Novel flange manufacturing machine tool

A flange and machine tool technology, which is applied in the field of new flange manufacturing machine tools and flange manufacturing machine tools, can solve the problems of high initial equipment cost, not suitable for small batch, multi-variety production needs, etc., and achieves low equipment investment cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

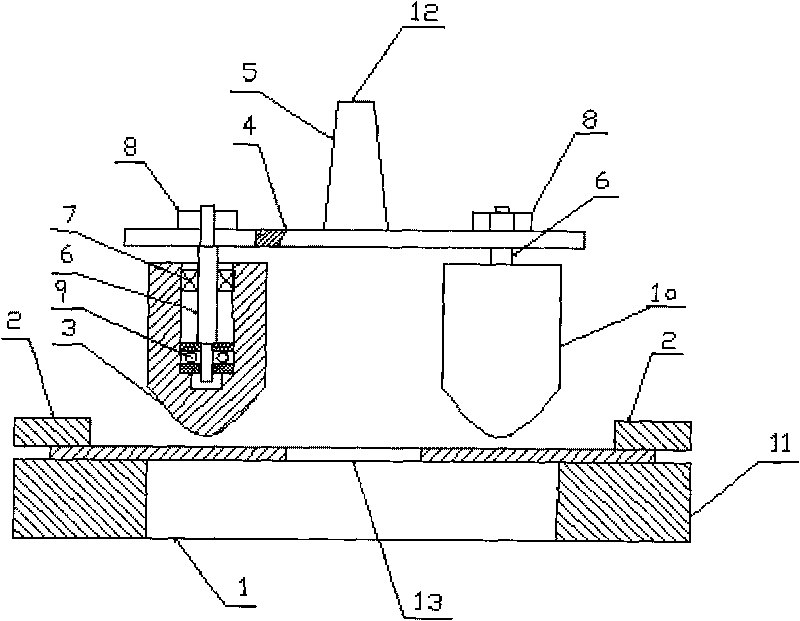

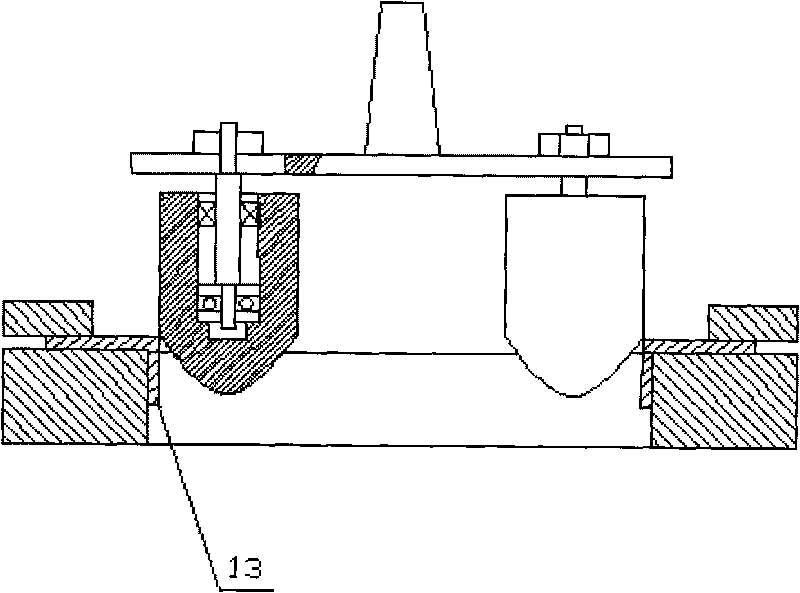

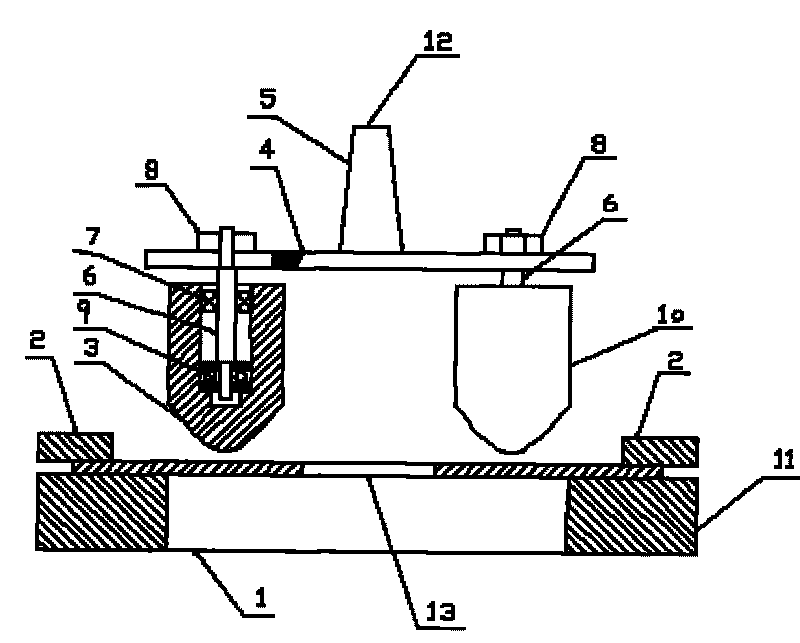

[0009] According to the relevant process of mechanical assembly, assemble the spinning head shaft (6), the radial bearing (7), the plane thrust bearing (8) with the spinning head (3), and the spinning head body (10), and ensure that the spinning head The shaft (6) rotates flexibly, and then the above-mentioned components are installed on the spinning head fixed disk (4) with nuts (9), and the spinning head fixed disk (4) and the drive shaft handle (5) are formed by an appropriate method. For fixed connection, in order to ensure the effect of spinning, the spinning head (3) should be evenly distributed in the circumferential direction of the fixed disk (4), and its number should be as appropriate as possible. The size of the transmission shaft handle (5) is matched with the corresponding drilling machine to facilitate use. After the above-mentioned components are installed, the blank material can be placed on the base (1) and pressed with the pressure plate (2), and the drilling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com