Isoprenerubber post-treatment one-step processing technique and dehydrating and drying machine

A technology of isoprene rubber and processing technology, which is applied in the direction of drying solid materials, drying solid materials, drying, etc. by combining methods, can solve the problems of large operating costs, large floor space, and high energy consumption indicators, and achieve reduction The effect of equipment investment cost, reduced floor area and simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

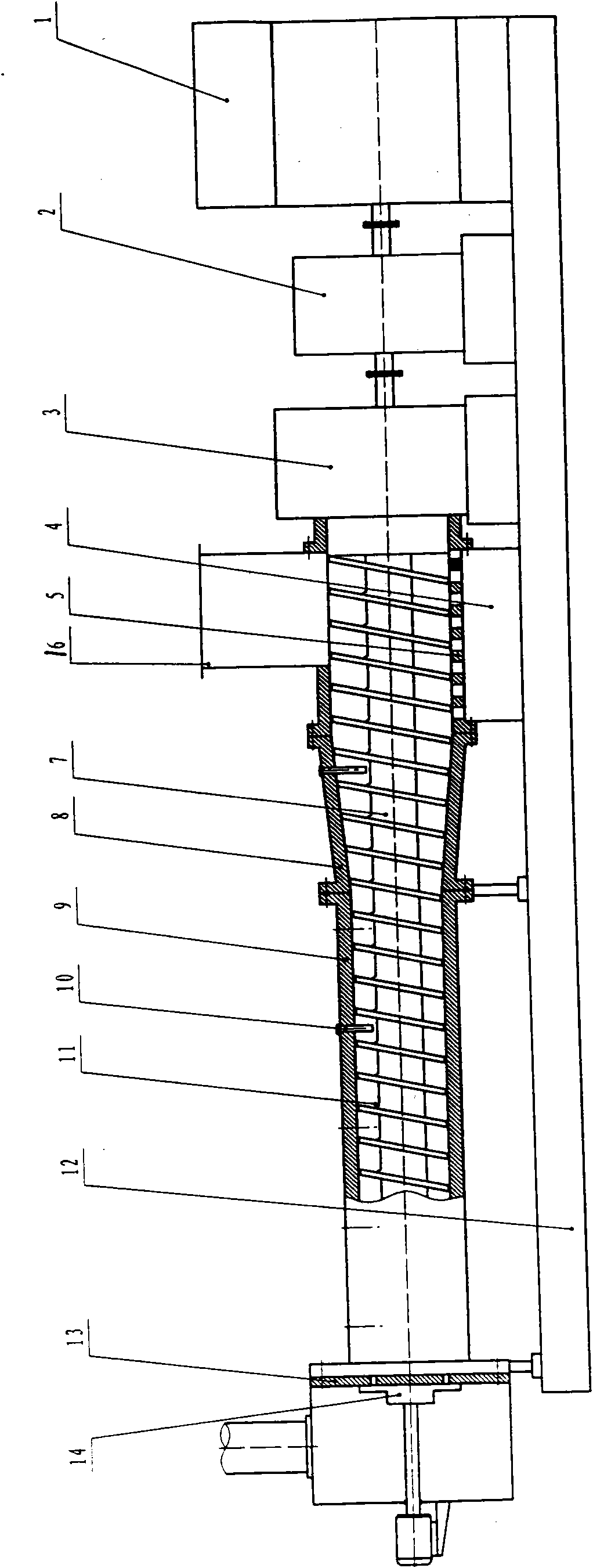

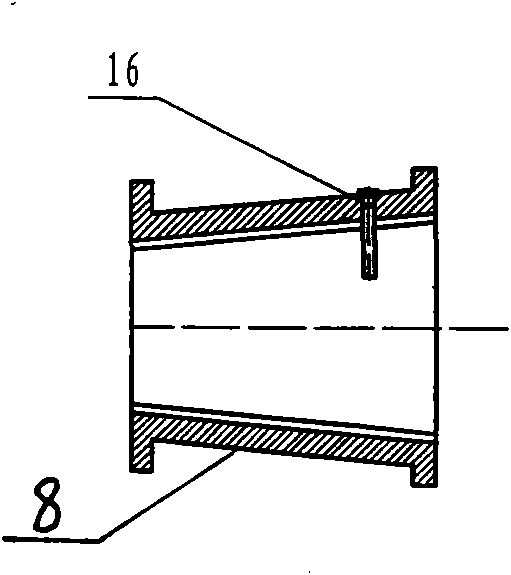

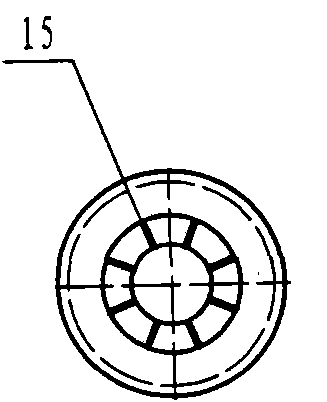

[0020] Isoprene rubber post-treatment one-step processing technology, the specific processing technology is: the two processes of extrusion dehydration and expansion drying are integrated into one continuous processing process; water-containing colloidal particles are pushed into the extrusion dehydration of the conical cylinder structure section, increase the compression ratio and dehydration amount, so that the water-containing colloidal particles can be quickly dehydrated; push the dehydrated rubber material into the expansion drying section, increase the compression ratio, and pass through the multi-row shear screws on the straight cylinder of the expansion drying section, to reduce the moisture content. The rubber material is sheared, mixed and heated; it enters the melting and homogenizing discharge section to increase the compression ratio, so that the rubber material is subjected to short-term strong shearing and heating, and the pressure and energy reserves are prepared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com