Method for preparing sulfuric acid and hydrogen bromide from sulfur dioxide waste gas

A technology of sulfur dioxide and hydrogen bromide, applied in chemical instruments and methods, bromine/hydrogen bromide, inorganic chemistry, etc., can solve problems such as environmental pollution, and achieve the effects of being suitable for popularization and application, simple operation, and low equipment investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

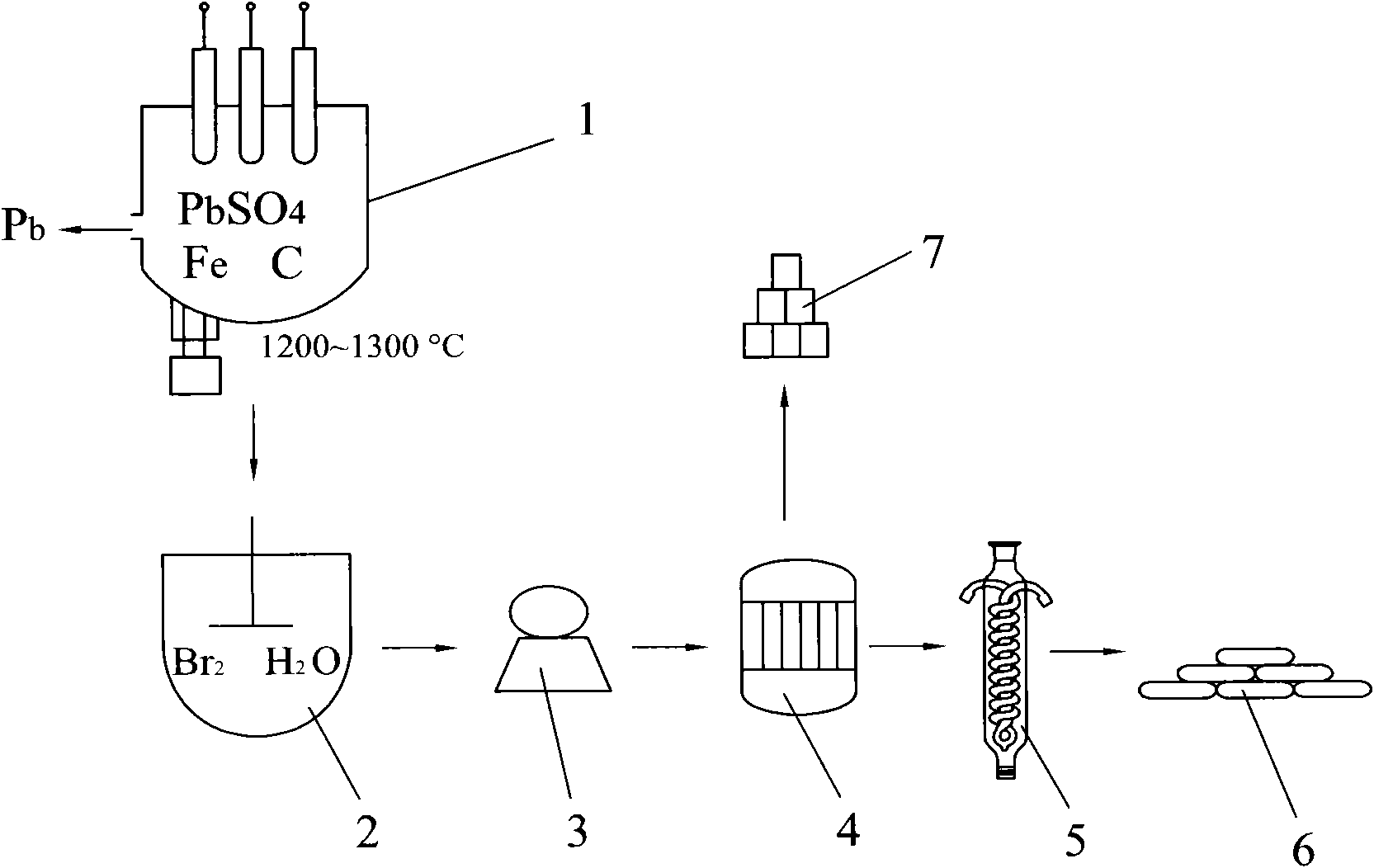

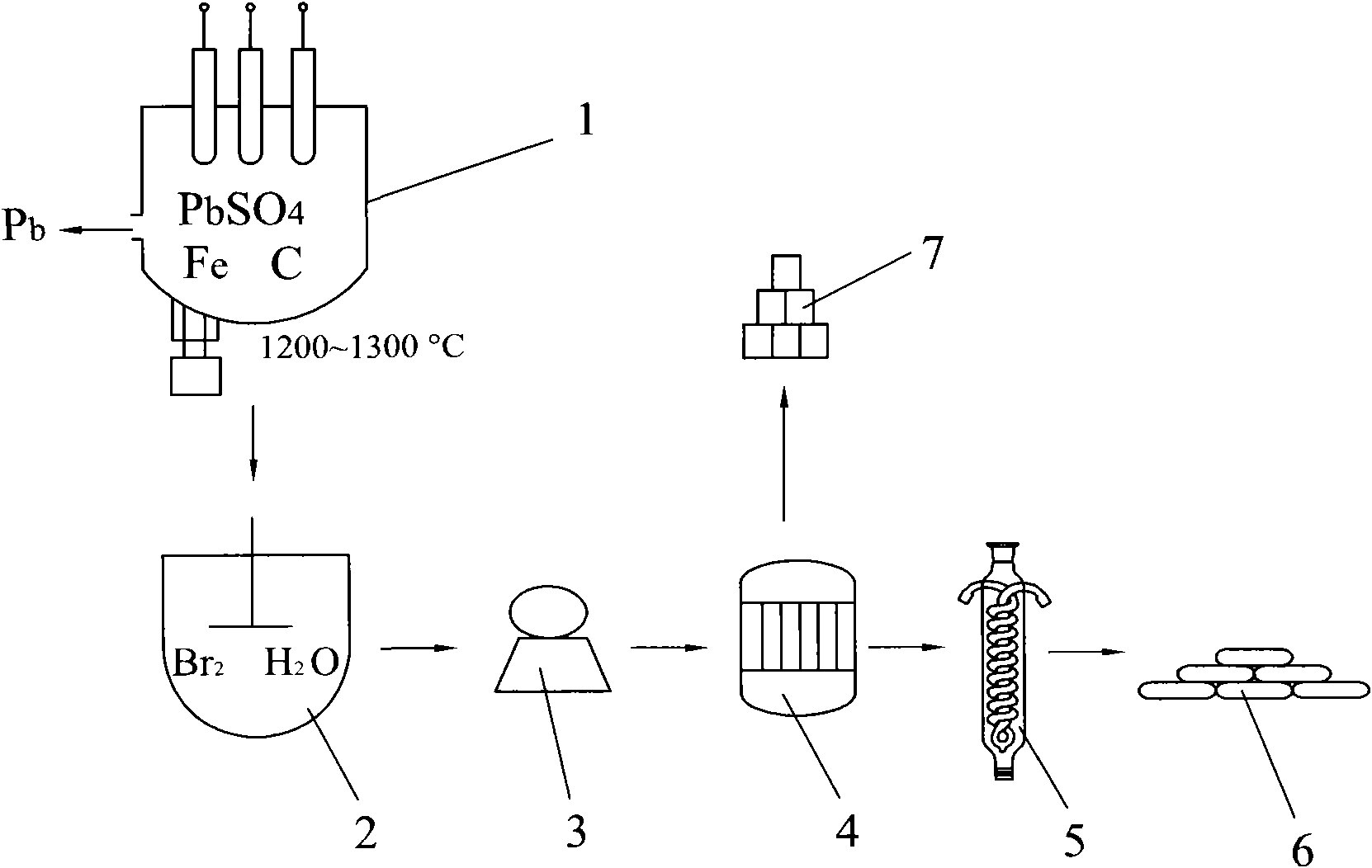

[0023] refer to figure 1 , a method for preparing sulfuric acid and hydrogen bromide from sulfur dioxide waste gas, the sulfur dioxide gas containing 64kg of sulfur dioxide is passed into the enamel reactor (2) containing bromine aqueous solution according to the mass ratio of bromine and sulfur dioxide as 1:0.4 , slowly start the stirrer to make it carry out chemical reaction, obtain the reaction liquid containing sulfuric acid and hydrogen bromide; With the suction filtration of the reaction liquid containing sulfuric acid and hydrogen bromide through suction filter (3), obtain clear solution and a small amount of Filter cake impurities; filter cake impurities are incinerated; the resulting clear solution is sent to the evaporator (4) for evaporation, hydrogen bromide is first distilled out, and then cooled by a serpentine cooling tube (5) to obtain hydrogen bromide (6) product , wherein the pure substance quality of hydrogen bromide is 162kg; When the residual liquid contin...

Embodiment 2

[0026] refer to figure 1 , a kind of method that prepares sulfuric acid and hydrogen bromide with sulfur dioxide exhaust gas, the sulfur dioxide gas that will contain 96kg sulfur dioxide = is 1: 0.2-0.6 according to the pure matter mass ratio of bromine and sulfur dioxide, pass into the enamel reactor that fills the aqueous solution of bromine ( 2) In, slowly start the agitator to make it carry out chemical reaction, obtain the reaction liquid containing sulfuric acid and hydrogen bromide; Suction filter the reaction liquid containing sulfuric acid and hydrogen bromide through suction filter (3), obtain clear solution and a small amount of filter cake impurities; filter cake impurities are incinerated; the clarified solution of the gained is sent into the evaporator (4) to evaporate, and the hydrogen bromide is first distilled out, and then cooled through the serpentine cooling pipe (5) to obtain hydrogen bromide ( 6) product, wherein the pure substance quality of hydrogen bro...

Embodiment 3

[0029] refer to figure 1, a method for preparing sulfuric acid and hydrogen bromide from sulfur dioxide waste gas, the sulfur dioxide gas containing 32kg sulfur dioxide is passed into the enamel reactor (2) containing bromine aqueous solution according to the mass ratio of bromine and sulfur dioxide as 1:0.2 , slowly start the stirrer to make it carry out chemical reaction, obtain the reaction liquid containing sulfuric acid and hydrogen bromide; With the suction filtration of the reaction liquid containing sulfuric acid and hydrogen bromide through suction filter (3), obtain clear solution and a small amount of Filter cake impurities; filter cake impurities are incinerated; the resulting clear solution is sent to the evaporator (4) for evaporation, hydrogen bromide is first distilled out, and then cooled by a serpentine cooling tube (5) to obtain hydrogen bromide (6) product , wherein the pure substance mass content of hydrogen bromide is 81kg; When the residual liquid contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com