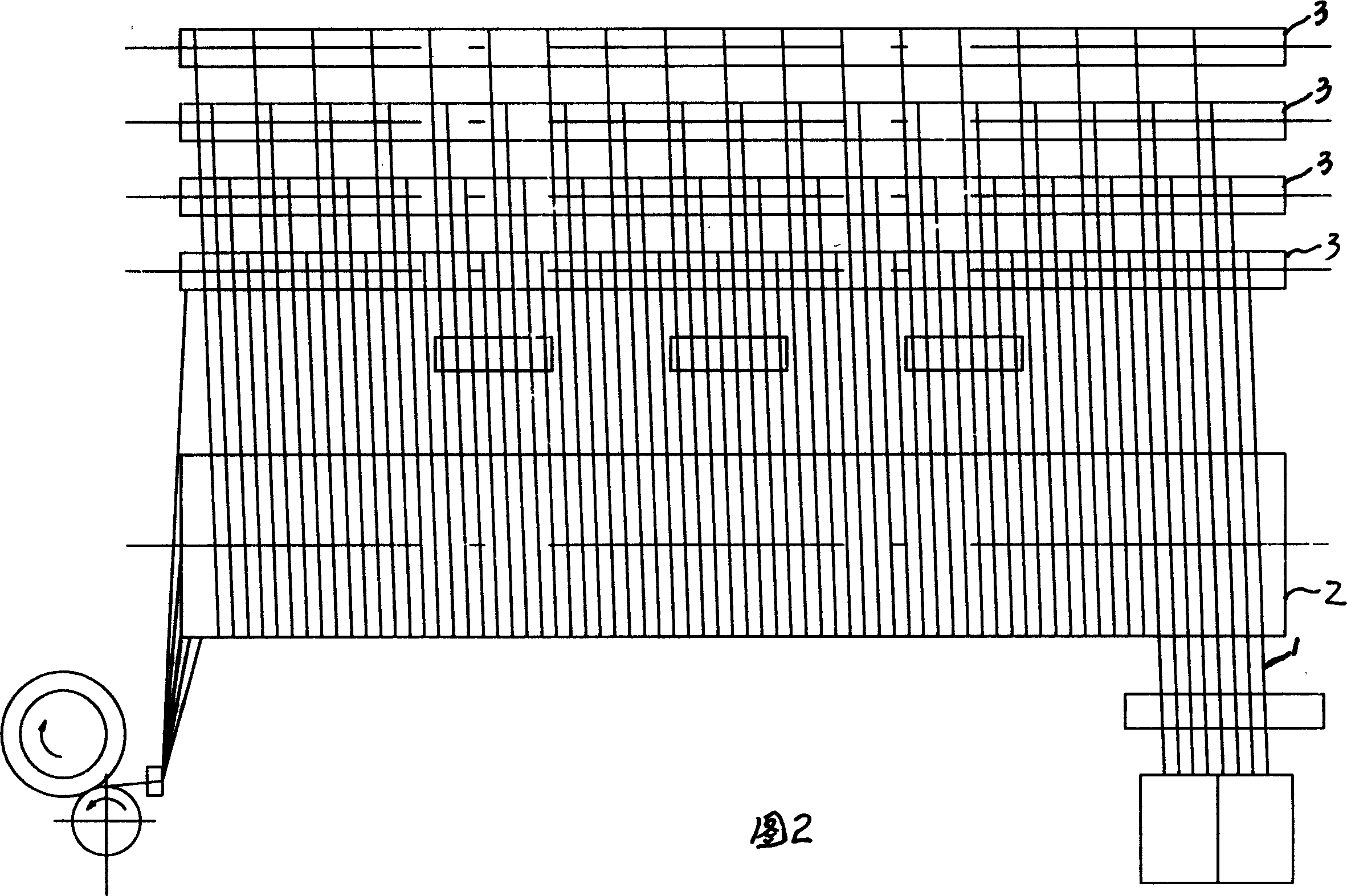

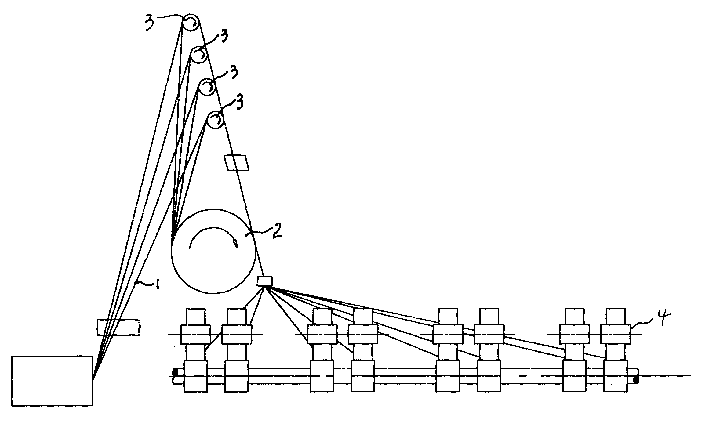

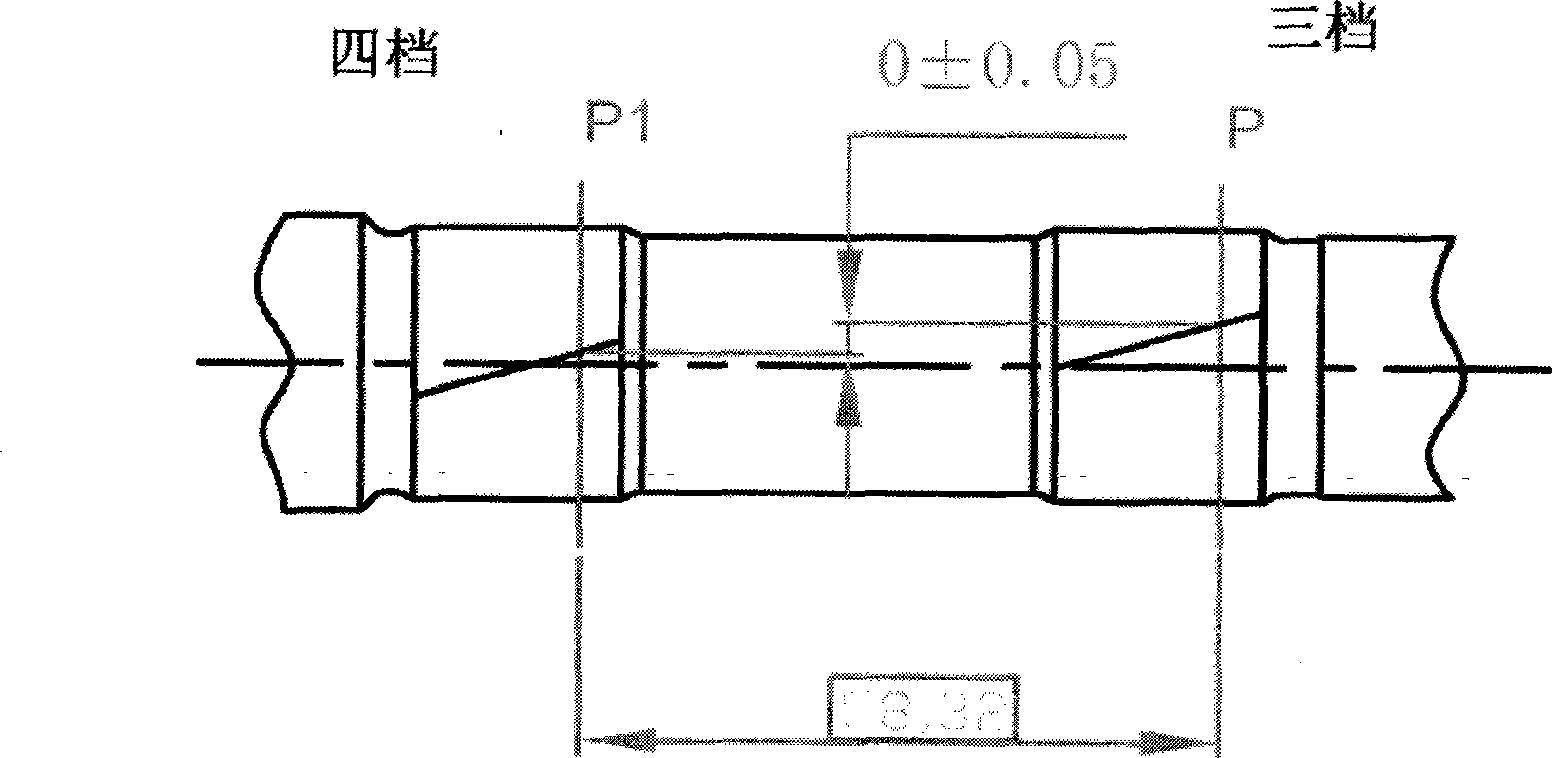

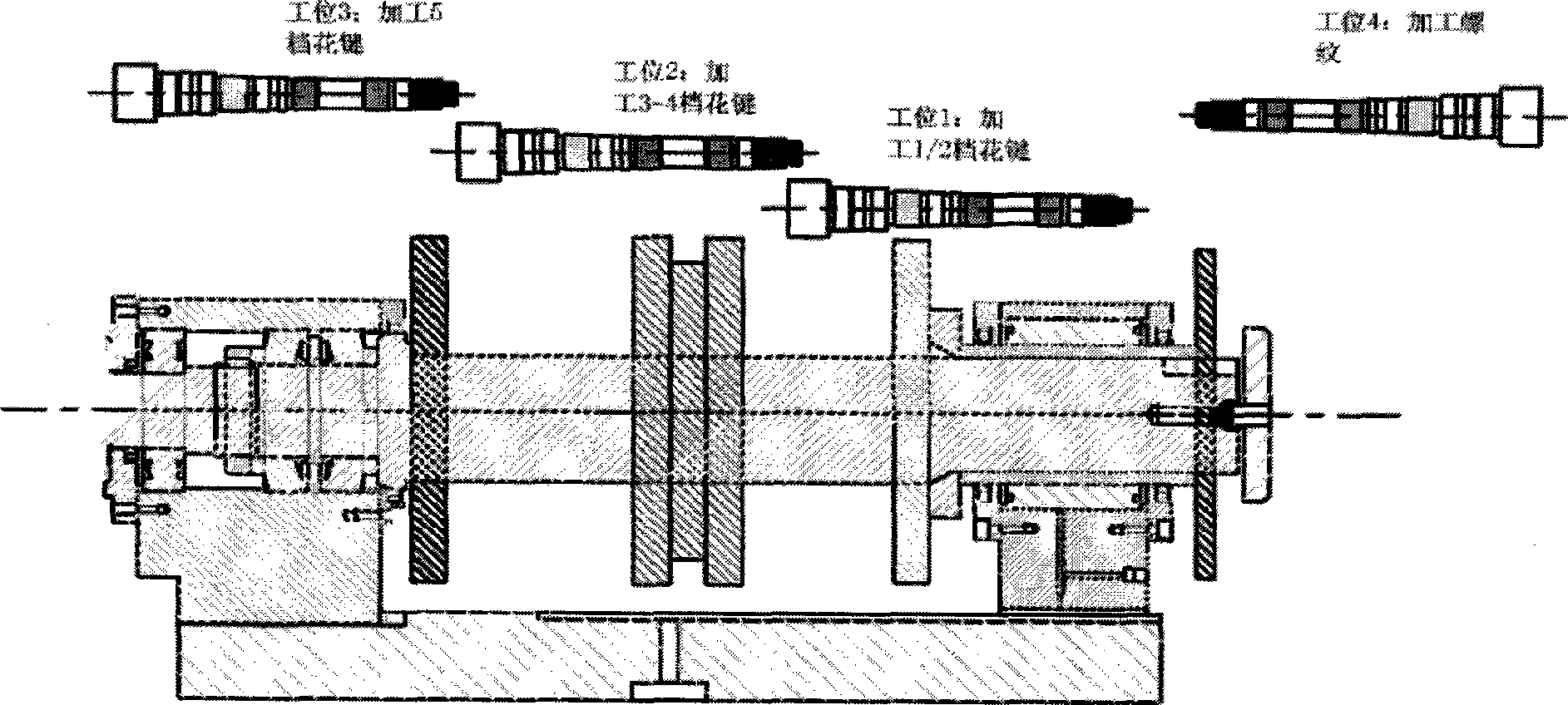

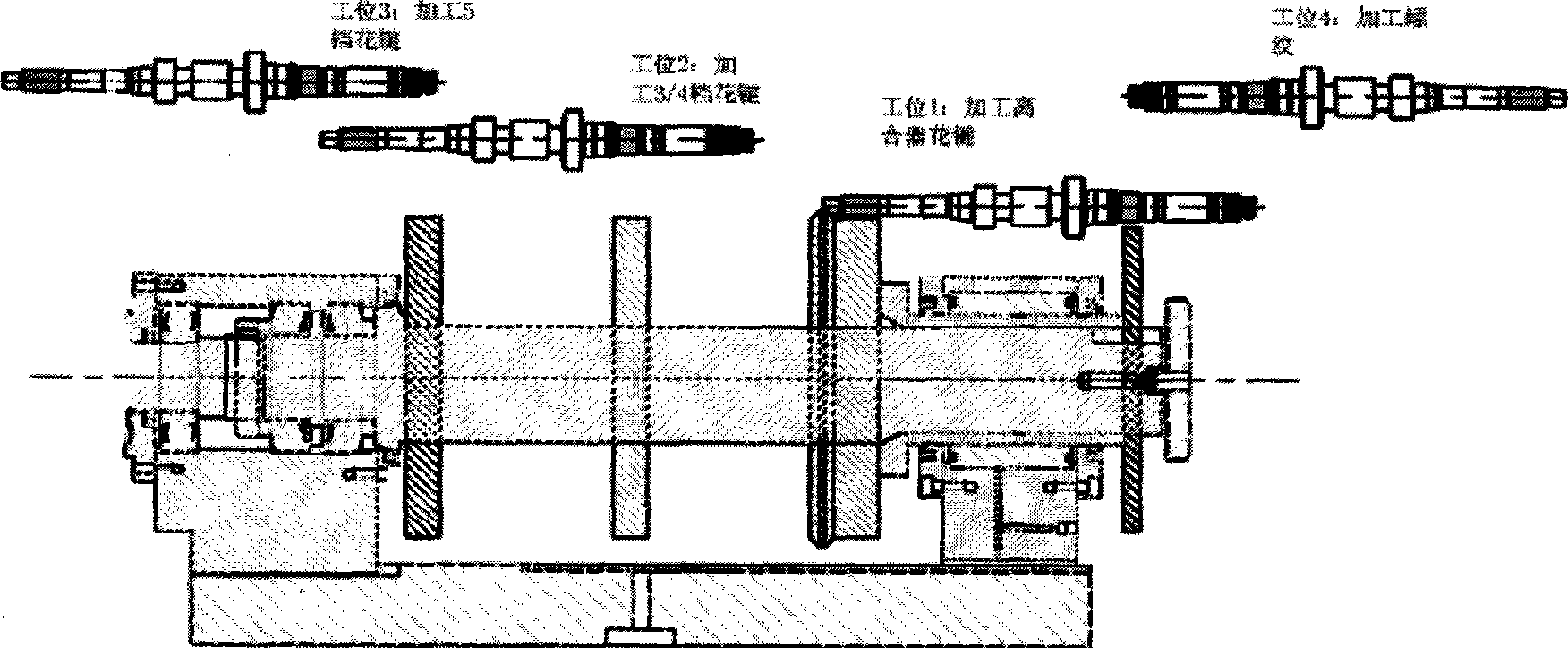

Technique for rolling multiple-variety multiple-station spline threaded shaft

ActiveCN101439384ALow equipment investment costEasy to adjustScrew-threads articlesMetal rollingEngineeringAutomotive transmission

The invention relates to a technology for rolling various multi-station spline threaded shafts, belonging to the technical field of automobile gear box spline threaded shaft processing technology. The technology mainly solves the problem that the existing technology only can process BE uniaxial or biaxial spline and thread by three rolling devices and a gear rolling device. The technology is mainly characterized in that a rolling machine with five numeric control shafts is adopted; a principal axis is provided with four stations sequentially and is correspondingly provided with rolling wheels or screw rolling wheels, wherein, 3-4 rolling wheels are formed by two same rolling wheels which are alternatively fixed along the same straightness; a BE biaxial or uniaxial workpiece is respectively moved to the position 1, the position 2, the position 3 and the position 4 to be processed into a corresponding spline and thread; and the BE biaxial work piece after processing is returned to an initial position. The invention has the characteristics of using one device to process the BE uniaxial or biaxial spline and thread, meeting the requirement of processing quality and least invest cost. The technology is mainly used for processing the BE uniaxial or biaxial spline and thread.

Owner:DONGFENG PEUGEOT CITROEN AUTOMOBILE

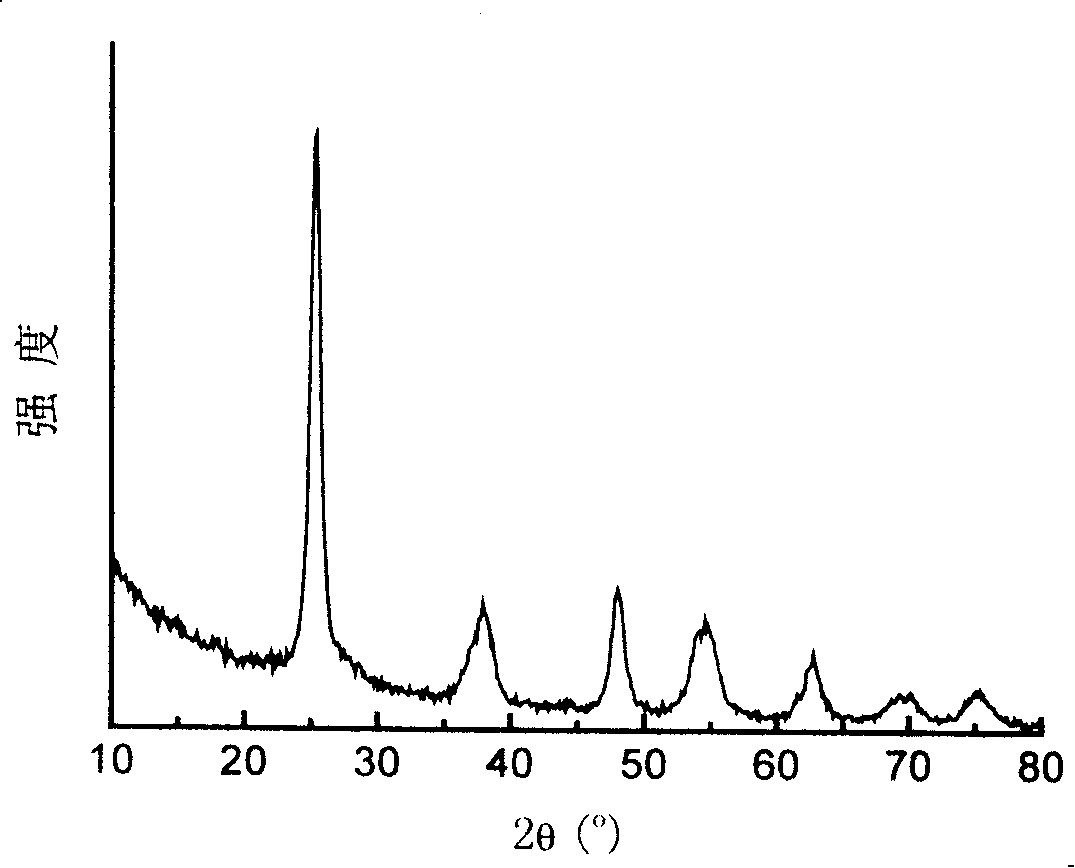

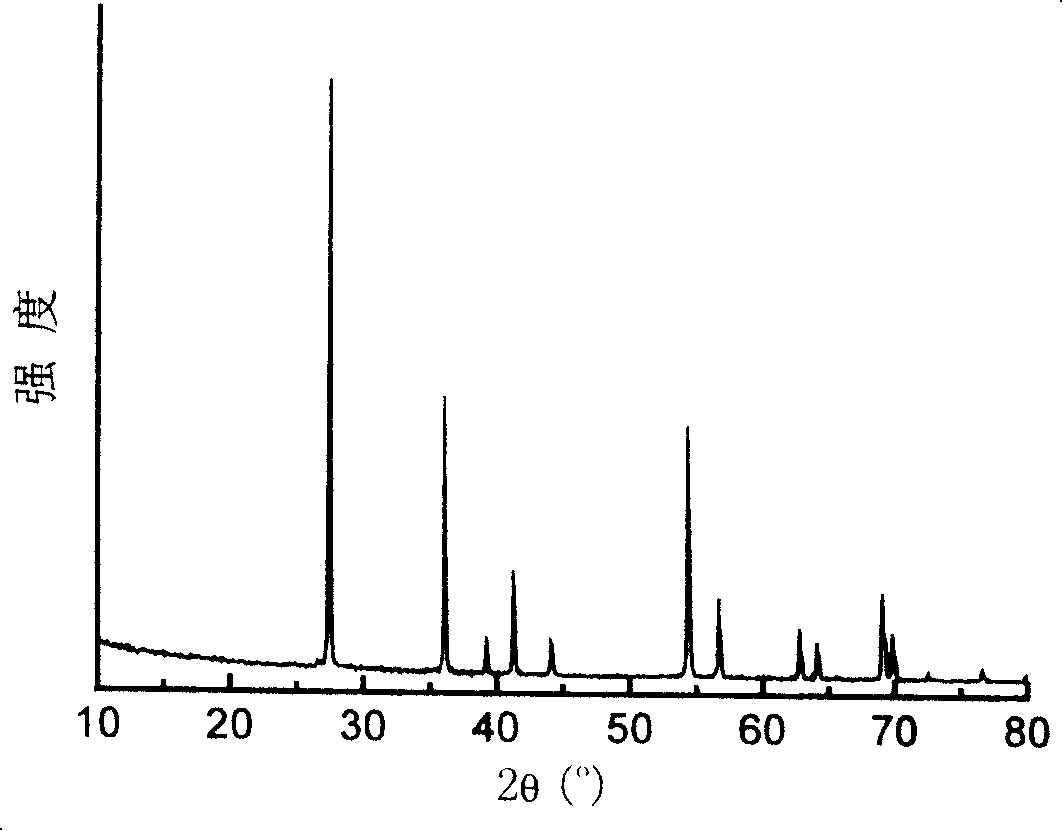

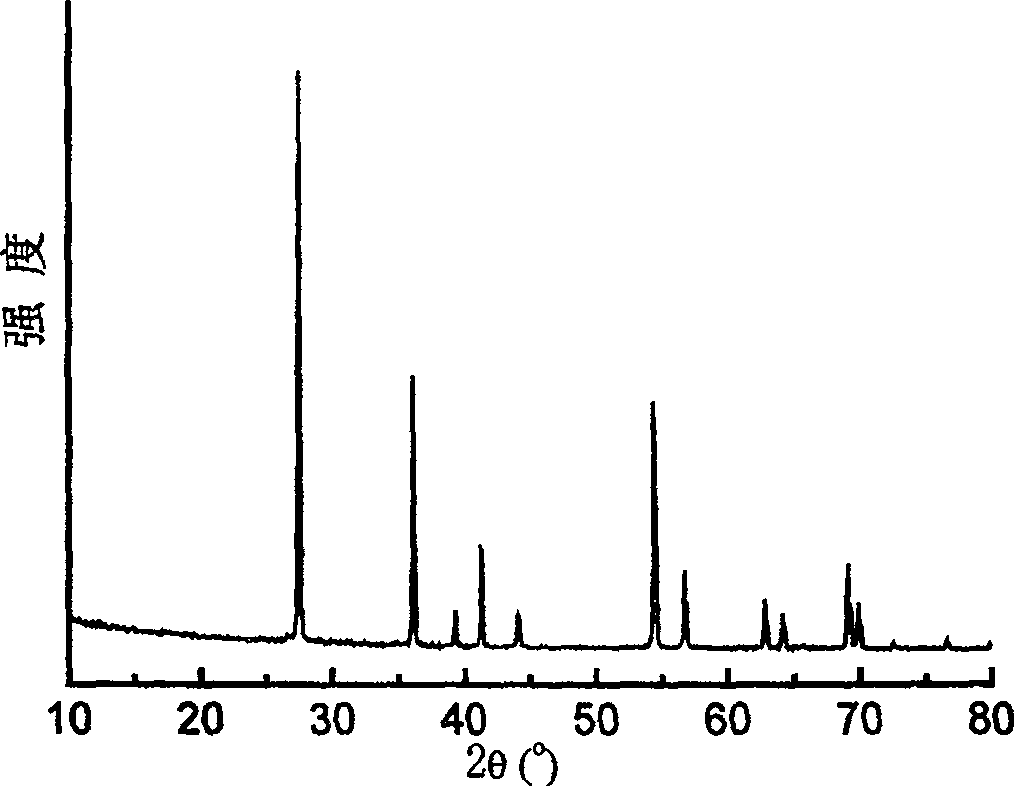

Method for clean production of titanium dioxide by using potassium hydroxide

ActiveCN101172649AObvious superiorityLow reaction temperaturePigmenting treatmentTitanium dioxideSeparation technologyPotassium hydroxide

The invention belongs to the preparation of inorganic metallic compound and the processing filed of mineral resource, in particular to a preparation method for preparing titanium dioxide (titanium pigment) through high titanium slag and sodium hydroxide without pollution. The invention is characterized in that the high titanium slag is taken as the raw material; the high titanium slag and the potassium hydroxide having temperature range from 350 DEG C to 550 DEG C are reacted to prepare a medium product; the medium product is then washed through water (or carbonatation), acid solubled, reduced, hydrolyzed and burned to prepare anatase or rutile titanium dioxide. The alkali circulation, the acid circulation and the separation technology of the invention greatly reduce the production energy consumption, simplify the production process, reduce the device investment and increase the technology maneuverability, thereby providing an effective method for the comprehensive use of the titanium resource and the preparation of titanium dioxide (titanium pigment).

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

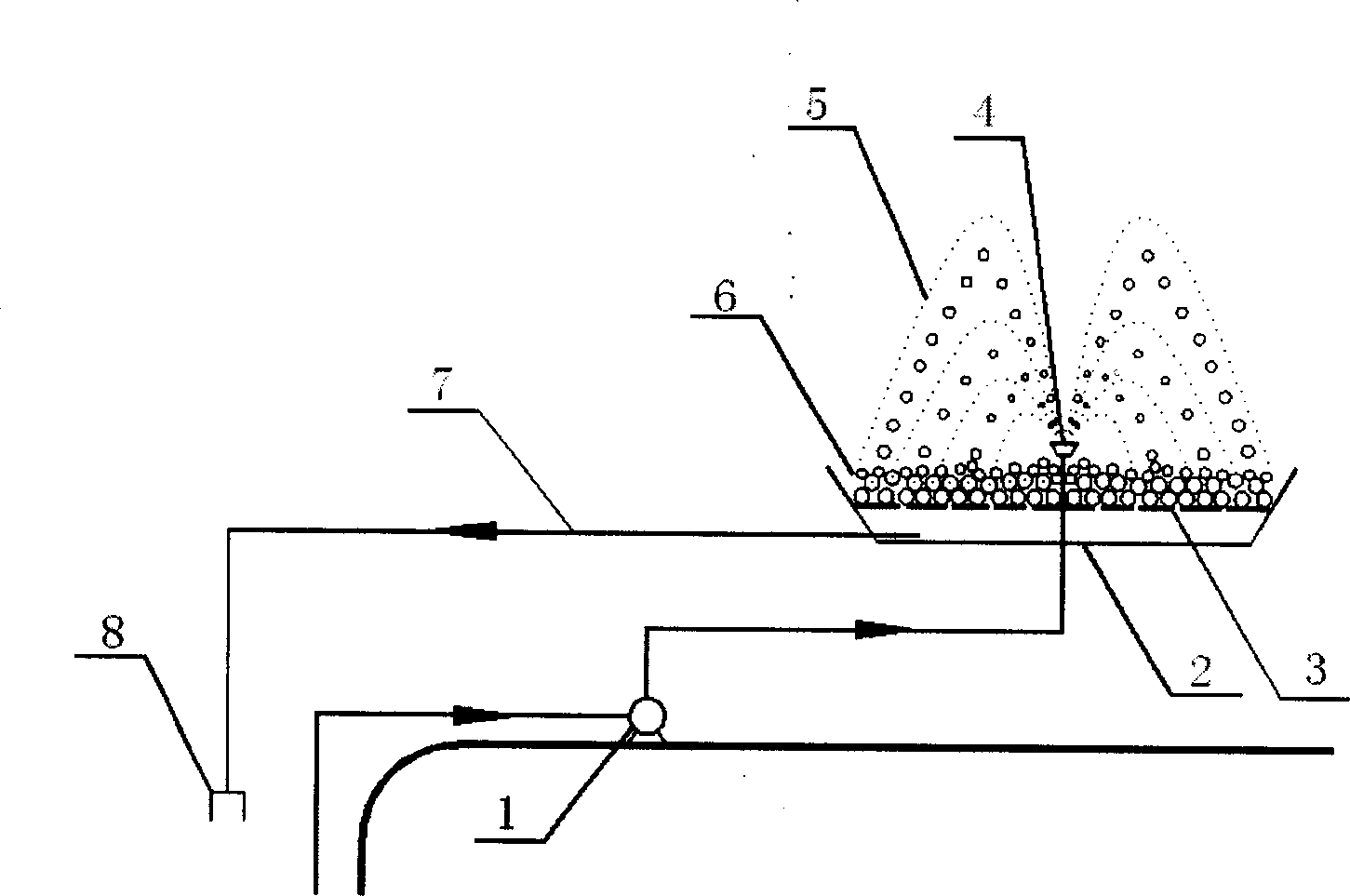

Desalination method for naturally freezing seawater at freezing point

InactiveCN1843949ASimple installationLow equipment investment costGeneral water supply conservationSeawater treatmentSeawaterInjector

The invention relates to a method of natural seawater desalination at freezing point, belonging to technology of seawater desalination. The device used in mentioned method comprises: pump, pipe, injector, collecting tank, draining support board, granular ice, drainage conduit and draining discharge port; the pump is connected with injector through pipe to provide flow capacity and pressure for spraying seawater into atmosphere frog droplet; said draining supporting board on bottom of collecting pool acts for supporting granular ice and seawater of granular ice draining. The seawater is injected to atmosphere through injector, then seawater exchanges heat with atmosphere, the temperature is reduced and ice crystal is generated and grows into large granular ice, draining supporting board catches it and drains out seawater in granular ice; thus realizes seawater desalination process. The invention is characterized by simple desalination device, reliable operation, low energy consumption and special suitness for seawater deep desalination.

Owner:TIANJIN UNIV

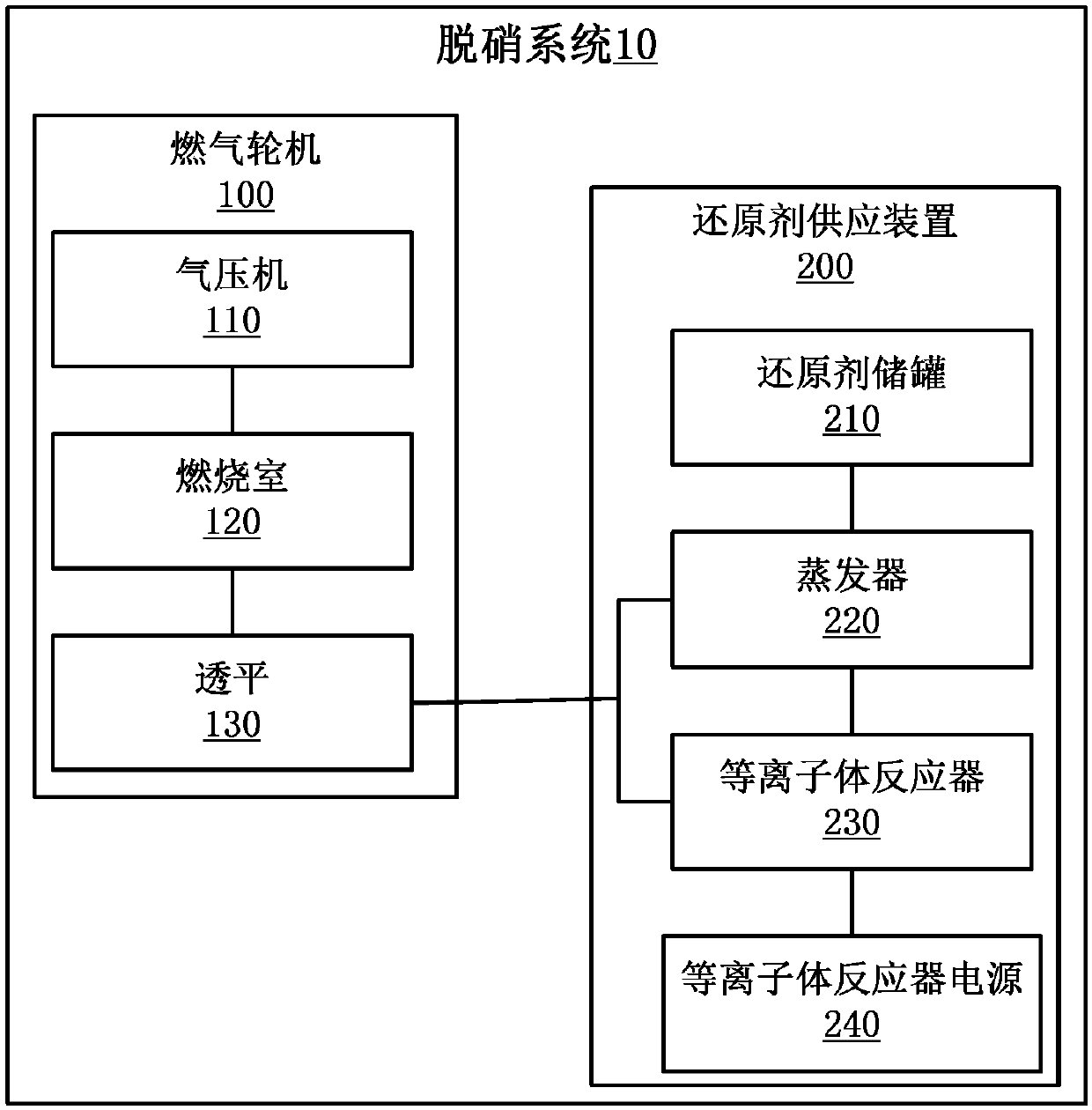

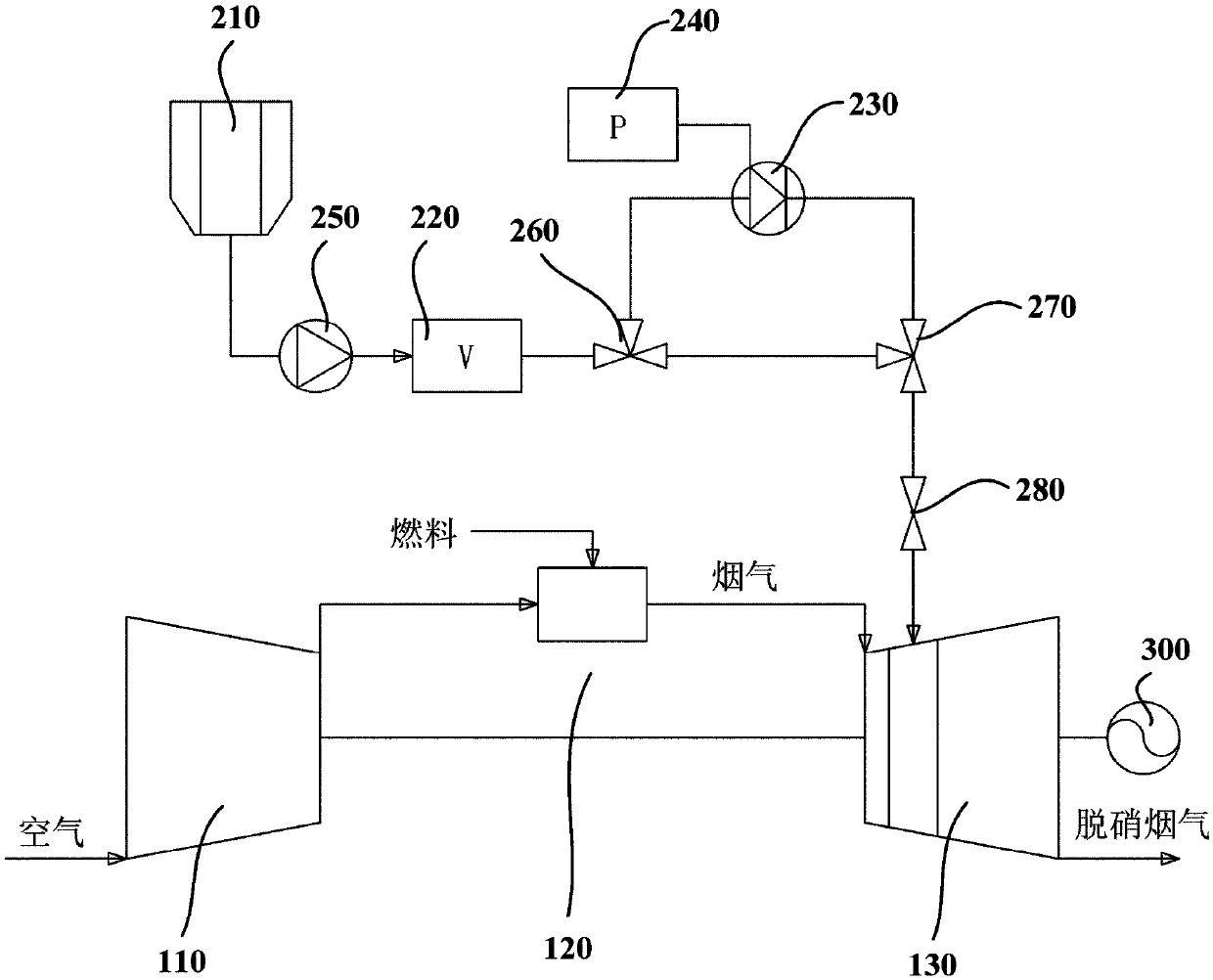

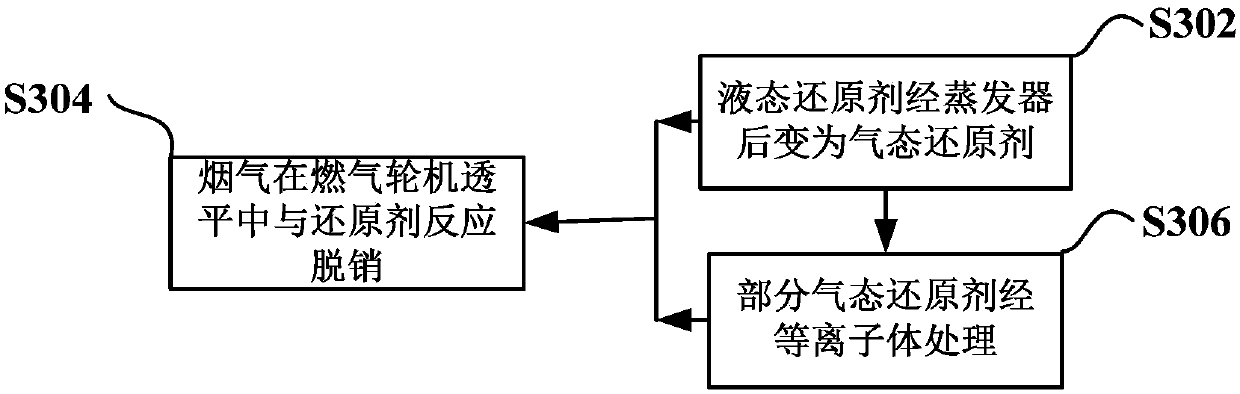

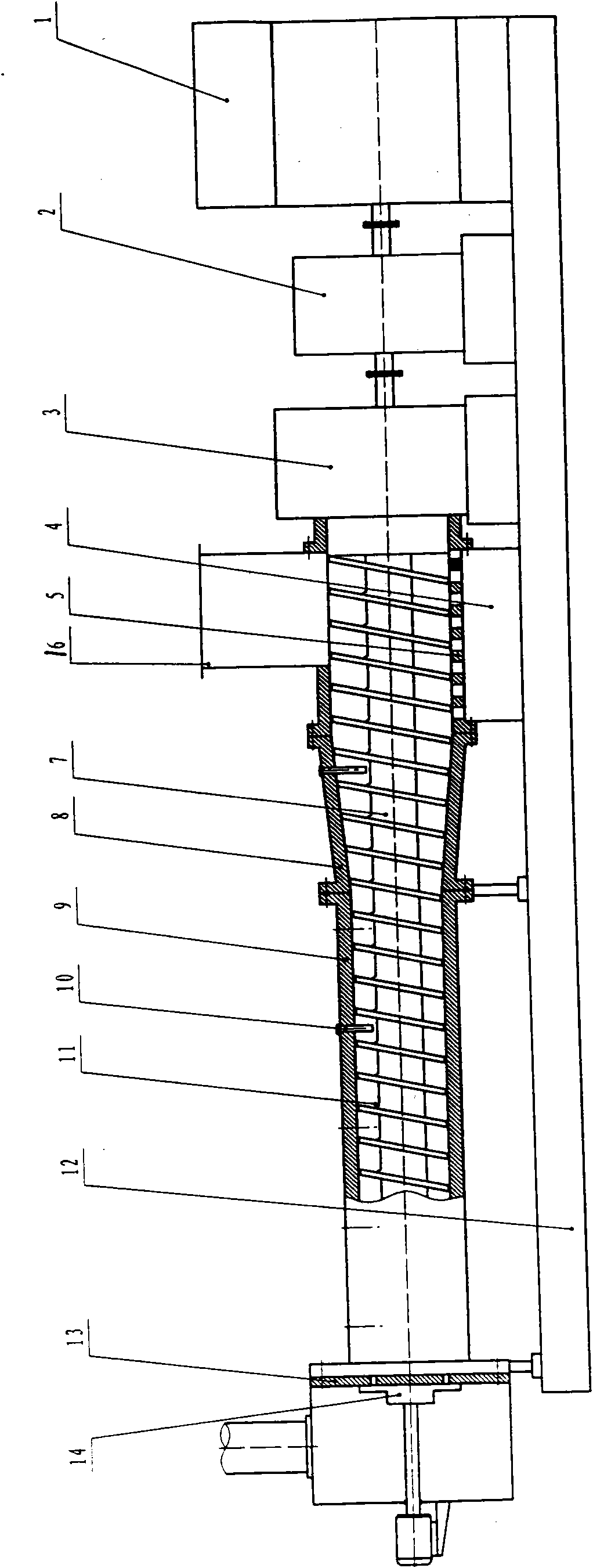

Denitrification system and denitrification method for gas turbine

ActiveCN107789984AImprove efficiencyHelp mixDispersed particle separationGas turbine plantsCombustion chamberNitric oxide

The invention provides a denitrification system and a denitrification method for a gas turbine. The denitrification system comprises the gas turbine and a reducing agent supplying system. A denitrification reducing agent is provided for a turbine by using a reducing agent output pipeline communicated to the rear part of a first-stage moving blade of the turbine of the gas turbine; nitric oxide influe gas, exhausted from a combustion chamber of the gas turbine, is contact with the denitrification reducing agent in the turbine of the gas turbine to carry out selective non-catalytic reduction reaction, and denitrification of the flue gas is finished, wherein before the reducing agent enters the turbine for reacting, more free radicals can be generated by plasma treatment and facilitate a denitrification reaction. By using the technical scheme provided by the invention, denitrification is realized in the turbine of the gas turbine, and high pressure and high rotating speed of the turbineof the gas turbine are sufficiently utilized, so that the mixing of the reducing agent and the flue gas is benefited, the denitrification reaction is promoted, and the denitrification efficiency is improved; besides, post treatment equipment also can be reduced, so that the complexity of the system and investment expenses of equipment are reduced.

Owner:TSINGHUA UNIV

Salt-bath furnace quenching method for teeth of chain wheel

InactiveCN103820624AImprove reliabilityLow equipment investment costFurnace typesHeat treatment bathsQuenchingHeating time

The invention relates to a salt-bath furnace quenching method for teeth of a chain wheel. The method comprises the following steps of (1) placing a mixture containing BaCl2 and KCl in an intermediate-temperature salt-bath furnace for heating, wherein based on the total amount of 100 parts, the mixture contains 65 to 75 parts by weight of BaCl2 and 25 to 35 parts by weight of KCl, the mixture is heated to be completely melted at the heating temperature of 720 to 940 DEG C, and the melted mixture is the melt of a salt bath; (2) placing the teeth of the chain wheel in the salt bath for heating, wherein the heating temperature of the salt bath is 900 to 920 DEG C, and the heating time is set to be 26 to 30 seconds per millimeter of the tooth thickness of the chain wheel; (3) performing rapid quenching by utilizing a quenching medium after heating and heat preservation; (4) performing tempering heat preservation for 3.5 to 4.5 hours after quenching, and after heat preservation, discharging the teeth of the chain wheel out of the furnace, and air-cooling the teeth. According to the method, a salt-bath furnace quenching process for the teeth of the chain wheel is adopted, so that the hardened layer depth can reach more than 12mm; moreover, hardened layers with different depths can be obtained by regulating the heating time of the salt-bath furnace; the salt-bath furnace quenching process is high in the heating speed and convenient to operate, a workpiece is difficult to oxidize and decarburize, and the temperature is easy to control.

Owner:LINZHOU HEAVY MACHINERY GROUP

Isoprenerubber post-treatment one-step processing technique and dehydrating and drying machine

InactiveCN101967206ASimple processLow equipment investment costDrying using combination processesProcessing typeEngineering

The invention discloses an isoprenerubber post-treatment one-step processing technique. In the technique, an extrusion dehydration procedure and an expansion drying procedure are combined to form a continuous processing type procedure; water-containing rubber particles are pushed into an extrusion dehydration section of a conical cylinder structure, a compression ratio and dehydrating amount are increased; the dehydrated rubber material is pushed into the expansion drying section, the compression ratio is increased, and the rubber material is sheared and blended by a plurality of rows of shearing screws on the straight cylinder in the expansion drying section, and the rubber material is heated; and the rubber material is delivered to a fusion, homogenization and discharging section, a compression ratio is increased, the rubber material, which is sheared and heated intensively in a short time, is discharged out from template holes when the mooney viscosity of the rubber particles does not drop suddenly, the rubber particles are expanded instantly, and the rubber material is separated from volatile matters. In the technique, the isoprenerubber industrial production process flow is simplified, a 'two-step' post-treatment process is simplified into a 'one-step' process; and about 40 percent of equipment investment cost, about 50 percent of floor area and about 27 percent of energy are saved, the single-machine yield is improved by over 5 percent, labor intensity of workers is lowered and obvious economic benefit is achieved.

Owner:罗天韵

Method for preparing reverse osmosis antisludging agent

InactiveCN101186393AExcellent anti-scaling performanceLow equipment investment costScale removal and water softeningConcentration ratioReverse osmosis

The invention relates to a preparation method of reverse osmosis scale inhibitor and comprises the steps that: (1) 1 portion of tricyanamide, 1-3 portions of PHMA with a weight concentration ratio of 30-40 percent, 1-3 portions of ammonium chloride and 1-3 portions of formaldehyde are added into a container and react for 0.5-2 hours at the temperature of 80 plus / minus 5 DEG C after stirred and dissolved; (2) 1-3 portions of urea, 1-3 portions of ammonium chloride and 1-3 portions of formaldehyde are then added for reaction for 2-4 hours at the temperature of 90 plus / minus 5 DEG C; (3) 1-3 portions of polyacrylic acid with a weight concentration ratio of 15-30 percent and 1-3 portions of cationic polyacrylamide with a weight concentration ratio of 0.5-2 percent are next added for reaction for 0.5-1 hour at the temperature of 70 plus / minus 5 DEG C; (4) the mixture obtained is then cooled to the room temperature to get finished products. In addition, the portion of the raw materials means the weight portion. The reverse osmosis scale inhibitor prepared by the method of the invention is multi-polymeric copolymer which is particularly applicable to the water quality with metallic oxides, silicon and high content of scale salts and has high scale inhibiting efficiency(with the scale inhibiting rate above 95 percent ) as well as produces no immiscible polymer through coagulation with residual flocculant or silicon compounds of rich aluminum and iron.

Owner:WUHAN UNIV OF TECH

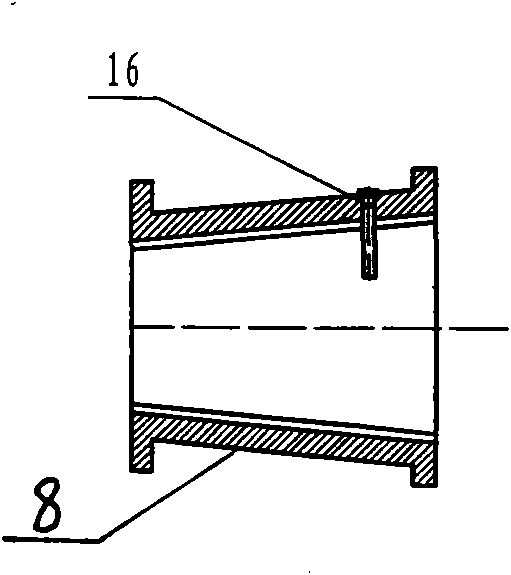

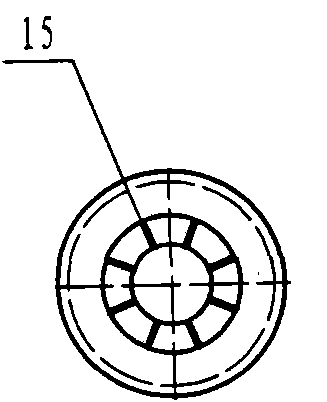

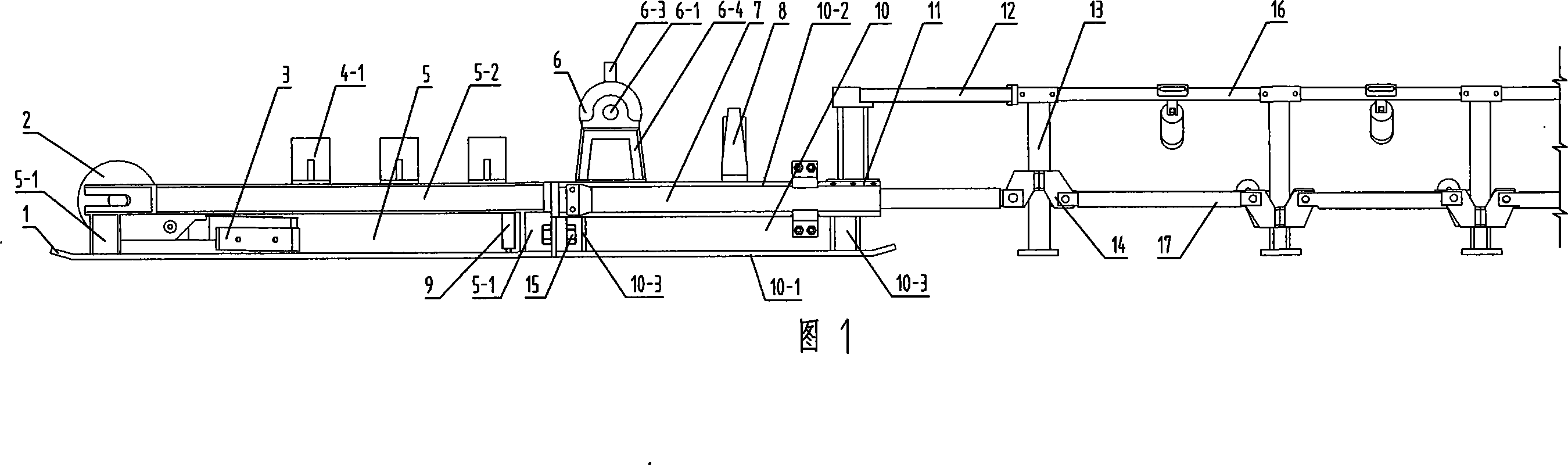

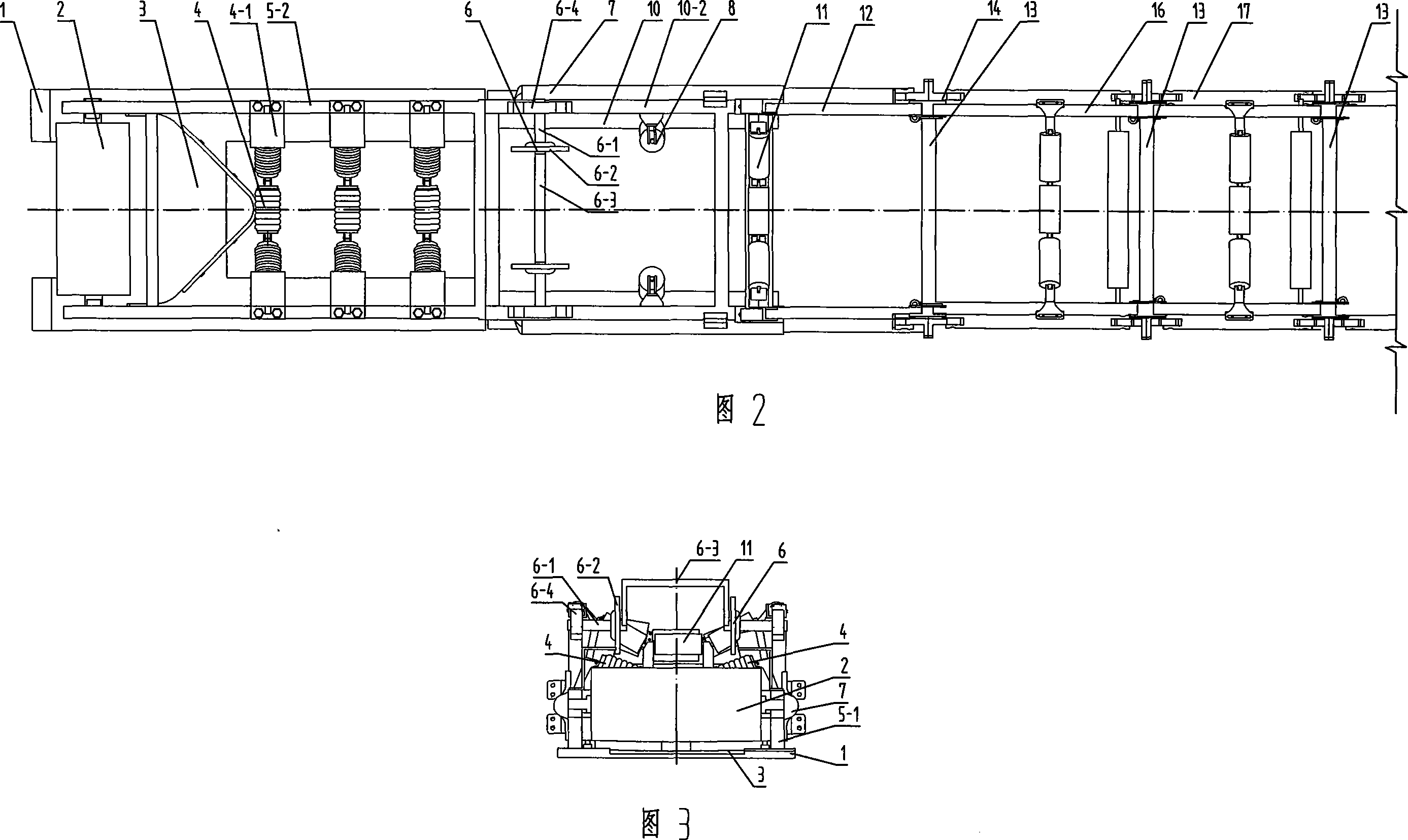

Ultra-low and mobile tail for belt conveyer

InactiveCN101104474ALow equipment investment costLabor savingConveyorsEarth drilling and miningEngineeringPiston rod

The present invention discloses a super-low and mobile belt conveyor tail, which is arranged on the end part of the feeding end of the belt conveyor. The conveyor tail is composed of a front section and a rear section, wherein, the front section and the rear section are connected together through a tightening bolt; the rear section is connected with the end part of the belt conveyor through an oil cylinder and an adjusting longeron; the front section and the rear section are respectively provided with a belt steering roller, three apron-supporting rollers, a pressing belt position limit wheel, a trough type roller, upper and lower anti-deviation vertical rollers and a cleaner. Automatic tail movement and auxiliary belt tightening can be achieved through the changes of the length of the adjusting longeron and the extending length of an oil cylinder piston rod. In coal mining production, the position of the conveyor tail can be timely adjusted along the movement of a working scraper. The invention is simple and easy to be operated, which is also energy saving and time saving and can be applied to different types of retractable belt conveyors.

Owner:汪允岭

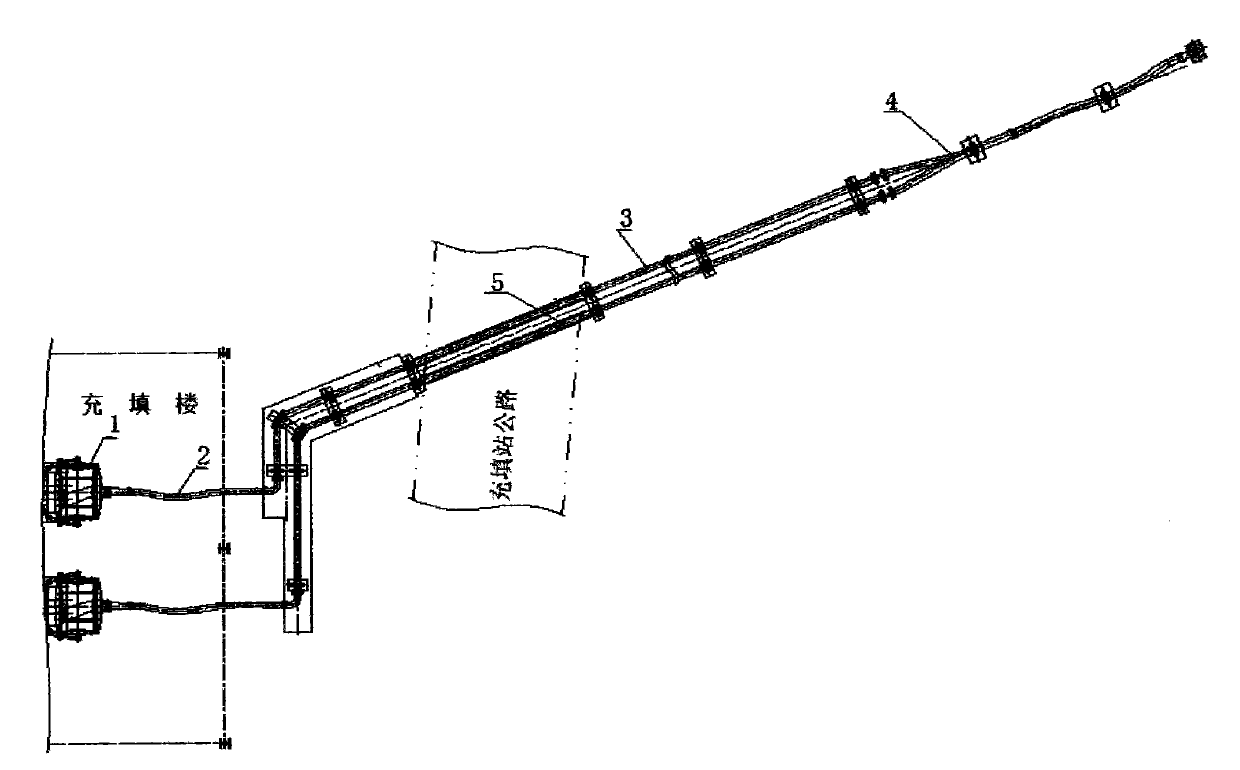

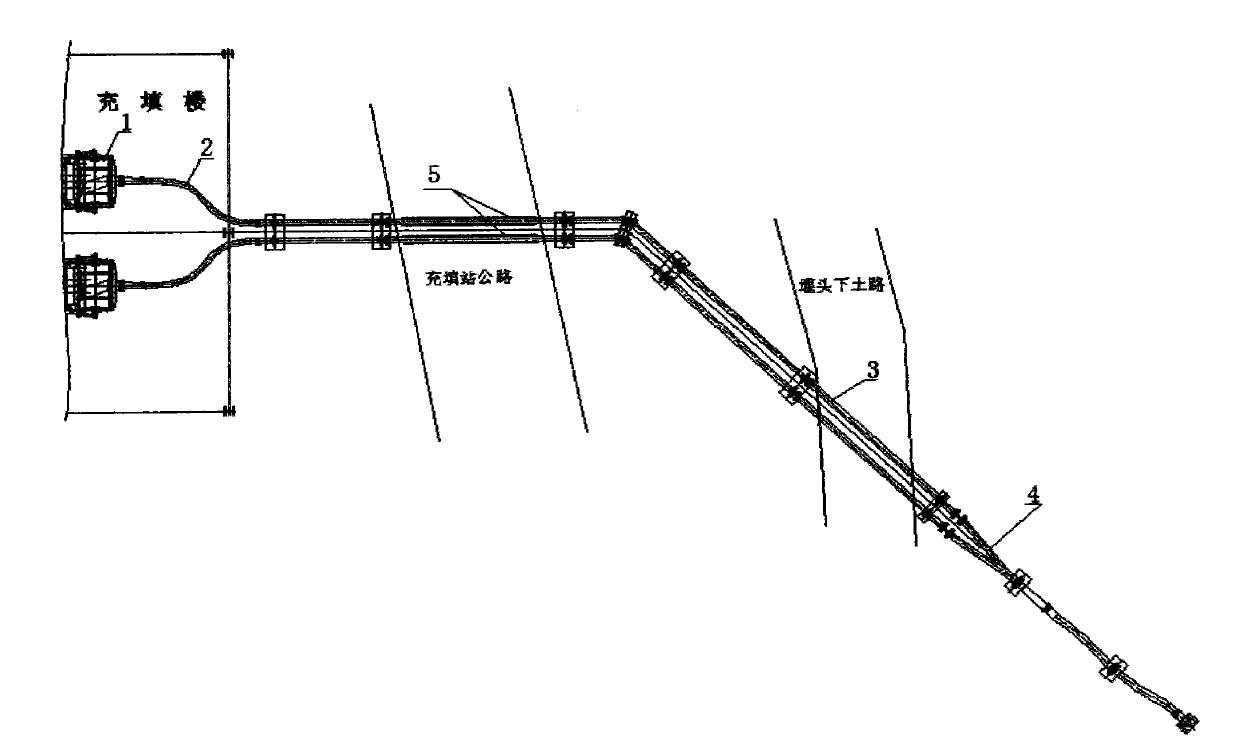

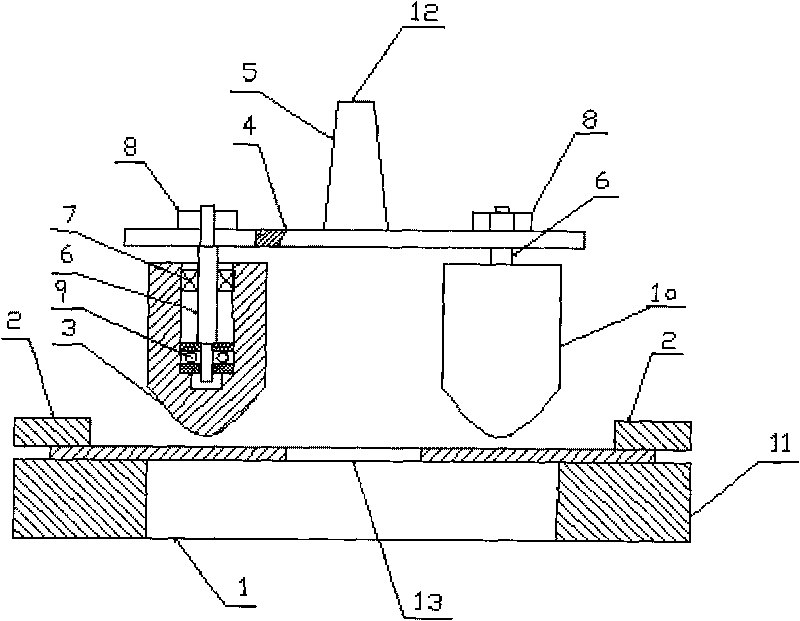

Piston type industrial pump parallel using system and method

InactiveCN103216409AReduce the stand-alone capability of the deviceLow equipment investment costPositive displacement pump componentsPump installationsPistonManufacturing engineering

The invention provides a piston type industrial pump parallel using system and method in a paste filling system, wherein the vacancy rate of equipment can be eliminated, the capability of allocation of system device can be reduced and the operational reliability of the system can be effectively ensured. The piston type industrial pump using system comprises two parallel piston type industrial pumps and a connecting pipeline. The outlet of each piston type industrial pump is sequentially connected with a hose and two hard pipes. The two hard pipes are combined jointly through a converging three-way joint. According to the piston type industrial pump using system provided by the invention, two piston type industrial pumps in small capacity are parallelly used, therefore conventional configuration mode of one pump with a backup is broken. The pumps in small capacity replace pumps in great capacity, and the one-machine capacity of the device is reduced, so that the investment expense of the device is reduced. The two pumps are parallelly connected in operation, so that the vacancy rate of equipment can be eliminated, and the operational reliability of the system can be effectively ensured.

Owner:JIZHONG ENERGY FENGFENG GRP

Novel flange manufacturing machine tool

The invention relates to a novel flange manufacturing machine tool, according to the relative technologies of the machine assembly, a spinning head axle radial bearing and a surface thrust bearing are assembled with spinning heads and spinning head bodies, and the spinning head axle is ensured to flexibly rotate, and then the above components are arranged on a spinning head fixed plate by screw nuts, a spinning head fixed plate is fixedly connected with a transmission shaft handle by a proper method, in order to ensure the spinning effect, the spinning heads are evenly arranged around the periphery of the fixed plate, the number of the spinning heads is proper as far as possible. The size of the transmission shaft handle is matched with a relative drilling machine to use conveniently, after the above components are arranged, blank material can be put on a base and is pressed tightly by a pressing plate, the drilling machine is moved to a suitable gear, a main shaft of the drilling machine is pulled to press a workpiece until the part is formed.

Owner:叶春

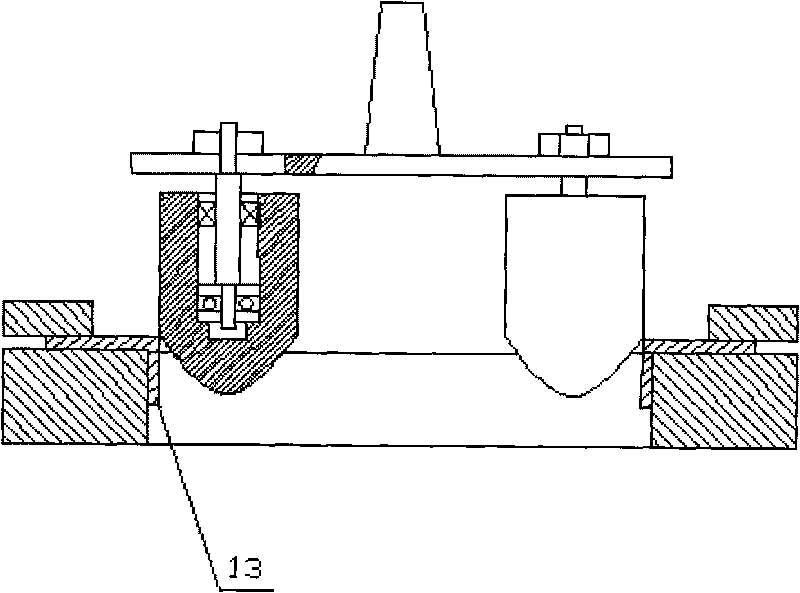

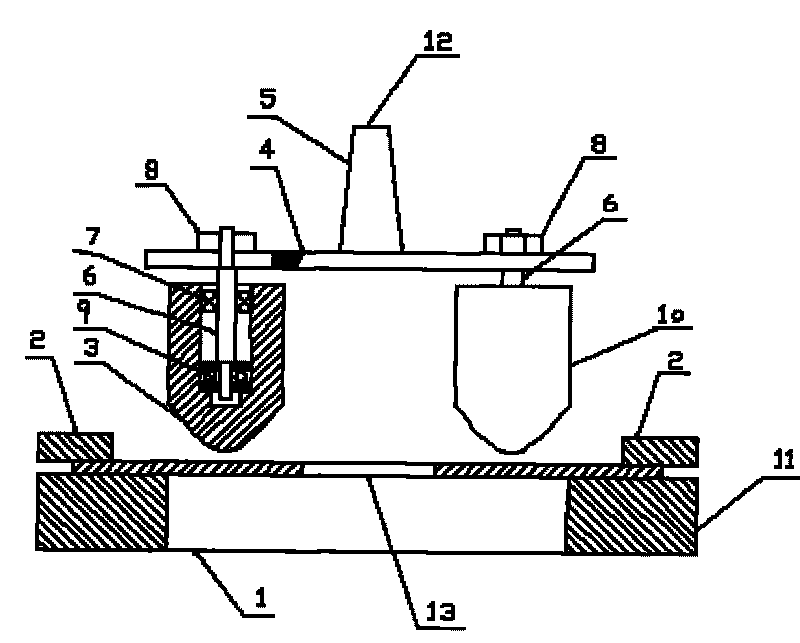

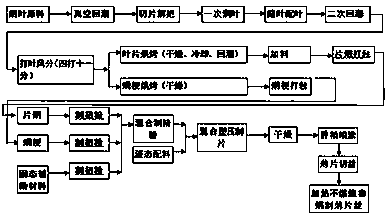

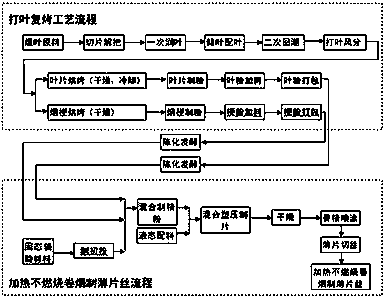

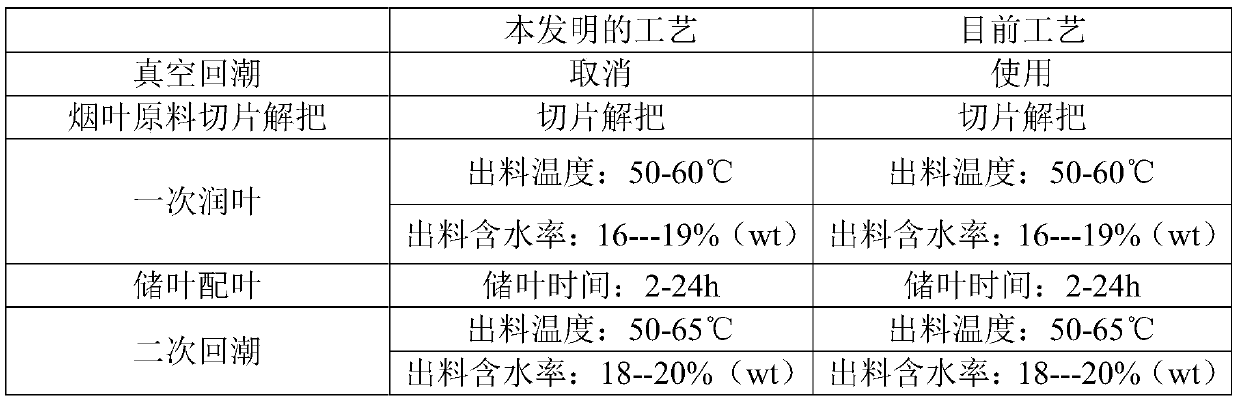

Raw material preparation process based on heating non-combustible cigarette

ActiveCN111038909ALow equipment investment costReduced steam consumptionTobacco preparationTobacco treatmentProcess engineeringEnvironmental geology

The invention relates to a raw material preparation process based on a heating non-combustible cigarette, and belongs to the technical field of non-combustible cigarette processing. The raw material preparation process combines the requirements of the heating non-combustible cigarette for making sheets, aims at the requirements of tobacco enterprises for heating non-combustible cigarette special tobacco sheets for tobacco raw materials, comprehensively designs a redrying process flow and a manufacturing process flow of heating non-combustible cigarette special tobacco sheet shreds, and comprehensively optimizes the flow. The process comprises the following steps of a threshing redrying vacuum moisture regaining process is cancelled, a threshing air segmentation screening process is cancelled, a leaf baking machine moisture regaining link is cancelled, a leaf powder making process is added in a leaf finished product section, a tobacco stem powder making process is added in a tobacco stem treatment section, and fermentation is carried out after powder making, so that the tobacco leaf loss is reduced, the equipment investment and the production operation energy consumption are saved,meanwhile, the tobacco leaf sheets which better meet the requirements of the heating non-combustible cigarette are prepared, the cigarette quality is higher, the process belongs to the initiation of the preparation process of the heating non-combustible cigarette sheets, and has a pilot effect on the preparation process of the heating non-combustible cigarette sheets.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

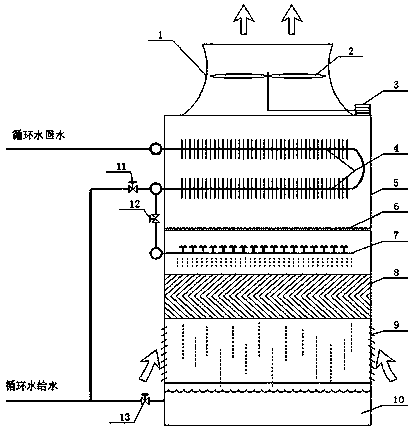

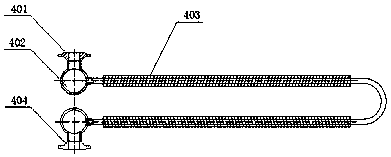

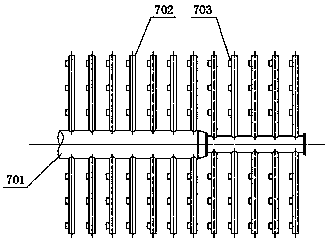

Dry and wet combined circulating water cooling tower

PendingCN107631648ALong time without waterLow equipment investment costStationary conduit assembliesStationary tubular conduit assembliesChemical industryElectricity

A dry and wet combined circulating water cooling tower comprises a tower body. The cooling tower is of an air drawing type structure. A dry cooling section and a wet cooling section are sequentially installed on the portion, below the air drawing structure, of the tower body. A dry cooling section body is a horizontally arranged dry pipe bundle. The wet cooling section sequentially comprises a dehydrator, a water distributing device, spraying filler, blinds and a water tank. The dry pipe bundle is divided into two branches at the outlet, wherein one branch is provided with a dry pipe bundle outlet valve, then communicates with a circulating water supply pipeline and leads into the water tank via a water tank outlet valve, and the other branch is provided with a water distributing header pipe valve and then communicates with a water distributing header pipe of the water distributing device. The dry and wet combined circulating water cooling tower solves the problems that an open type circulating water cooling tower is large in water consumption, and a closed type circulating water cooling device is large in investment, high in electricity consumption and difficult to popularize, andthe dry and wet combined circulating water cooling tower saves energy and water and is suitable for various circulating water cooling stations of the metallurgy industry, the electrical industry, theoil refining industry, the chemical industry and the like.

Owner:GANSU LANPEC TECH +2

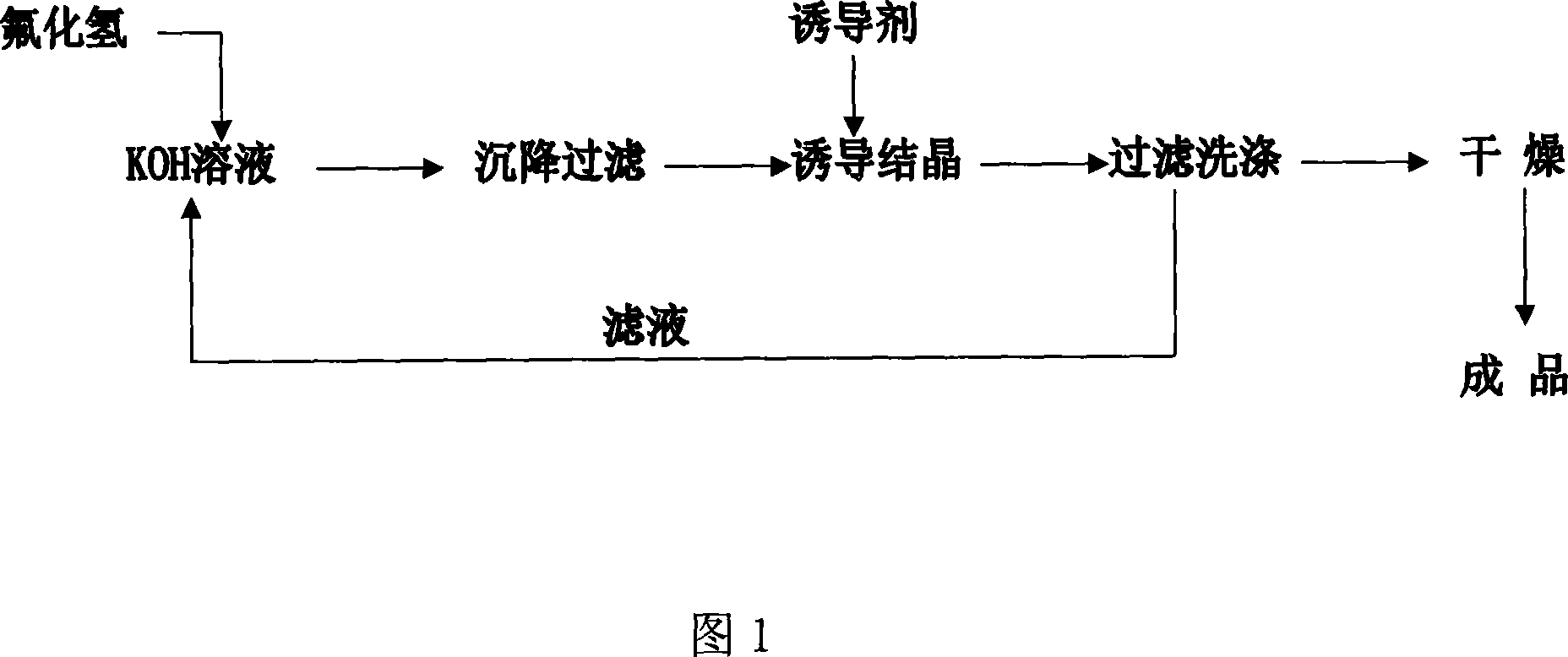

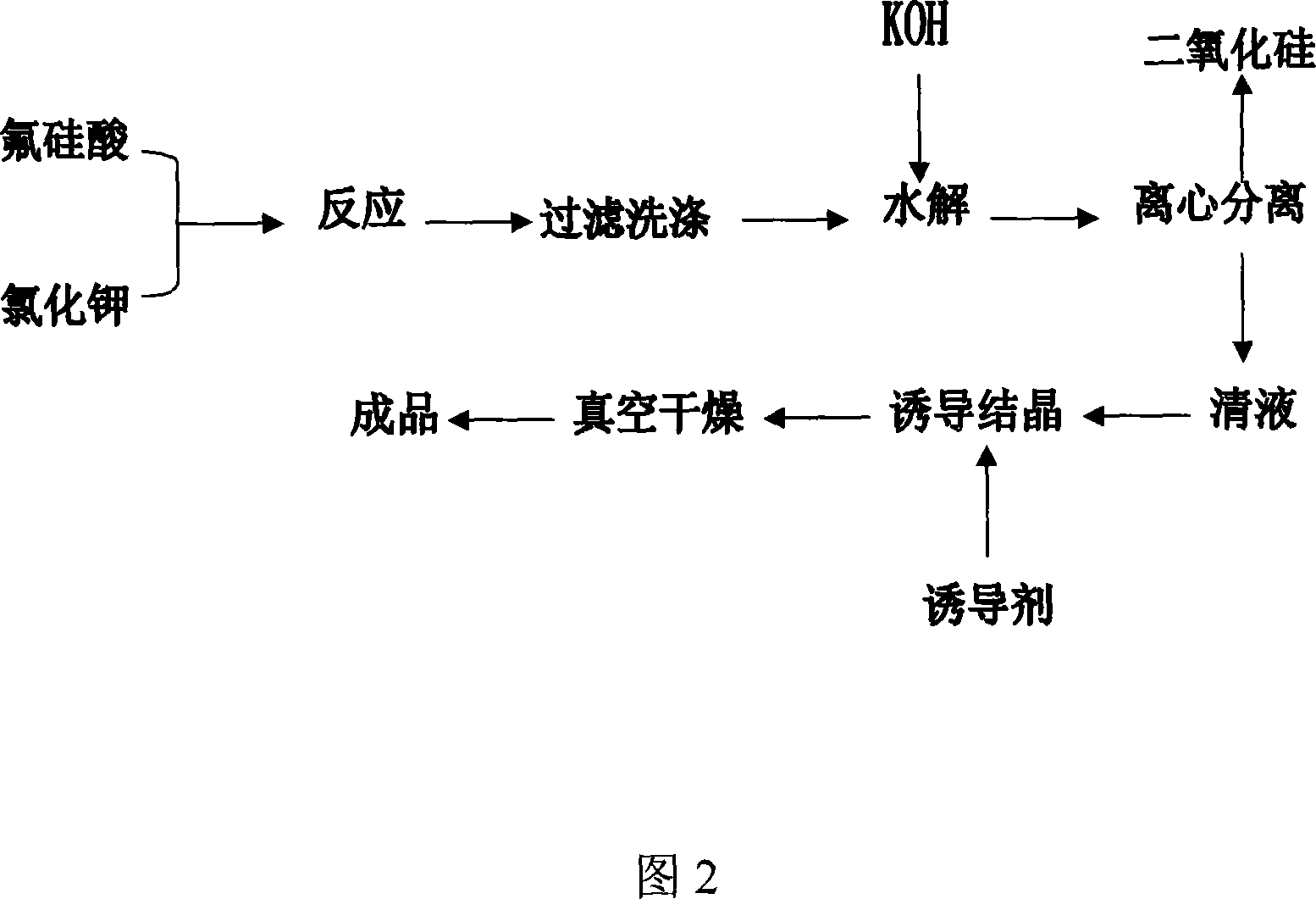

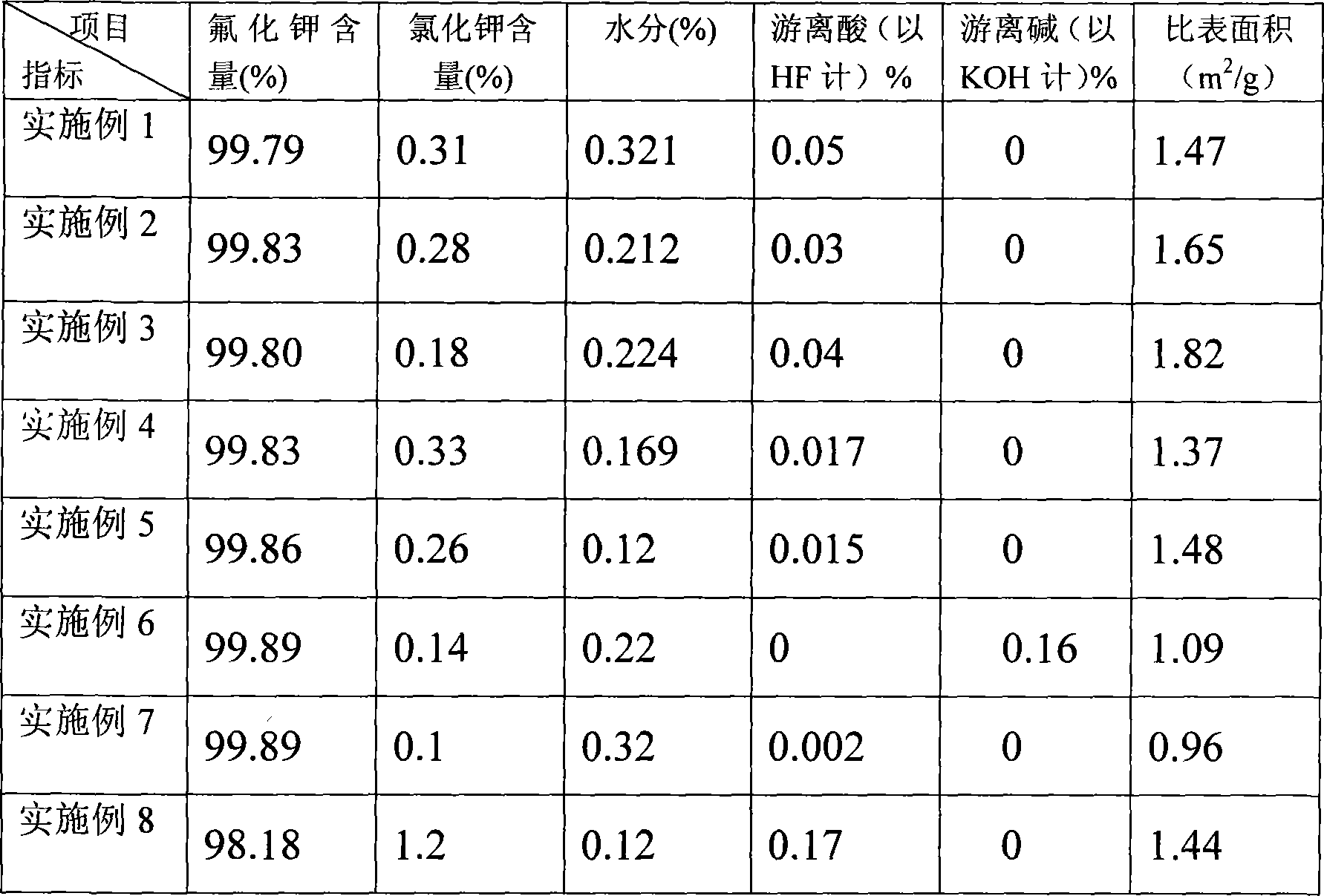

Method for preparing potassium fluoride in high activity

InactiveCN101049947AShorten drying timeLarge specific surface areaAlkali metal fluoridesPotassium fluorideChemical products

This invention relates to a method for preparing a chemical product, i.e., high-activity KF. This invention adopts the traditional method for preparing KF, i.e., neutralization method or hydrolysis method, which comprises: (1) preparing KF aqueous solution by neutralization method or hydrolysis method; (2) controlling the ratio of the raw materials to control the end pH value of the reaction as well as the final concentration of the reaction solution; (3) precipitating the reaction solution, and taking the supernatant to obtain KF aqueous solution; (4) cooling KF aqueous solution, and adding inducer to obtain KF crystal; (5) vacuum-filtering the KF crystal, and drying the filter cake to obtain high-activity KF product. The method large reduces the energy consumption for preparing high-activity KF.

Owner:云南云天化国际化工有限公司

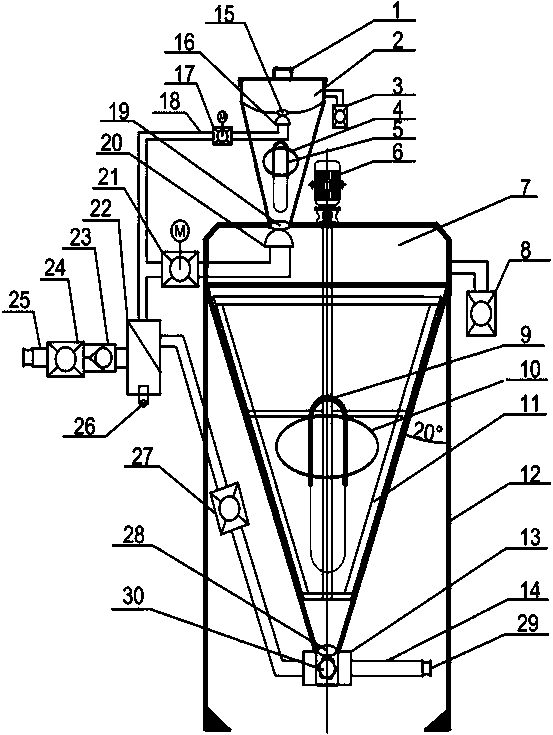

Dry reagent powder spraying system

InactiveCN110201575AReduce usageSolve processingRotary stirring mixersTransportation and packagingSewageTherapeutic effect

The invention discloses a dry reagent powder spraying system. The dry reagent powder spraying system is characterized in that the dry reagent powder spraying system comprises a reagent feeding system,an air feeding system, a mixing system, a reagent discharging system, a regulating system and a drying system; the body of the dry reagent powder spraying system is a circular tank with a tapered bottom, and is used as a mixing tank for the dry reagent powder spraying system, and the reagent feeding system, the air feeding system, the reagent discharging system, the regulating system and the drying system are all attached and fixed to the mixing tank, and are mutually regulated to control the feeding of a dry reagent powder. In previous sewage treatment, bubbles are often generated at the surface of sewage due to the drop, and the reagent powder cannot sufficiently react with the sewage and is discharged after meeting the bubbles, so the addition amount of the reagent powder is increased,poor sewage treatment effect and reagent wastes are caused, and the sewage treatment cost is increased. The dry reagent powder spraying system provided by the invention can overcome the above deficiencies of the prior art, and can directly and fully contact the reagent powder with the sewage, improve the treatment effect, reduce the use amount of the reagent powder and reduce the running cost.

Owner:北京耐思特环境科技有限公司

Method for producing high-purity zinc sulfide and co-producing acetic acid and sodium chloride by using sodium hydrosulfite filter residues

InactiveCN102092779AEasy to operateLow equipment investment costPreparation from carboxylic acid saltsZinc sulfidesChemistryHydrogen chloride

The invention provides a method for producing high-pure zinc sulfide and co-producing acetic acid and sodium chloride by using sodium hydrosulfite filter residues. The method is as follows: reacting the sodium hydrosulfite filter residues with hydrogen chloride so as to obtain a mixture liquid containing zinc chloride; filtering to obtain a zinc chloride containing solution, a sodium acetate solution and a hydrogen sulfide solution; carrying out a reaction on the zinc chloride-containing solution, sodium acetate solution and hydrogen sulfide solution in a pure substance mass ratio of zinc chloride to sodium acetate to hydrogen sulfide so as to obtain a zinc sulfide-containing precipitate, the mixture of sodium acetate and hydrogen sulfide; filtering the mixture of zinc sulfide-containing precipitate, sodium acetate and hydrogen sulfide to obtain zinc sulfide filter cakes and a solution containing acetic acid and sodium chloride; washing, drying and smashing the zinc sulfide filter cakes so as to obtain a zinc sulfide powder product; carrying out reduced pressure distillation on the solution containing acetic acid and sodium chloride, wherein the acetic acid is evaporated and escaped in a form of acetic acid gas; carrying out condensation rectification to obtain pure high-concentration acetic acid, wherein the residual is a sodium chloride solution after the acetic acid is evaporated and escaped; continuously distilling the sodium chloride solution so as to obtain a saturated or supersaturated sodium chloride solution, cooling so as to precipitate out sodium chloride crystals; and filtering the sodium chloride crystals in the filter to obtain the sodium chloride product.

Owner:汪晋强

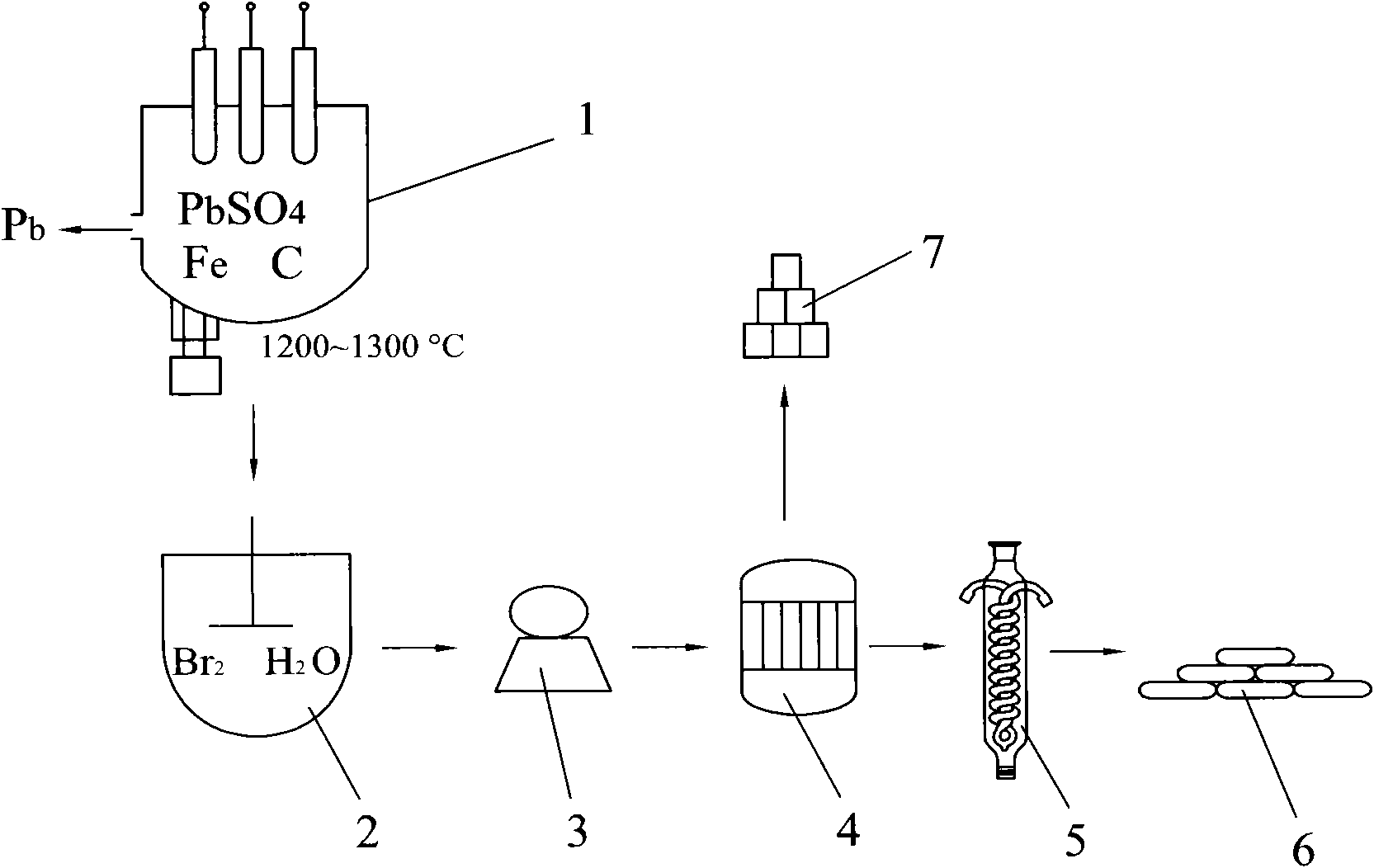

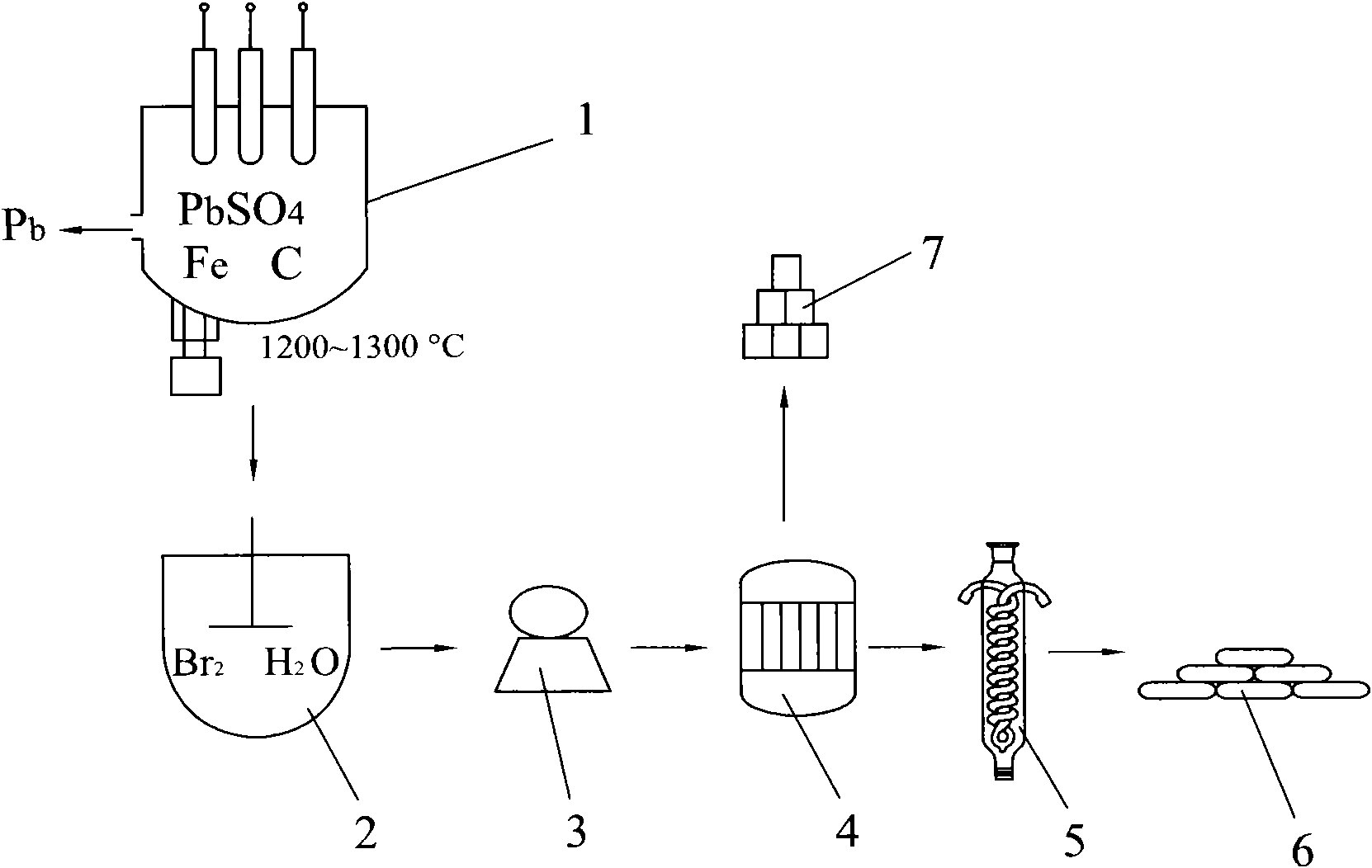

Method for preparing sulfuric acid and hydrogen bromide from sulfur dioxide waste gas

InactiveCN101966983AEasy to operateLow equipment investment costSulfur compoundsBromine/hydrogen-bromideChemistryHigh concentration

The invention provides a method for preparing sulfuric acid and hydrogen bromide from sulfur dioxide waste gas. The method comprises the following steps of: performing chemical reaction of sulfuric dioxide and bromine water to obtain sulfuric acid and hydrogen bromide-containing reaction solution; suction filtering to obtain clear solution and a little amount of filter cake impurity; burning the filter cake impurity; evaporating the clear solution to first distill the hydrogen bromide and cooling the solution to obtain a hydrogen bromide product; and continuously evaporating and concentrating the remaining solution to obtain saturated solution of sulfuric acid and cooling the solution to obtain the high-concentration sulfuric acid product. By the method, waste material is changed into things of value, the sulfuric dioxide waste gas is effectively converted into zinc sulfite with great economic significance and the potential economic value is fully explored and utilized; meanwhile the method solves the problem of environmental pollution caused by comprehensive utilization and treatment of waste slag obtained from the production of lithopone and provides environmental guarantee for the comprehensive utilization and treatment of the waste slag obtained from the production of the lithopone.

Owner:汪晋强

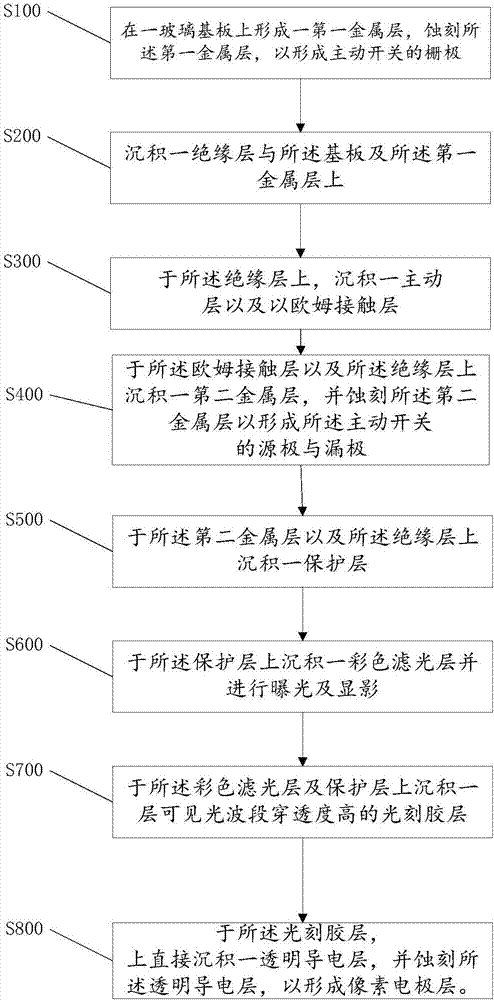

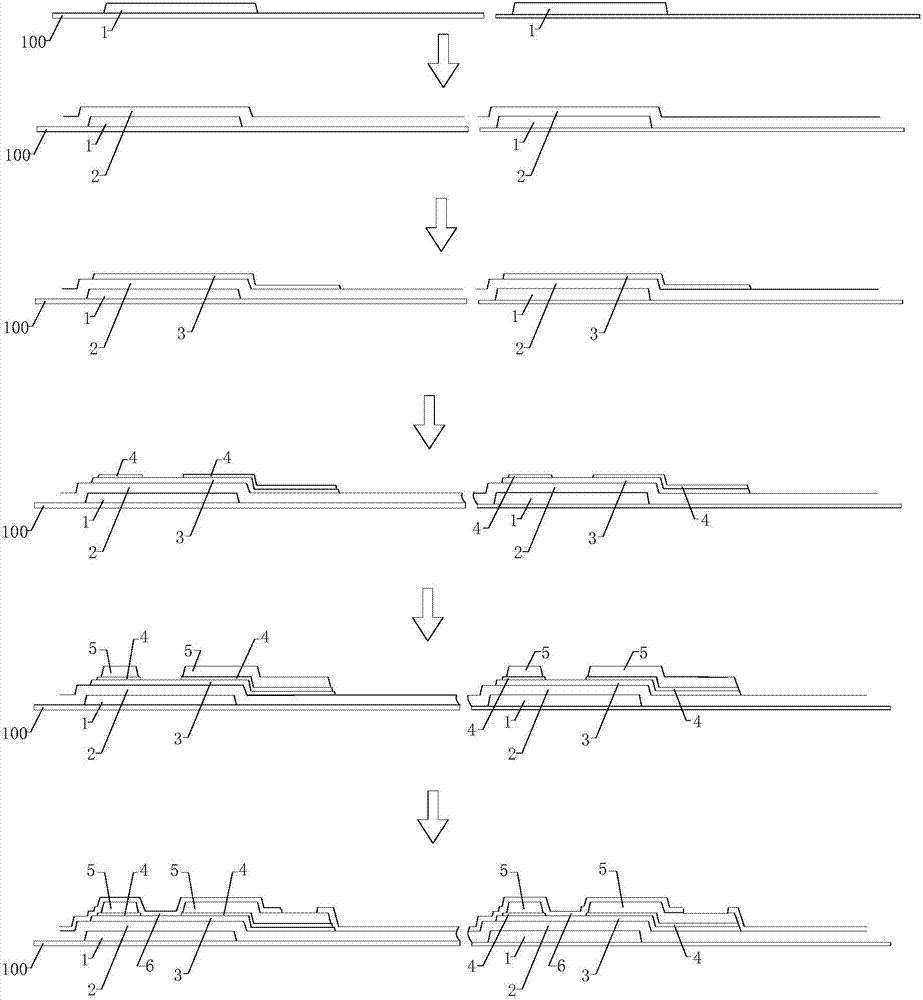

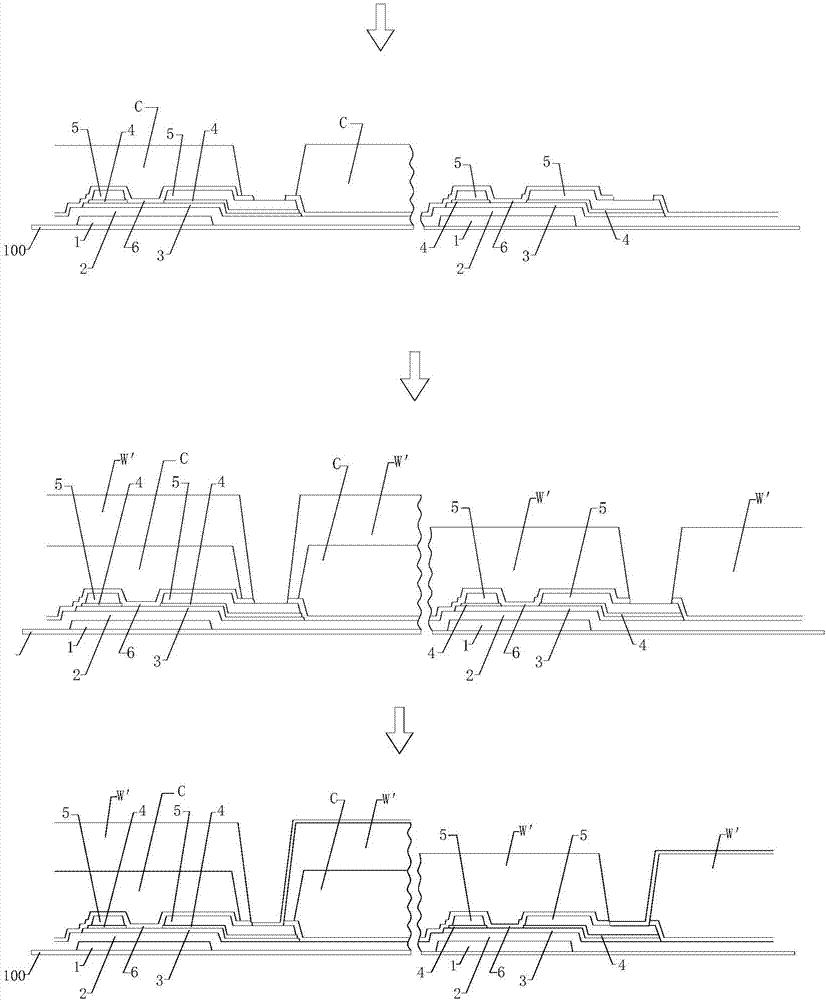

Active switch array substrate and manufacturing method thereof and display panel

InactiveCN107086220ALow equipment investment costShorten production timeSolid-state devicesSemiconductor/solid-state device manufacturingPhotoresistActive switch

The invention is suitable for the technical field of display screens, and provides an active switch array substrate and a manufacturing method thereof and a display panel. The coating, exposure and development process of transparent photoresistance is not required in the manufacturing process of the substrate, and film forming operation of a second insulating layer is not required; and a photoresist layer is not required to be removed subsequently and the photoresist layer is reserved on the panel and the subsequent pixel electrode manufacturing process is continued. Therefore, the equipment investment cost for producing the transparent photoresistance and the subsequent mask plate cost can be saved by producing the substrate and the display panel having the substrate, and a white, red, green and blue four-color technical panel can be produced under the condition of slightly changing the red, green and blue three-color production line; meanwhile, the production time can be shortened, the production cost can be reduced and the efficiency and the productivity of the production line can be enhanced.

Owner:HKC CORP LTD +1

Method for clean production of titanium dioxide by using sodium hydroxide

ActiveCN100542968CObvious superiorityLow reaction temperaturePigmenting treatmentTitanium dioxideResource utilizationSeparation technology

The invention belongs to the field of preparation of inorganic metal compounds and processing of mineral resources, and in particular relates to a method for cleanly producing titanium dioxide (titanium self-powder) from high-titanium slag and using sodium hydroxide. Using high-titanium slag as raw material, make it react with sodium hydroxide at 350-550°C to prepare an intermediate product, then wash (or carbonate), acid dissolve, reduce, hydrolyze, and calcinate the intermediate product to prepare anatase or Rutile titanium dioxide. The alkali cycle, acid cycle and separation technology of the present invention greatly reduces production energy consumption, simplifies the production process, reduces equipment investment, improves process operability, and provides comprehensive utilization of titanium resources and preparation of titanium dioxide (titanium dioxide) an effective way.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method and device for producing mono-nitro toluence by adiabatic nitration through self-mixing tubular reactor

InactiveCN103396316BWell mixedGood radial blending effectNitro compound preparationPhase splittingNitration

Owner:JIANGSU HUAIHE CHEM

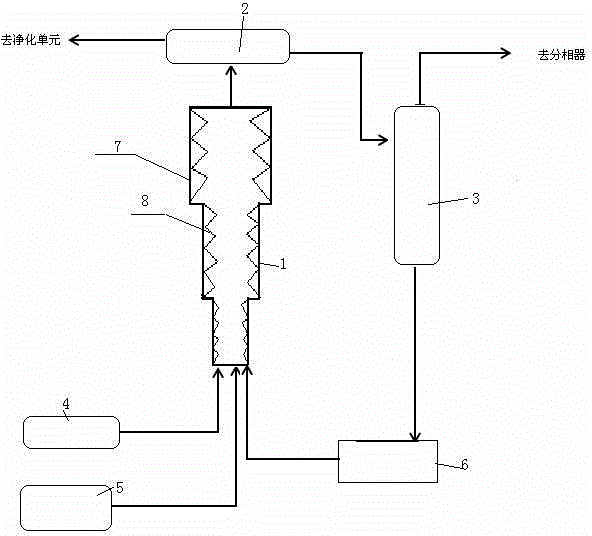

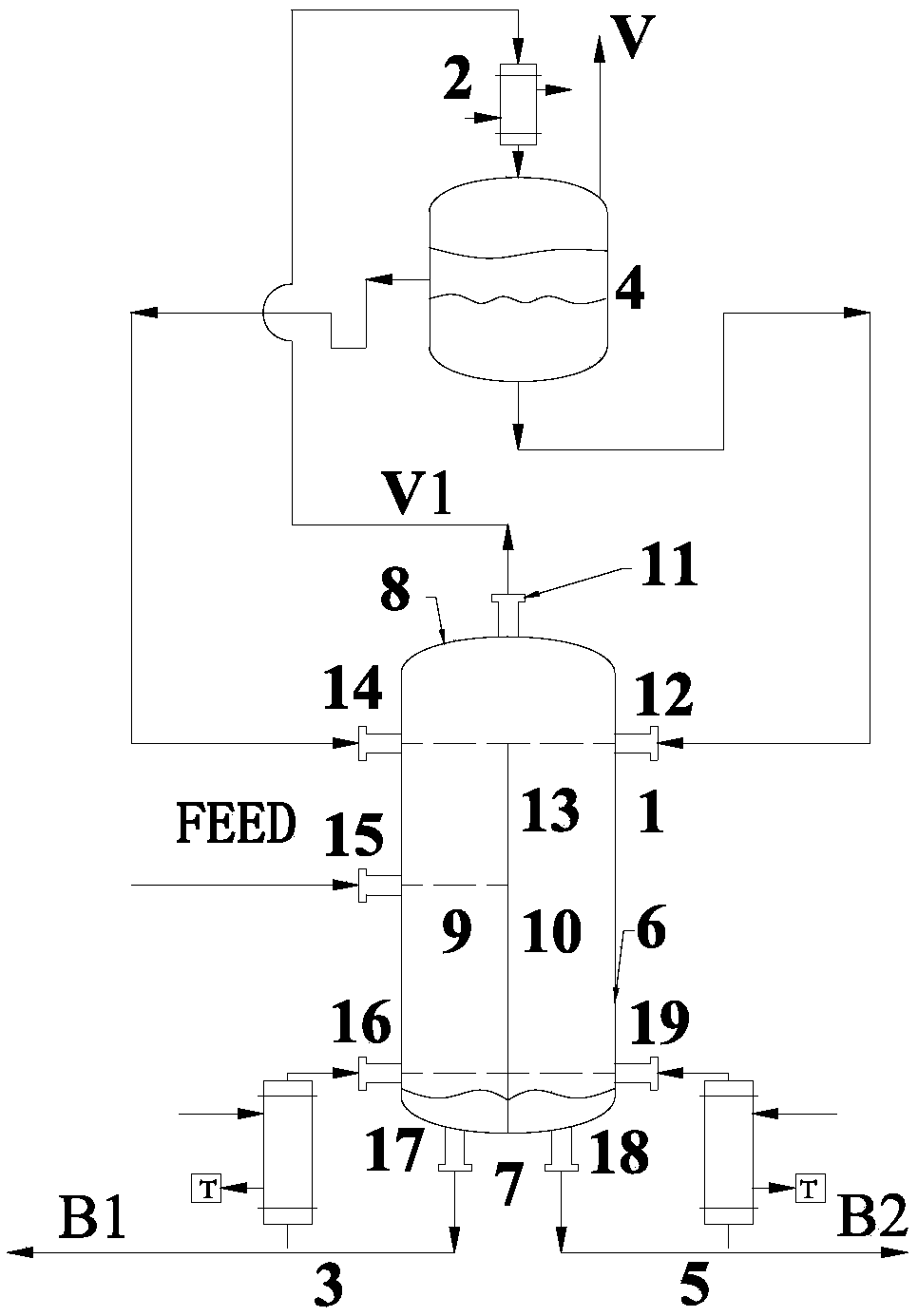

Separation process of higher ketone, water and carbon dioxide mixture

InactiveCN109608319ASimple processLow equipment investment costOrganic compound preparationCarbonyl compound separation/purificationChemistryKetone

The invention relates to a separation process of a higher ketone, water and carbon dioxide mixture. The process includes: letting to-be-separated higher ketone, water and carbon dioxide raw materialsenter a dividing wall column left half side (9) from a to-be-separated raw material inlet (15) for vapor-liquid separation, making the gas phase come out of a gas phase outlet (11) of the dividing wall column and enter a condenser (2), enabling the obtained condensate liquid to enter a vapor-liquid-liquid separator (4), conducting standing for 10-30min for full vapor-liquid-liquid balance, then performing separation to obtain a carbon dioxide-rich vapor phase, a ketone-rich phase and a water-rich phase, letting the ketone-rich phase flow back to the dividing wall column left half side (9) , making the water-rich phase flow back to a dividing wall column right half side (10), extracting the obtained carbon dioxide-rich vapor phase for exhausting, acquiring wastewater with trace ketone fromthe column bottom of the dividing wall column right half side (10), and acquiring a higher ketone product from the dividing wall column left half side (9). The process provided by the invention has the advantages of good separation effect, and substantial saving of equipment investment cost and installation space.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com