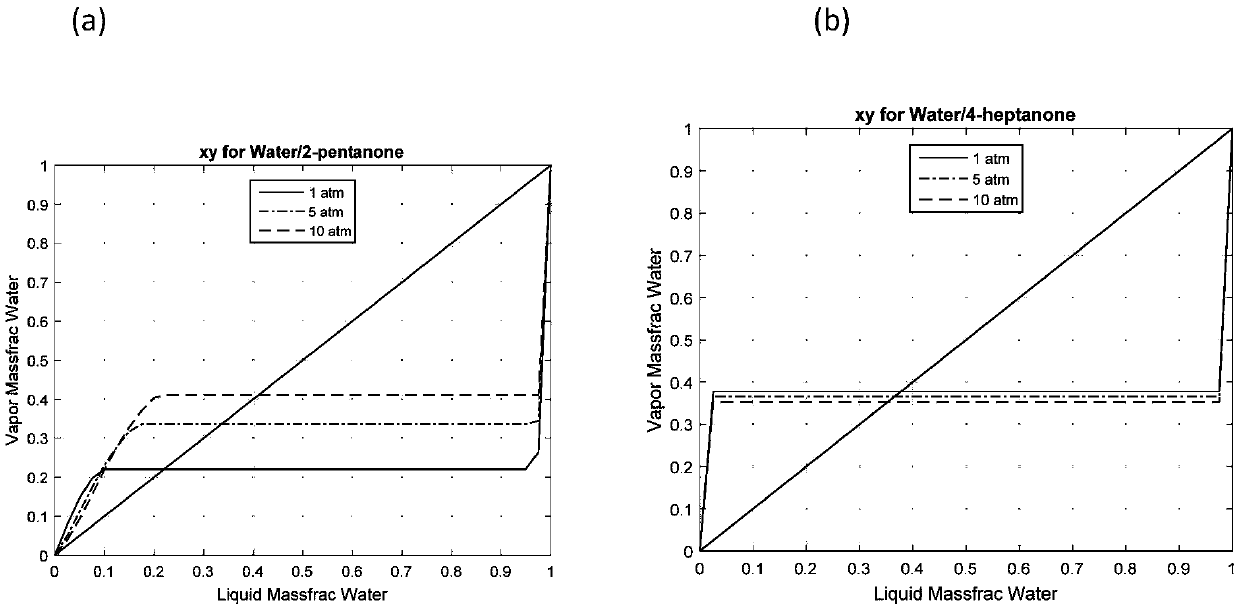

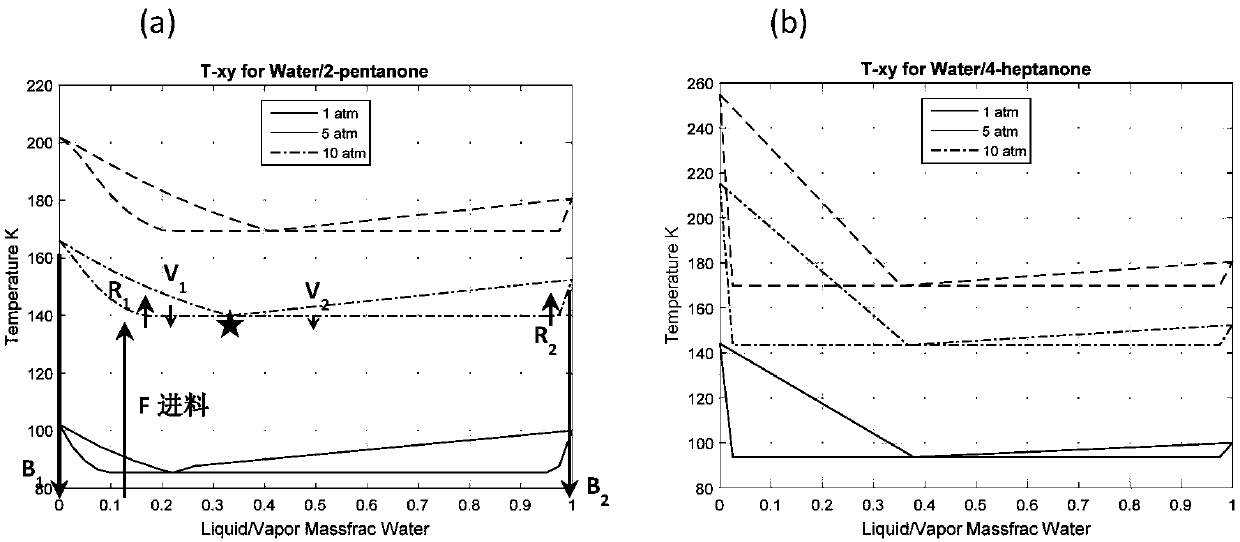

Separation process of higher ketone, water and carbon dioxide mixture

A technology for carbon dioxide and mixtures, which is applied in the separation/purification of carbonyl compounds, the preparation of organic compounds, and the preparation of carbon-based compounds. It can solve the problems of no research and patent reports on the separation of system mixtures, and it is difficult to achieve high-purity separation. The degree of equipment integration, the reduction of equipment investment costs, and the effect of low equipment investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

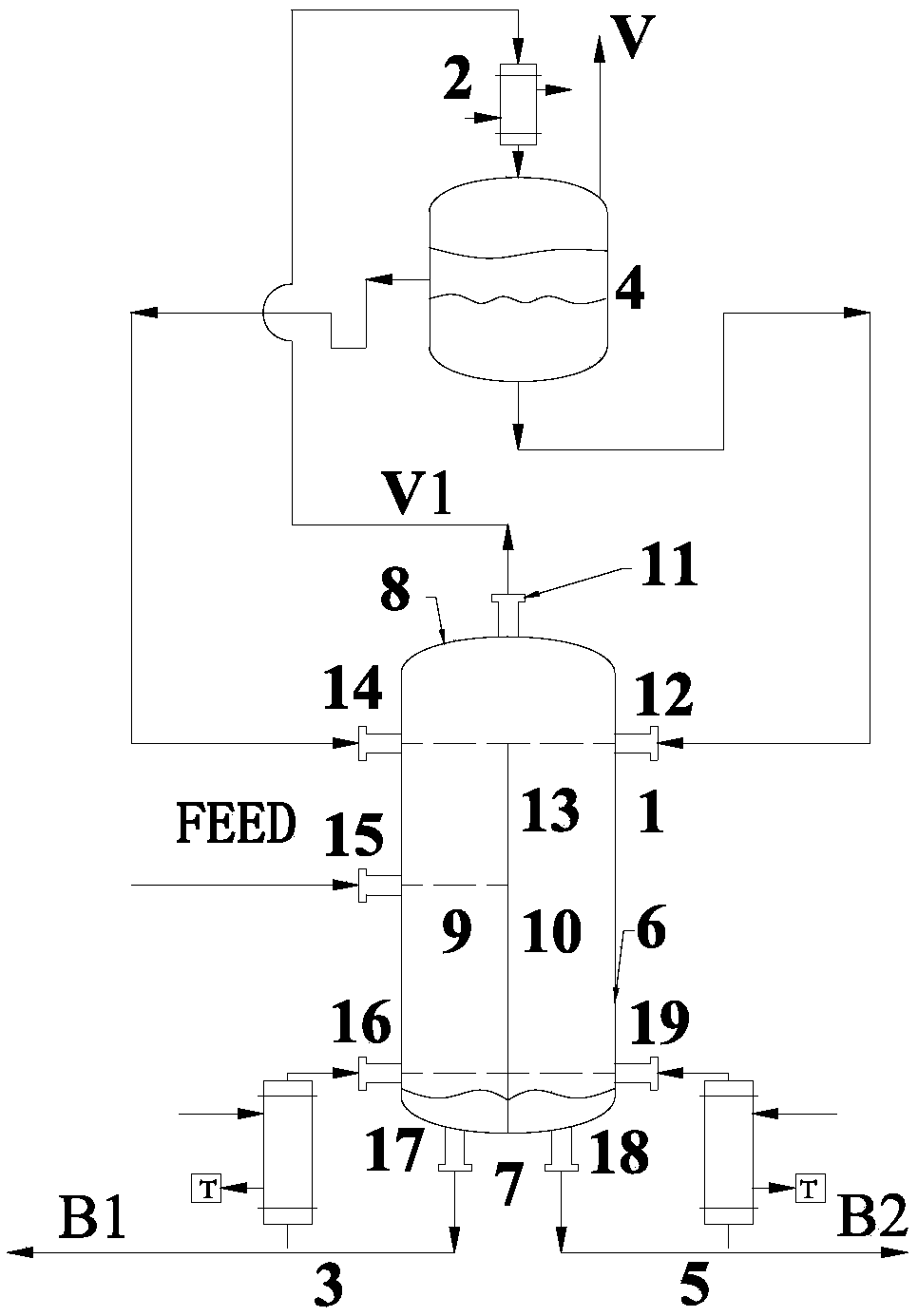

[0051] In specific embodiment 1, technique of the present invention comprises following configuration and step:

[0052] The partition tower is to add a partition parallel to the axial direction of the shell inside the ordinary rectification tower, and the shell is divided into the left half of the partition tower 9 and the right half of the partition tower 10; the bottom of the partition directly reaches the lower head of the casing , the top of the partition can directly reach the upper head, and some space can also be reserved on the top; the lower part of the partition and the edges on both sides are sealed with the shell; the left half of the next tower at the bottom 9 and the right half of the next tower The side 10 is equipped with a reboiler 3 and a reboiler 5 respectively, which are used to provide heat for the reboilers of the tower kettles on both sides of the tower; the top of the next wall tower is equipped with a condenser 2 and a vapor-liquid-liquid separator 4; ...

specific Embodiment 2

[0075] In specific embodiment 2, technique of the present invention comprises following configuration and step:

[0076] The partition tower is to add a partition parallel to the axial direction of the shell inside the ordinary rectification tower, and the shell is divided into the left half of the partition tower 9 and the right half of the partition tower 10; the bottom of the partition directly reaches the lower head of the casing , the top of the partition can directly reach the upper head, and some space can also be reserved on the top; the lower part of the partition and the edges on both sides are sealed with the shell; the left half of the next tower at the bottom 9 and the right half of the next tower The side 10 is equipped with a reboiler 3 and a reboiler 5 respectively, which are used to provide heat for the reboilers of the tower kettles on both sides of the tower; the top of the next wall tower is equipped with a condenser 2 and a vapor-liquid-liquid separator 4; ...

specific Embodiment 3

[0096] In specific embodiment 3, technique of the present invention comprises following configuration and step:

[0097] The partition tower is to add a partition parallel to the axial direction of the shell inside the ordinary rectification tower, and the shell is divided into the left half of the partition tower 9 and the right half of the partition tower 10; the bottom of the partition directly reaches the lower head of the casing , the top of the partition can directly reach the upper head, and some space can also be reserved on the top; the lower part of the partition and the edges on both sides are sealed with the shell; the left half of the next tower at the bottom 9 and the right half of the next tower The side 10 is equipped with a reboiler 3 and a reboiler 5 respectively, which are used to provide heat for the reboilers of the tower kettles on both sides of the tower; the top of the next wall tower is equipped with a condenser 2 and a vapor-liquid-liquid separator 4; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com