Sludge garbage chemical condition deep dewatering method and dewatering system thereof

A deep dehydration and chemical conditioning technology, applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of low level of reduction, high treatment cost, and damage to the ecological balance of the environment. , to achieve the effect of reducing the difficulty and cost of processing, simple and convenient operation, and protecting the balance of the natural ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and more comprehensible, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

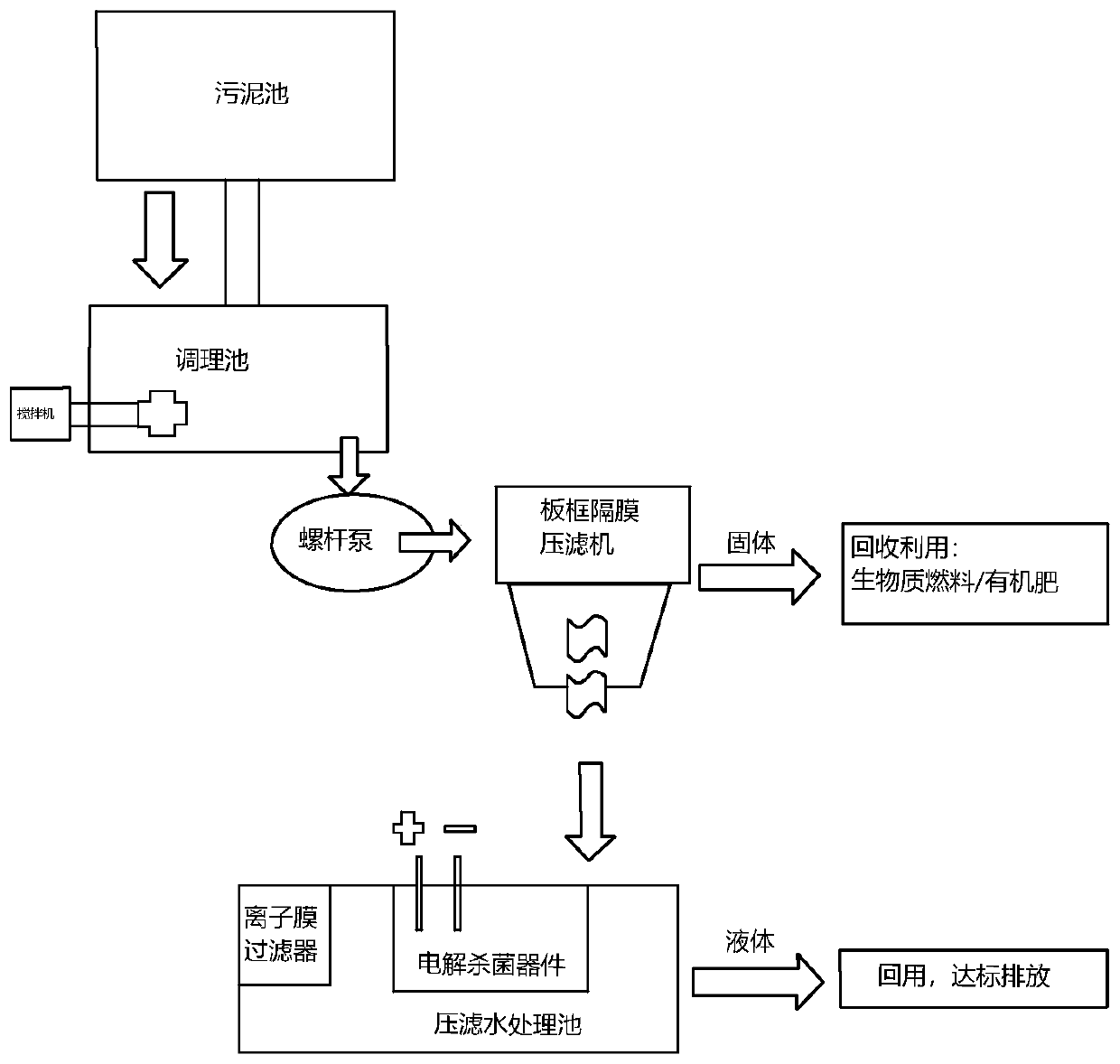

[0019] Please refer to figure 1 As shown, a deep dewatering method for chemical conditioning of sludge and waste is described below in conjunction with the embodiments, and the method flow is as follows:

[0020] Sludge waste is a hydrophilic organic aggregate with extracellular polymer as skeleton produced during sewage treatment. The hydrophilic organic aggregate is composed of organic debris, inorganic particles and bacterial cells; the Sludge waste is divided into domestic sewage sludge, water supply sludge, industrial sewage sludge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| dehydration rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com