Processing method for reducing and recycling organic waste water and processing system

A treatment method and technology for organic wastewater, applied in water/sewage treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of high treatment cost, high treatment cost and high pollutant concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

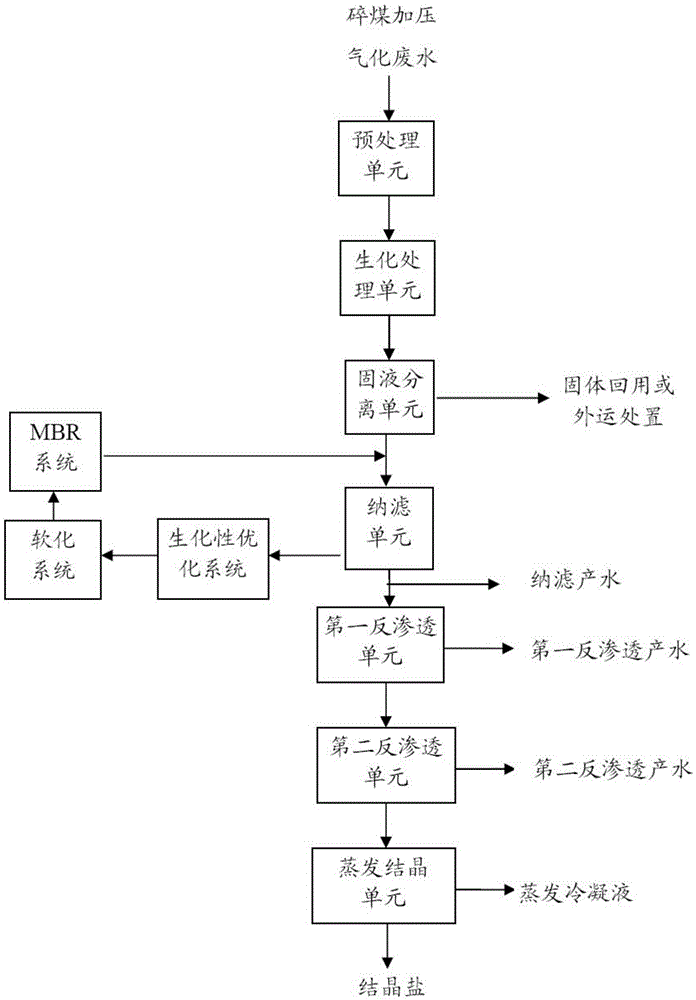

[0062] This embodiment is used to illustrate the waste water reduction and recycling treatment method and treatment system of the crushed coal pressurized gasification of the present invention.

[0063] Such as figure 1 The crushed coal pressurized gasification wastewater reduction and recycling treatment system shown mainly includes a pretreatment unit, a solid-liquid separation unit, a nanofiltration unit, a first reverse osmosis unit, and a second Two reverse osmosis units, an evaporation crystallization unit, and a nanofiltration concentrated water treatment unit connected between the concentrated water outlet of the nanofiltration unit and the outlet of the solid-liquid separation unit.

[0064] The technological parameters of the processing system are set as follows:

[0065] pre-processing unit

[0066] The subunits of the pretreatment unit are: pretreatment system and biochemical treatment system.

[0067] The subsystems of the pretreatment system are: inclined tube...

Embodiment 2

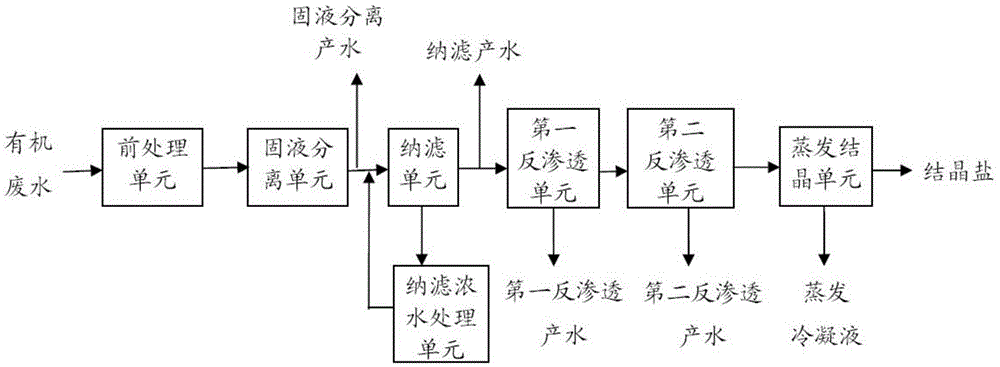

[0115] This embodiment is used to illustrate the petroleum refining wastewater reduction and resource recovery treatment method and its treatment system of the present invention.

[0116] Such as figure 2 The shown oil refinery wastewater reduction and resource recovery treatment system mainly includes a pretreatment unit, a solid-liquid separation unit, a nanofiltration unit, a first reverse osmosis unit, and a second reverse osmosis unit in sequential fluid communication , an evaporation crystallization unit, and a nanofiltration concentrated water treatment unit connected between the concentrated water outlet of the nanofiltration unit and the water outlet of the solid-liquid separation unit. The technological parameters of the processing system described in the present embodiment are set as follows:

[0117] (1) Pre-processing unit

[0118] The sub-units of the pre-treatment unit are: pre-treatment system, biochemical treatment system and advanced treatment system.

...

Embodiment 3

[0169] This embodiment is used to illustrate the printing and dyeing wastewater reduction and recycling treatment method and its treatment system of the present invention.

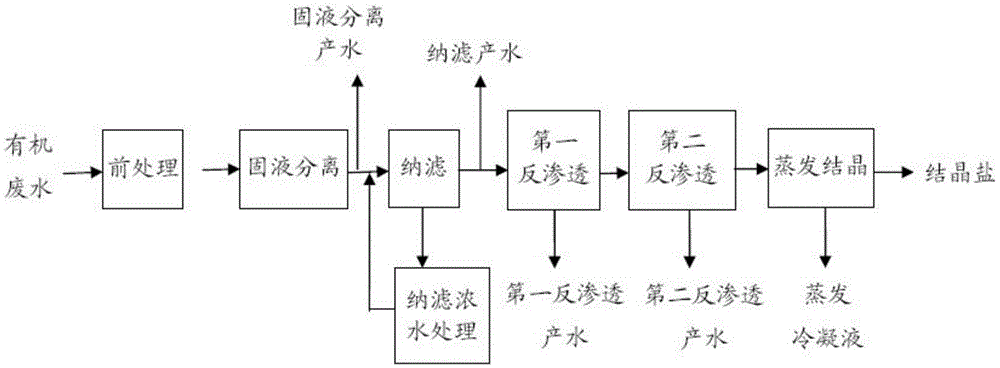

[0170] Such as image 3 The printing and dyeing wastewater reduction and recycling treatment system shown, the treatment system includes a pretreatment unit, a solid-liquid separation unit, a nanofiltration unit, a first reverse osmosis unit, a second reverse osmosis unit, an evaporation crystallization unit, and a sequentially connected unit, and a nanofiltration concentrated water treatment unit connected between the concentrated water outlet of the nanofiltration unit and the outlet of the solid-liquid separation unit. The technological parameters of the processing system of the present embodiment are set as follows:

[0171] (1) Pre-processing unit

[0172] The sub-systems of the pre-treatment unit are: hydrolytic acidification pool, aerobic pool, the main parameters:

[0173] The hydraulic retentio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cod | aaaaa | aaaaa |

| Turbidity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com