Dry and wet combined circulating water cooling tower

A combined cycle and water cooling tower technology, applied in the field of heat transfer, can solve the problems of high one-time investment of evaporative air coolers, large water consumption of open cooling water towers, and poor economy, and achieve easy promotion, small air volume, and water stop time long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further clarified through the following examples, but the present invention is not limited to the following examples.

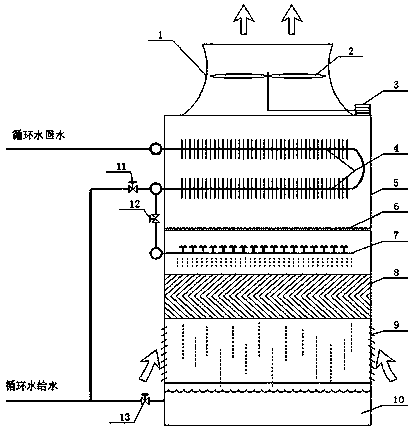

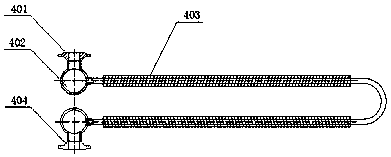

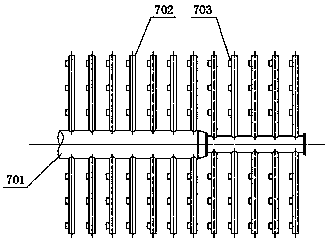

[0022] figure 1 It is a schematic diagram of the structure of the dry-wet combined cycle water cooling tower, including: ventilator 1, fan 2, motor 3, dry tube bundle 4, tower body 5, water eliminator 6, water distribution device 7, spray packing 8, louvers 9, water tank 10. Dry pipe bundle outlet valve 11, water distribution main pipe valve 12, water tank outlet valve 13.

[0023] The dry-wet combined cycle water cooling tower adopts an induced-air structure. The ventilator 1, the fan 2 and the motor 3 are arranged on the top of the cooling tower. The ventilator 1 is a kinetic energy recovery type air duct, which is composed of an air inlet contraction section, an air duct and a diffuser. , the material is carbon steel or fiberglass. The kinetic energy of the air at the air outlet is recovered to save the energy consumption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com