Washing, dehydration and drying continuous processing process

A processing technology, continuous technology, applied in the direction of liquid/gas/steam removal by centrifugal force, equipment configuration for processing textile materials, etc., can solve problems such as uneven dehydration of inner and outer layers, waste of manpower, and inability to realize continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

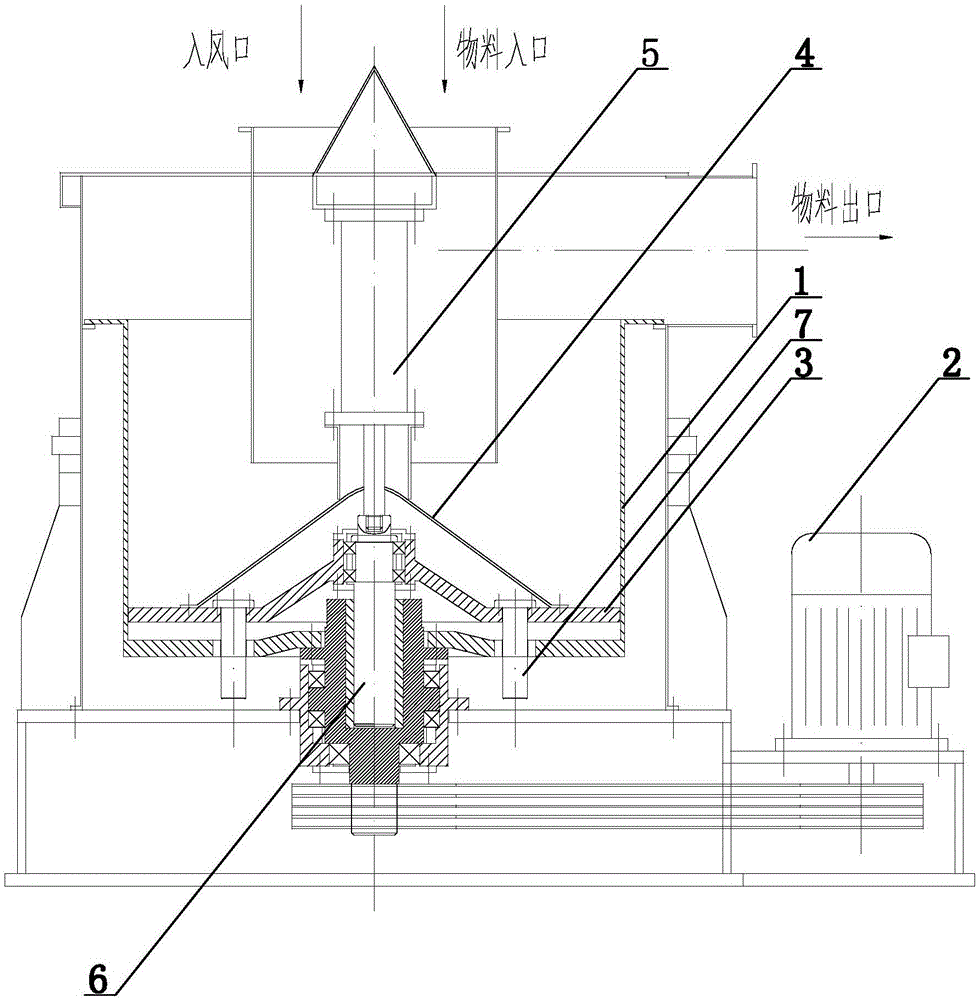

[0024] In this embodiment, the elution drying continuous processing technology combines figure 1 , including the cleaning process, dehydration process and drying process carried out in sequence. After the materials to be processed are cleaned by the cleaning process, they are sent to the dehydration process. The dehydration process is completed in the dehydration mechanism. The dehydration mechanism includes a drum 1, a material inlet , material outlet, motor 2, pallet 3, hydraulic cylinder or cylinder 5, lifting shaft 6, guide rod 7, drum 1 is driven by motor 2; pallet 3 is slidably installed in drum 1 through guide rod 7, hydraulic cylinder Or the cylinder 5 is located above the supporting plate, and the supporting plate 3 is connected with the hydraulic cylinder or cylinder 5 through the lifting shaft 6. Under the pull of the hydraulic cylinder or cylinder 5, the guide rod 7 is used as the track to reciprocate up and down relative to the drum 1. The cleaned material enters ...

Embodiment 2

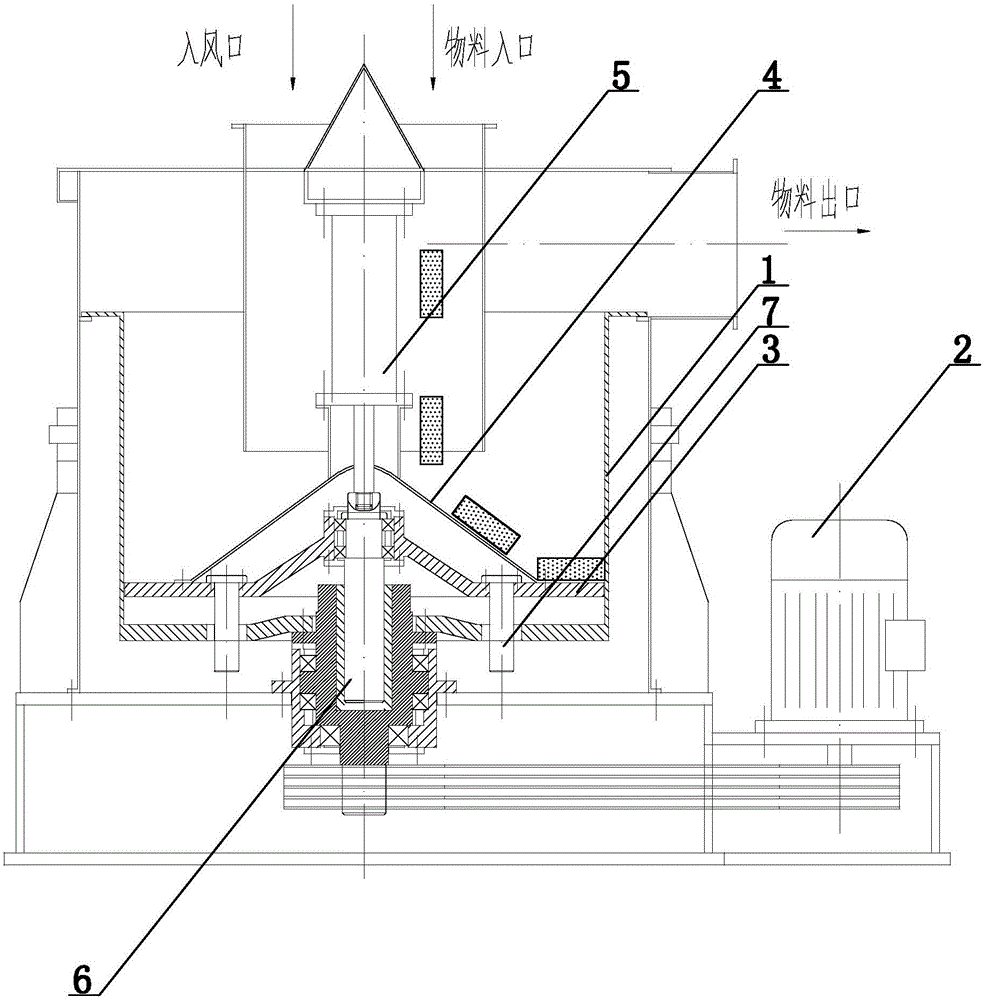

[0028] The setting and working principle of this embodiment are the same as those of Embodiment 1, the difference is that: the supporting plate 3 is provided with a cover 4, and the cover 4 is located below the material inlet. When the cover 4 is set as a structure with a high center (that is, below the material inlet, preferably directly below the material inlet) and low sides, the material falls on the cover 4 and, under its own inertial force and gravity, moves along the middle The slopes on both sides automatically slide down to both sides, effectively preventing materials from accumulating below the material inlet.

Embodiment 3

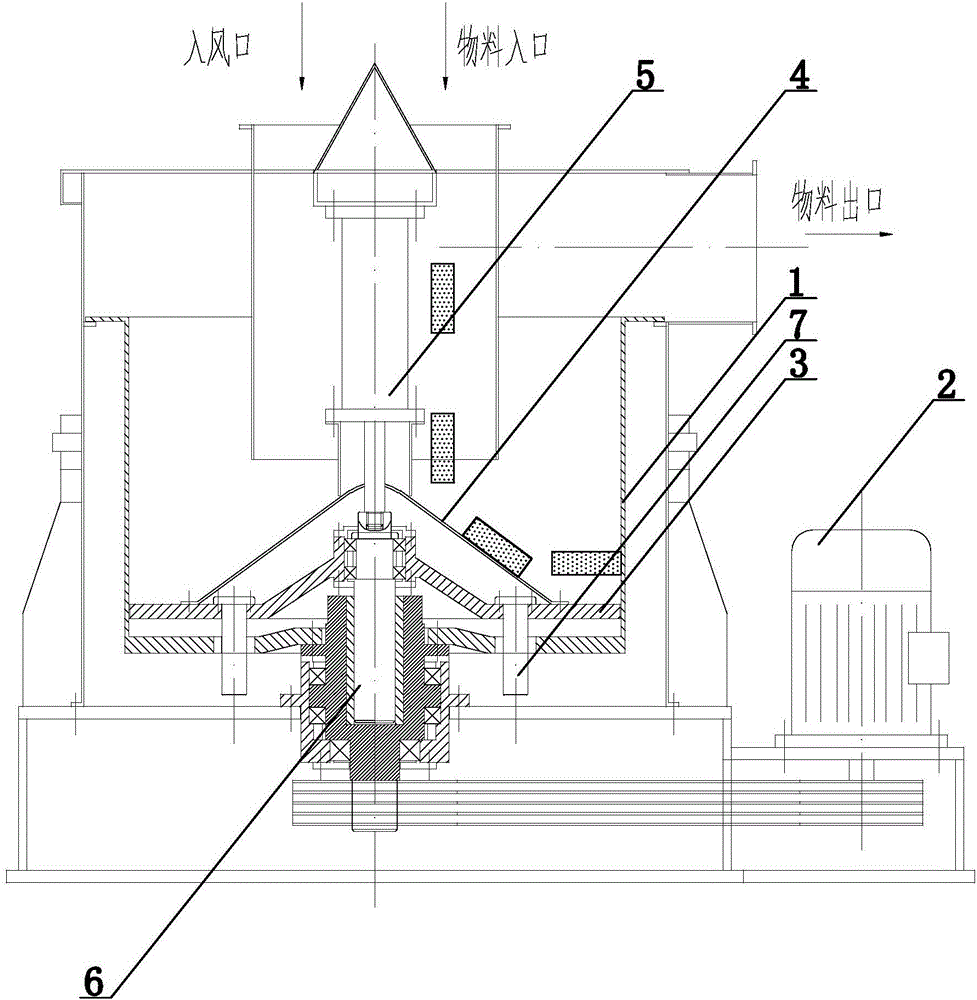

[0030] The setting and working principle of this embodiment are the same as those of Embodiment 1, the difference is that the drum 1 is driven by a motor to rotate, and is driven to reciprocate up and down by hydraulic pressure or air pressure, and the supporting plate 3 only changes its position as the drum 1 rotates. Invariably, when the drum 1 moves downward along the guide rod 7 relative to the supporting plate 3 , the material gradually moves upward until it enters the material outlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com