Chemical conditioning type deep dehydration method for kitchen waste and dehydration system

A technology for kitchen waste and deep dehydration, which is applied in chemical instruments and methods, sterilization/microdynamic water/sewage treatment, sludge treatment, etc. Advanced problems, to achieve the effect of protecting the balance of the natural ecological environment, simple and convenient operation, and reducing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

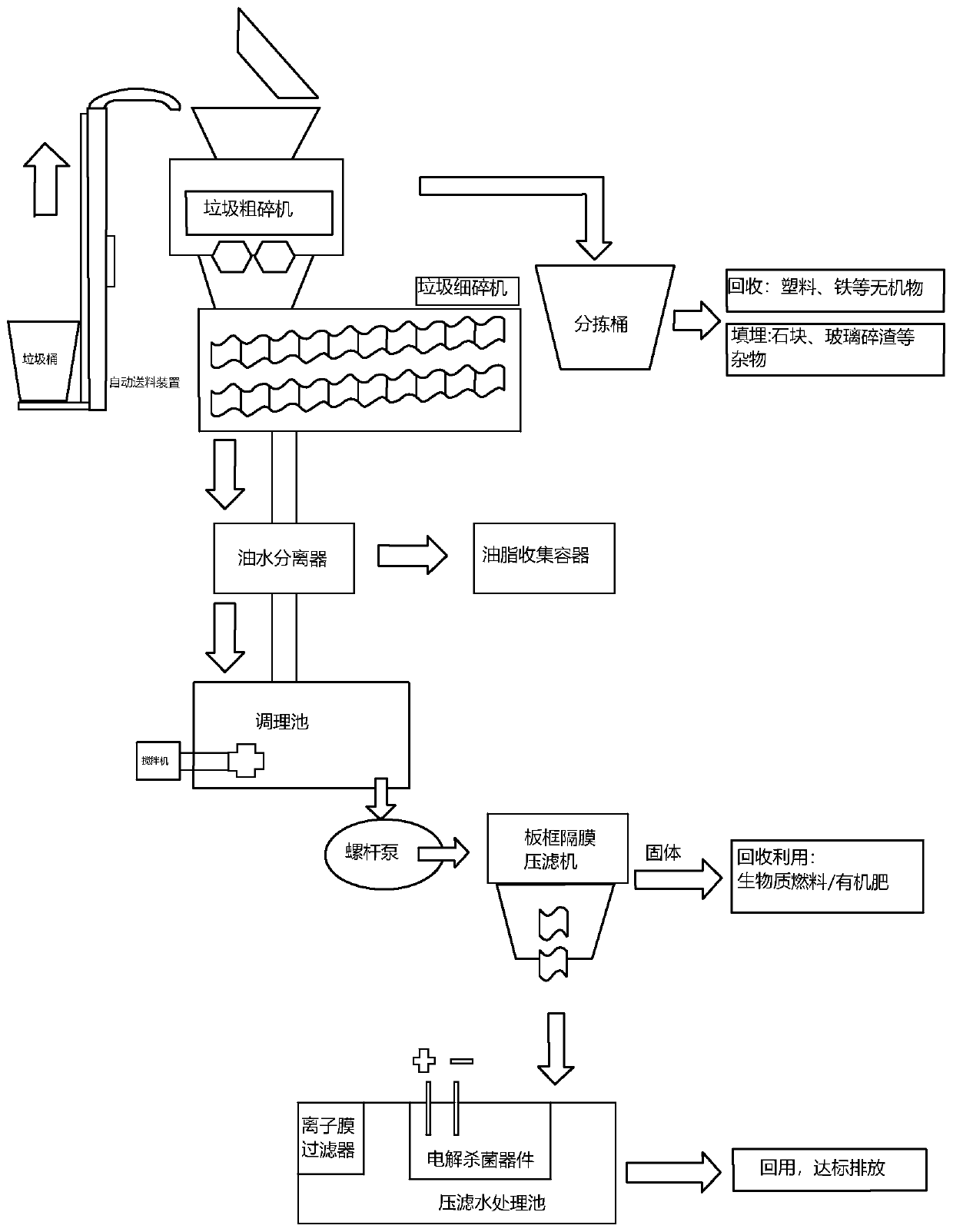

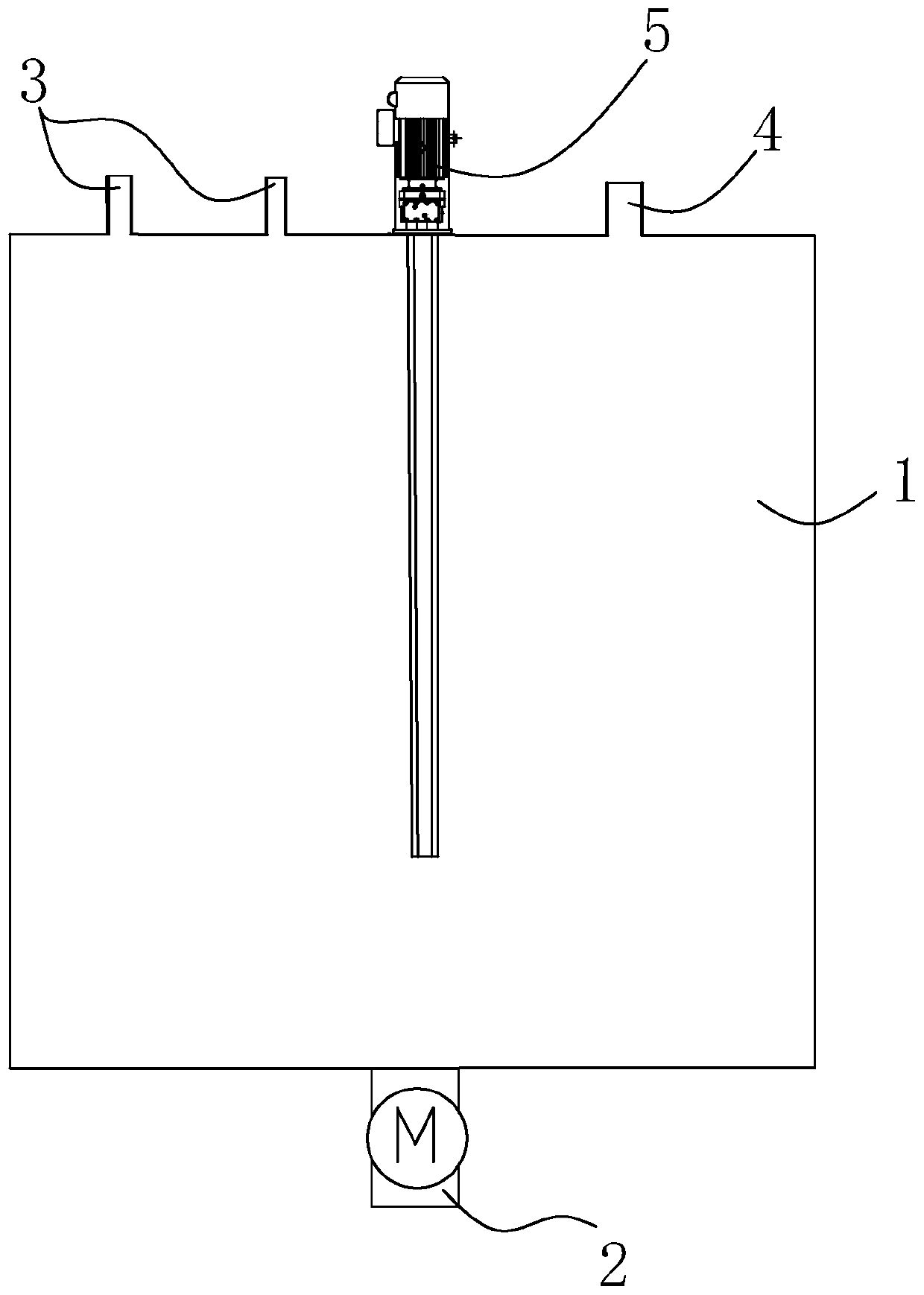

[0022] Please refer to figure 1 and figure 2 As shown, a kind of food waste chemical conditioning deep dehydration method is illustrated below in conjunction with embodiment, and its method process is:

[0023] First of all, the food waste is a general term for food waste and kitchen waste, and the food waste refers to the leftovers of the food and beverage establishments and the waste of meat, grease, fruits and vegetables and pastry in the back kitchen. Refers to the discarded fruits and vegetables and food scraps, leftovers, and perishable organic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com