Dry reagent powder spraying system

A technology of dry powder and air intake system, applied in the direction of dissolution, mixer, chemical instruments and methods, etc., can solve the problems of complex equipment structure, complex process flow, difficult operation, etc., to achieve improved treatment effect, simple operation, and reduced operation cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

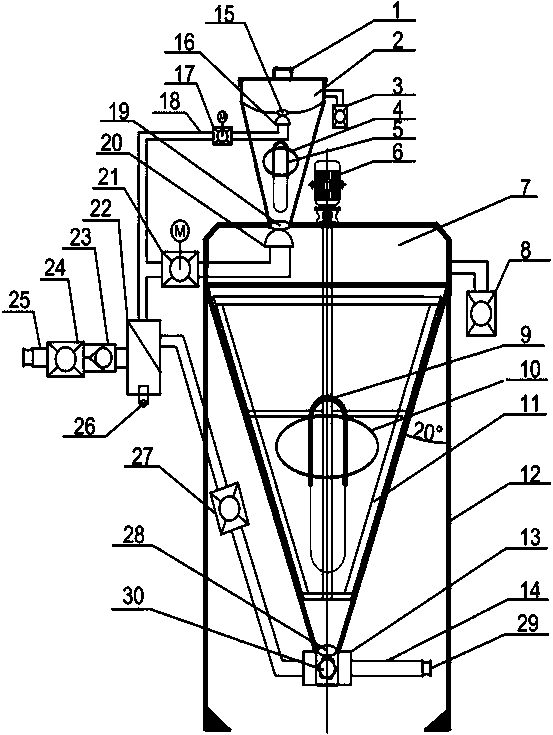

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

[0009] A dry powder spraying system of the present invention is mainly composed of a medicine storage tank 2, a gas-solid mixing tank 7, and a mixer 6 as the main equipment; the medicine storage tank 2 is equipped with a medicine storage tank sealing cover 1, a vent valve I, an inspection port I, and a sight glass Ⅰ, drug inlet Ⅰ, sealing air cap Ⅰ, solenoid valve Ⅰ, air pipeline 18; gas-solid mixing tank 7 is equipped with vent valve Ⅱ, sight glass Ⅱ, inspection port Ⅱ, drug inlet Ⅱ, sealing gas cap Ⅱ, electromagnetic Valve II, air dehumidifier 22, air pipeline 18, one-way valve 23, air intake valve 24, regulating valve 27; drug storage tank 2 is fixed on the top of gas-solid mixing tank 7 and passes through drug inlet II and gas-solid mixing tank 7 connected; the stirring blade 11 is connected with the stirrer 6, and the stirrer 6 is fixed at the top center of the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com