Control method for barrel washing machine dehydration procedure

A technology of a drum washing machine and a control method, which is applied to the control device of the washing machine, washing device, textile and paper making, etc., can solve the problems of noise, washing machine vibration, increase in production cost, etc., and achieve the effect of reducing noise and reducing eccentric load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

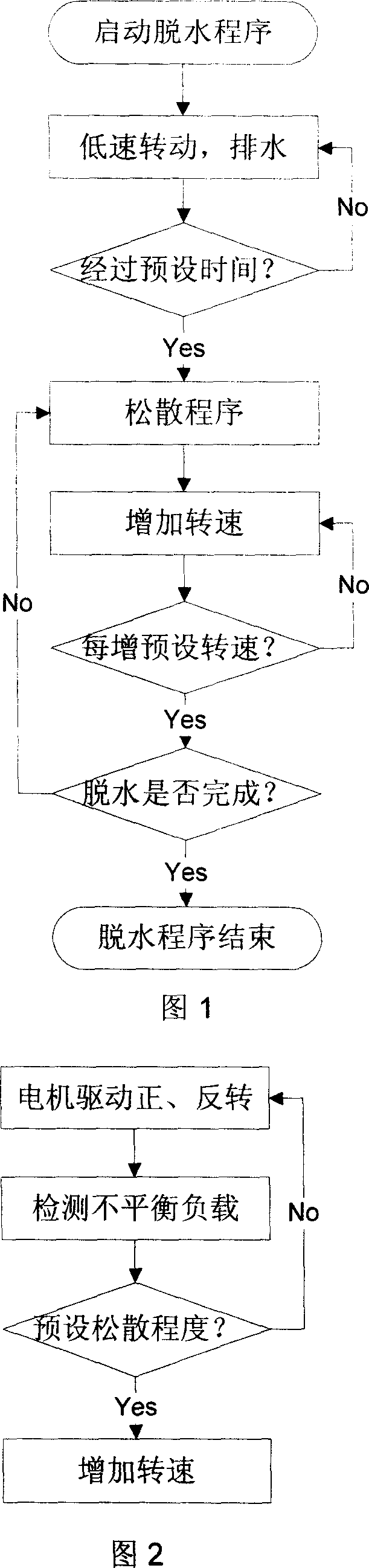

[0018] During the washing process of the drum washing machine, the user first puts the laundry into the drum, and then selects the mode required by the user for washing. After the washing program is completed, it generally enters the draining program, dehydration program or drying program. Of course, it is also possible that the user directly puts the clothes washed by hand or other washing methods into the drum to perform the dehydration program. Therefore, according to the control method of the dehydration program of the drum washing machine of the present invention, when the user starts or the washing machine executes the initial stage of the dehydration program, the washing machine is first controlled to execute a drain program, as shown in FIG. 1 , in the drain program, the washing machine drives the drum to A preset lower speed is operated, for example, the rotation speed of the drum is lower than 200 rpm.

[0019] After the draining program runs for a certain period of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com