Preparation method of multielement composite scale inhibitor

A multi-component composite and antiscalant technology, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., can solve the problems of low scale inhibition rate and large performance difference, and achieve anti The effect of high scale efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

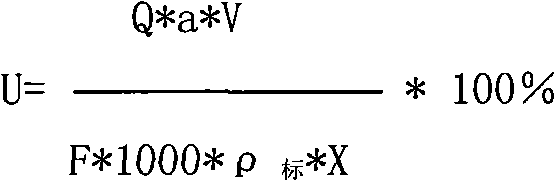

Image

Examples

Embodiment 1

[0018] The method embodiment 1 of the present invention, its steps are:

[0019] (1) Add 50kg of melamine, 100kg of 40% hydrolyzed maleic anhydride, 100kg of ammonium chloride, and 100kg of formaldehyde into a container with a volume of 1000L, stir and dissolve, and react for 1 hour at 80±5°C;

[0020] (2) Add 100kg of urea, 100kg of ammonium chloride, and 100kg of formaldehyde, and react for 3 hours at 90±5°C;

[0021] (3) Add 100kg of 30% polyacrylic acid and 100kg of 2% cationic polyacrylamide, and react at 70±5°C for 0.5 hours;

[0022] (4) After cooling to room temperature, the multi-component polymeric reverse osmosis scale inhibitor can be prepared.

Embodiment 2

[0023] The method embodiment 2 of the present invention, its steps are:

[0024] (1) Add 50kg of melamine, 50kg of 30% hydrolyzed maleic anhydride, 100kg of ammonium chloride, and 150kg of formaldehyde into a constant temperature reaction kettle with a volume of 1200L and a stirrer. After stirring and dissolving, react at 80±5°C for 2 hours ;

[0025] (2) Add 100kg of urea, 150kg of ammonium chloride, and 100kg of formaldehyde, and react at 90±5°C for 2 hours;

[0026] (3) Add 100kg of 15% polyacrylic acid and 100kg of 0.5% cationic polyacrylamide, and react for 1 hour at 70±5°C;

[0027] (4) After cooling to room temperature, the multi-component polymeric reverse osmosis scale inhibitor can be prepared.

Embodiment 3

[0028] Embodiment 3 of the inventive method, its steps are:

[0029] (1) Add 50kg of melamine, 50kg of 40% hydrolyzed maleic anhydride, 50kg of ammonium chloride, and 100kg of formaldehyde into a container with a volume of 1000L, stir and dissolve, and react at 80±5°C for 0.5 hours;

[0030] (2) Add 50kg of urea, 50kg of ammonium chloride, and 150kg of formaldehyde, and react at 90±5°C for 4 hours;

[0031] (3) Add 150kg of 30% polyacrylic acid and 150kg of 2% cationic polyacrylamide, and react for 1 hour at 70±5°C;

[0032] (4) After cooling to room temperature, the multi-component polymeric reverse osmosis scale inhibitor can be prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com