Denitrification system and denitrification method for gas turbine

A gas turbine and denitrification technology, which is applied in the field of flue gas denitrification, can solve the problems of low temperature and ineffective work, and achieve the effect of promoting denitrification reaction, improving efficiency and improving denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

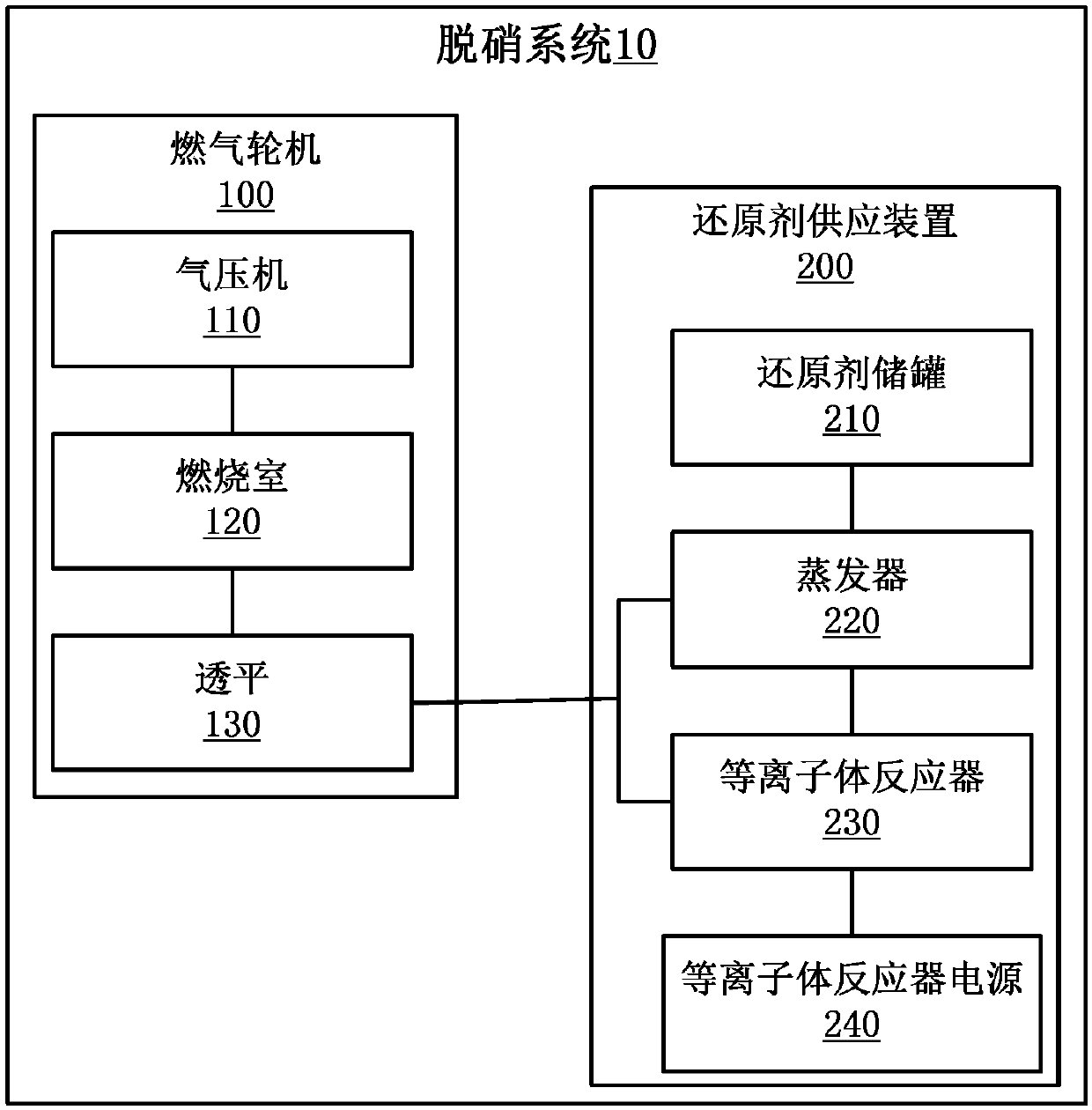

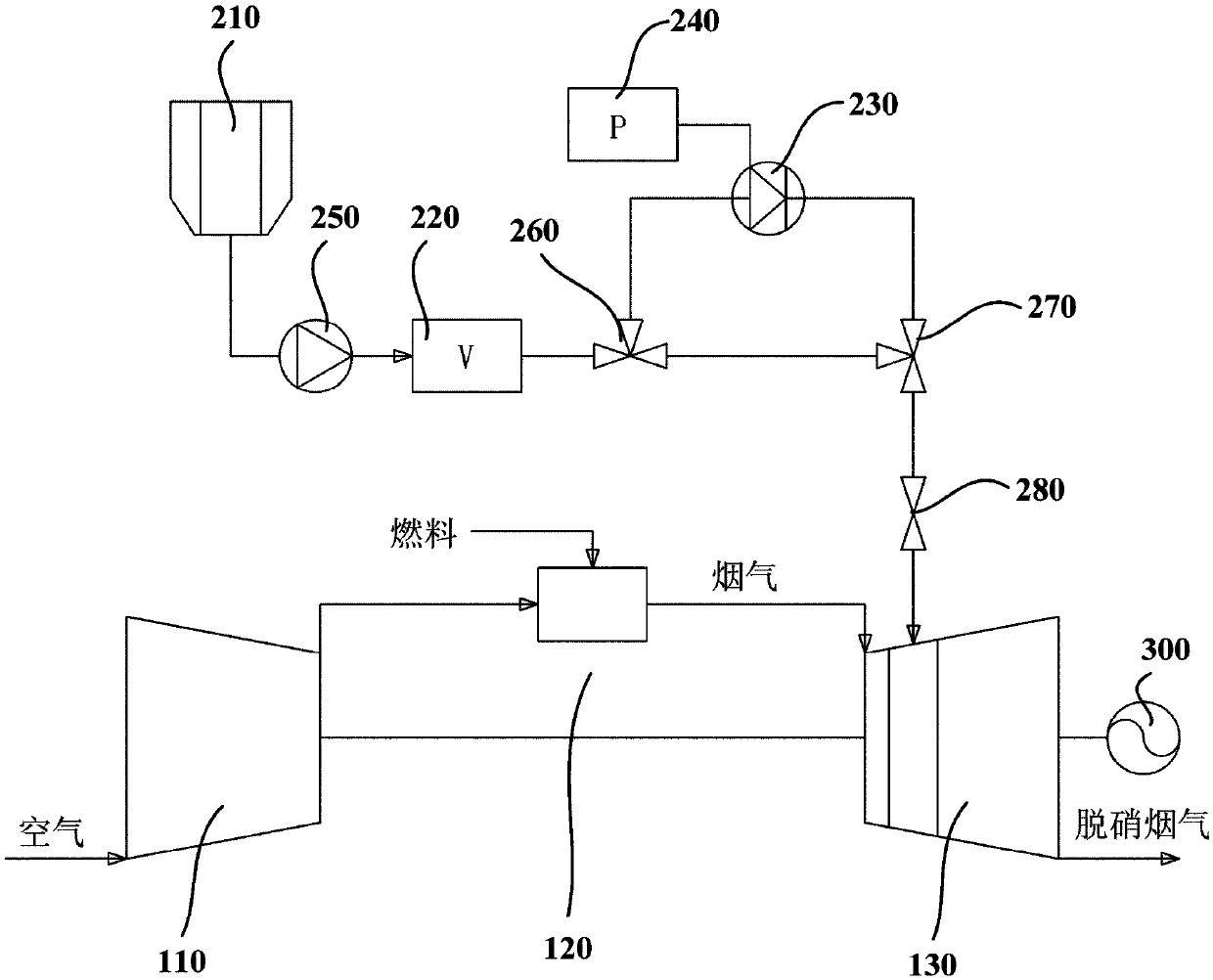

[0026] figure 1 is a schematic structural diagram of a denitrification system according to an embodiment of the present invention. This denitrification system 10 includes a gas turbine 100, as known to those skilled in the art, the gas turbine 100 includes: a gas turbine compressor 110, which continuously sucks in air from the atmosphere and compresses it; The air mixed combustion; the gas turbine turbine 130 converts the energy generated by the fuel combustion in the gas turbine combustor 120 into mechanical energy, and the flue gas generated after converting the energy of the fuel into mechanical energy contains nitrogen oxides. Generally, a generator 300 is connected after the gas turbine turbine 130 to convert mechanical energy into electrical energy for output.

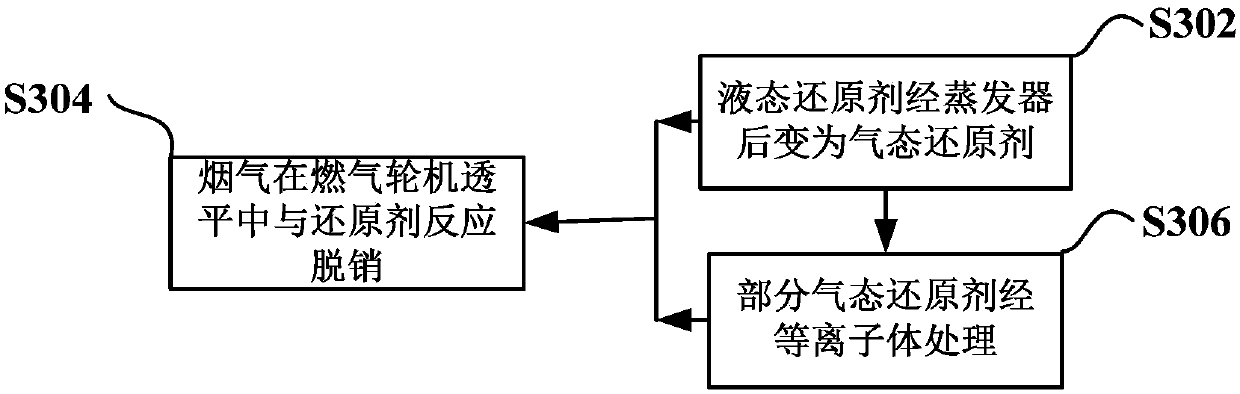

[0027] In some embodiments, the denitrification system 10 of the present invention further includes a reducing agent supply device 200, which is used to provide a denitration reducing agent for reducing nitrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com