Patents

Literature

100 results about "Dehydration Procedure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

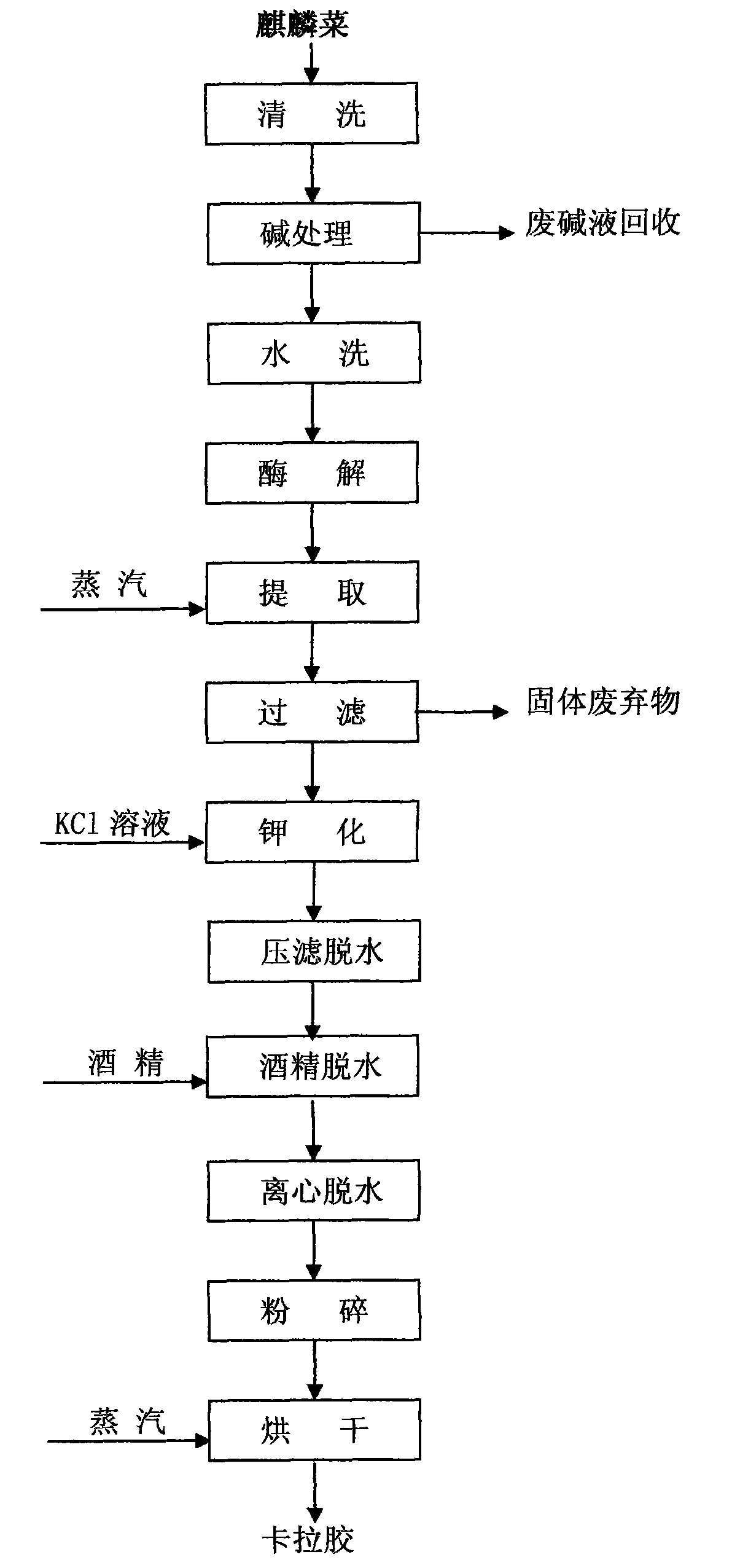

Extracting and processing technique of carrageen

The invention relates to an extracting and processing technique of carrageen by utilizing eucheuma, which comprises the procedures of cleaning, alkali treatment, washing, enzymatic hydrolysis, extracting, filtering, potassic alteration, dehydration, crushing and drying. By adopting enzyme biotechnology technology, the extraction rate and quality of carrageenan are improved, while the production cycle and energy consumption thereof being lowered. Colloid dissolves out of carrageen cells completely after the organization of cellulose in carrageen cell wall being destroyed during the procedure of enzymatic hydrolysis, thus improving the extraction rate of carrageenan. Meanwhile, the time of boiling procedure is shortened and the temperature thereof is lowered. The yield of products is increased and steam consumption during the process is reduced. Small molecule pigments also dissolve out of carrageen cells during the procedure of enzymatic hydrolysis, thus improving the transparency and purity of the obtained carrageenan. Since alcohol is adopted in dehydration procedure, the water content of the products is greatly reduced. Meanwhile, bactericidal effect of alcohol is favorable to inhibit the breeding of microorganisms during the process, thereby fulfilling the objective of disinfection and bacteriostasis. The above technique has the advantages of high extraction efficiency, high utilization rate of raw materials and high transparency and purity of the obtained carrageenan.

Owner:青岛聚大洋藻业集团有限公司

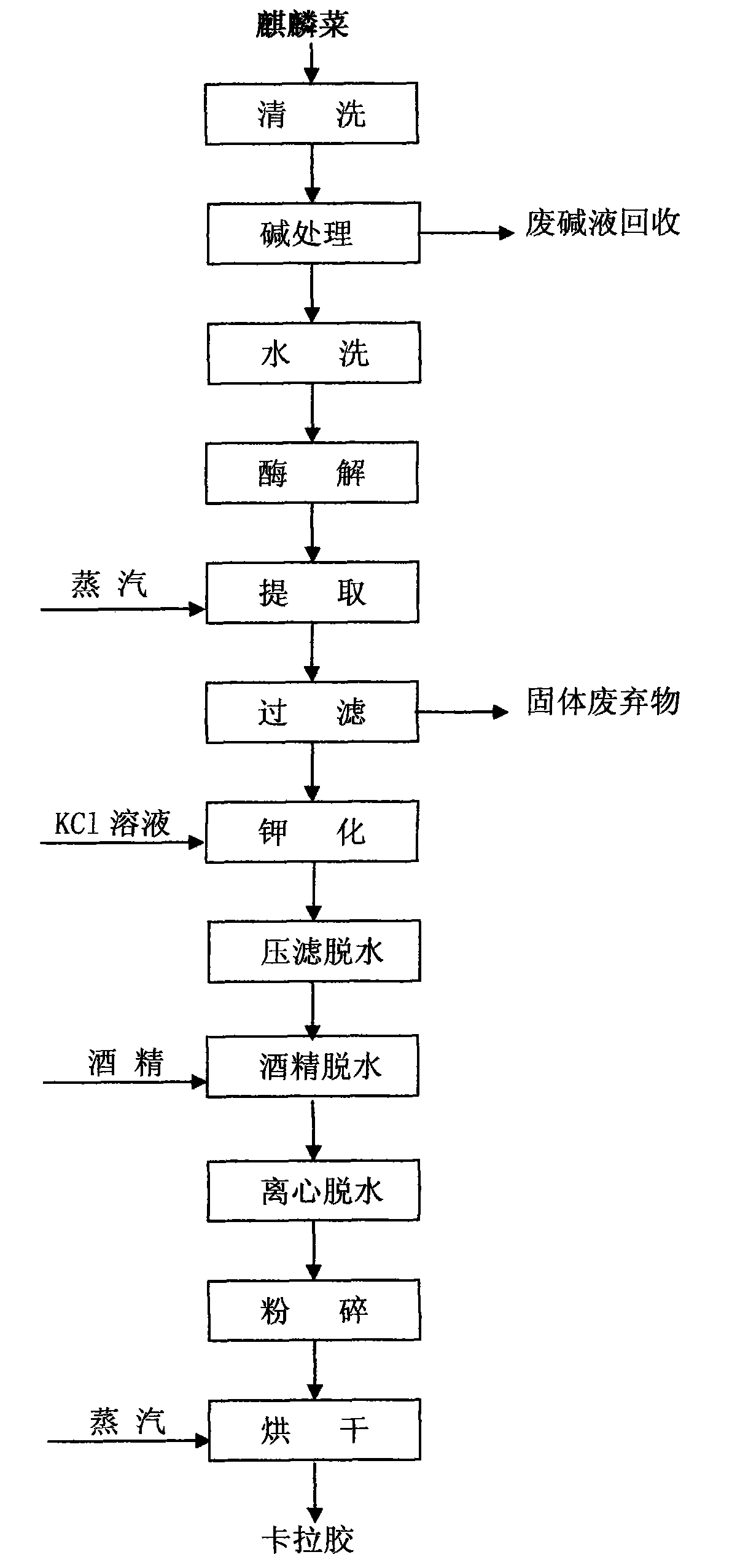

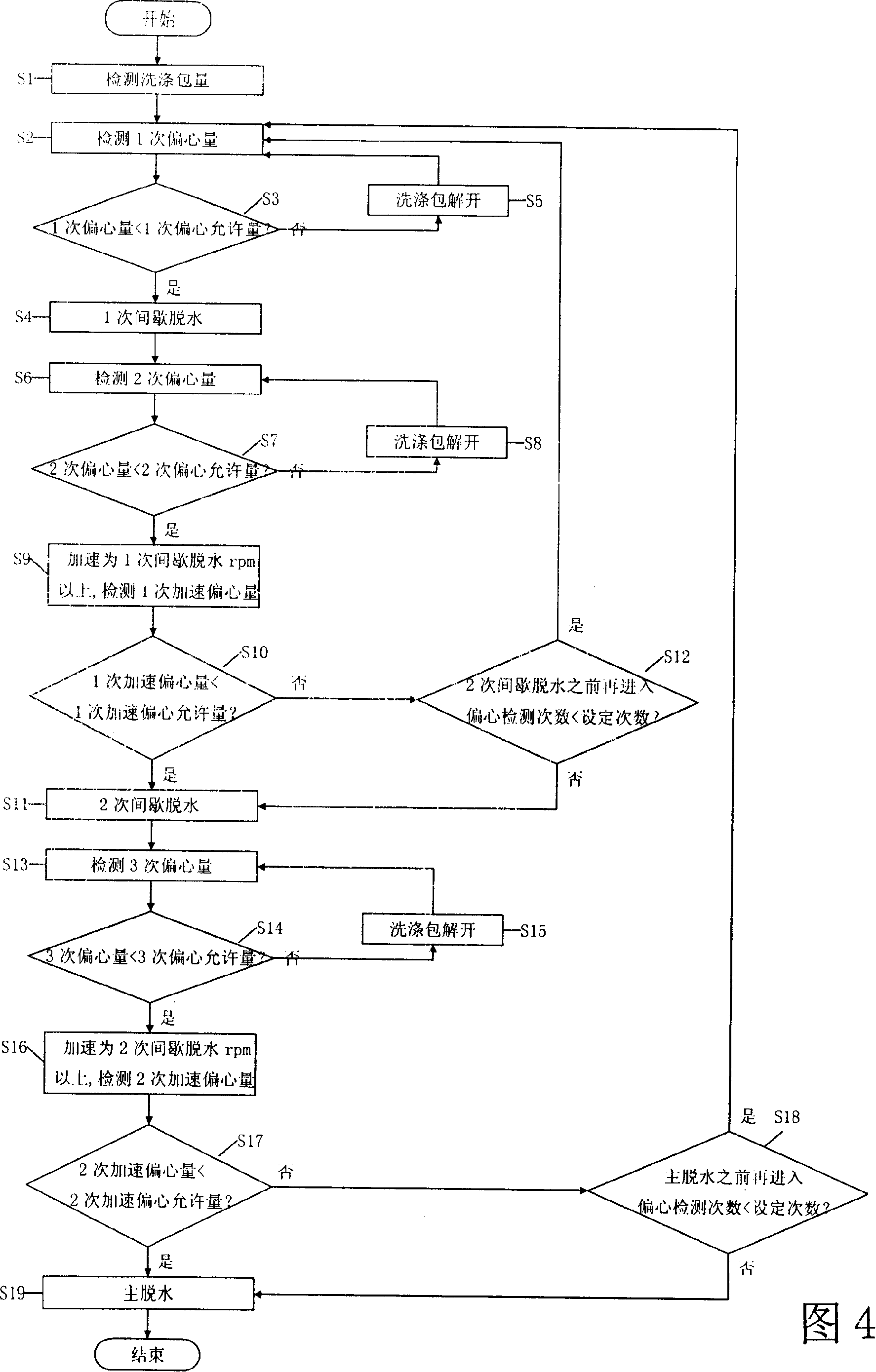

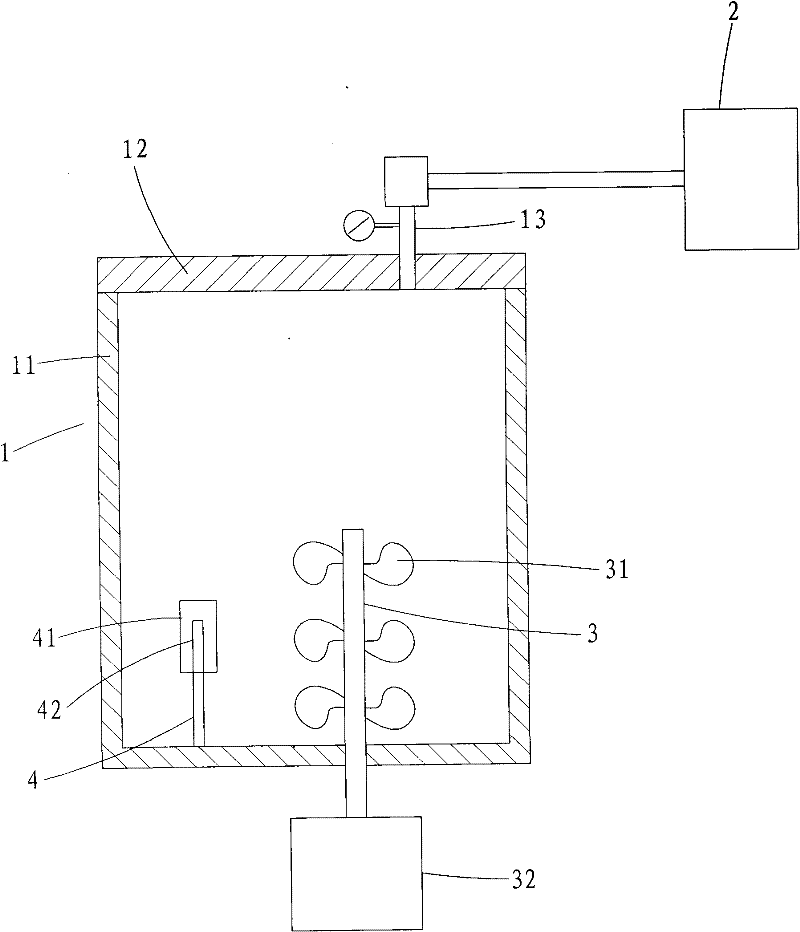

Control method for barrel washing machine dehydration procedure

InactiveCN101082168AReduce noiseReduce eccentric loadControl devices for washing apparatusTextiles and paperPulp and paper industryDehydration Procedure

The dewatering controlling program for drum-type washing machine includes one dewatering starting step, one washings loosening step, one dewatering step including increasing rotation speed and re-loosening, etc. The washings loosening step is always repeated after each step of increasing the dewatering rotation speed, so that the twisted washings are loosened effectively. The present invention can reduce vibration and noise caused by the twisted washings during dewatering greatly.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU

Preparation method of lozenges

ActiveCN101283726AImprove liquidityImprove qualityConfectionerySweetmeatsMicrowave ovenEnergy consumption

The invention provides a production method of jelly soft candies. The method comprises the following steps: dissolving sweeteners in a preset amount of water, mixing with gelling agent, molding, cooking in a microwave oven, cooling and demoulding. In the production method, the molding and cooking operations are performed in sequence, so that the jelly soft candy has good transparency. Additionally, the method omits the dehydration procedure and thereby reduces production time and energy consumption. The invention provides a new approach to soft candy production with simple process and continuous production.

Owner:广东富味健康科技有限公司

Method for processing high moisture grilled shrimps

The invention provides a method for processing high moisture grilled shrimps, and relates to the technology of processing shrimps. The invention provides the method for processing the ready-to-eat high moisture grilled shrimps. According to the technical scheme of the invention, fresh or frozen shrimps serving as raw materials are subjected to steaming, unshelling, seasoning, drying, roasting, hot-water sterilizing, inspecting and packaging. The method is characterized by: steaming the shrimps before unshelling; damaging the combination of astaxanthin and proteins in the shrimps by heating the shrimps; recovering the original redness, which makes the shrimps show bright red, of the astaxanthin; executing the drying dehydration procedure, controlling the water content in the product to be between 40 and 43 percent and the water activity in the product to be between 0.90 and 0.92, and inhibiting the growing development of the remained sporeformer, particularly the clostridium botlinum; controlling the temperature of the hot water to be between 85 and 90 DEG C; performing the hot water secondary sterilization for 30 and 40 minutes so as to kill majority of microorganisms; and inhibiting the sporeformer remained in the product after sterilization by controlling the water activity of the product to ensure the normal-temperature preservability of the product. The method is used for processing the high moisture grilled shrimps.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

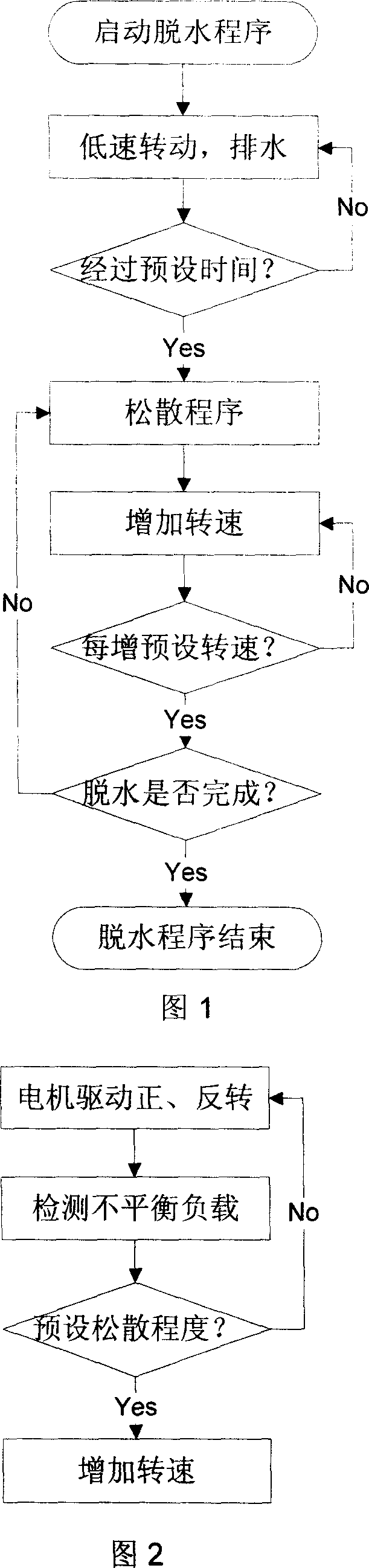

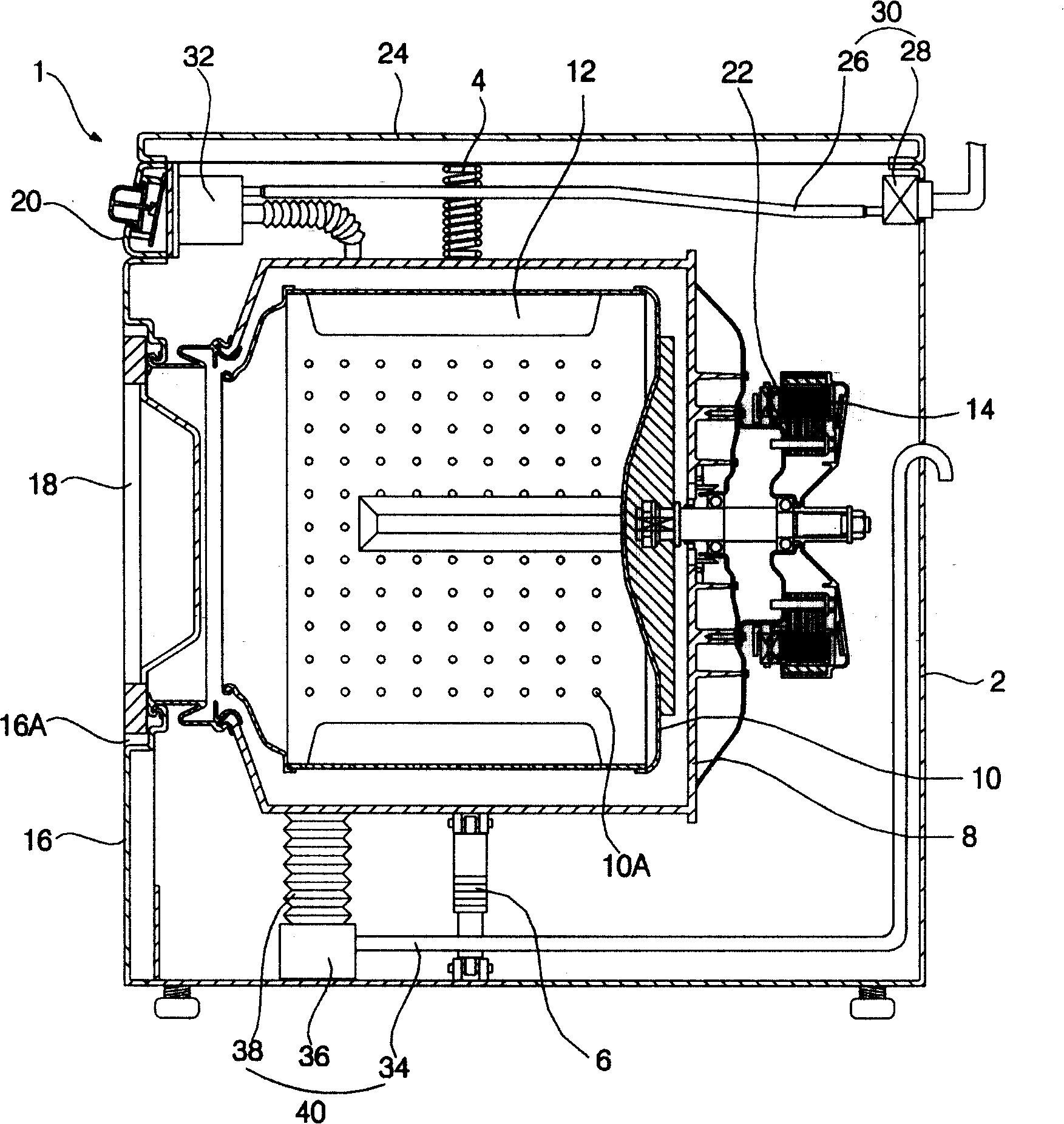

Eccentricity detection method of roller washing machine

ActiveCN105088661AImprove stabilityThe test result is accurateOther washing machinesControl devices for washing apparatusPulp and paper industrySpeed reduction

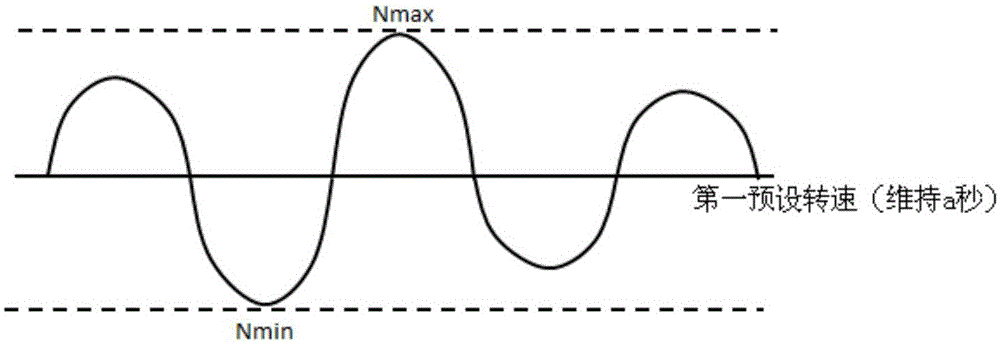

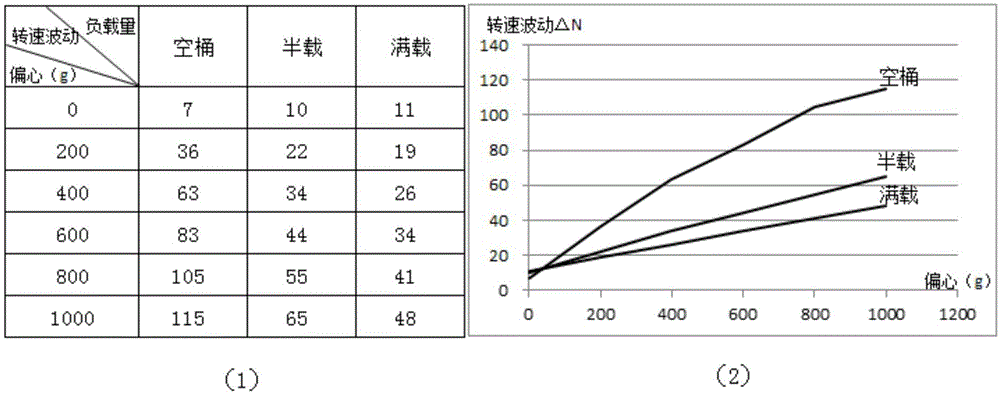

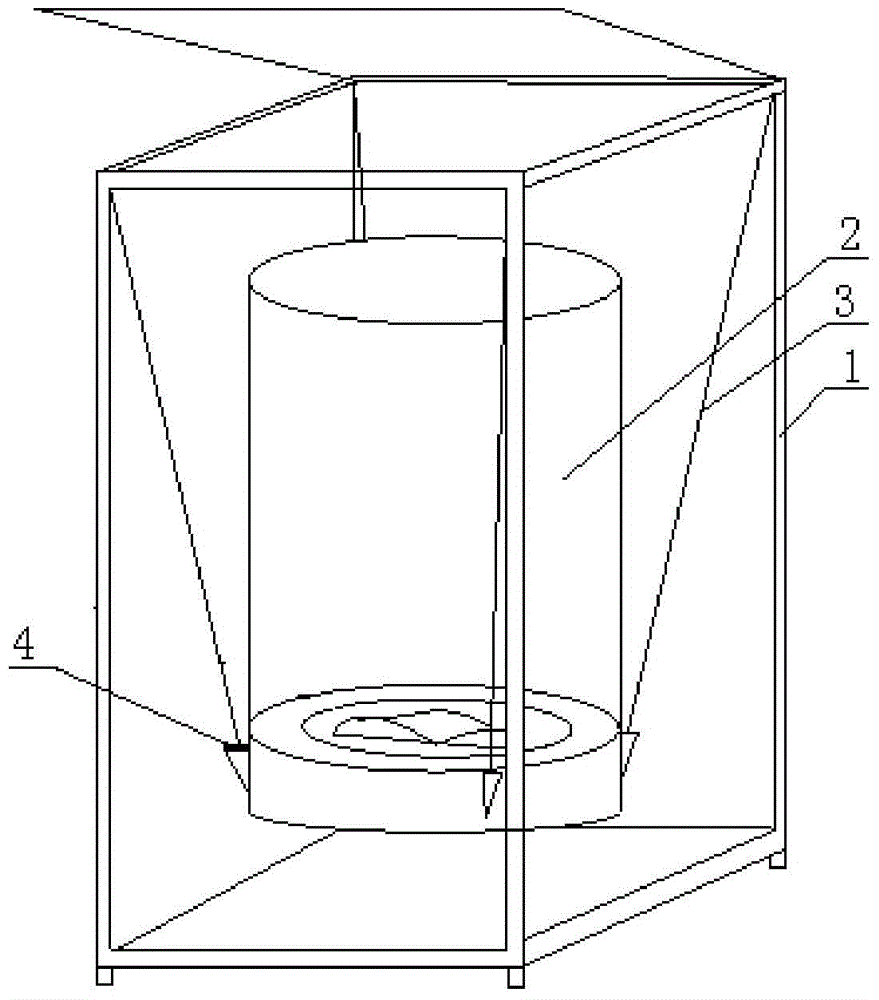

The invention discloses an eccentricity detection method of a roller washing machine, wherein the roller washing machine comprises a series excited machine. The eccentricity detection method comprises the steps that the series excited machine is controlled to be started when starting of a dehydration procedure is detected; a rotation speed of the series excited machine is controlled to be accelerated to a first preset rotation speed, the first pre-set rotation speed is maintained for a first pre-set period, and a fluctuation value of the rotation speed of the series excited machine during the first pre-set period is calculated; the rotation speed of the series excited machine is naturally reduced to a second pre-set rotation speed, a speed reduction period for the rotation speed of the series excited machine to decrease from the first pre-set rotation speed to the second pre-set rotation speed is detected, and the second pre-set rotation speed is lower than the first pre-set rotation speed; and an eccentricity value is acquired according to the fluctuation value and the speed reduction period. The eccentricity detection method of the roller washing machine provided by the invention can realize more accurate eccentricity detection and can increase stationarity of the roller washing machine.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

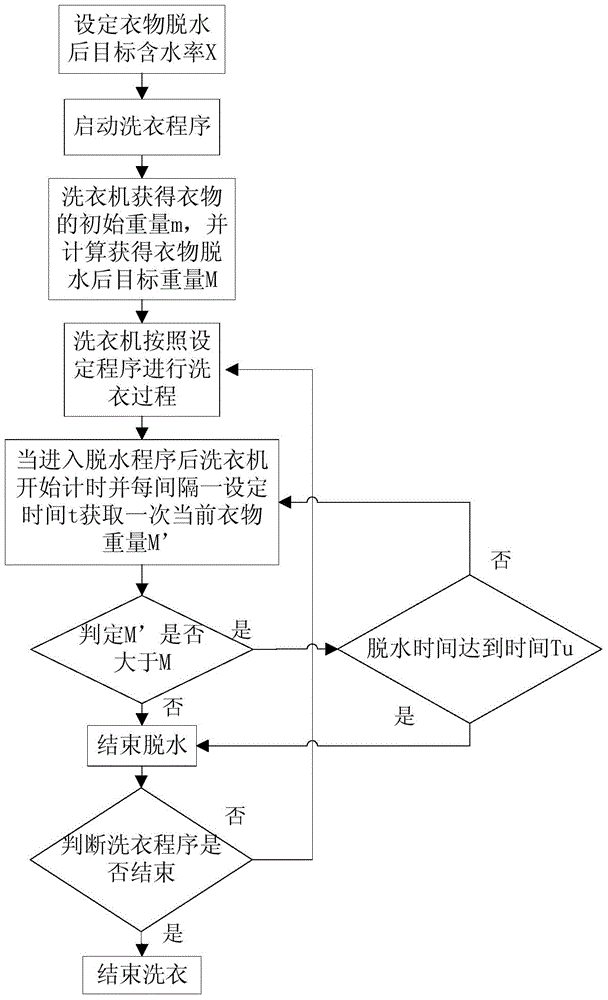

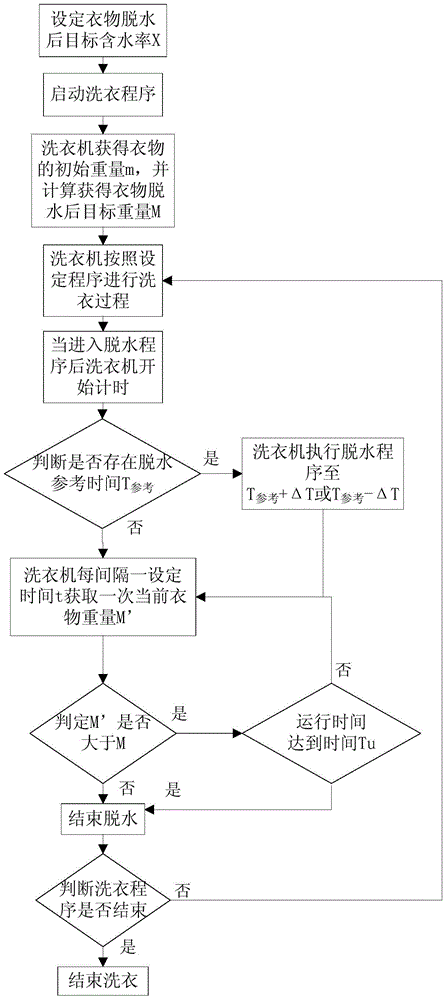

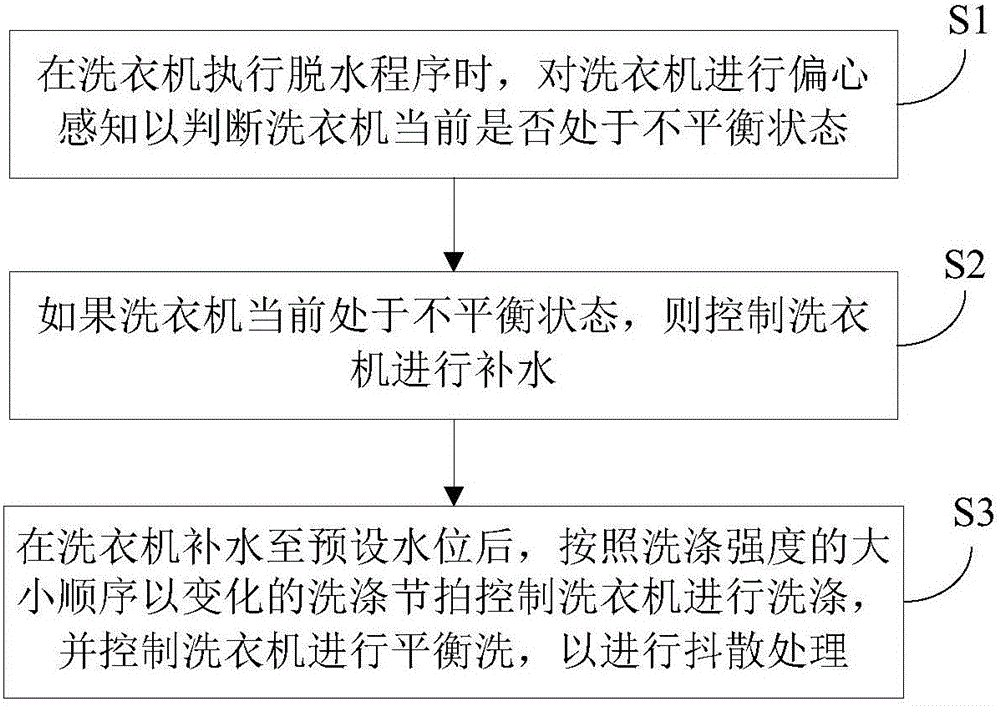

Washing machine control method and washing machine

ActiveCN105316895AImprove experienceMeet different needsControl devices for washing apparatusWashing machine with receptaclesMachine controlProcess engineering

The invention discloses a washing machine control method and a washing machine, which relate to the technical field of washing machines and are designed for solving the problems that a dehydration rate of an existing washing machine cannot be controlled and the like. The washing machine control method comprises the steps of setting moisture content X to be reached after clothes dehydration, detecting initial weight m of clothes in the washing machine, determining target weight M after clothes dehydration, measuring the weight M minute of the clothes during dehydration in real time, and comparing the M minute with the target weight M after dehydration, and stopping a dehydration procedure by the washing machine when the preset moisture content X is reached. Because the weight of the clothes during dehydration can completely reflect the whole dryness of the clothes, the detection accuracy is high, and the automation degree is high; each user can set the clothes dehydration rate according to his / her need, so that different needs of different users can be met, and the user experience is good.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

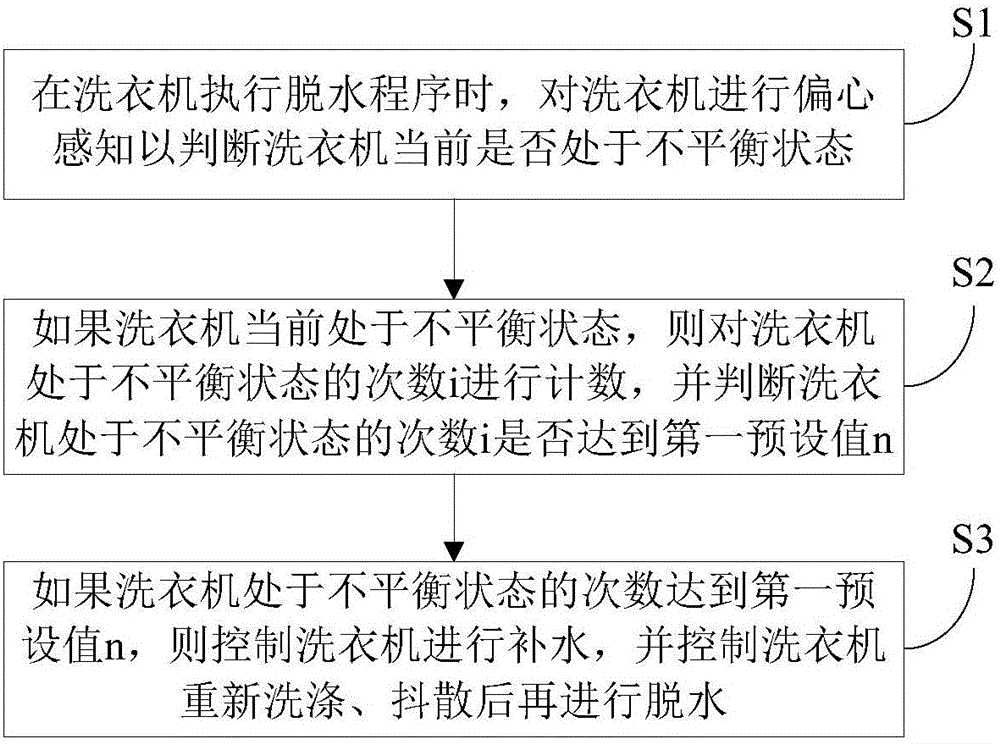

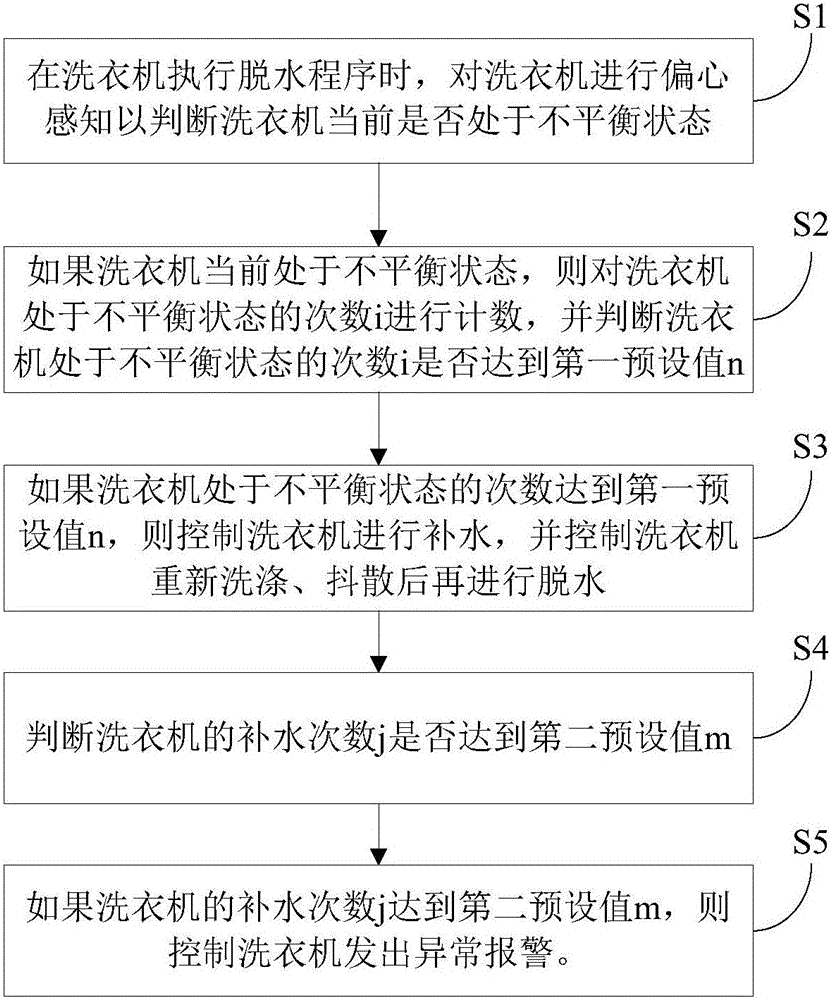

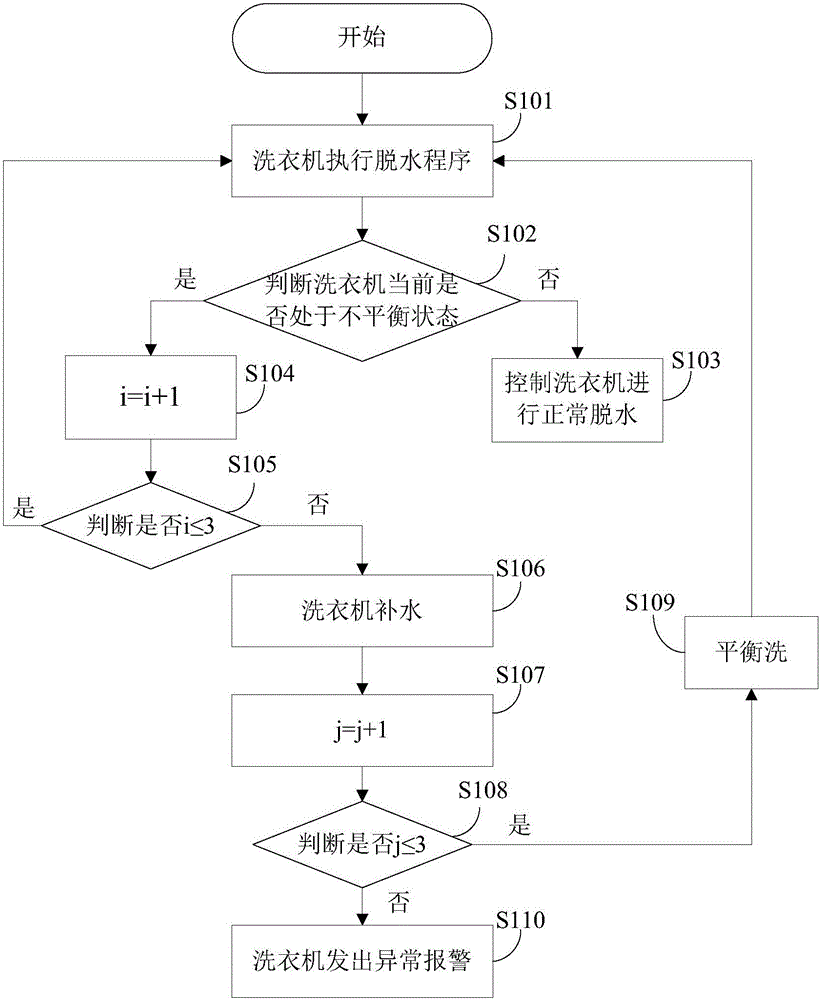

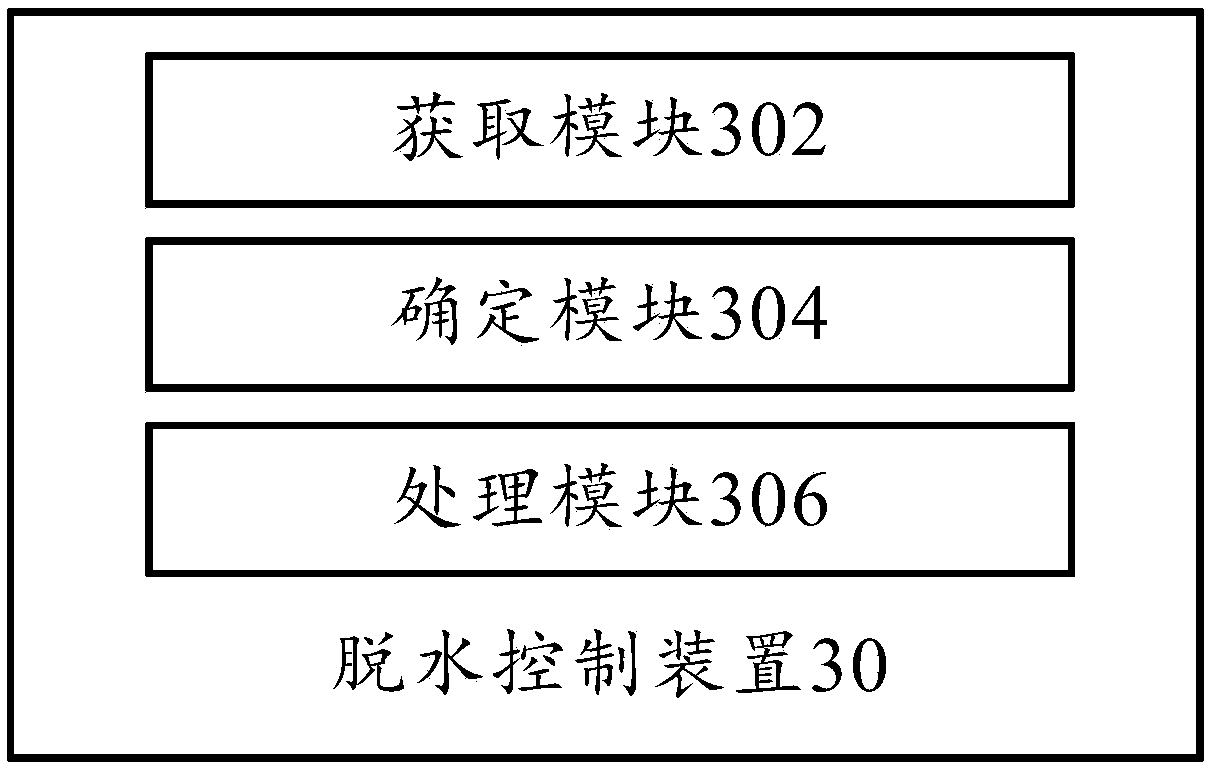

Washing machine as well as dehydration control method and device thereof

InactiveCN105951355AReduce misjudgmentReduce water consumptionControl devices for washing apparatusTextiles and paperEngineeringProcess engineering

The invention discloses a washing machine as well as a dehydration control method and device thereof. The method comprises the following steps of: when the washing machine carries out the dehydration procedure, carrying out eccentric sensing on the washing machine to judge whether the washing machine is in the unbalanced state at present; if the washing machine is in the unbalanced state at present, counting the number of times the washing machine is in the unbalanced state and judging whether the number of times the washing machine is in the unbalanced state reaches a first preset value; and if the number of times the washing machine is in the unbalanced state reaches the first preset value, controlling the washing machine to replenish water and controlling the washing machine to carry out re-washing and shaking loose and then carry out dehydration. By adopting the method, when eccentric sensing is carried out on the washing machine, the probability of misjudgment occurrence can be reduced and the success rate of dehydration can be increased, thus reducing occurrence of water waste behaviors to some extent.

Owner:WUXI LITTLE SWAN CO LTD

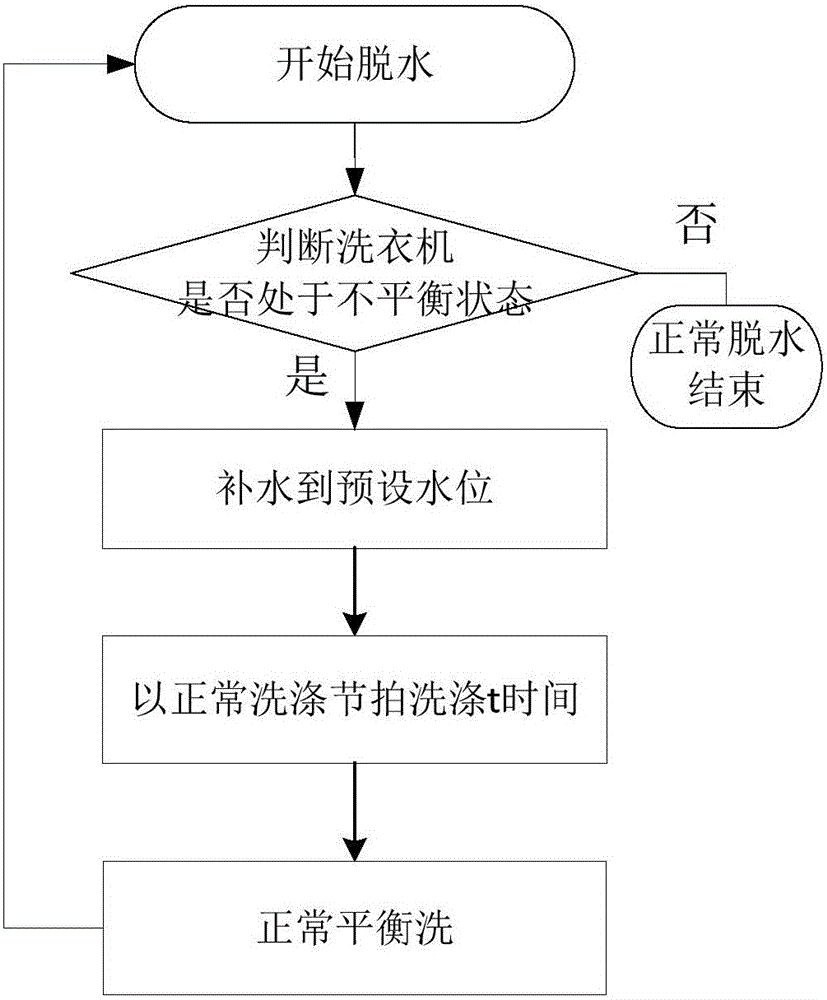

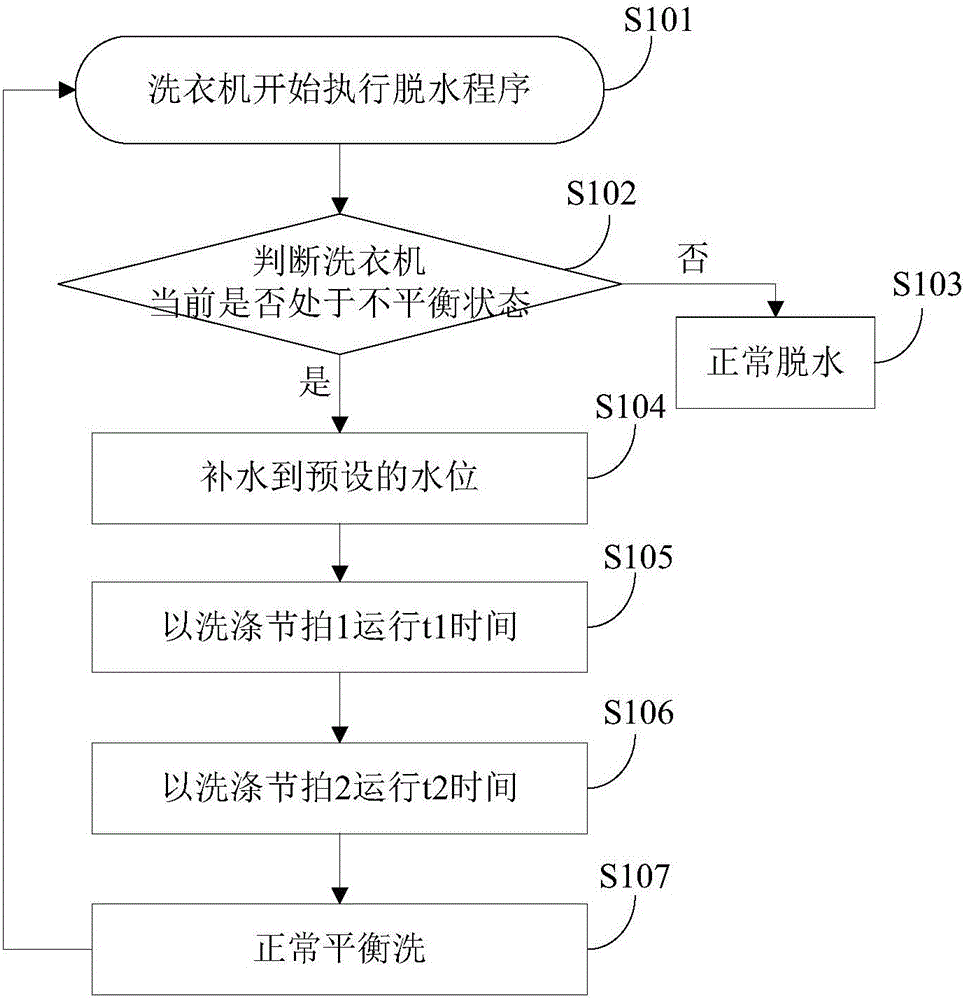

Washing machine and control method and device thereof

ActiveCN105937126AReduce water replenishment rateImprove the success rate of dehydrationOther washing machinesControl devices for washing apparatusElectricityEngineering

The invention discloses a washing machine and a control method and device thereof. The method comprises the following steps that when the washing machine executes a dehydration procedure, eccentric sensing is carried out on the washing machine so as to judge whether the washing machine is in the unbalanced state at present; if the washing machine is in the unbalanced state at present, the washing machine is controlled to supplement water; when water in the washing machine reaches a preset water level after being supplemented, the washing machine is controlled to carry out washing in a changing washing rythme according to the washing strength sequence and controlled to carry out balanced washing so as to carry out shaking treatment. According to the method, when the washing machine is in the unbalanced state, by the adoption of the changing washing rythme, the shaking effect of clothes can be improved, and the balanced washing role is brought into full play, so that the eccentric magnitude is reduced, the probability of supplementing water to the washing machine is lowered, the dehydration success rate is improved, and time, water and electricity are saved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Manufacturing method for liquid film closed type plant primary-color herbarium specimens

InactiveCN102499234ASimple storage conditionsExtended service lifeDead plant preservationPolyethylene glycolTransmittance

The invention discloses a manufacturing method for liquid film closed type plant primary-color herbarium specimens. The manufacturing method comprises the procedures of dehydrating the specimens, spraying, drying and storing, wherein the specimen dehydration procedure is to clear leaves of the collected fresh plants, remove dust and dirt and absorb water by using absorbent paper or perform plasticizing dehydration by using polyethylene glycol; the spraying procedure is to spray varnish serving as a film medium onto the surfaces of the plant leaves, so that one layer of paint film covers the surfaces of the leaves uniformly; the painted leaves are placed on a rack and the varnish film is dried; and the specimens which are inspected to be qualified are stored. The varnish is sprayed on the herbarium specimens based on a paint film-forming technological principle, so that one layer of paint film is adhered to and wrapped on the surface of each specimen; and each herbarium specimen is subjected to film sealing by drying the surface of each specimen. The adopted varnish is transparent and colorless; and after the film is sealed, the light transmittance is high, the original state of the specimen is not damaged and destroyed and the original color can be observed. After the varnish is formed into the film, air can be isolated, so color fading and deterioration are avoided, the storage condition is simplified and the service life is prolonged.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

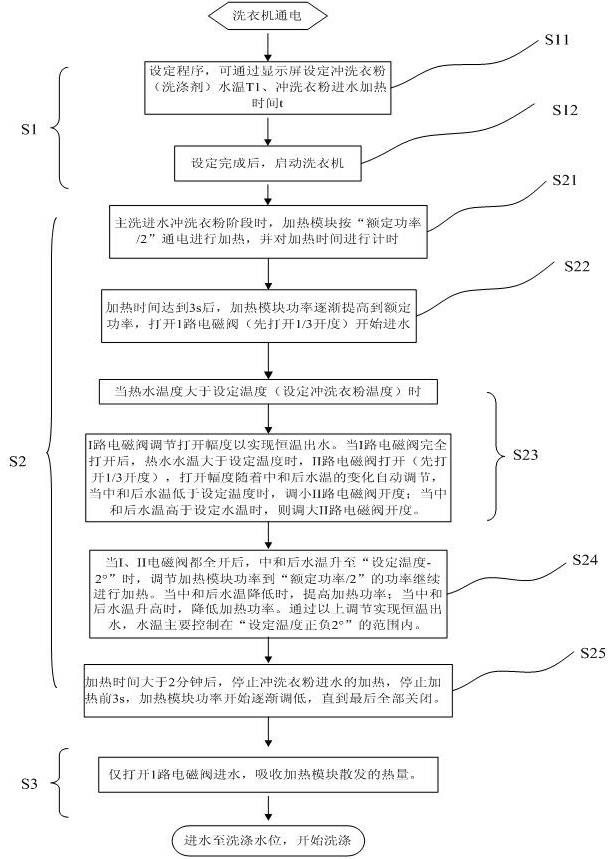

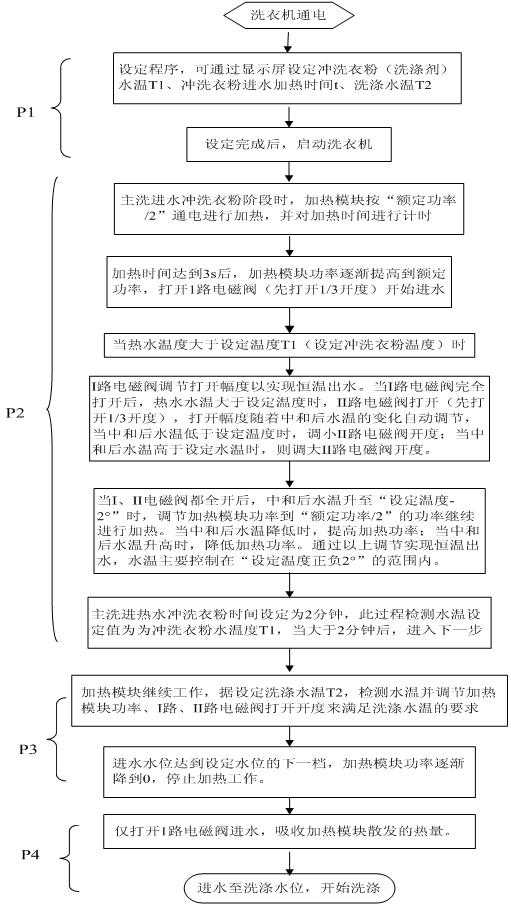

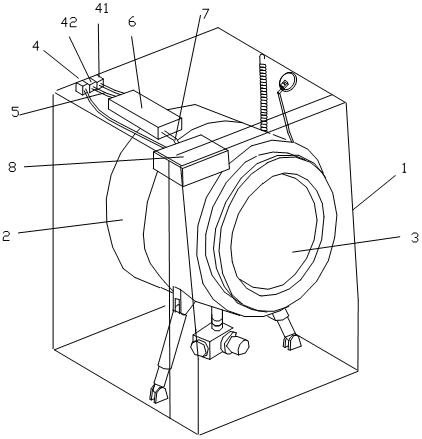

Washing machine and clothes washing control method of washing machine

ActiveCN102425050ABest washing temperatureOther washing machinesControl devices for washing apparatusLaundry washing machineTap water

The invention discloses a clothes washing control method of a washing machine and the washing machine adopting the method. A water inlet device of the washing machine comprises an electromagnetic valve, a constant-power heating module and a water injection box. Clothes washing procedures comprise a washing procedure, a rinsing procedure and a dehydration procedure, wherein the washing procedure comprises a water inlet process, a washing process and a drainage process, and the water inlet process sequentially comprises a step of setting the temperature of water for dissolving washing powder, a step of heating inlet water and regulating and controlling water temperature and a repeated water inlet step of enabling the non-heated inlet water to achieve the washing water level. By adopting the technical scheme, the washing machine is simple and reliable in structure; furthermore, through the procedure control, tap water is heated to the optimal temperature for dissolving the washing powder in the water inlet process, thereby using efficiency of the washing powder is improved and further washing efficiency is improved.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

Dewater technology of isooctyl nitrate

The present invention relates to a dehydration process of isooctyl nitrate, belonging to the field of carbon and nitrogen bearing compound technology whose carbon frame is further connected by single bond and is substituted by oxygen atom. It includes dehydration procedure, utilizes sedimentation separation to remove most of water content, and further utilizes anhydrous sodium sulfate to remove micro water content. Said invention can stably control water content in the product and make it be below 0.01%.

Owner:SHANDONG LIANHE CHEM

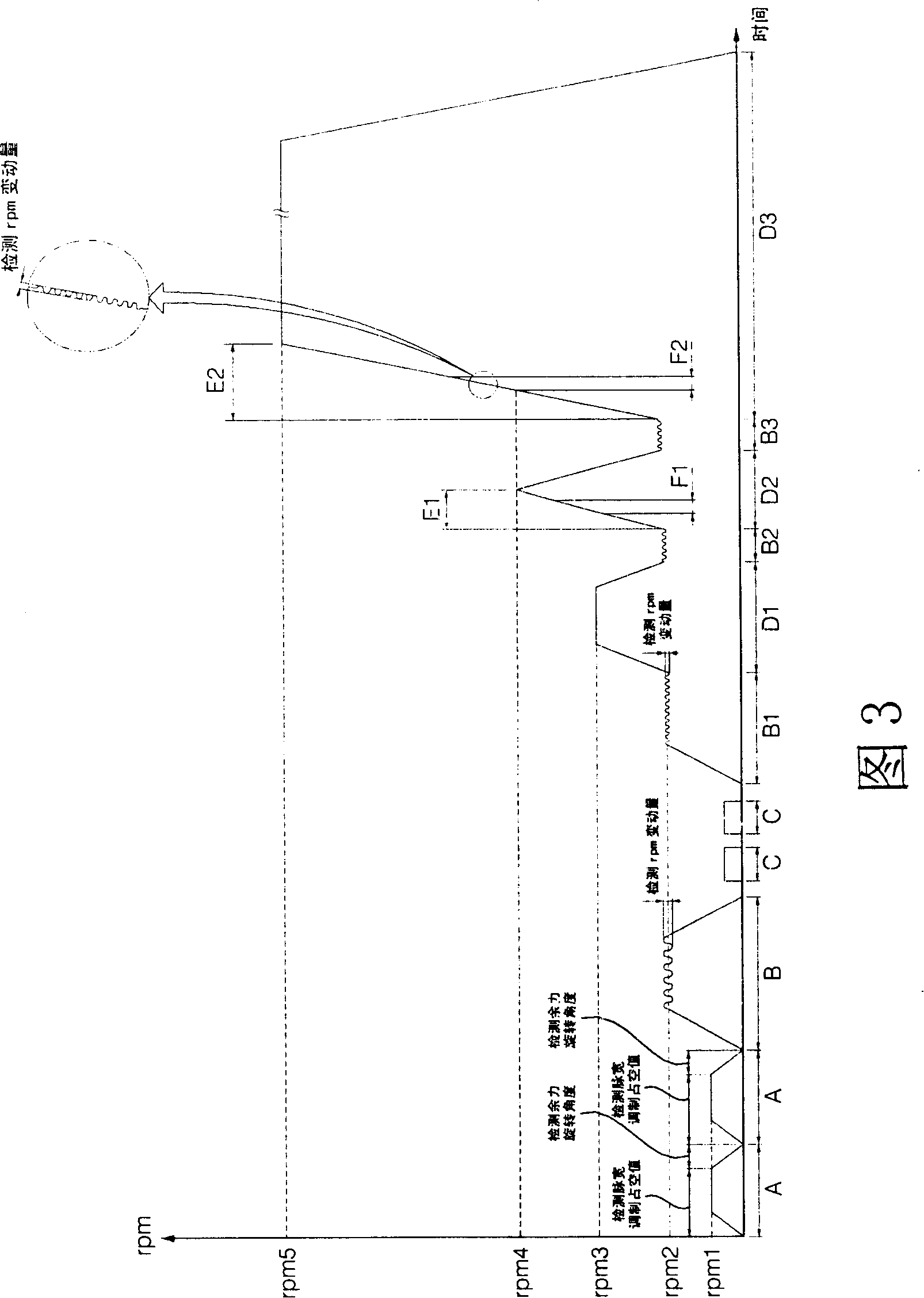

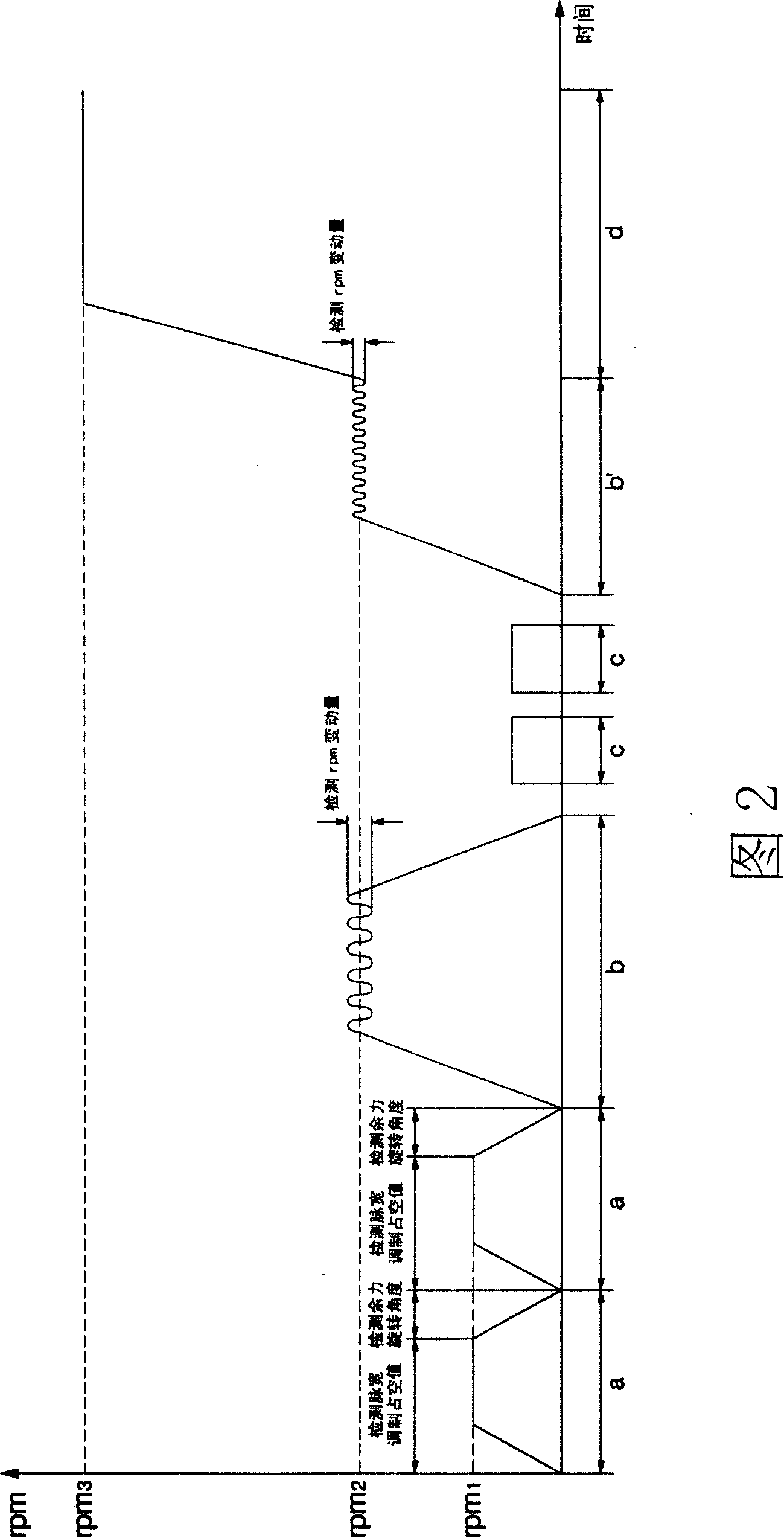

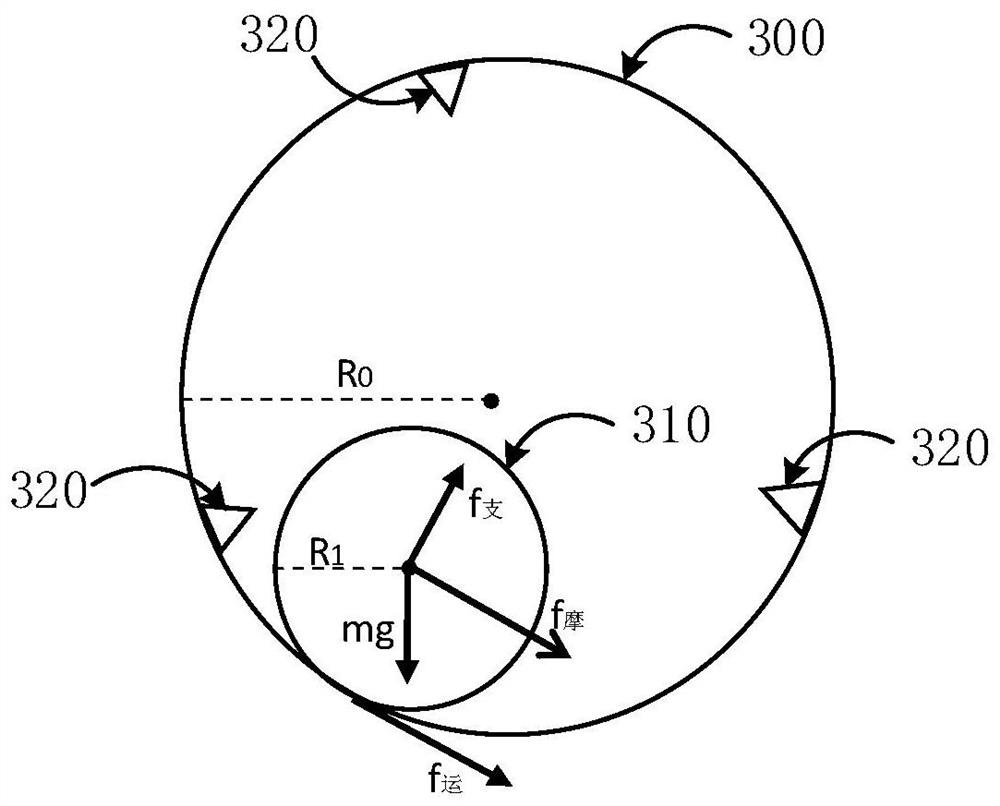

Dewatering process of washing machine

InactiveCN101173459AAccurately judge the statusPrevents phenomenon recognized as double eccentric stateControl devices for washing apparatusTextiles and paperEngineeringAcceleration Unit

The invention relates to a dehydration method for the washing machines, comprising an eccentricity detection procedure for detecting the eccentric magnitude of the washes. At the drum acceleration area of the dehydration procedure, the acceleration eccentric magnitude of the washes is detected. If the eccentric magnitude is higher than the allowable amount, the washes are judged to be at double eccentricity status, and then enter an acceleration eccentricity detection procedure of the eccentricity detection procedure. According to the invention, the double eccentricity status and no-load status of the washes are accurately detected through the acceleration eccentric magnitude and the acceleration eccentricity allowable amount; thereby the washes at double eccentricity status are prevented from entering the dehydration procedure. Moreover, if the acceleration eccentricity allowable amount of the acceleration eccentricity detection procedure is assigned sensitively, the washes at no load status can be prevented from being identified at double eccentricity status in advance.

Owner:NANJING LG PANDA APPLIANCES

Biogas decarburization and tertiary desorption process

InactiveCN102861509AGuaranteed purityPromote absorptionGaseous fuelsDispersed particle separationAbsorption capacityResidual carbon

The invention discloses a biogas decarburization and tertiary desorption process. The biogas decarburization and tertiary desorption process includes that desulfurized biogas is compressed by a compressor and then is fed into an absorption tower to be subjected to spray washing, the washed and purified biogas is divided into two portions, one portion of biogas is subjected to a follow-up dehydration procedure, and the other portion of biogas is fed to a tertiary desorption tower; washing liquid of the absorption tower is decompressed and then is fed into a primary desorption tower, the primarily desorbed washing liquid is decompressed again and then is fed into a secondary desorption tower; the secondarily desorbed washing liquid is fed into the tertiary desorption tower from the top of the tertiary desorption, the purified biogas from the top of the absorption tower is fed into the tertiary desorption tower from the bottom of the tertiary desorption tower, and residual carbon dioxide in the washing liquid from the secondary desorption is desorbed deeply; and the washing liquid after the tertiary desorption is fed back to the top of the absorption tower to perform spray washing for desulfurized biogas, and circulation is realized. The process is simple in flow, safe in operation, high in carbon dioxide absorption capacity, product gas recovery rate and desorption capacity and free of environmental pollution.

Owner:开封黄河空分集团有限公司

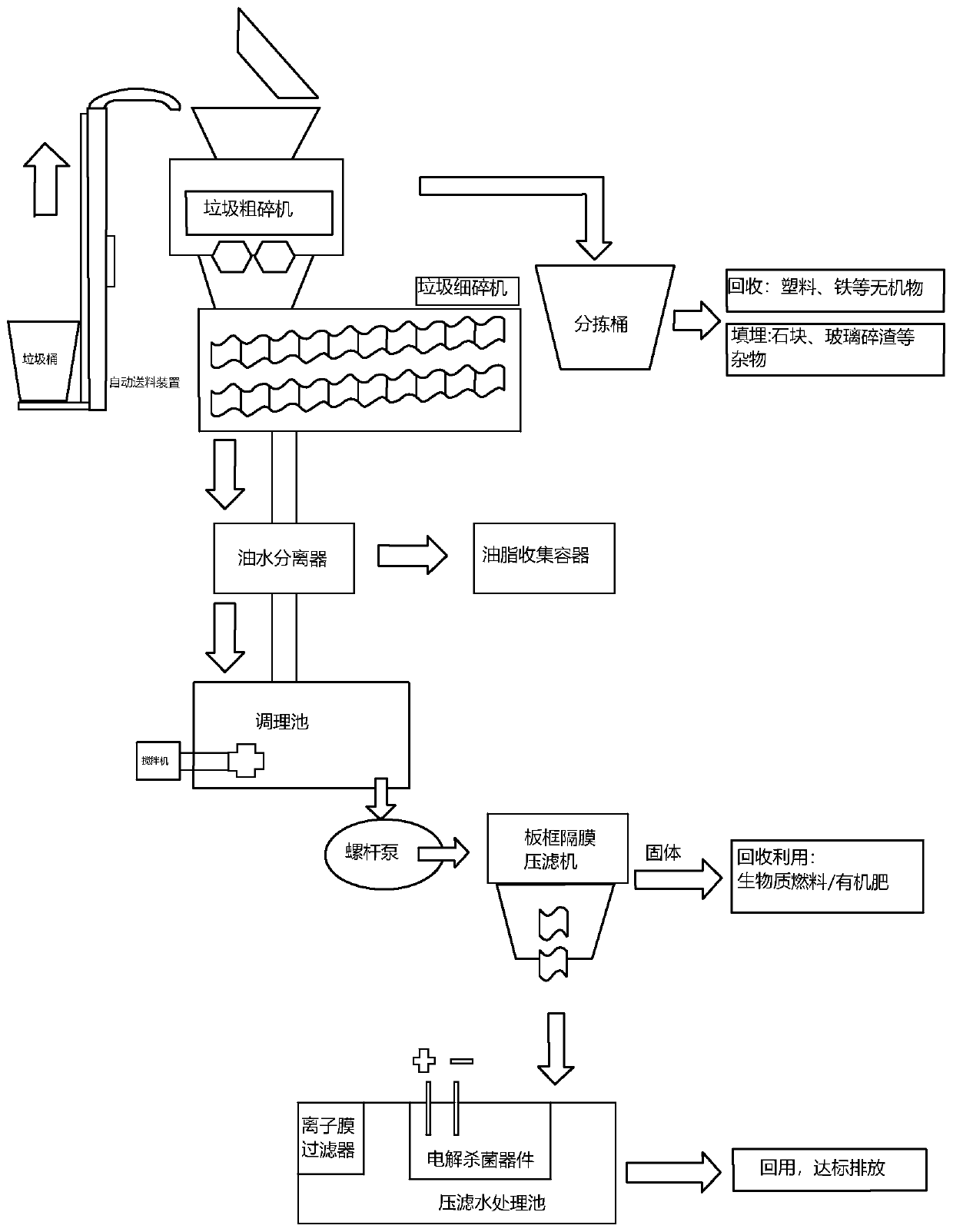

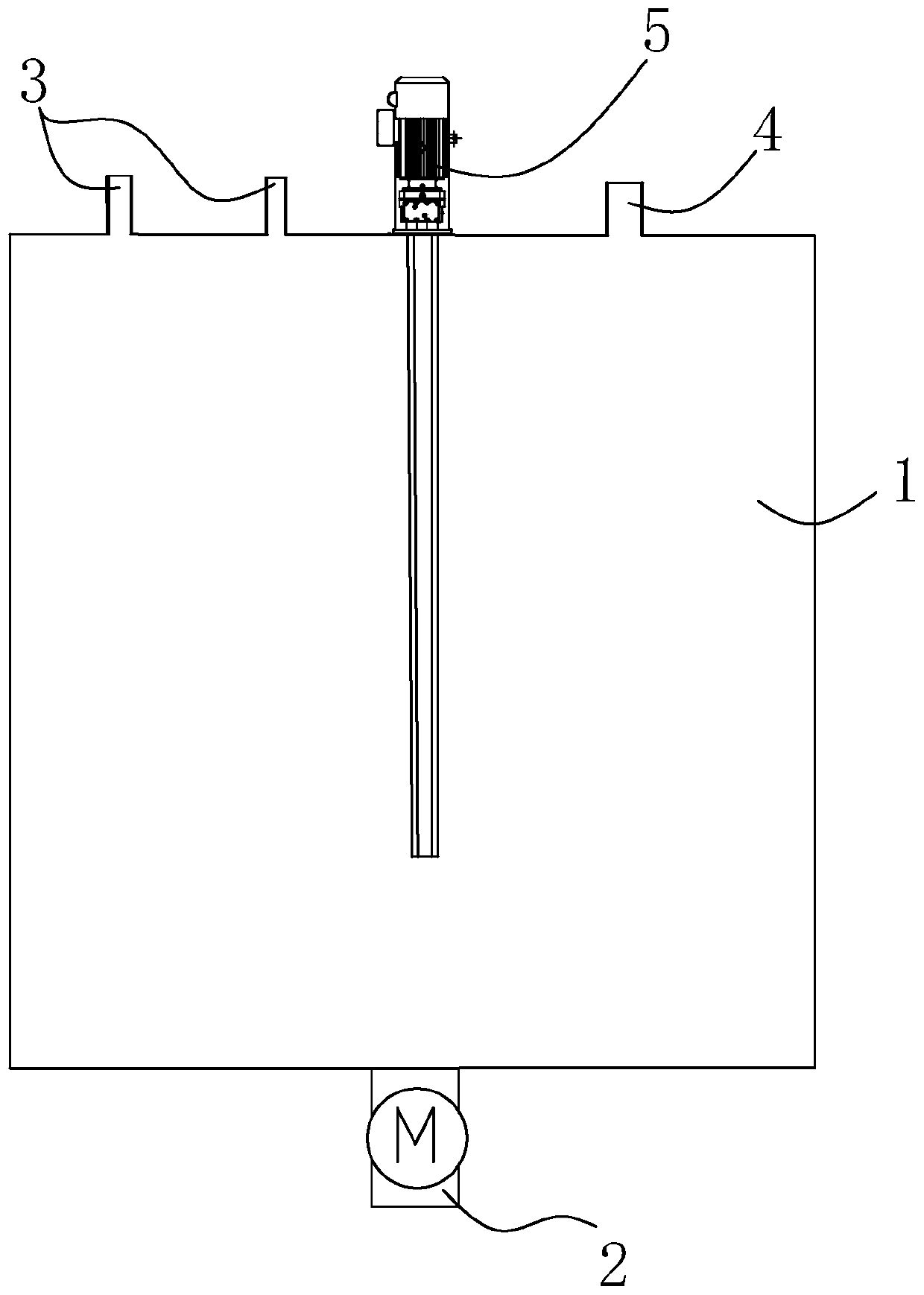

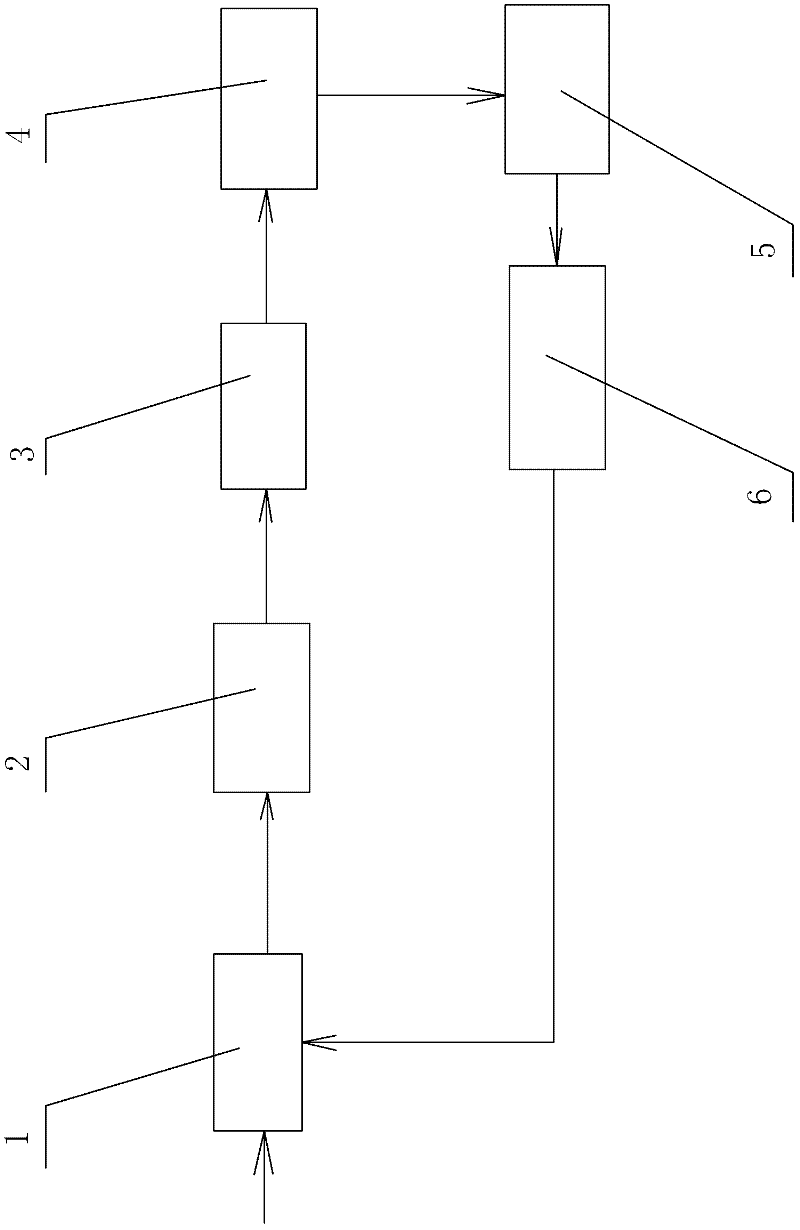

Chemical conditioning type deep dehydration method for kitchen waste and dehydration system

InactiveCN110723846AImprove the degree of processing reductionReduce moisture contentFatty/oily/floating substances removal devicesSludge treatmentAluminum sulphateEnvironmental engineering

The invention relates to a chemical conditioning type deep dehydration method for kitchen waste. The process comprises the following steps: treating the kitchen waste with a waste coarse crushing machine and a waste fine crushing machine in sequence to obtain kitchen waste slurry; then enabling aluminum sulfate (Al2(SO4)3), cationic polyacrylamide (PAM) and hydrogen peroxide (H2O2) to be subjectedto a chemical reaction with components in the kitchen waste slurry in a conditioning tank in sequence, so as to damage inner structures between granular cells in the kitchen waste slurry and surfaceadsorption structures of granular cell walls, and decompose inner bound water between the granular cells or on the surfaces of the granular cells; then carrying out a squeezing deep dehydration procedure on the kitchen waste slurry through a plate and frame membrane filter press, so as to obtain the dehydrated kitchen waste with the moisture content lower than 60%. By adopting the chemical conditioning type deep dehydration method for the kitchen waste, the moisture content of dehydrated kitchen waste residues is greatly reduced, and the improvement on the reduction degree of the treatment ofthe kitchen waste and the protection on the balance of a natural ecological environment are facilitated. The dehydration system provided by the invention achieves the aim of reducing the treatment cost.

Owner:余粮

Environment-friendly energy-saving chip water-scrubbing process and production line apparatus

InactiveCN102240592AMeet washing requirementsEmission reductionCleaning using liquidsWet separationProduction lineSlag

The invention discloses an environment-friendly energy-saving chip water-scrubbing process, comprising the following procedures: 1, a chip water-scrubbing procedure in a rinsing machine; 2, a dehydration procedure of water and chips in a screw dehydrator; 3, a slag-water separation procedure performed on water, silt, fine suspended matters and the like discharged from the screw dehydrator, which includes three steps of: (1) separating out the suspended matters and coarse soil sediments; (2) precipitating the silt; and (3) filtering the water; and 4, a procedure of feeding the filtered water back to the rinsing machine. The invention also discloses an environment-friendly energy-saving chip water-scrubbing production line apparatus comprising the rinsing machine, the screw dehydrator, a revolving grate, a rotary liquid tank and a fine filter, all of which are orderly communicated with each other, wherein the water outlet of the fine filter is communicated with the water inlet of the rinsing machine through a circulating water tank provided with a water pump. The process and the apparatus of the invention, compared with the traditional process and the traditional apparatus, are lower in production cost, and further meet the water scrubbing requirements for the chips and greatly reduce drainage of sewage, thereby reducing pollution on the environment.

Owner:GUILIN HUIZHONG CHEM EQUIP

Control method of washing machine and washing machine

ActiveCN111893707AImprove experienceShorten the timeControl devices for washing apparatusTextiles and paperLaundry washing machineControl engineering

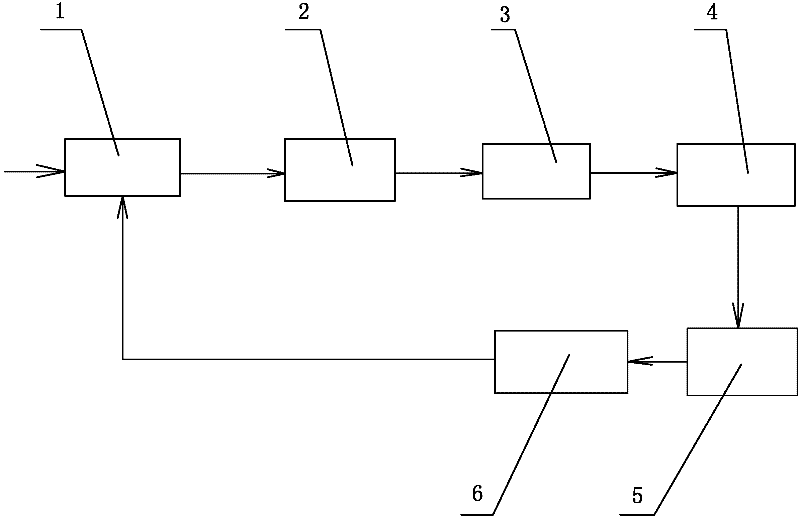

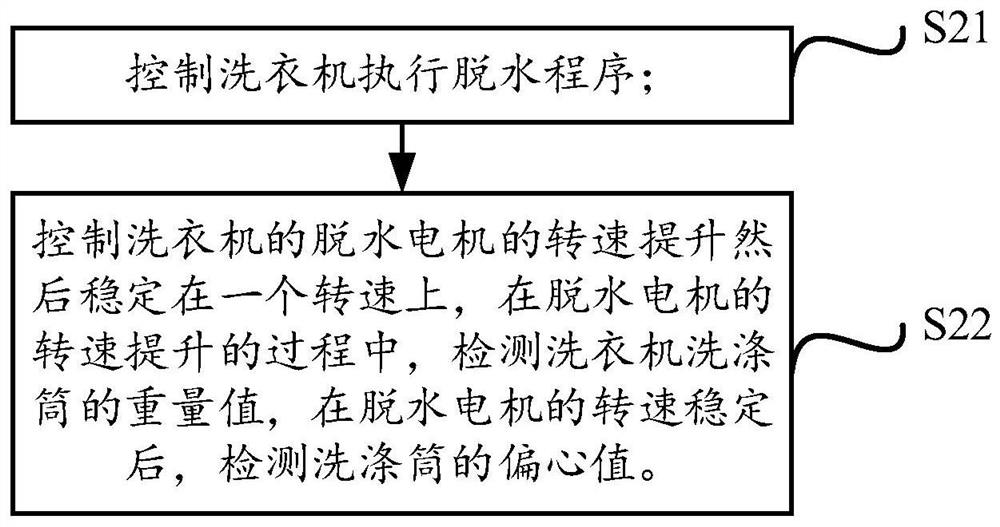

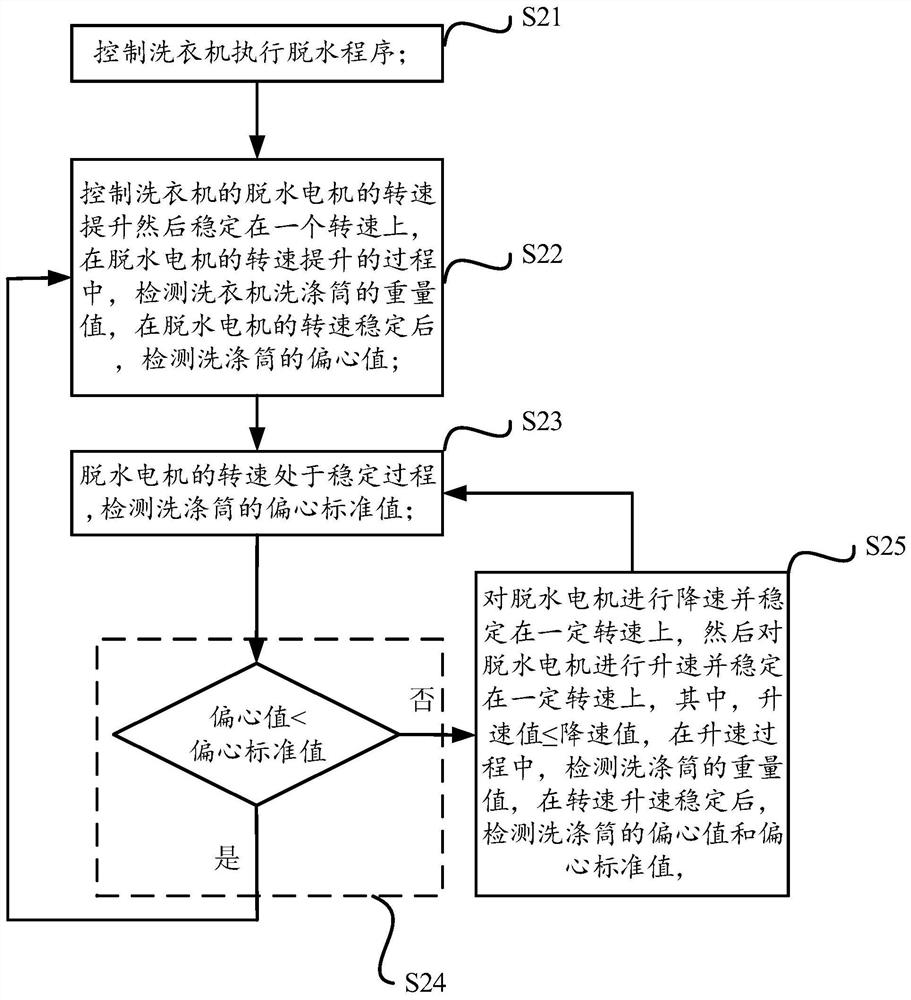

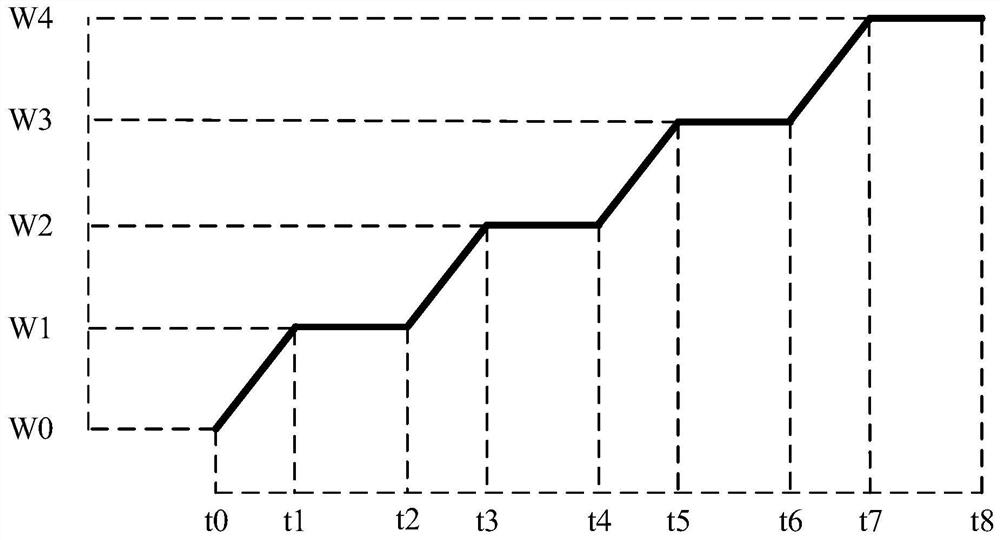

The invention provides a control method of a washing machine. The control method comprises a dehydration program S2, wherein the dehydration program S2 comprises the following steps: S21, controllingthe washing machine to execute the dehydration program; and S22, controlling the rotating speed of a dehydration motor of the washing machine to be increased and then stabilized at one rotating speed,detecting the weight value of a washing drum of the washing machine in the rotating speed increasing process of the dehydration motor, and detecting the eccentric value of the washing drum after therotating speed of the dehydration motor is stabilized. The invention further provides the washing machine. By adopting the control method of the washing machine, the weight value of the washing drum of the washing machine is detected in the rotating speed increasing process of the dehydration motor, and the eccentric value of the washing drum is detected after the rotating speed of the dehydrationmotor is stabilized, so that the speed increasing process of the dehydration motor can be fully utilized, the time is saved, the delay probability is reduced, the delay time is shortened, the electric quantity is saved, and the user experience is improved.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

Washing machine and dehydration control method and device thereof

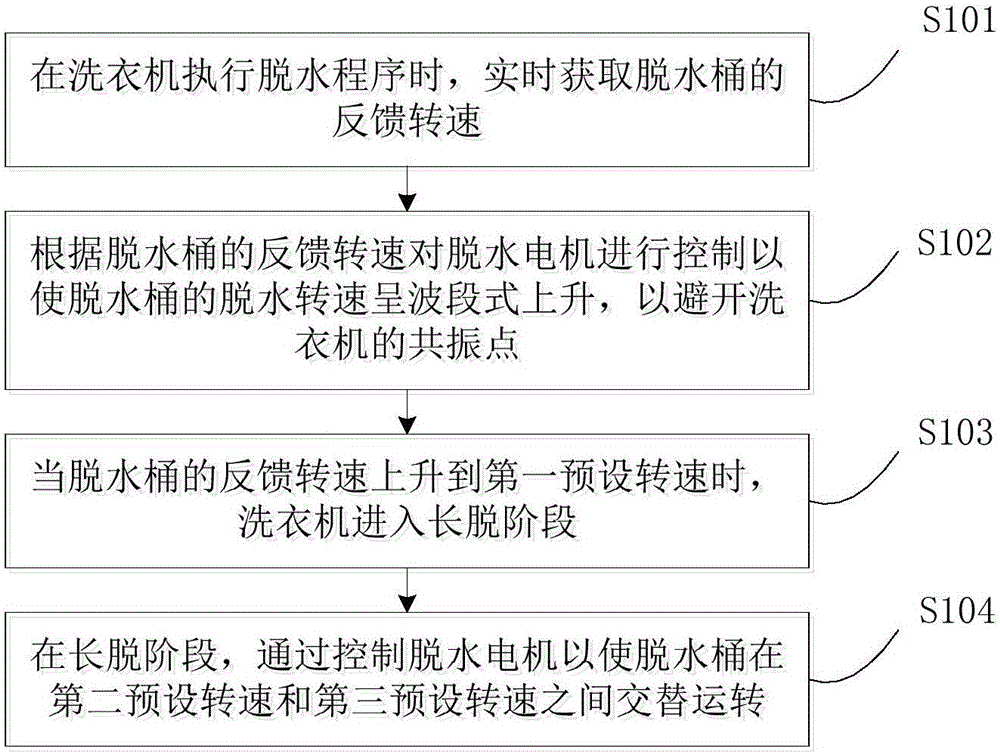

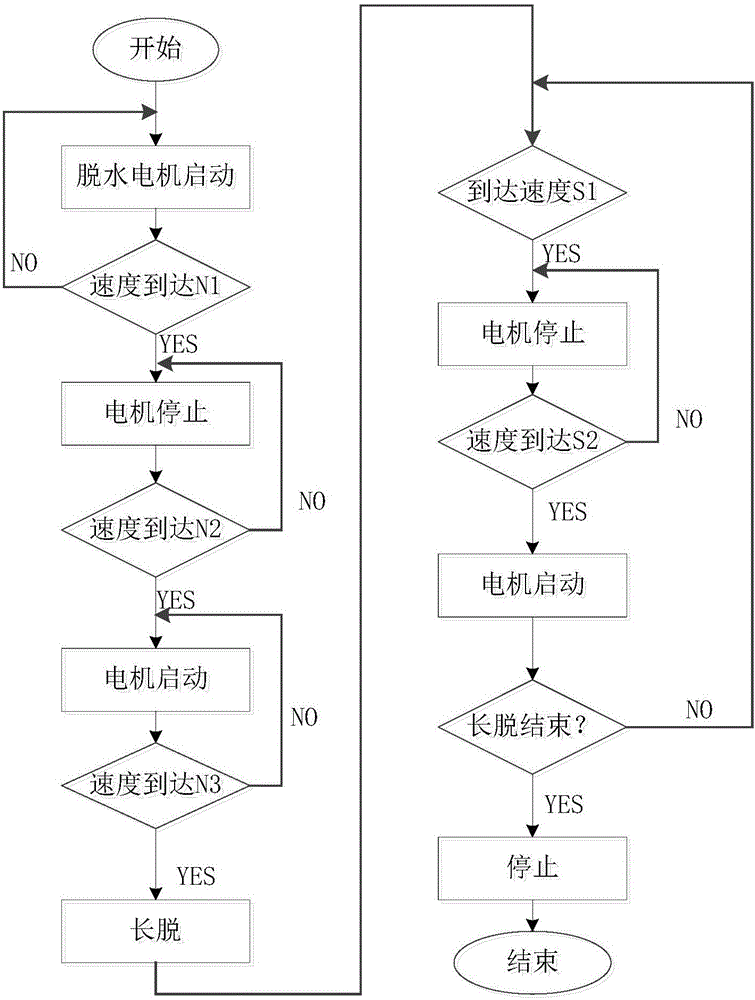

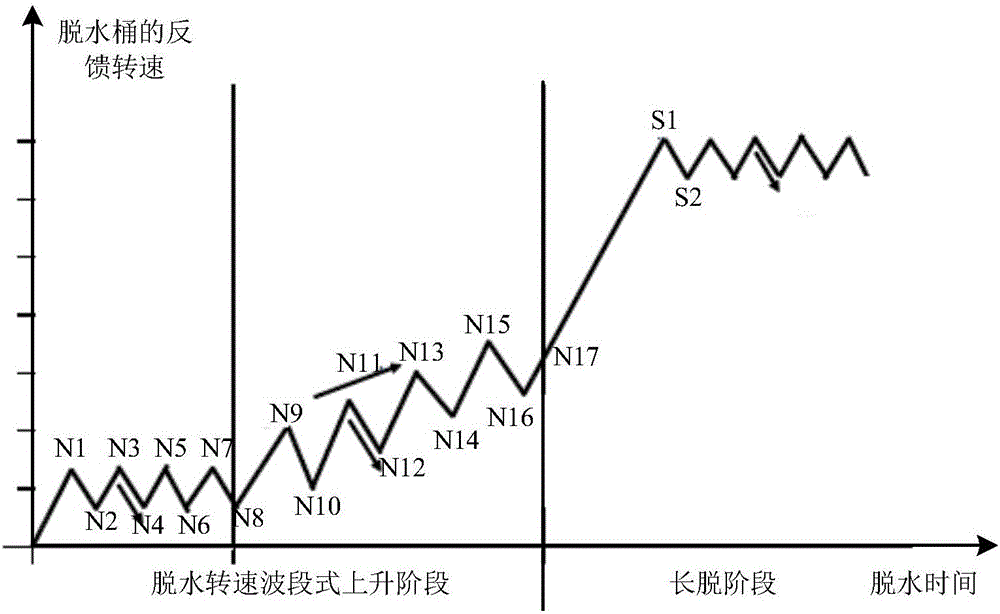

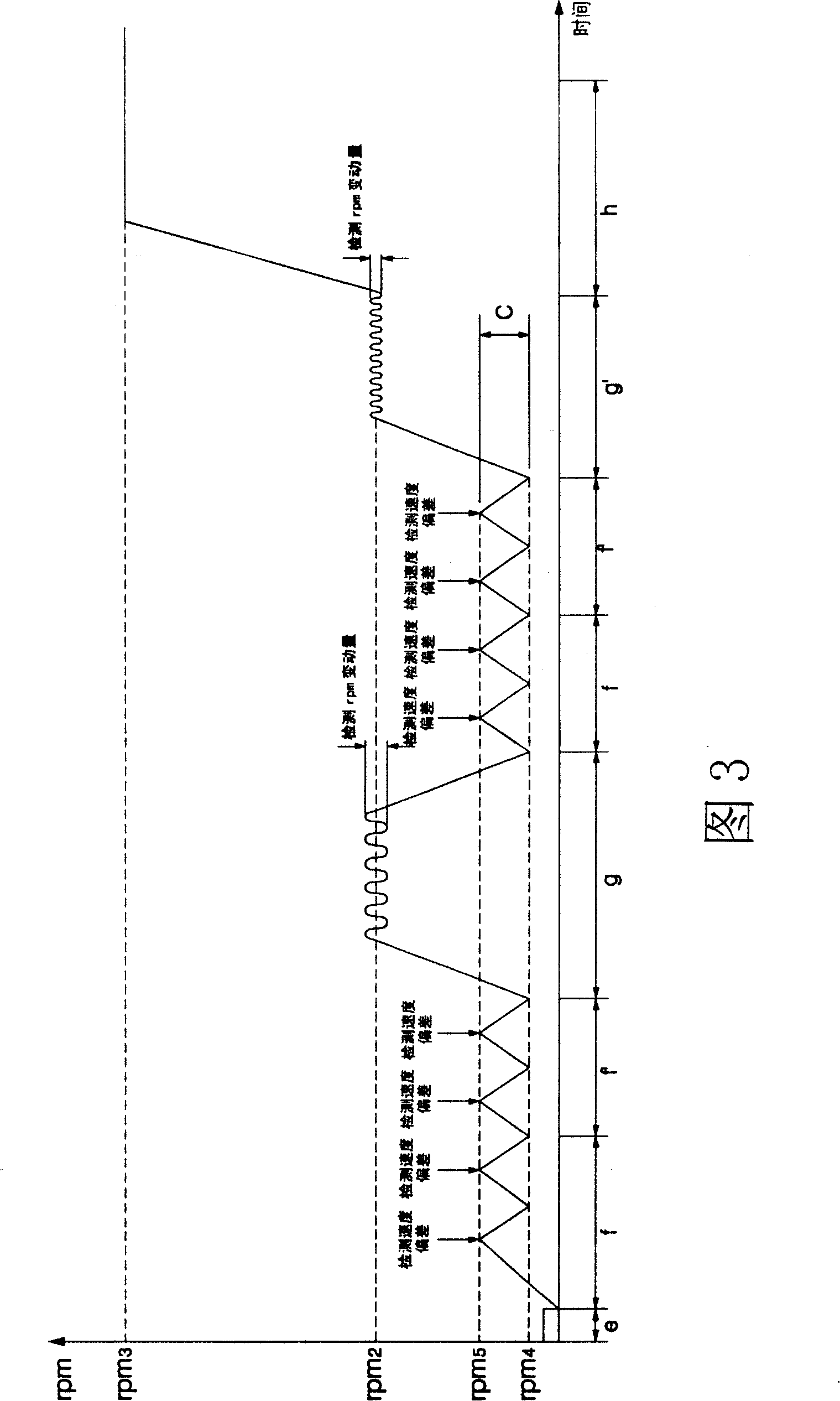

ActiveCN107177956AAvoid resonanceImprove dehydration effectOther washing machinesControl devices for washing apparatusWave formControl theory

The invention discloses a washing machine and a dehydration control method and device thereof. The washing machine comprises a dehydrating barrel and a dehydrating motor for driving the dehydrating barrel to run. The method comprises the steps of obtaining a feedback rotating speed of the dehydrating barrel in real time when the washing machine executes a dehydration procedure; controlling the dehydrating motor according to the feedback rotating speed of the dehydrating barrel to ascend the dehydrating rotating speed of the dehydrating barrel in a wave form to avoid a resonance point of the washing machine; when the feedback rotating speed of the dehydrating barrel ascends to a first preset rotating speed, entering the washing machine into a long dehydrating stage; driving the dehydrating barrel to alternately run at a second preset rotating speed and a third preset rotating speed through controlling the dehydrating motor at the long dehydrating stage, wherein the second preset rotating speed is greater than the third preset rotating speed and greater than the first preset rotating speed. According to the dehydration control method, the dehydration performance of the washing machine can be improved, abrasion of the dehydrating barrel is reduced and the implementation cost is low. The invention further discloses a computer-readable storage medium.

Owner:WUXI FILIN ELECTRONICS CO LTD

Washing machine and dehydration control method thereof

ActiveCN104846584AReduce wear and tearReduce consumptionControl devices for washing apparatusWashing machine with receptaclesEngineeringMechanical engineering

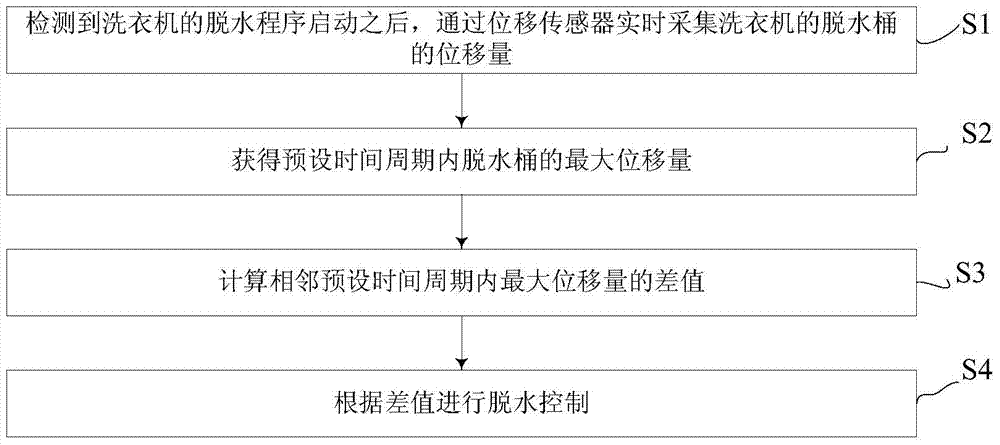

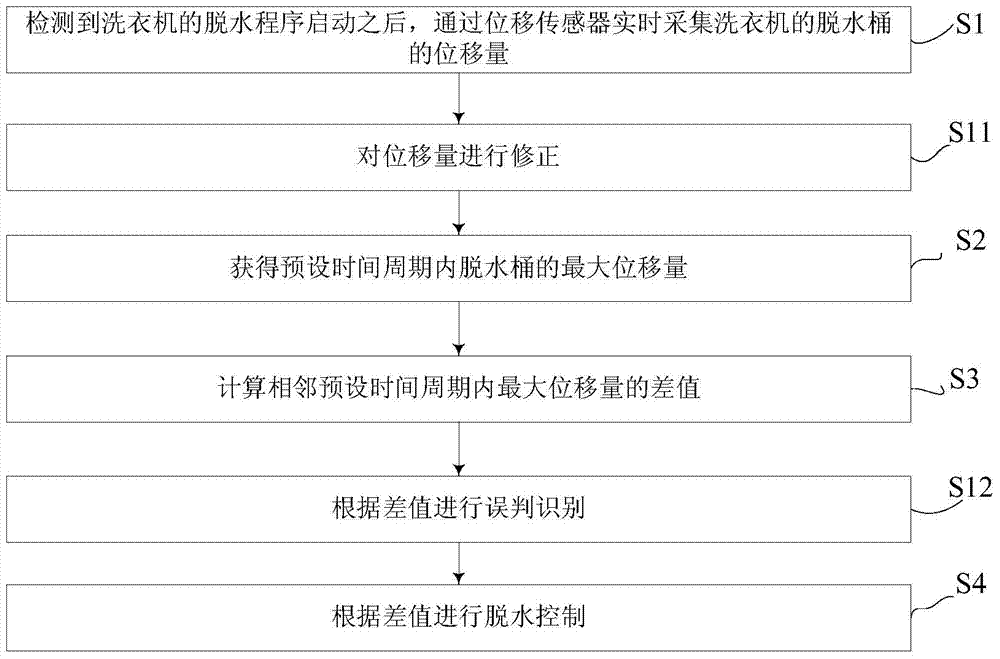

The invention discloses a dehydration control method of a washing machine. The washing machine comprises a displacement sensor. The dehydration control method comprises the following steps: collecting the displacement of a dehydrating barrel of the washing machine in real time through a displacement sensor after the dehydration procedure of the washing machine is started; obtaining the maximum displacement of the dehydrating barrel during a preset time period; calculating a differential value of the maximum displacement during adjacent preset time periods; and carrying out dehydration control according to the differential value. According to the dehydration control method of the washing machine provided by the invention, the wear of clothes can be reduced, and the energy consumption can be reduced. The invention further discloses the washing machine applying the dehydration control method.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Dehydration control method and device, computer readable storage medium and washing machine

PendingCN110938968AControl devices for washing apparatusTextiles and paperLaundry washing machineVibration acceleration

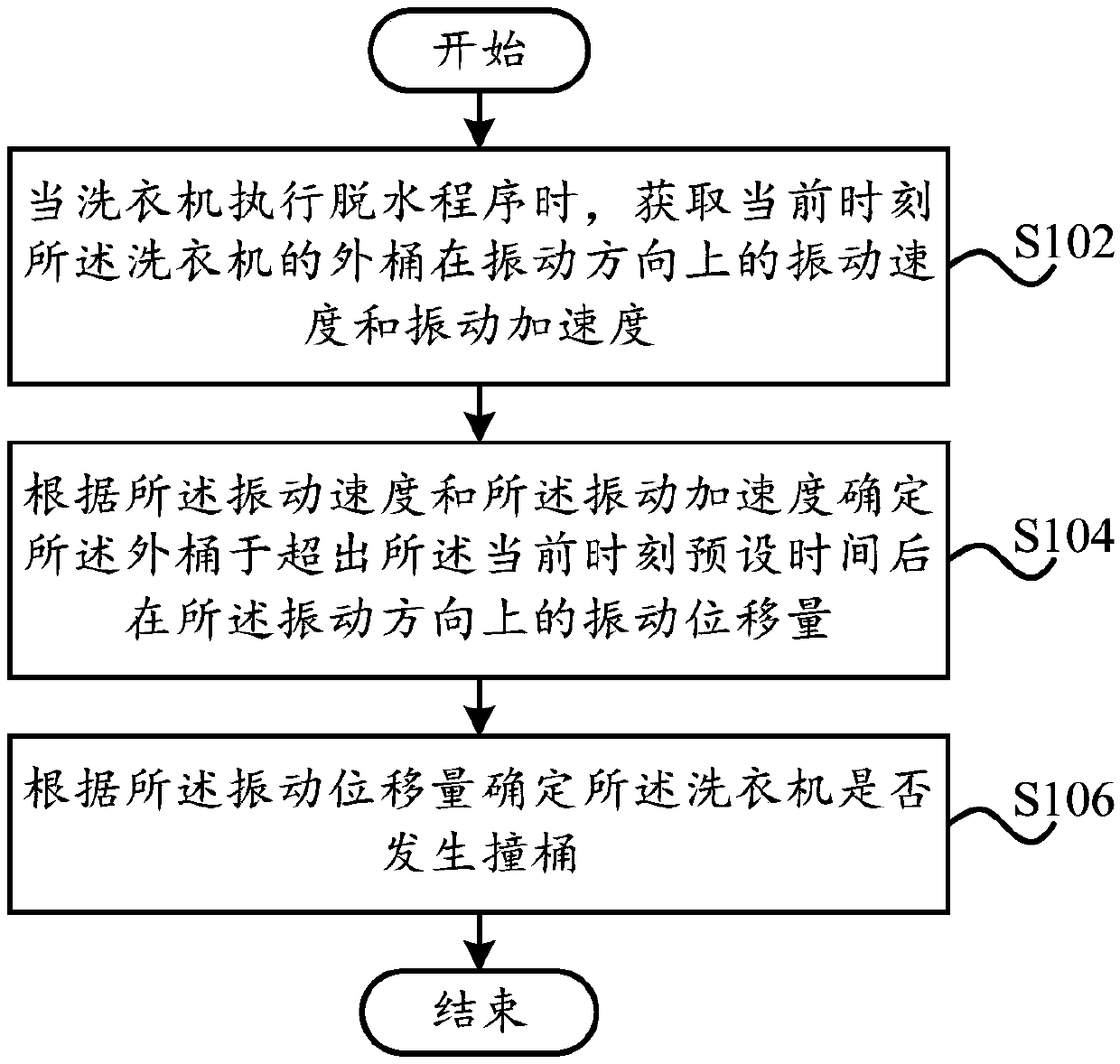

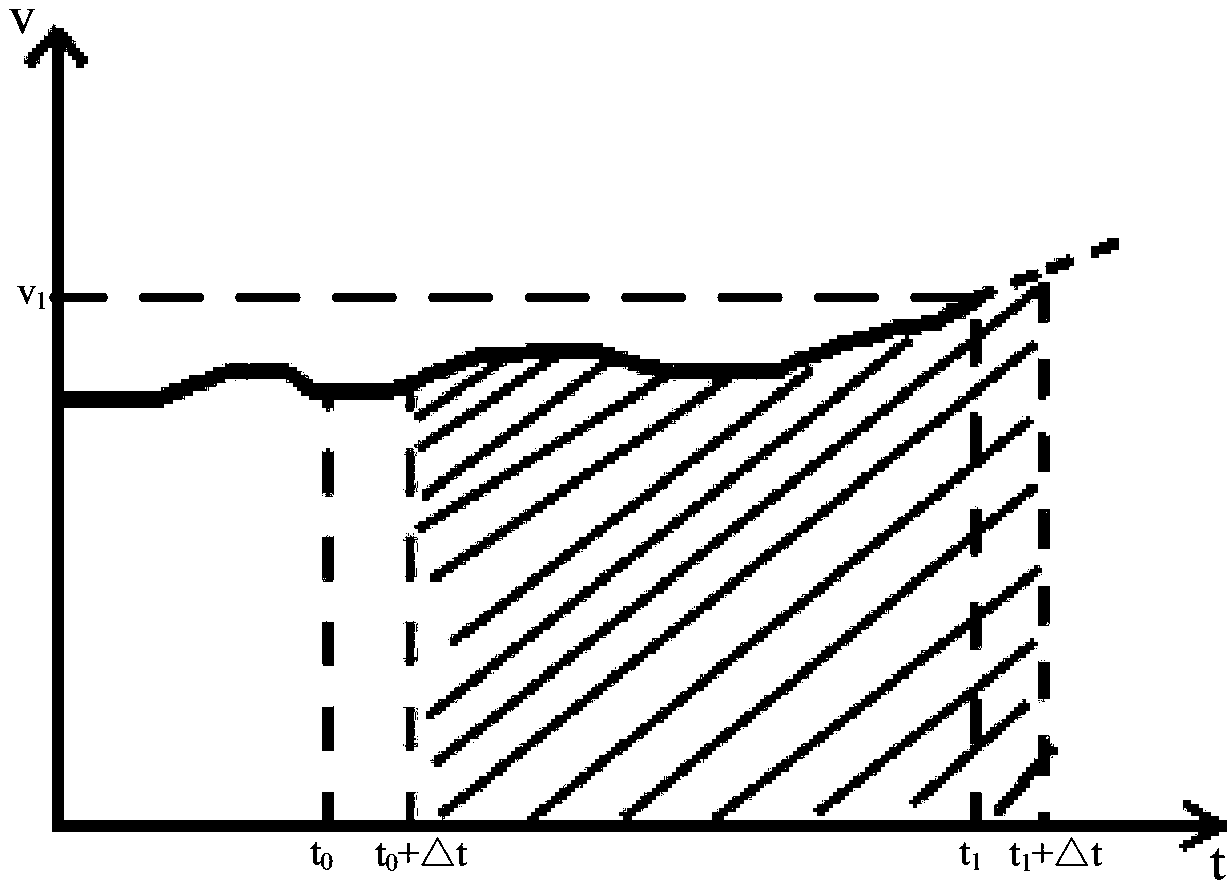

The invention provides a dehydration control method and device, a computer readable storage medium and a washing machine. The dehydration control method comprises the following steps of when the washing machine executes a dehydration program, acquiring the vibration speed and the vibration acceleration of an outer barrel of the washing machine in the vibration direction at the current moment; according to the vibration speed and the vibration acceleration, determining the vibration displacement amount of the outer barrel in the vibration direction after the current moment is exceeded by the preset time; and determining whether barrel collision of the washing machine occurs or not according to the vibration displacement amount. According to the technical scheme, the accuracy and timelinessof a judgment result of judging whether the barrel collision event of the washing machine occurs or not can be effectively improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD +1

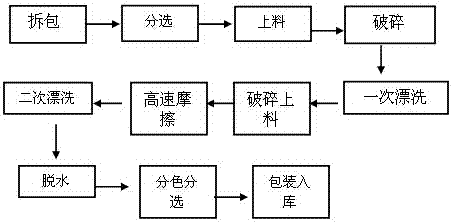

Polyethylene (PE) bottle scrap production process

InactiveCN106965345AEasy to cleanSimple production processPlastic recyclingMechanical material recoveryEconomic benefitsEngineering

The invention discloses a polyethylene (PE) bottle scrap production process. The process includes the following steps that a packaging bag of recycled bagged plastic bottles is automatically opened through an unpackaging machine; the plastic bottles taken out of the bag are classified and sorted; the sorted PE plastic bottles are conveyed through a plate chain feeding machine to a subsequent crushing procedure so as to be crushed; PE plastic scraps obtained after crushing are conveyed into a rinsing machine to be rinsed; rinsed crushed PE plastic scraps are conveyed into a high-speed friction machine behind to be further processed and broken; then the PE plastic scraps are rinsed again and subjected to a dehydration procedure; dehydrated PE bottle scraps are separated and sorted according to the colors through a color separation machine; and the PE scraps different in colors are conveyed to different packaging machines correspondingly to be packaged and delivered into a warehouse so as to be stored. According to the PE bottle scrap production process, the whole production process is simple, manual operation is convenient, the labor intensity is low, thus, the production and cleaning time is shortened, the cleaning efficiency is improved, the cost is reduced, and the economic benefits are high.

Owner:江苏力赛柯环保材料科技有限公司

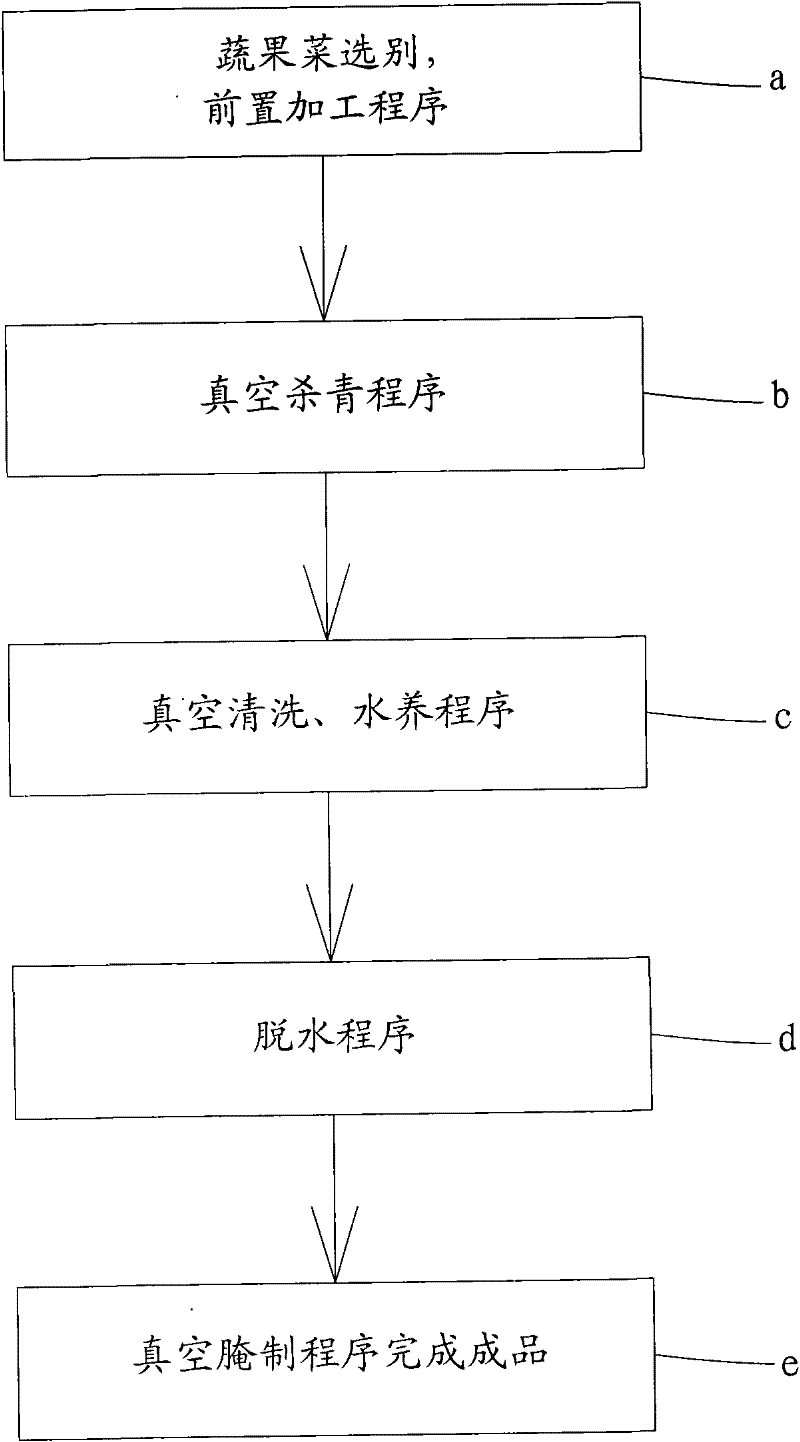

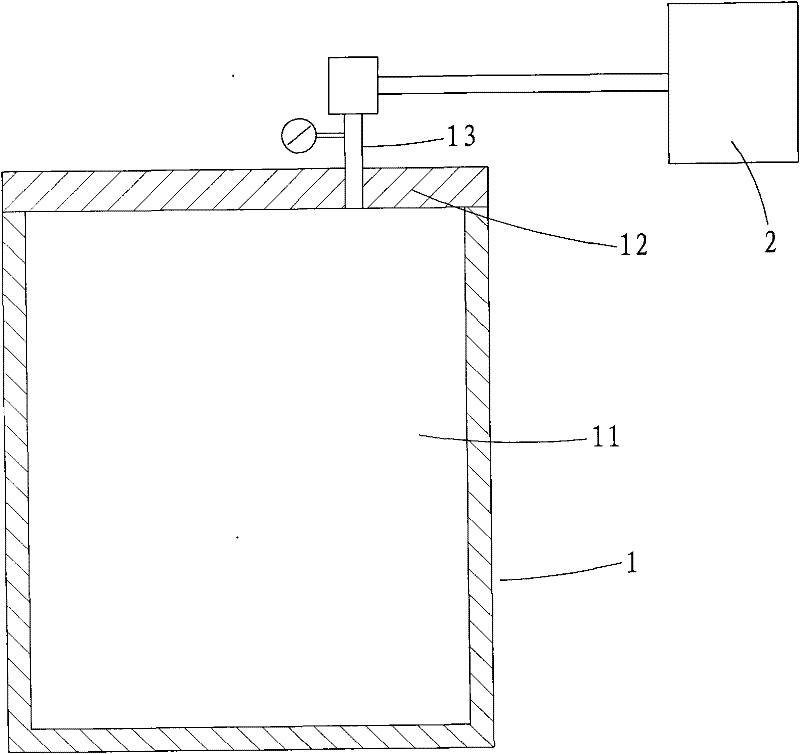

Pickling method of fresh vegetables and fruits

InactiveCN102266028AHygienic Freshness GuaranteeImprove freshnessClimate change adaptationFood preparationVacuum pressureSalt water

The invention discloses a pickling method for fresh vegetables and fruits. The method comprises the following steps: a. vegetables and fruits selection and a preprocessing procedure; b. a vacuum deactivation procedure: mixing the vegetables and fruits with salt water in a set proportion, and maintaining vacuum pressure and setting time by vacuum equipment; c. a vacuum cleaning and water maintenance procedure: dripping salt water from the deactivated vegetables and fruits, mixing the vegetables and fruits with clear water, maintaining a near vacuum pressure and setting time by vacuum equipment; d. a dehydration procedure: dehydrating surface water on vegetables and fruits after cleaning and water maintenance; e. a vacuum pickling procedure for finished products: mixing the dehydrated vegetables and fruits with flavorings, maintaining a near vacuum pressure and setting time by vacuum equipment, resuming to an atmospheric pressure and removing pickled vegetables and fruits to obtain finished products. The pickling method can increase freshness, sanitation and pickling rate of vegetables and fruits and realize rapid batch production, and has promising business value.

Owner:胡耀忠 +2

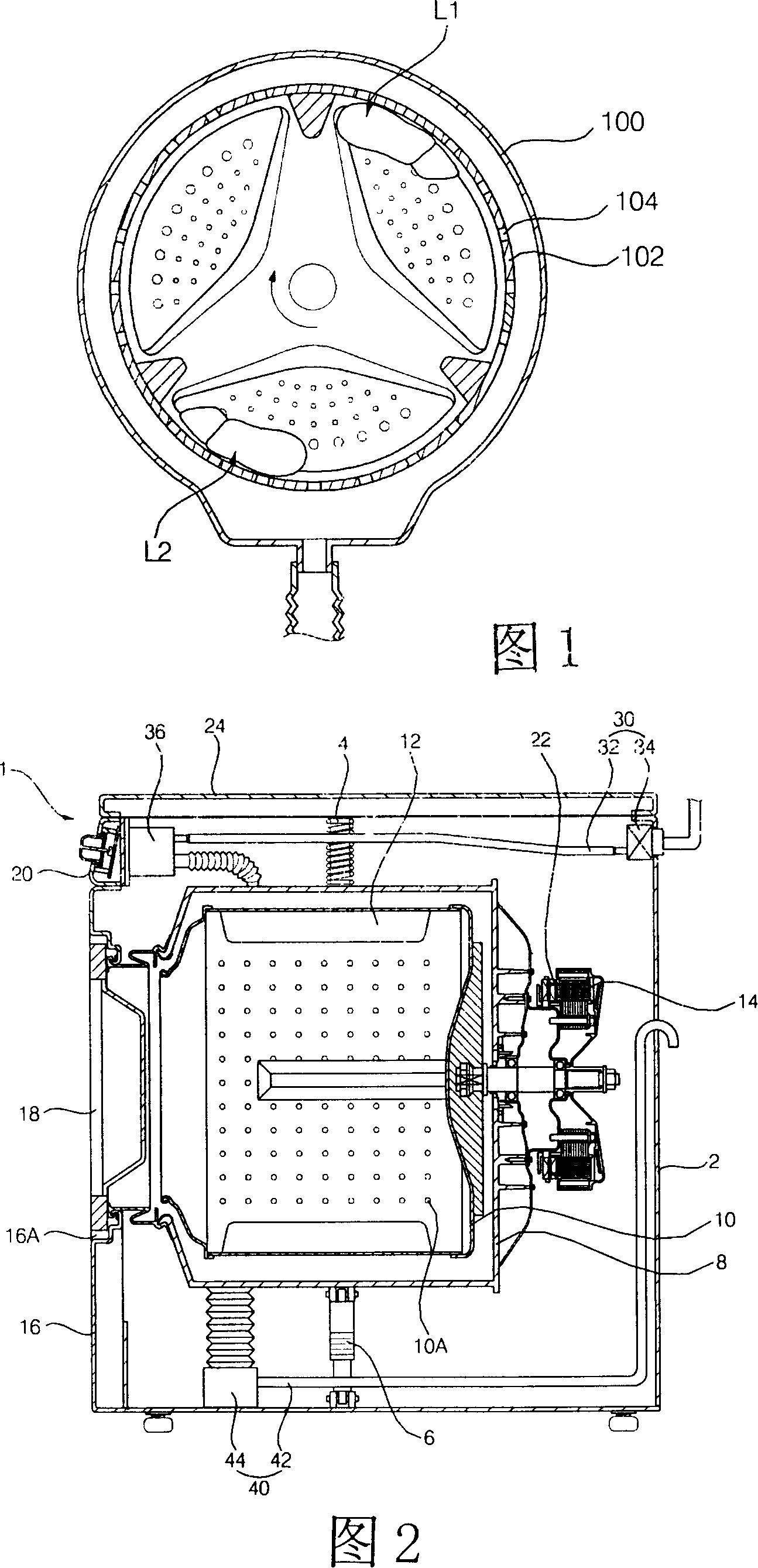

Dewatering method for drum washing machine

InactiveCN101173455AShorten spin timeControl devices for washing apparatusWashing machine with receptaclesControl theoryVoltage

The invention relates to a dehydration method for a cylinder washing machine, comprising a plurality of procedures: the single load detection procedure, after the motor accesses to a set voltage, the rotation number of the cylinder is detected at a set time to determine whether the washing packet in the cylinder is a single load. The washing packet opening procedure, if the washing packet is a single load, the motor is accelerated and decelerated repeatedly in the washing packet flowing rpm interval and the washing packet in execution is opened; simultaneously, the velocity deviation of the cylinder is detected to determine whether to do eccentricity detection. The single load eccentric magnitude detecting procedure, if the velocity deviation is lower than the reference velocity deviation, the eccentric magnitude of the washing packet is detected and is compared with the reference velocity deviation. The single load main dehydration procedure: if the eccentric magnitude is lower than the reference eccentric magnitude or the velocity deviation is higher than the reference velocity deviation, the cylinder rotates at a high speed through the motor and does centrifugal dewatering for the washing packet. The invention has the advantage of shortened single load dehydration time.

Owner:NANJING LG PANDA APPLIANCES

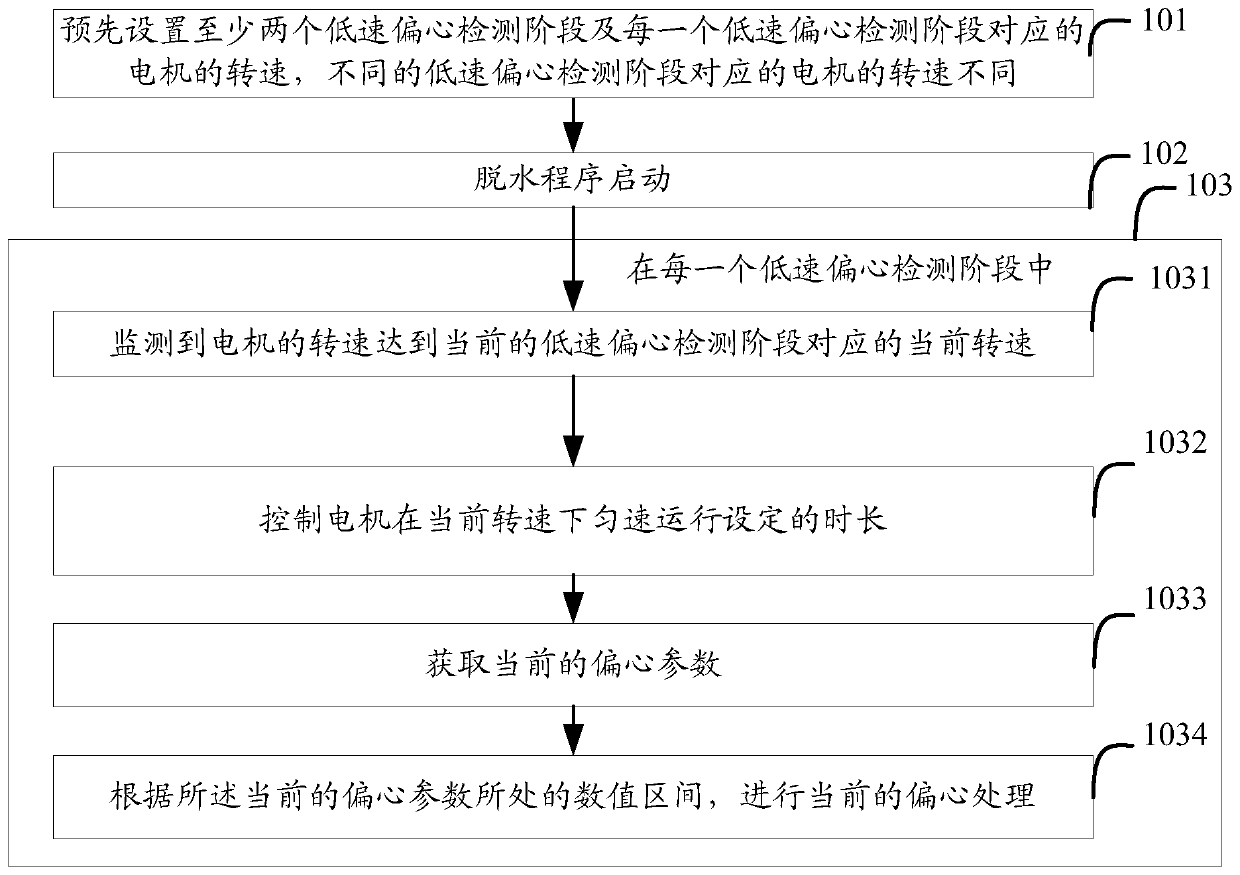

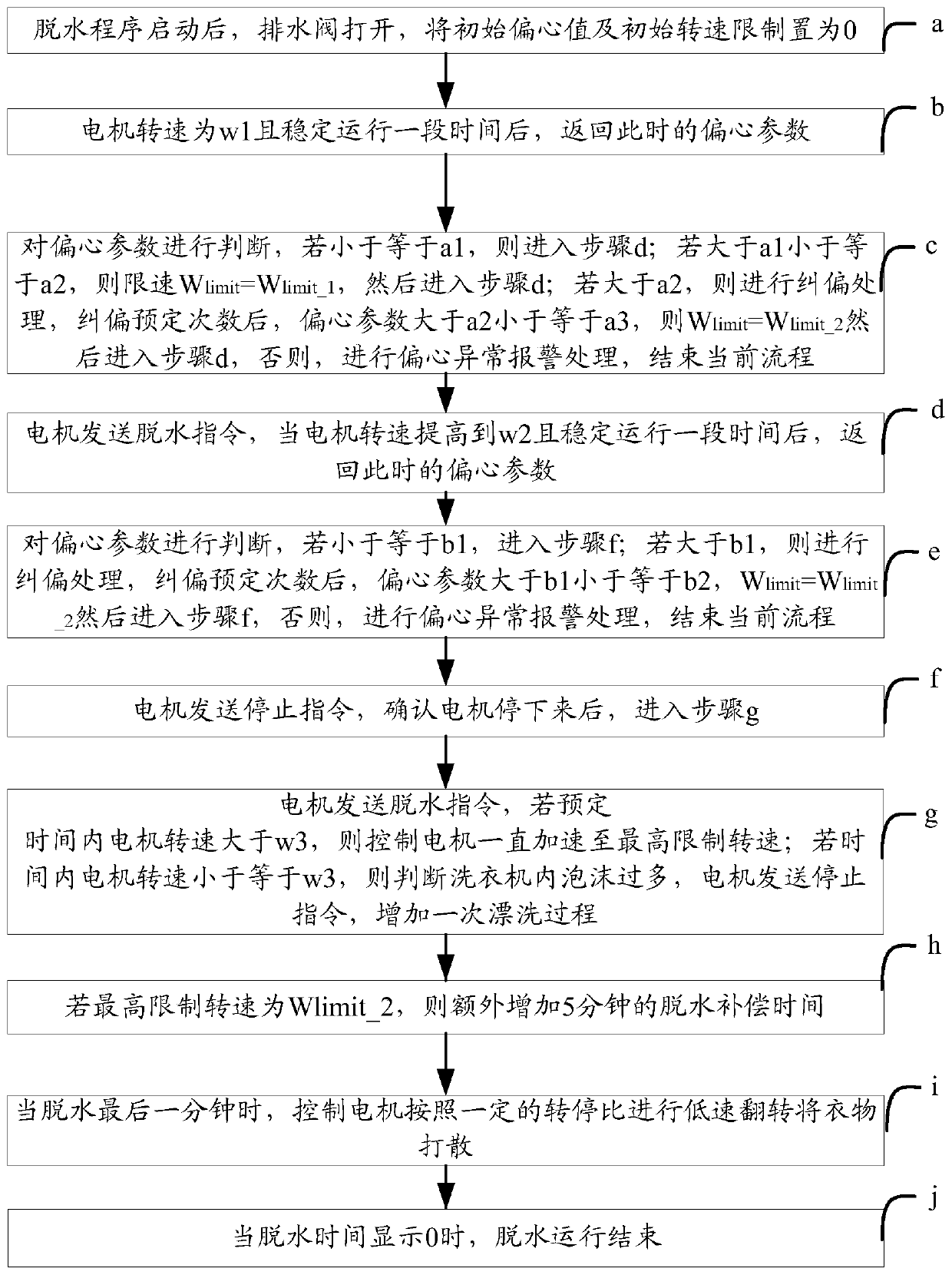

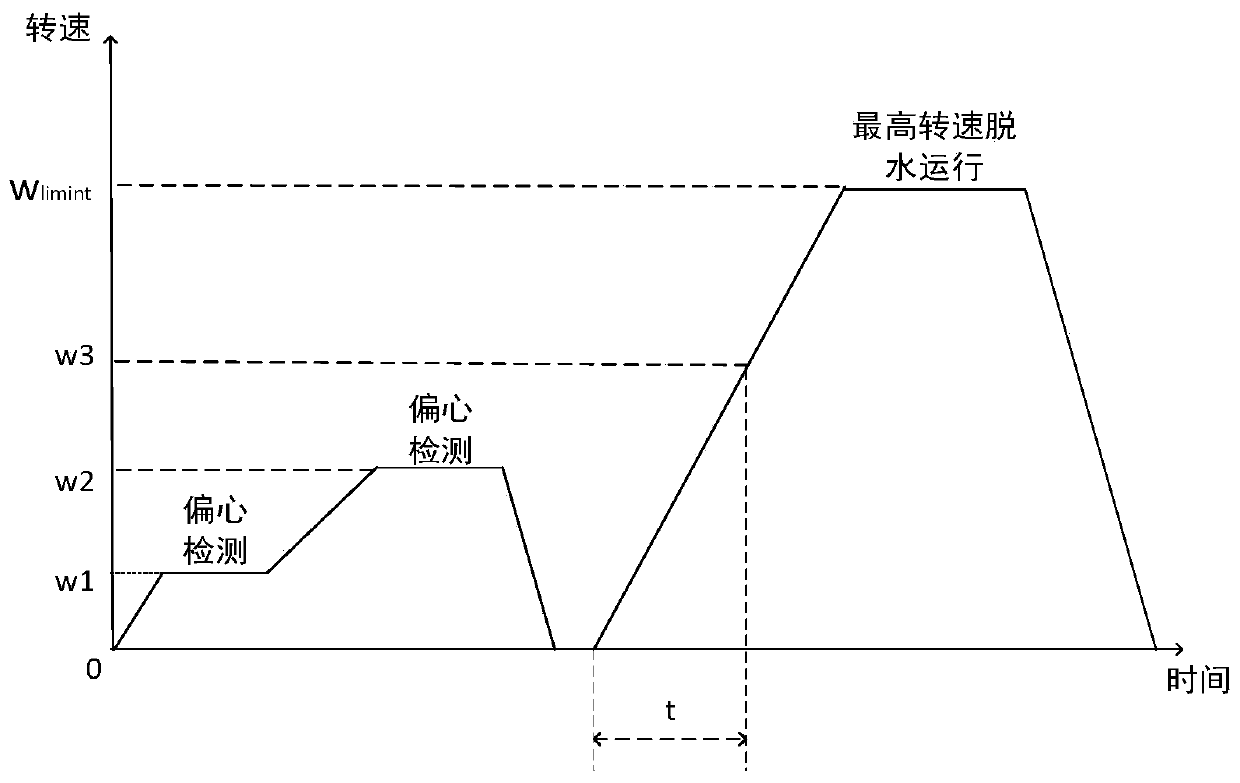

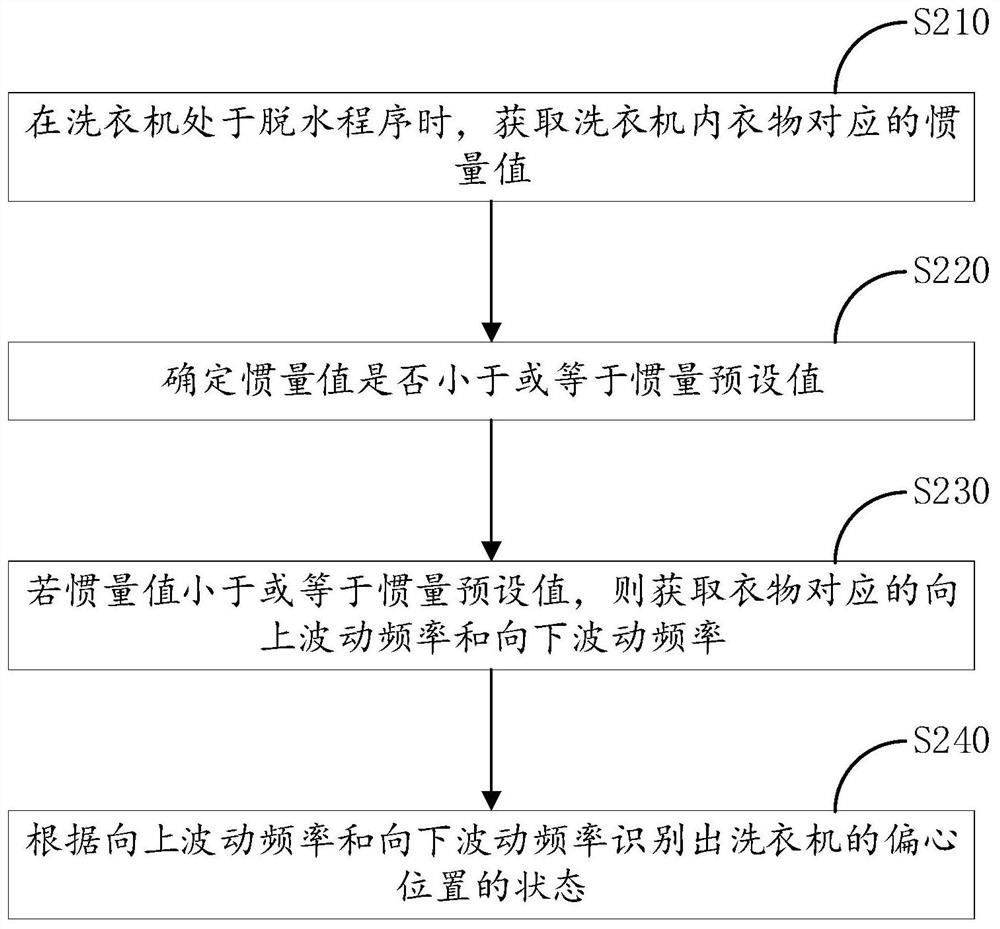

Dehydration control method of drum washing machine and drum washing machine

ActiveCN110924057AEnsure vibrationCheck result is accurateControl devices for washing apparatusTextiles and paperLaundry washing machineControl engineering

The invention provides a dehydration control method of a drum washing machine and the drum washing machine. The method comprises the following steps that at least two low-speed eccentric detection stages and the rotating speed of motors corresponding to each low-speed eccentric detection stage are set, and the rotating speeds of the motors corresponding to different low-speed eccentric detection stages are different; after a dehydration program is started, at each low-speed eccentric detection stage, the following operations are executed: when the rotating speed of the motor reaches the current rotating speed corresponding to the current low-speed eccentric detection stage, the motor is controlled to perform constant-speed operation for a set duration at the current rotating speed; a current eccentric parameter is obtained; and according to a located value interval of the current eccentric parameter, the current eccentric treatment is performed. The dehydration control method and the drum washing machine adopting the scheme have the advantage that the vibration of the washing machine can be more reliably enabled to be in a controlled range during high-speed dehydration.

Owner:SICHUAN HONGMEI INTELLIGENT TECH CO LTD

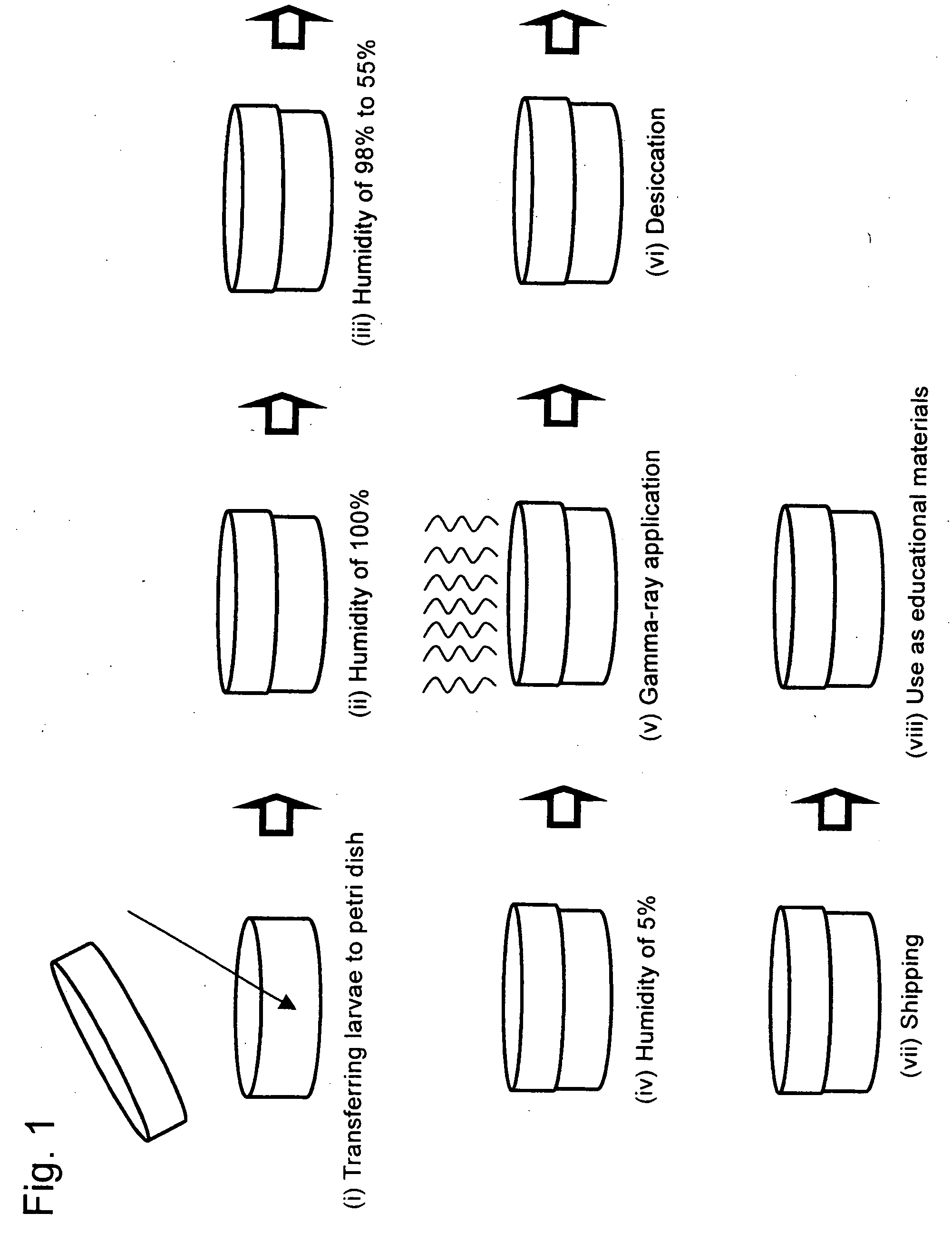

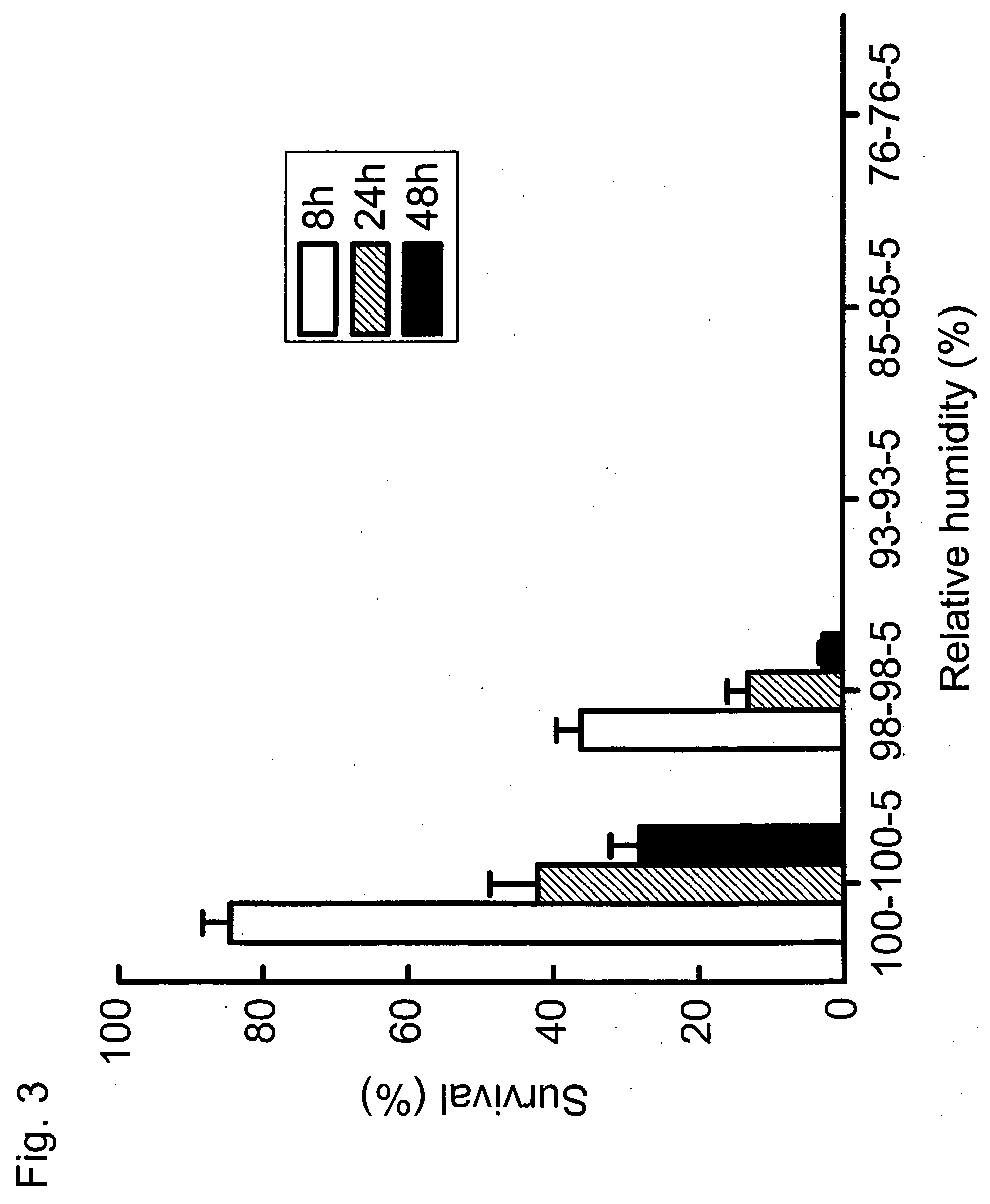

Dehydration procedures for induction of cryptobiosis in insect larvae

InactiveUS20060160061A1Efficient productionDo not damage the environmentDead animal preservationEducational modelsCryptobiosisZoology

This invention provides a method for effectively producing dehydrated larvae for educational materials without disrupting the environment. The cryptobiotic larvae for educational materials can be obtained by dehydrating larvae while gradually reducing humidity in 3 separate stages.

Owner:NAT INST OF AGROBIOLOGICAL SCI

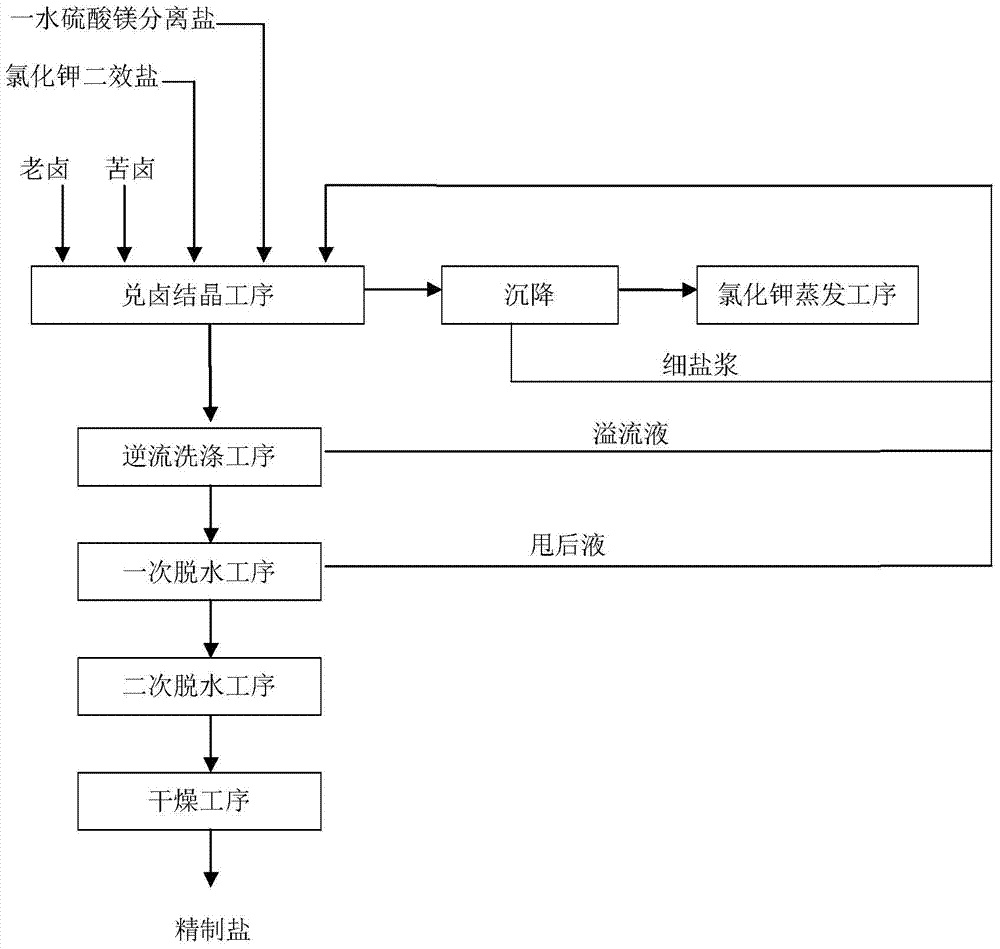

Method for improving granularity and purity of chemical salt byproducts of acrid bittern

InactiveCN103496719ASolve the problem of fine particle size and low purityFine granularityAlkali metal chloridesProcess engineeringChloride sodium

The invention discloses a method for improving the granularity and the purity of chemical salt byproducts of acrid bittern. The method comprises a brine mixing crystallization procedure, a countercurrent washing procedure, a primary dehydration procedure, a secondary dehydration procedure and a drying procedure. According to the method, the problems of lower granularity and low purity of the chemical salt byproducts of the acrid bittern are effectively solved; proper process measures are taken to collect three salt byproducts to one place for production; a brine mixing crystallizer and countercurrent washing equipment are used for remarkably improving the granularity and quality of the salt byproducts to a first-grade state refined salt standard. According to the technical scheme, changes in the ratio of potassium to magnesium in brine are avoided, and the technical scheme can be smoothly implemented in an acrid bittern chemical enterprise. By a mixing crystallization process, the sodium chloride content of mixed brine is lowered, and the quality of a downstream product can be more favorably improved.

Owner:天津长芦汉沽盐场有限责任公司

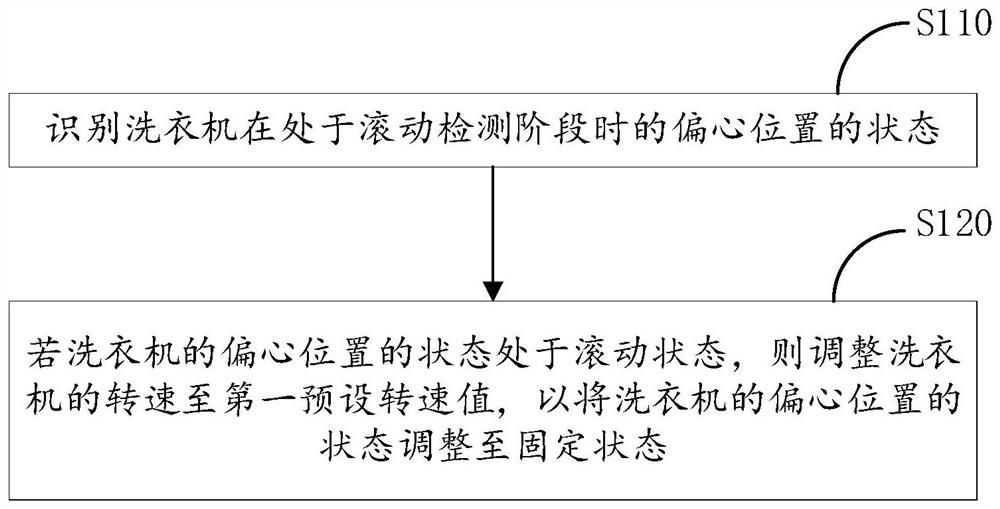

Washing machine control method and device and washing machine

PendingCN113652838AAvoid bad consequencesControl devices for washing apparatusTextiles and paperLaundry washing machineControl engineering

The invention belongs to the field of washing machines, and particularly relates to a washing machine control method and device and a washing machine. The washing machine has a dehydration program, and the dehydration program has an eccentric detection stage, and the control method comprises the steps that the state of the eccentric position of the washing machine in the rolling detection stage is recognized; if the state of the eccentric position of the washing machine is in a rolling state, the rotating speed of the washing machine is adjusted to a first preset rotating speed value so as to adjust the state of the eccentric position of the washing machine to a fixed state. The state of the eccentric position of the washing machine is recognized, when the state of the eccentric position of the washing machine is in the rolling state, the rotating speed of the washing machine is adjusted to adjust the state of the eccentric position of the washing machine to the fixed state, and therefore serious consequences caused by the fact that the washing machine is in the rolling state are avoided.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

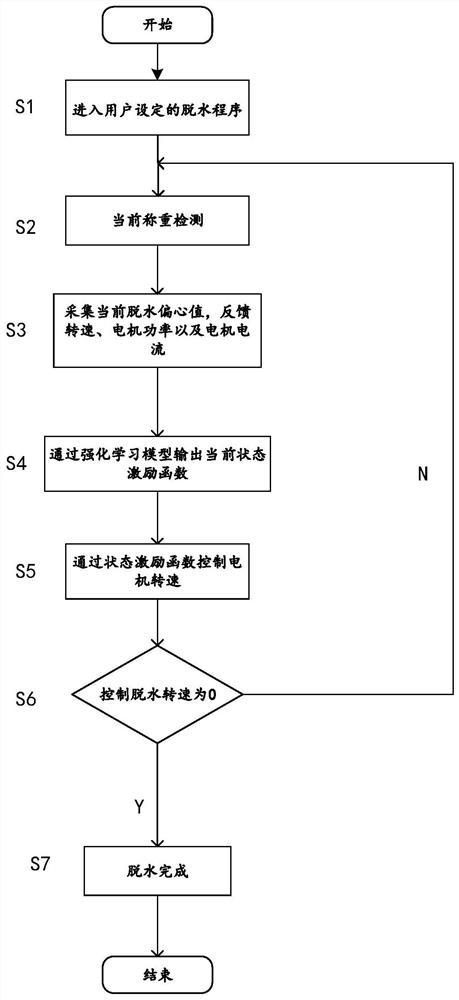

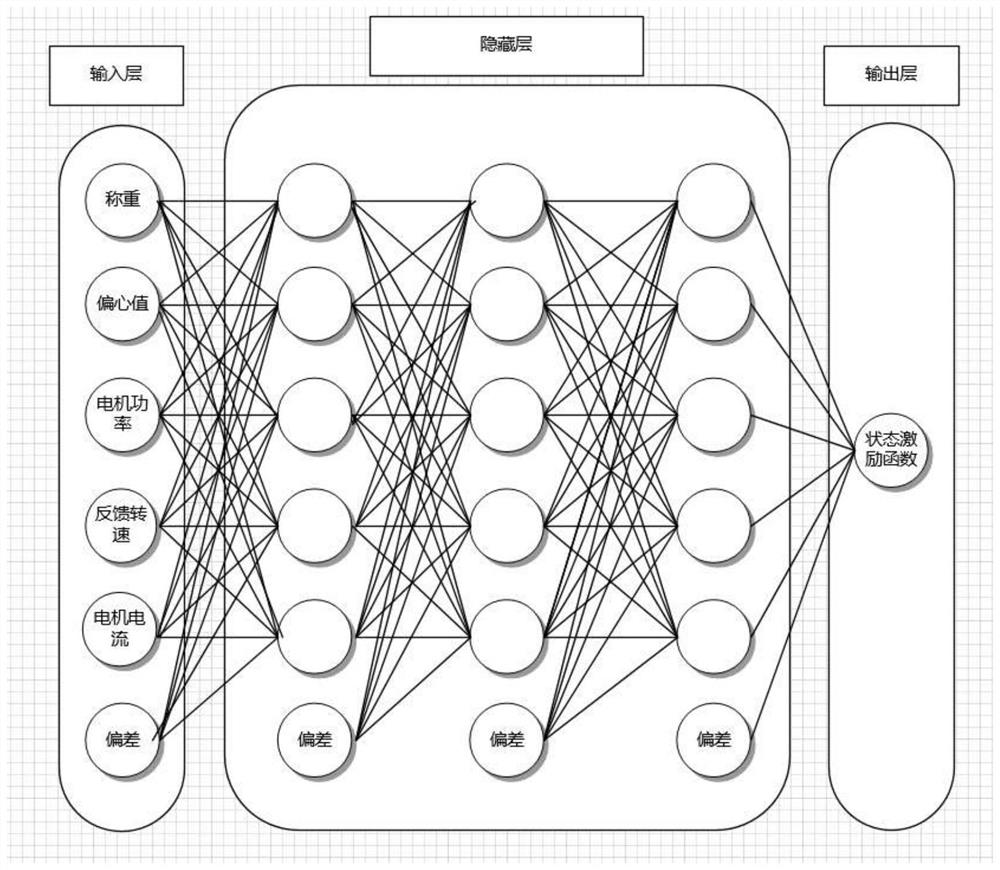

Washing machine dehydration control method and device based on deep reinforcement learning

ActiveCN112663282AReduce wearThoroughly dehydratedControl devices for washing apparatusTextiles and paperLaundry washing machineProcess engineering

The invention provides a washing machine dehydration control method based on deep reinforcement learning. The washing machine dehydration control method based on deep reinforcement learning comprises the steps of when a washing machine enters a dehydration program, collecting information related to dehydration; inputting the information related to dehydration into a deep reinforcement learning model for calculation, and outputting an excitation function of a dehydration state; and performing dehydration control on the washing machine through the excitation function. The invention further provides a washing machine dehydration control device based on deep reinforcement learning, a washing machine and a storage medium. By means of the scheme, the most appropriate dehydration rotating speed is obtained, abrasion to clothes is reduced, the clothes are dehydrated more thoroughly, unnecessary dehydration time is saved, and unnecessary electric energy loss is saved.

Owner:GREE ELECTRIC APPLIANCES INC

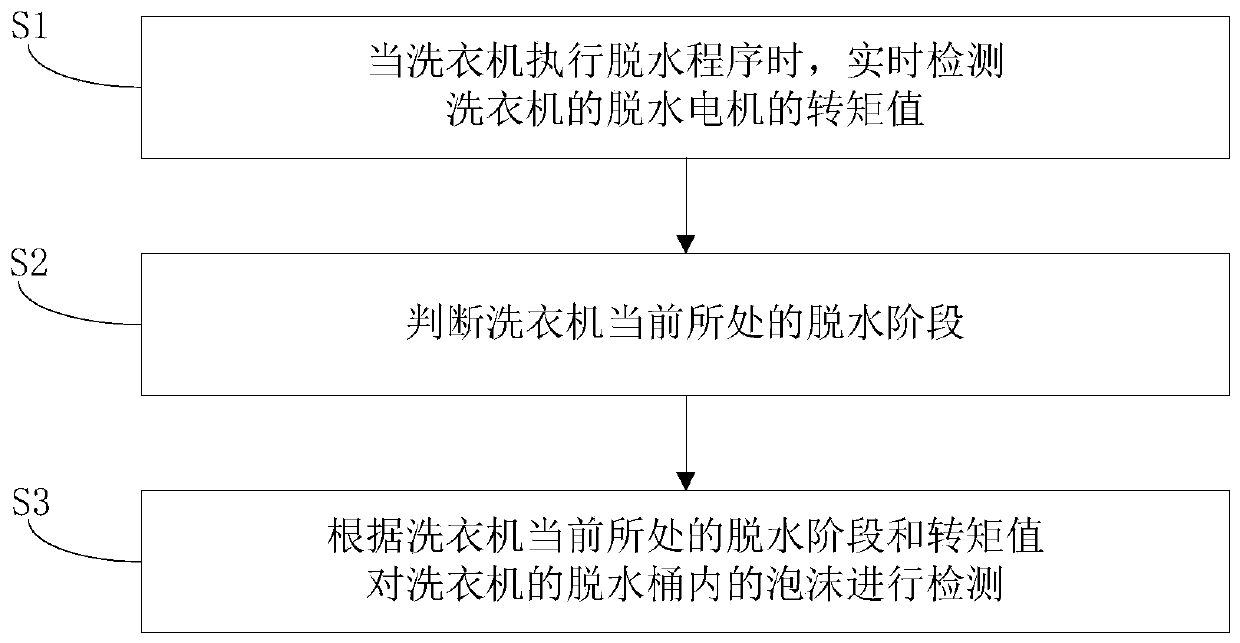

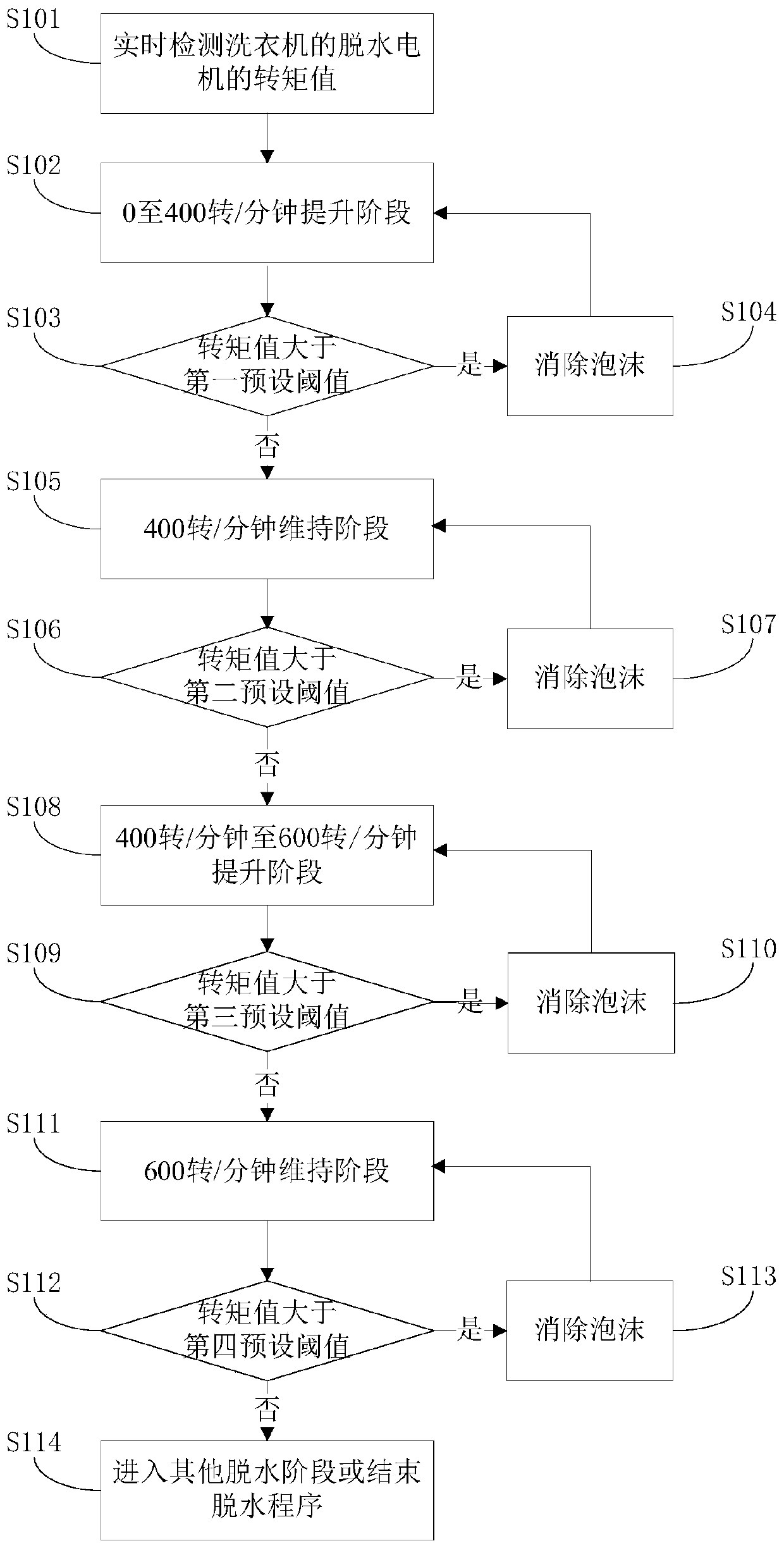

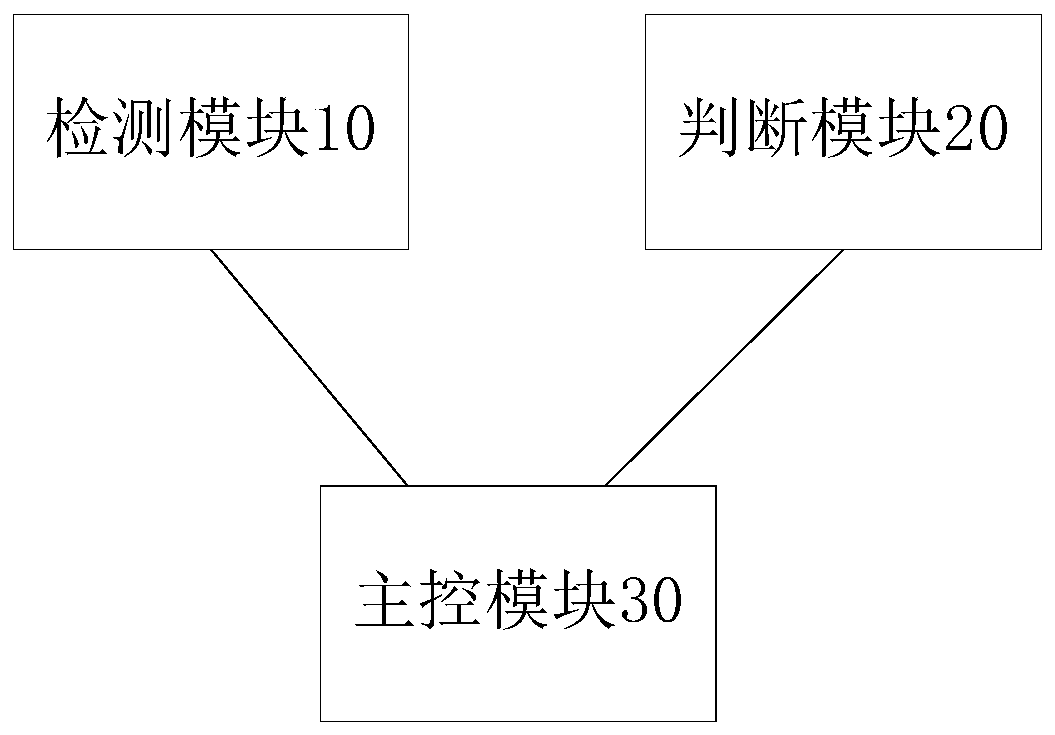

Washing machine and foam detection method and device thereof

ActiveCN107059353BGuaranteed uptimeOther washing machinesControl devices for washing apparatusPulp and paper industryLaundry washing machine

The invention discloses a washing machine and a foam detecting method and device thereof, wherein the method comprises the following steps: when the washing machine executes a dehydration program, detecting the torque value of the dehydrating motor of the washing machine in real time; determining the dehydration stage of the washing machine currently being located The foam in the dewatering bucket of the washing machine is detected according to the dewatering stage and the torque value at which the washing machine is currently located. According to the method of the present invention, it is possible to effectively detect whether the foam in the dewatering bucket is excessive, so as to take corresponding defoaming measures when the foam is excessive, so as to ensure safe and reliable operation of the washing machine.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

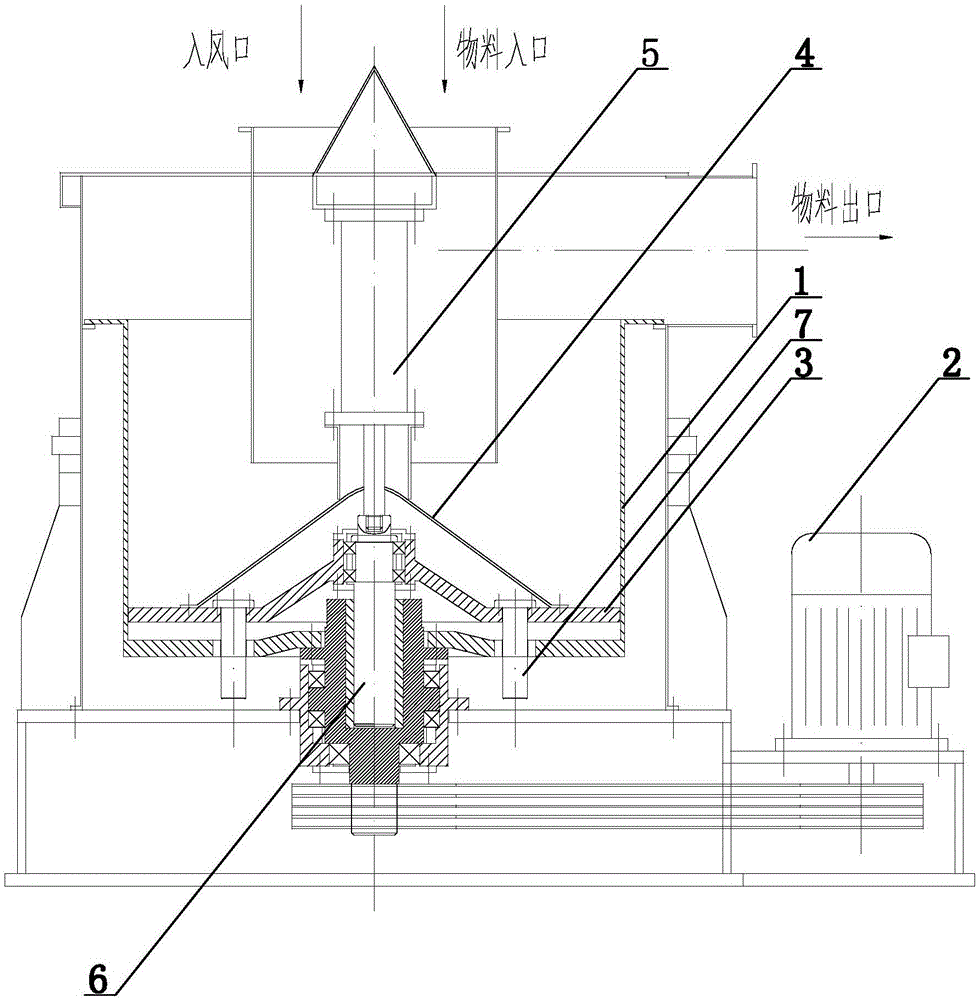

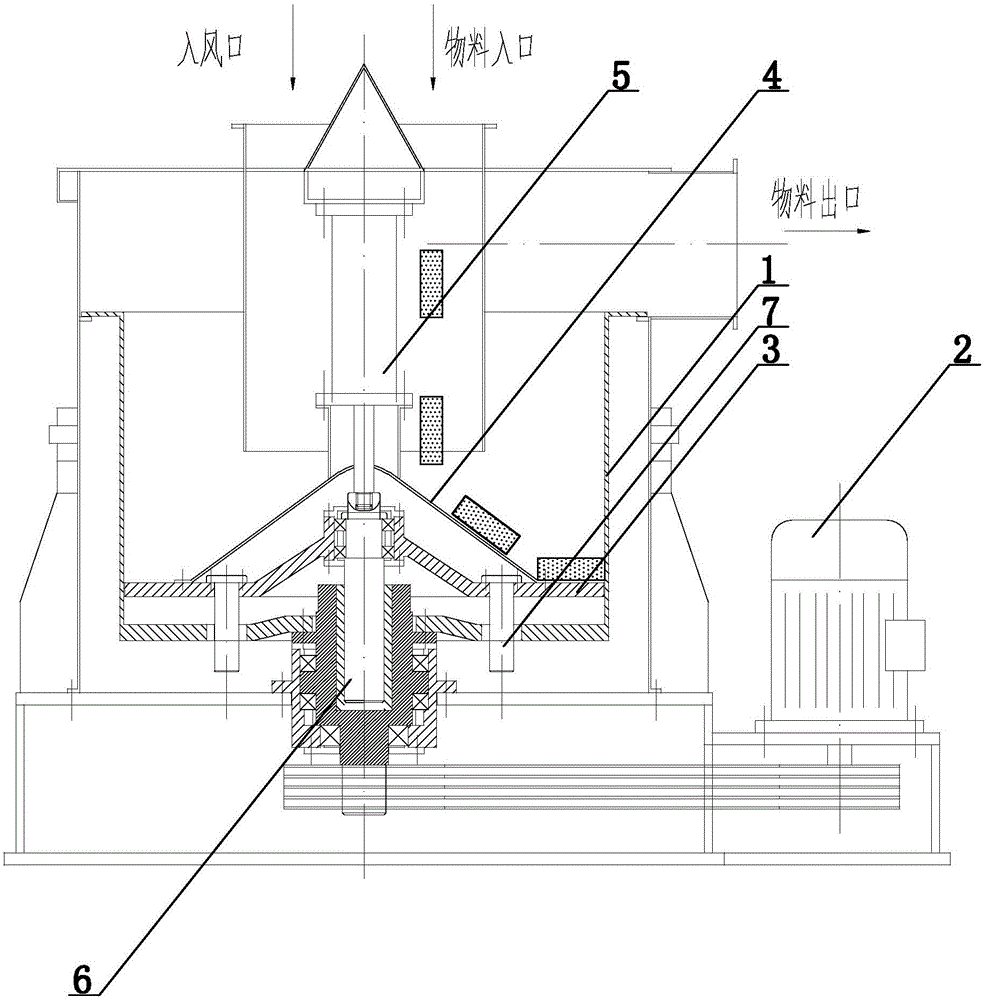

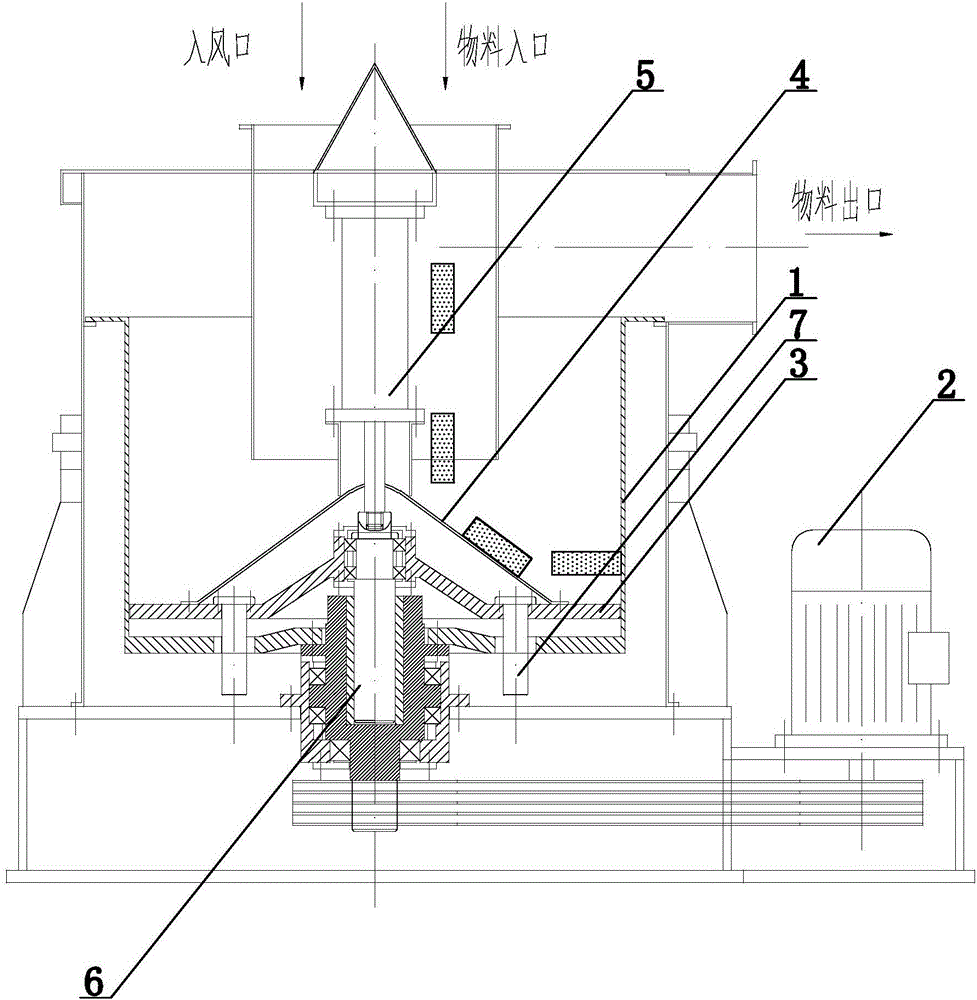

Washing, dehydration and drying continuous processing process

ActiveCN106835567ATextile treatment machine arrangementsLiquid/gas/vapor removal by centrifugal forceFiberMotor drive

The invention relates to a washing, dehydration and drying continuous processing process, and belongs to the technical field of fiber treatment. The process comprises a cleaning procedure, a dehydration procedure and a drying procedure which are set in sequence, and fibers to be treated are cleaned through the cleaning procedure and then fed into the dehydration procedure; the dehydration procedure is completed in a dehydration mechanism, and the dehydration mechanism comprises a rotary barrel, a material inlet, a supporting plate and a material outlet. The rotary barrel is driven by a motor, and the supporting plate is mounted in the rotary barrel in a sliding mode. The cleaned materials enter the rotary barrel through the material inlet, after the cleaned materials fall onto the supporting plate, the motor drives the rotary barrel and the supporting plate to rotate together, meanwhile, the supporting plate and the rotary barrel do vertical reciprocating motion, the materials are moved upwards, and after dehydration is completed in the moving process, the materials are conveyed into a drying mechanism through the material outlet to be dried. The process is applied to fiber cleaning treatment, and has the advantages of being fast in dehydration, even in drying, low in energy consumption, low in cost, capable of achieving continuous operation and the like.

Owner:绍兴国周针织科技有限公司

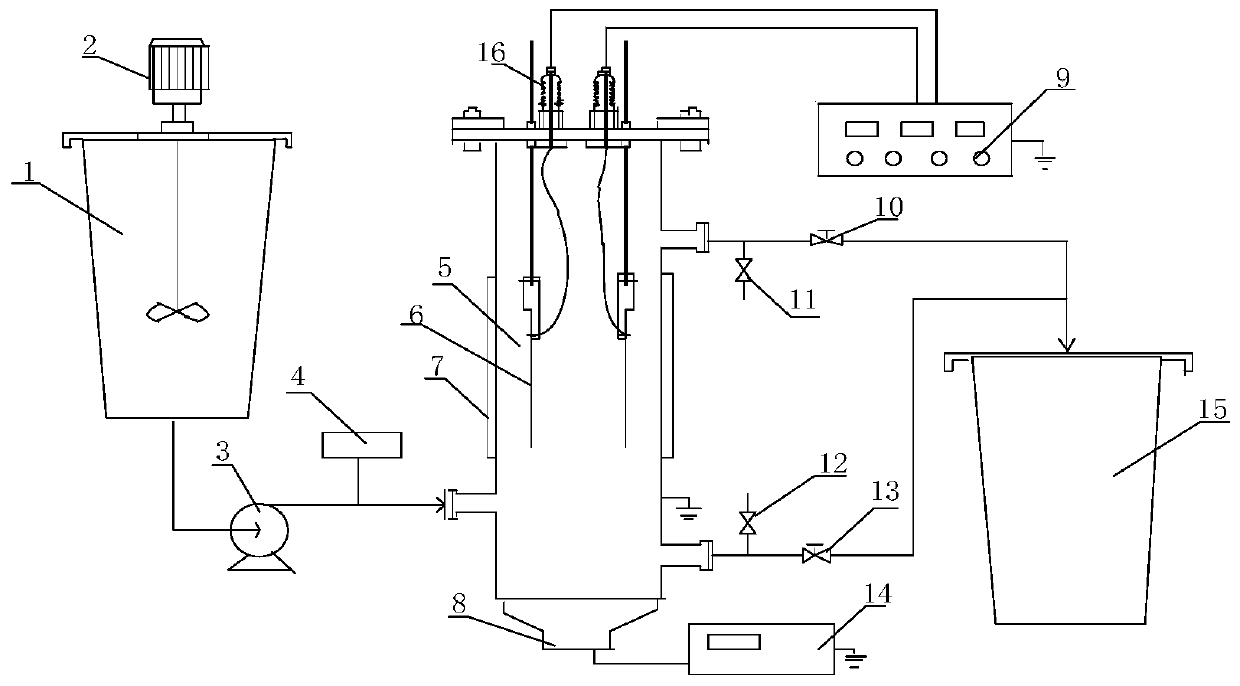

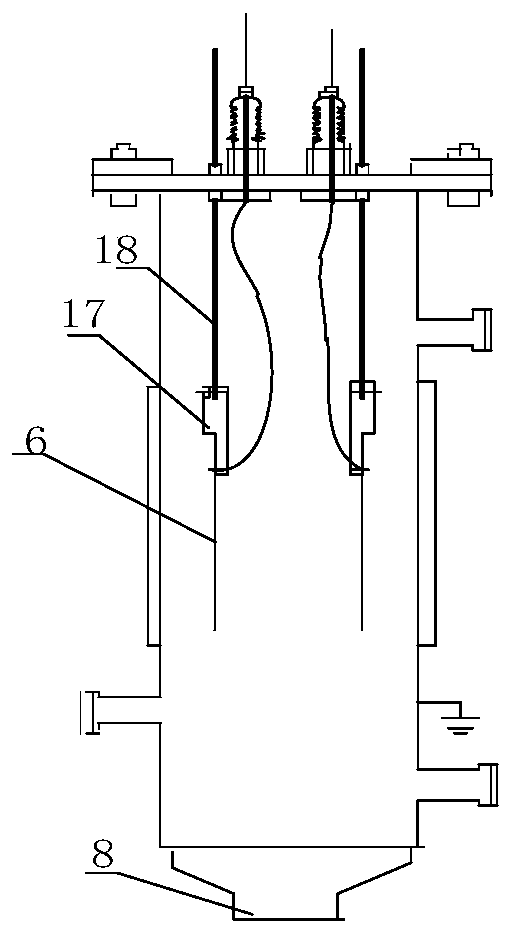

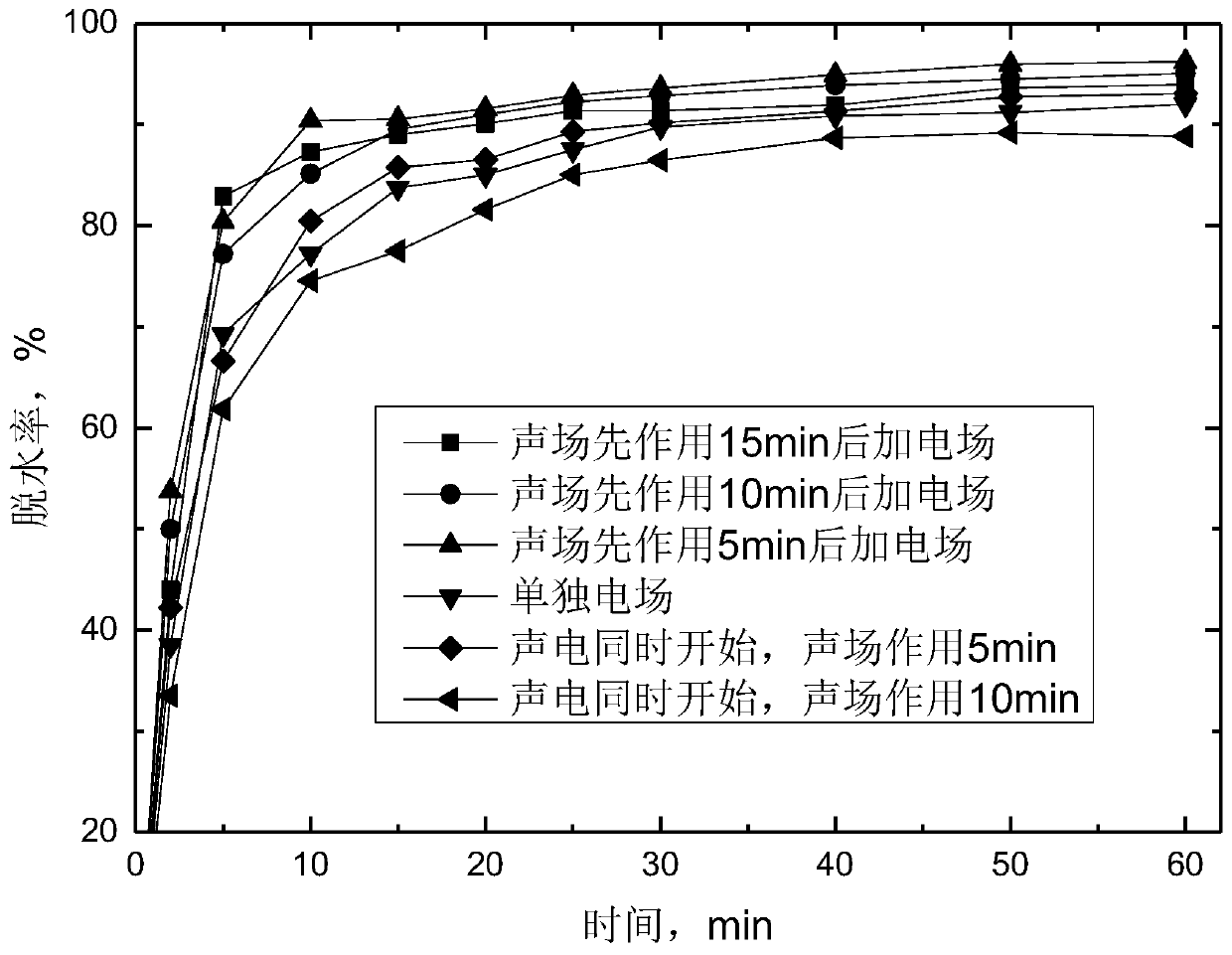

Crude oil dehydration device with ultrasonic wave and electric field and dehydration method

PendingCN110184088AEasy to collapseReduce volumeDewatering/demulsification with mechanical meansDewatering/demulsification with electric/magnetic meansDemulsifierHigh water content

The invention discloses a crude oil dehydration device with ultrasonic waves and an electric field and a dehydration method and belongs to the technical field that a high voltage is applied to a dehydration procedure of high-water-content high-viscosity crude oil. The invention aims to solve the problems that high-water-content crude oil cannot be deeply purified or dehydrated after being fed intoan electric dehydrator and secondary emulsification can be easily caused to low-water-content crude oil by ultrasonic waves. The device comprises an emulsification device, a dehydration device and arecycling device which are connected in sequence, wherein the emulsification device comprises an emulsification blending tank; the dehydration device comprises a dehydration tank; a liquid inlet, a water outlet and an oil outlet are formed in the side wall of the dehydration tank; an electrode component is mounted inside the dehydration tank; an ultrasonic component is mounted outside the dehydration tank; the emulsification blending tank is connected with the liquid inlet of the dehydration tank through a pipeline; and the water outlet and the oil outlet of the dehydration tank are respectively connected with a recycling device. By adopting the crude oil dehydration device, the crude oil demulsification dehydration effect can be improved, the dehydration efficiency can be improved, the amount of a demulsifier can be reduced, pollution can be reduced, and in addition, the applicability of the dehydrator to different types of crude oil can be improved.

Owner:HARBIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com