Patents

Literature

105 results about "Chemical condition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

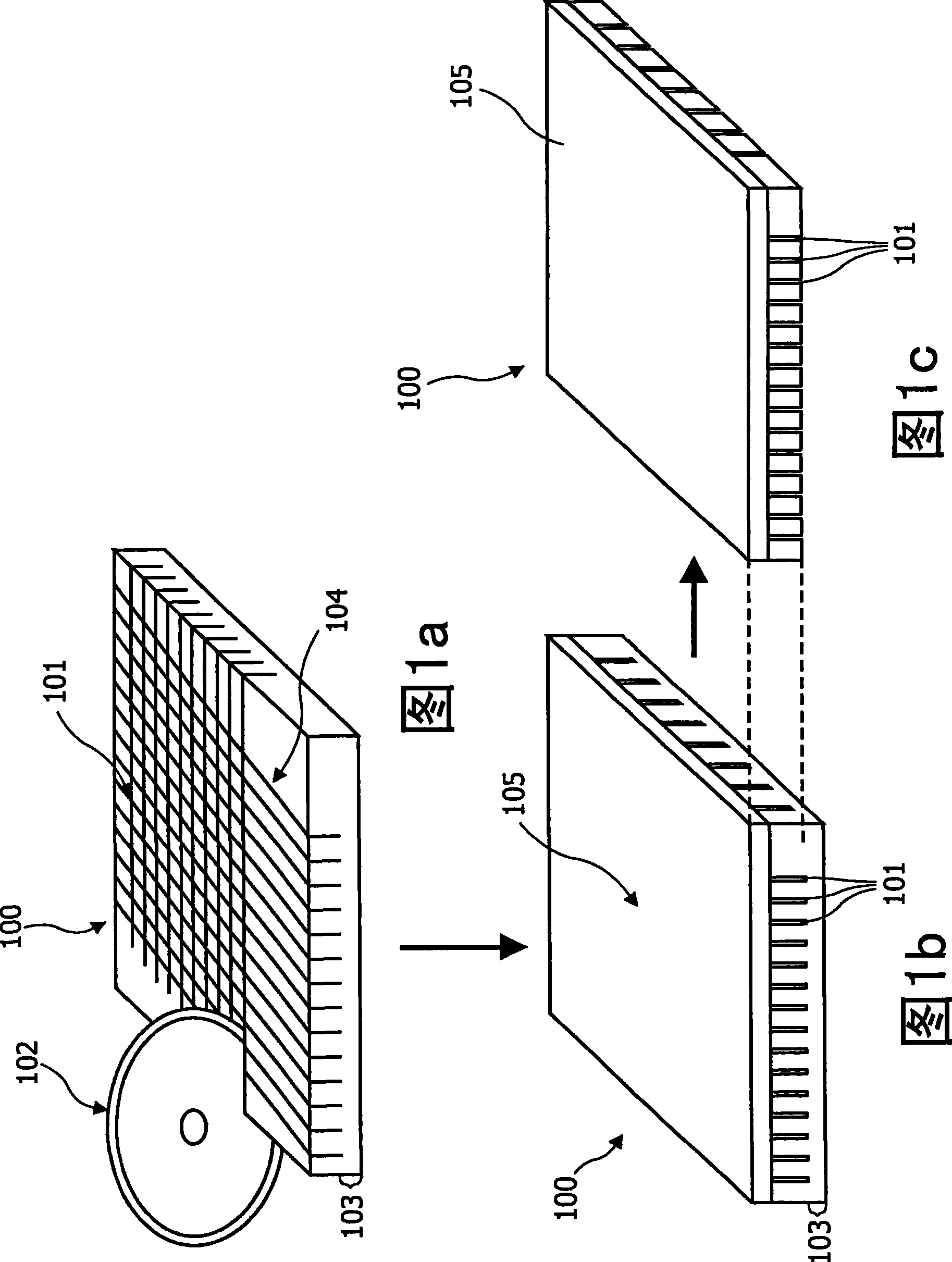

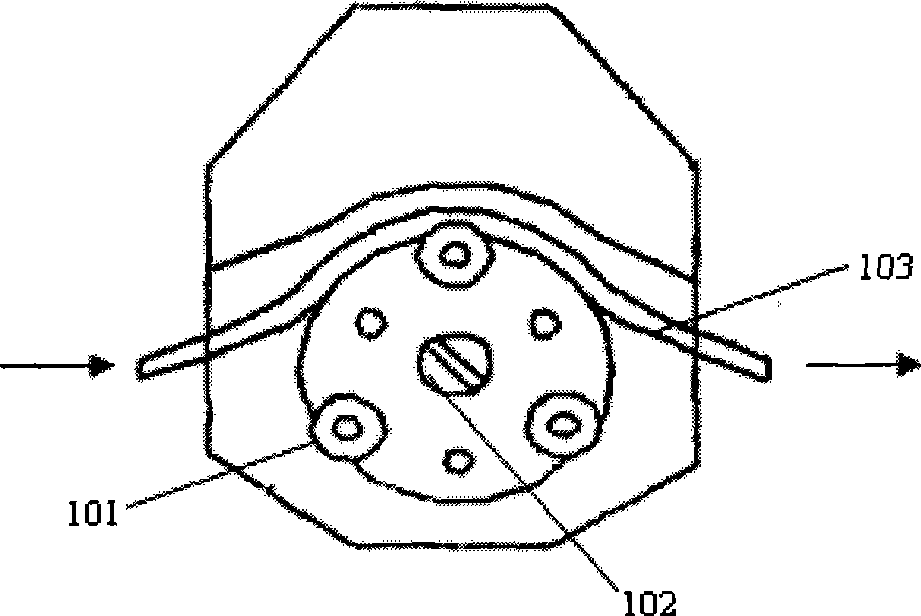

Fluidics device for assay

InactiveUS20100190265A1Improve dynamic rangeEasy to operateBioreactor/fermenter combinationsBiological substance pretreatmentsFluidicsChemical condition

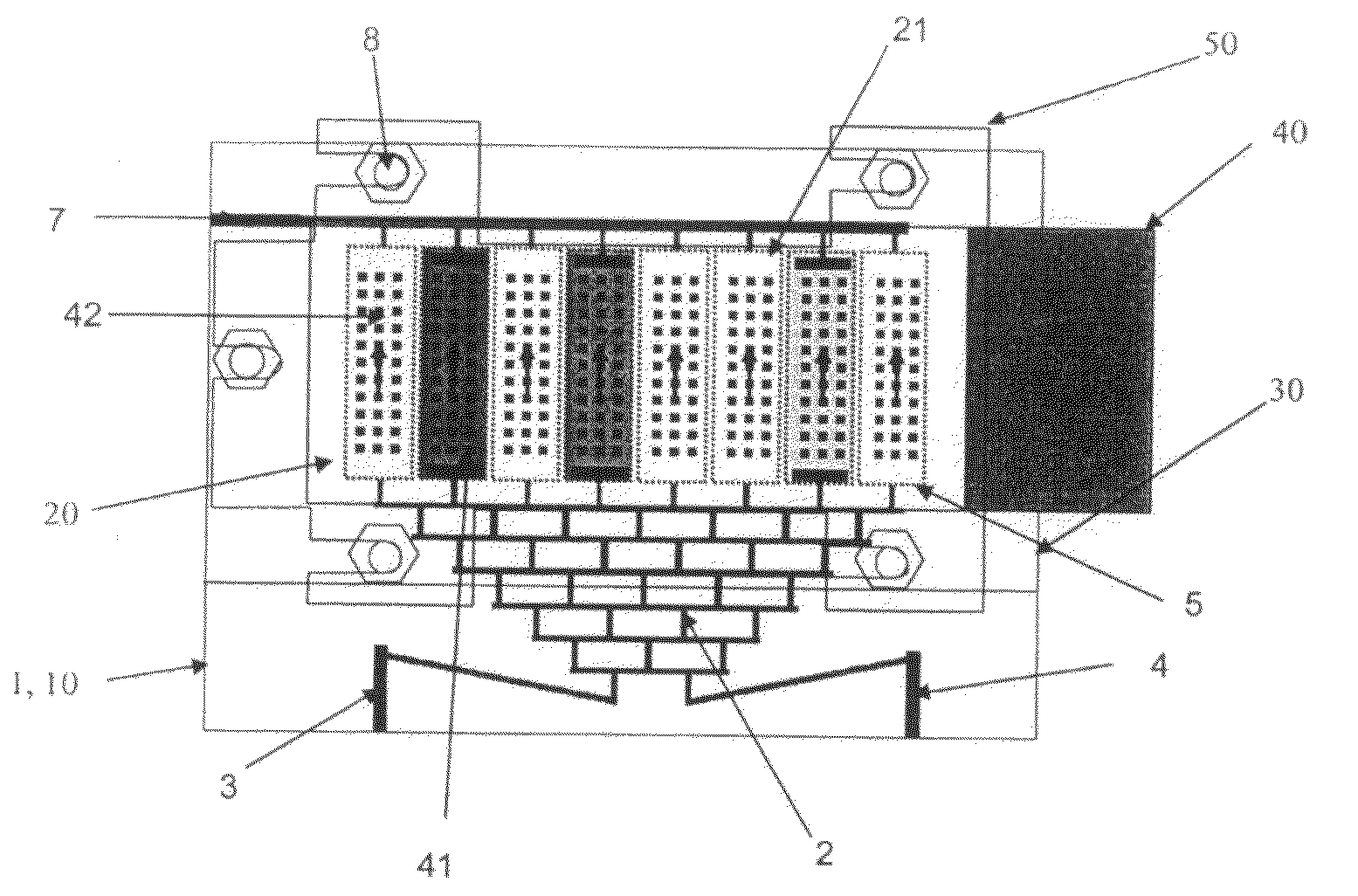

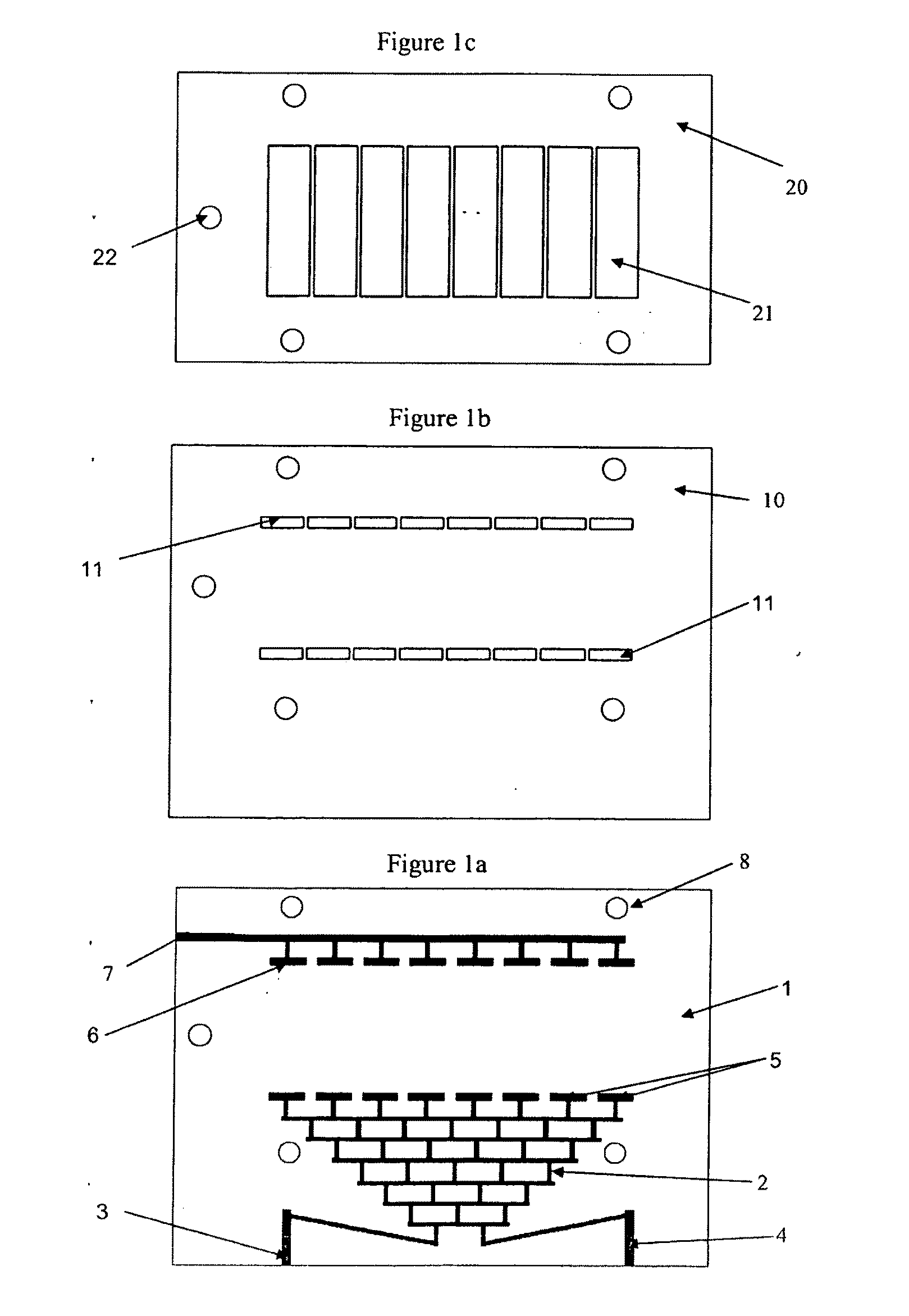

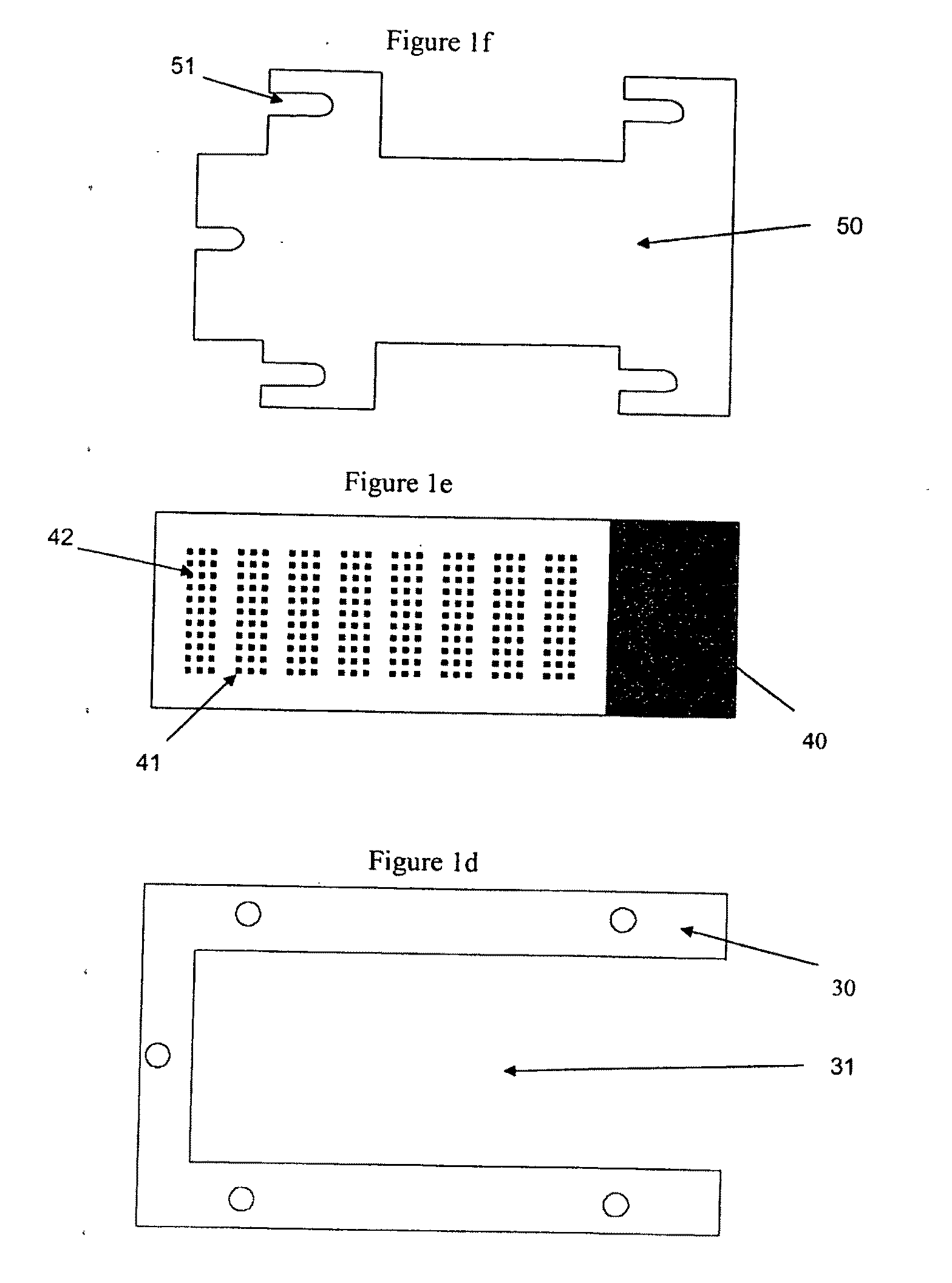

The present invention relates to a device for use in performing assays on standard laboratory solid supports whereon chemical entities are attached. The invention furthermore relates to the use of such a device and a kit comprising such a device. The device according to the present invention is adapted to receive one or more replaceable solid support(s) (40) onto which chemical entities (41) are attached, said device comprising a base (1, 60, 80, 300, 400, 10, 70, 140, 20, 90, 120, 150, 30, 100), one or more inlet(s) (5), one or more outlet(s) (6). The base and the solid support (40) defines, when operatively connected, one or more chambers (21) comprising the chemical entities (41), the inlet(s) (5) and outlet(s) (6) and chambers (21) being in fluid connection. The device further comprise means for providing differing chemical conditions in each chamber (21).

Owner:DANMARKS TEKNISKE UNIV

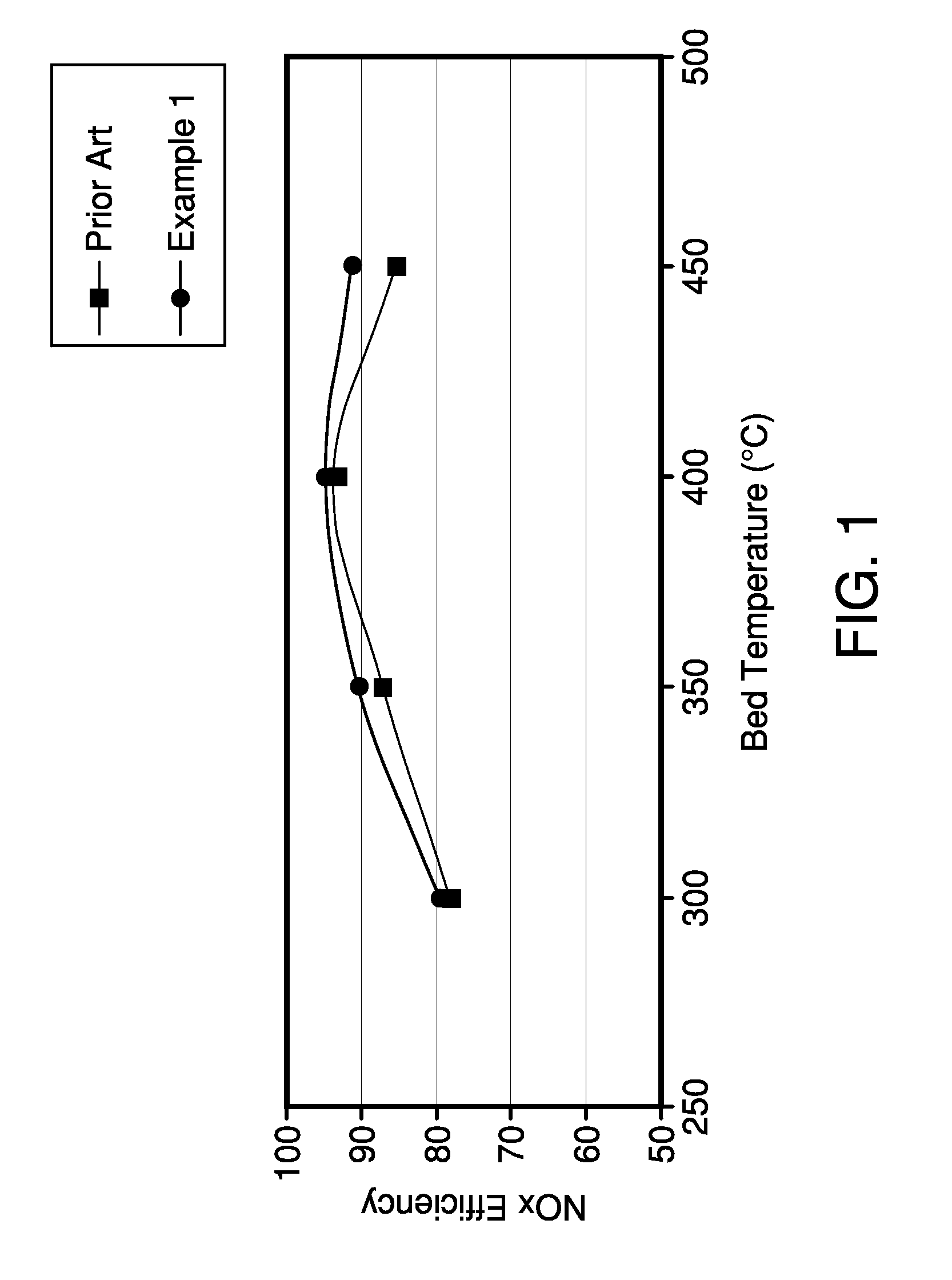

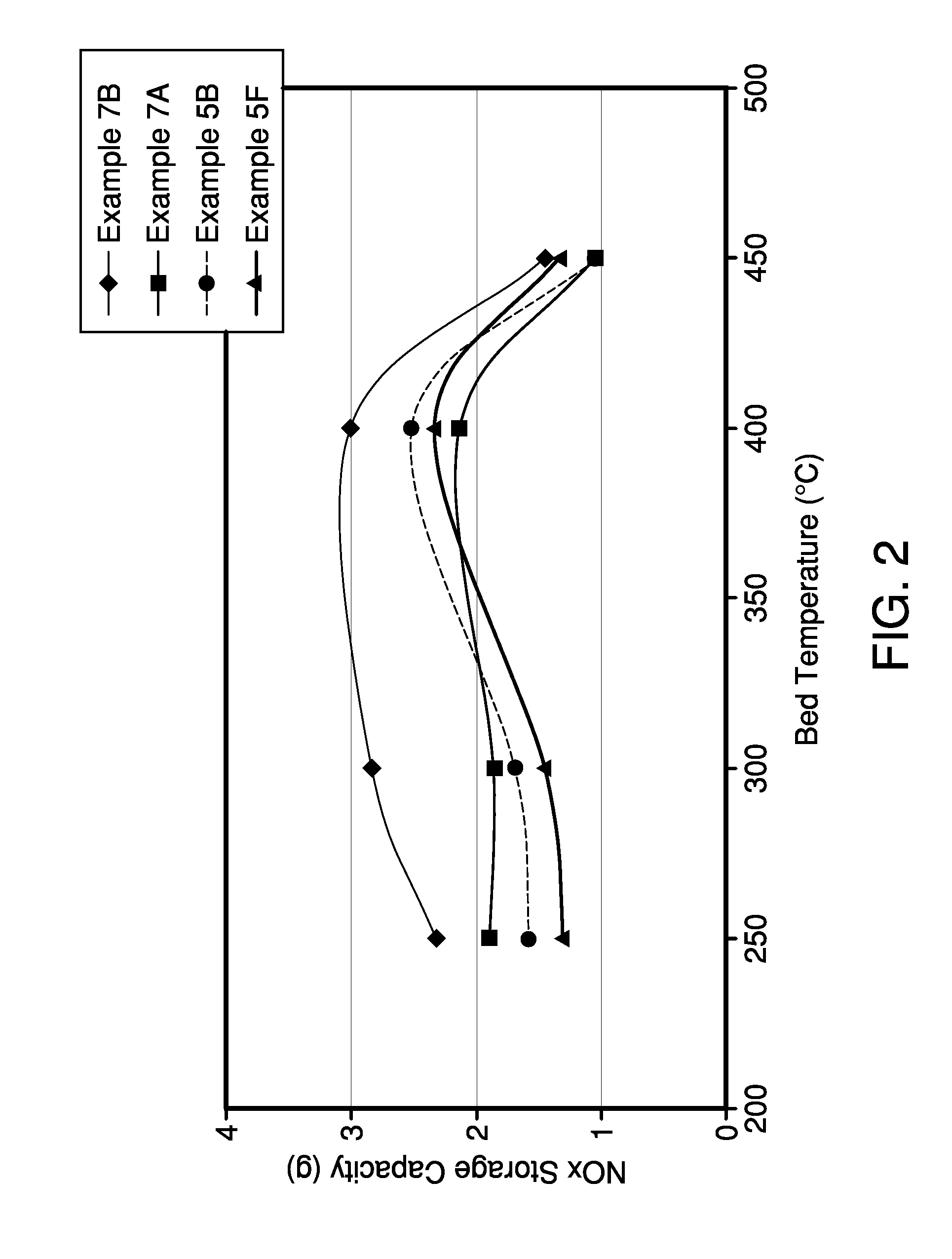

NOx Storage Materials and Traps Resistant to Thermal Aging

InactiveUS20080120970A1Promote lowerExhaust apparatusDispersed particle separationChemical conditionEarth materials

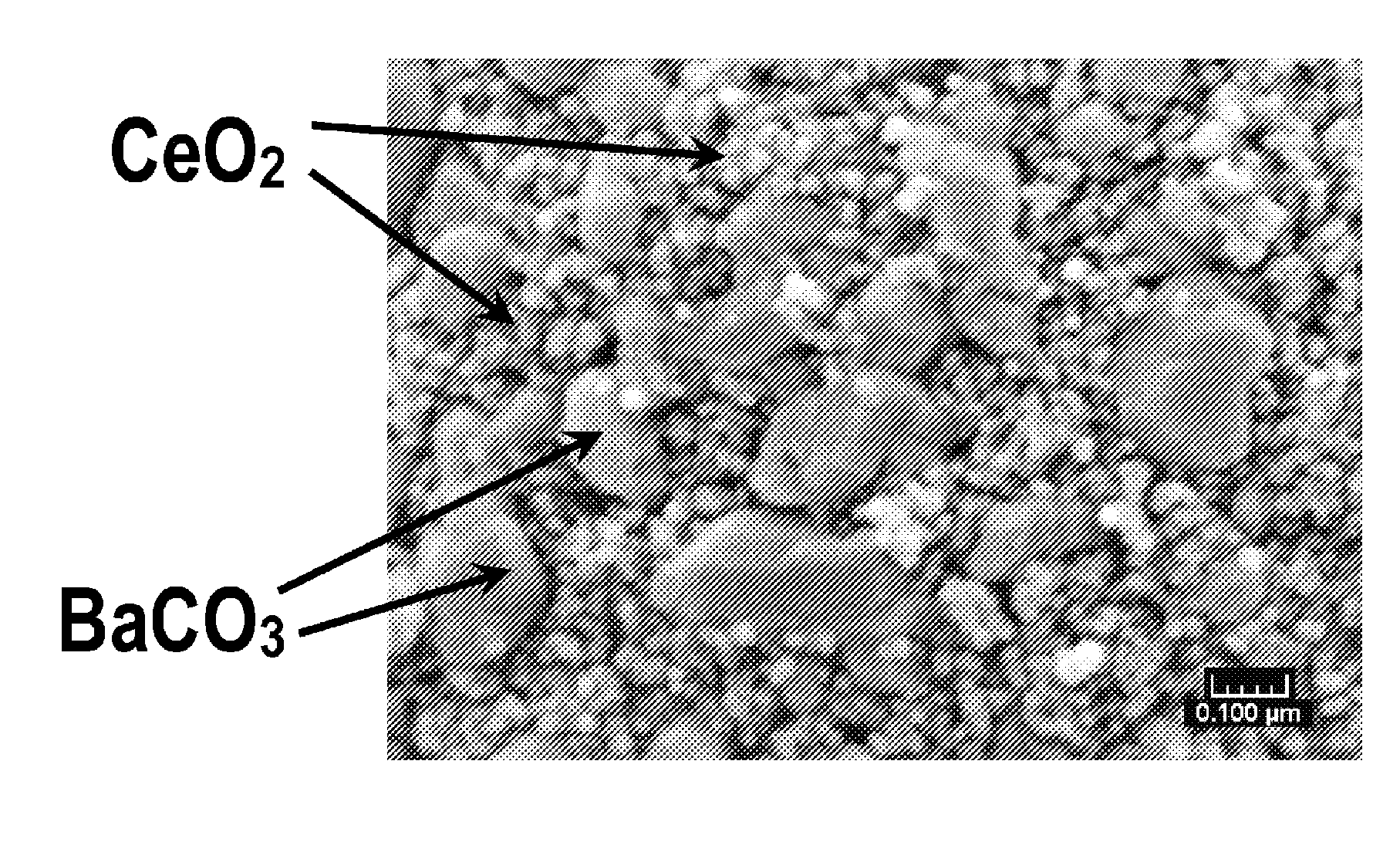

Nitrogen oxide storage materials and methods of manufacturing nitrogen oxide storage materials are disclosed. The nitrogen oxide storage materials can be used to manufacture catalytic trap disposed in an exhaust passage of an internal combustion engine which is operated periodically between lean and stoichiometric or rich conditions, for abatement of NOx in an exhaust gas stream which is generated by the engine. In one embodiment, the nitrogen oxide storage material comprises alkaline earth material supported on ceria particles having a crystallite size of between about 10 and 20 nm and the alkaline earth oxide having a crystallite size of between about 20-40 nm.

Owner:BASF CATALYSTS LLC

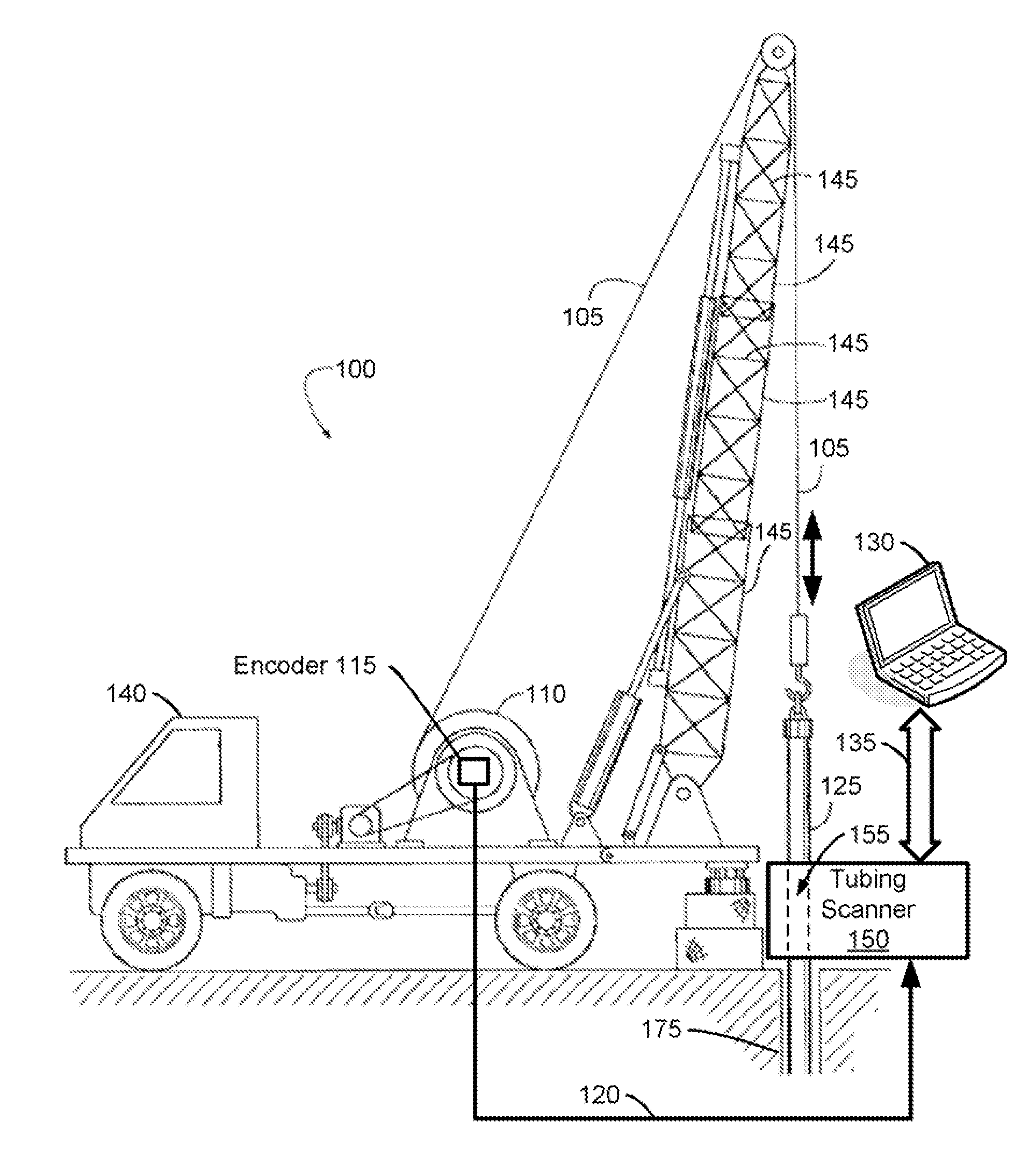

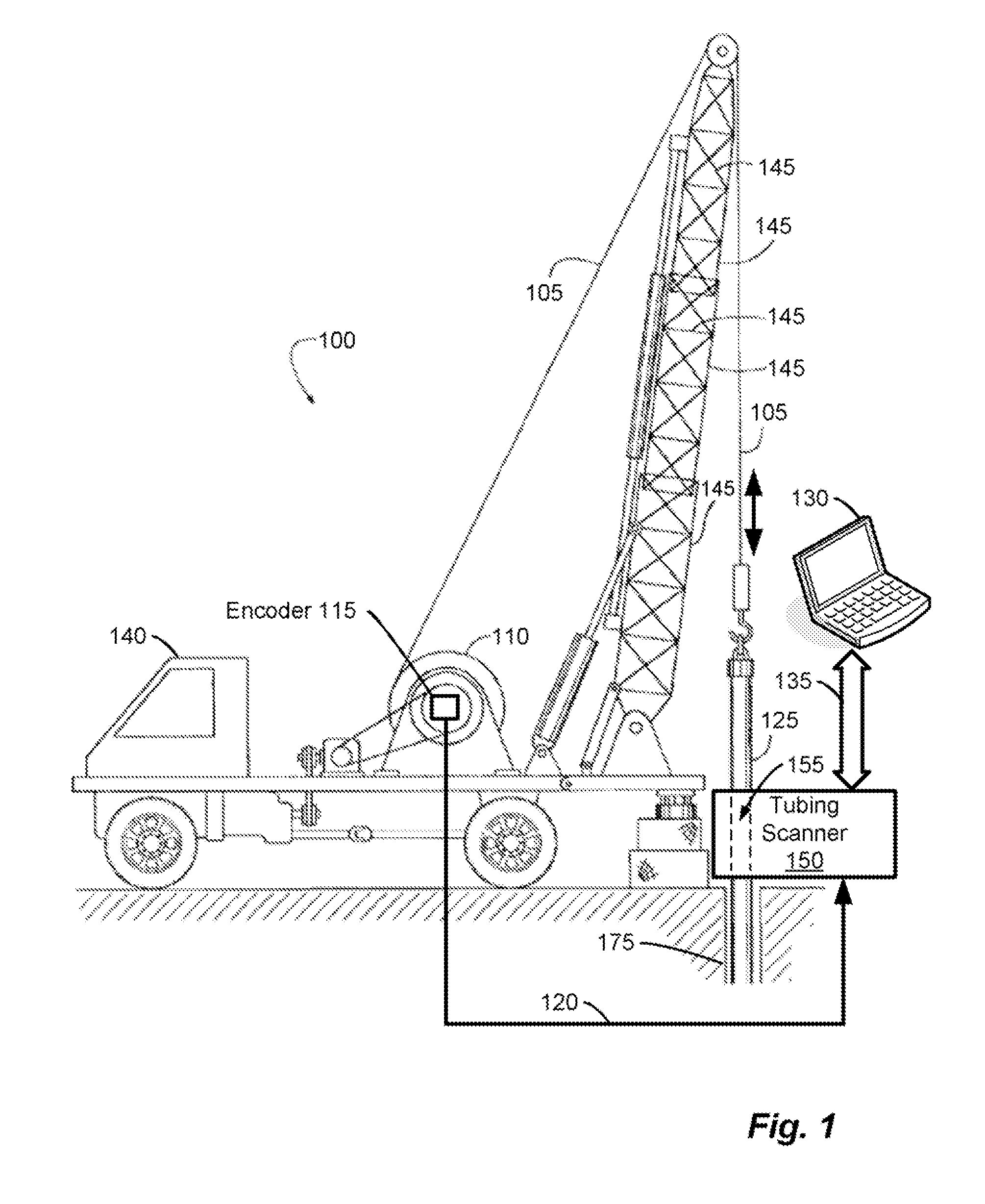

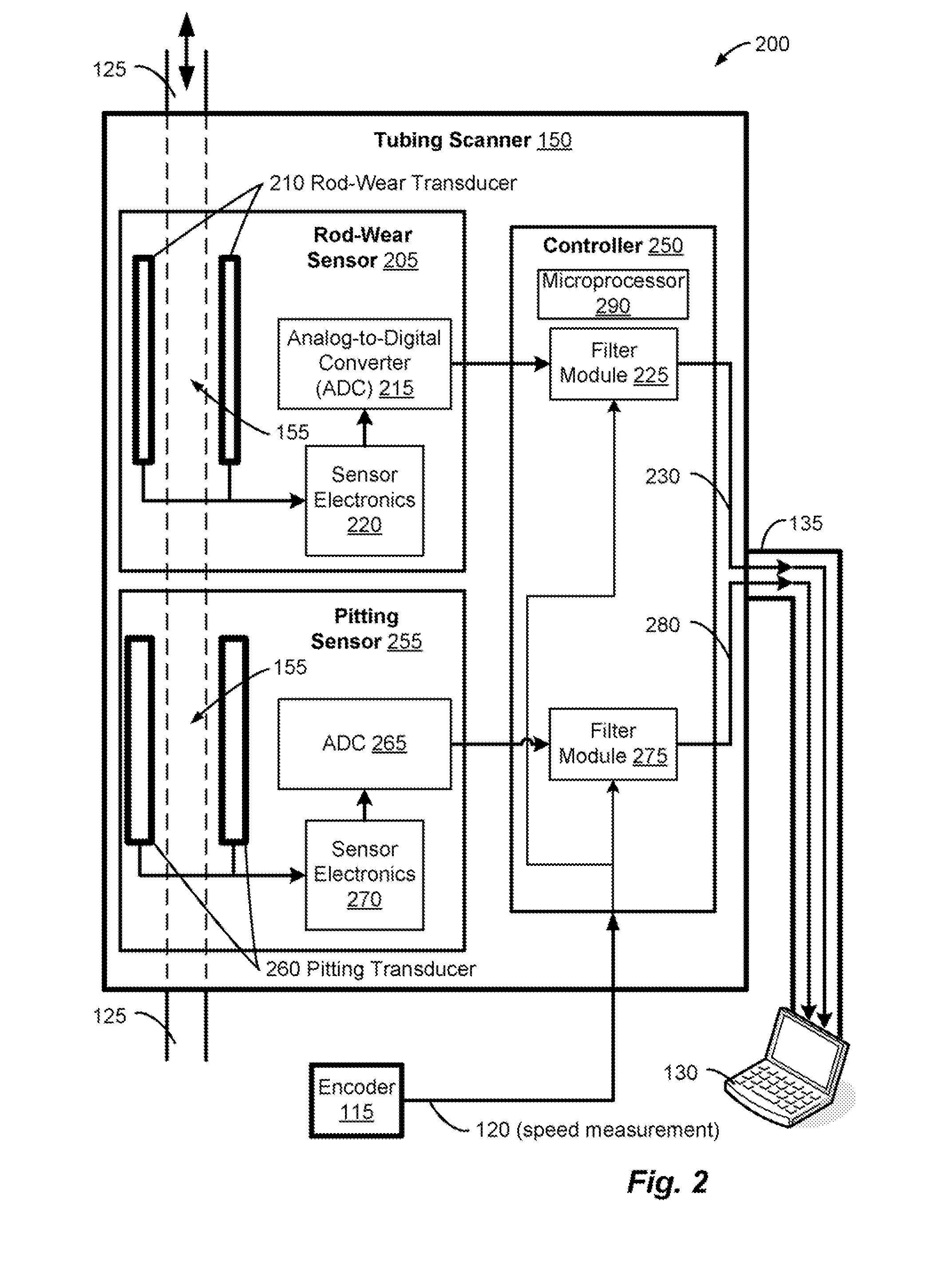

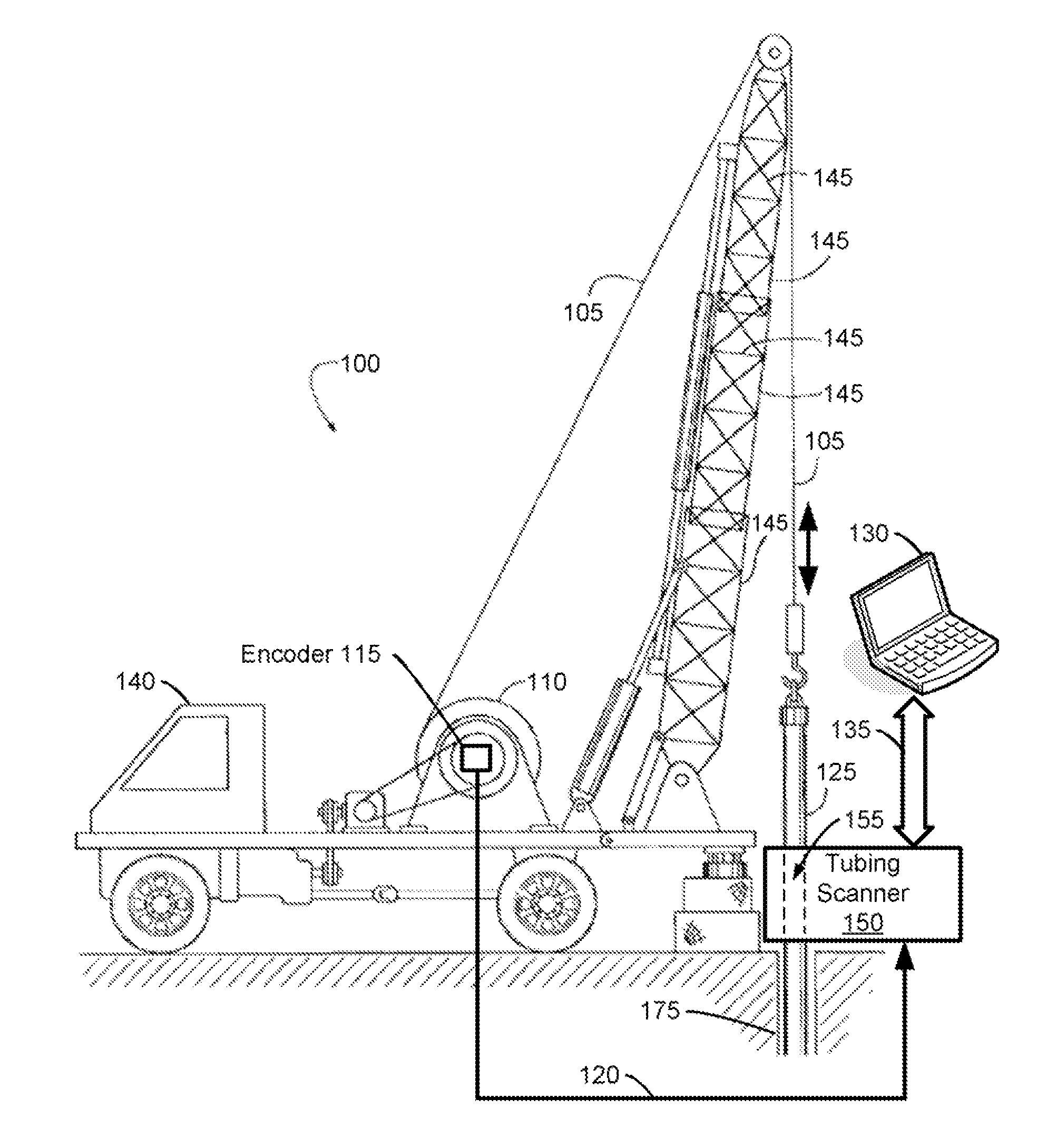

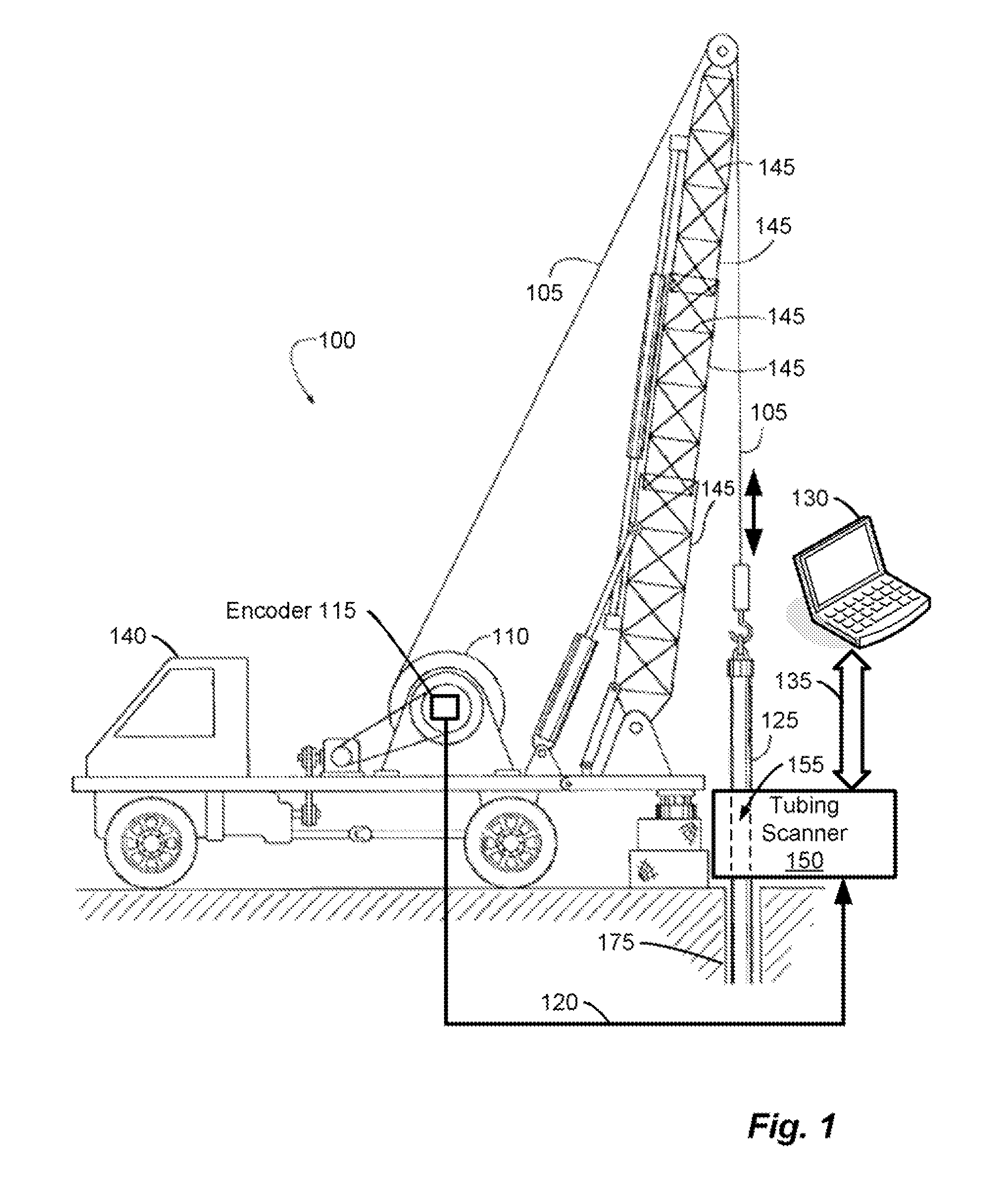

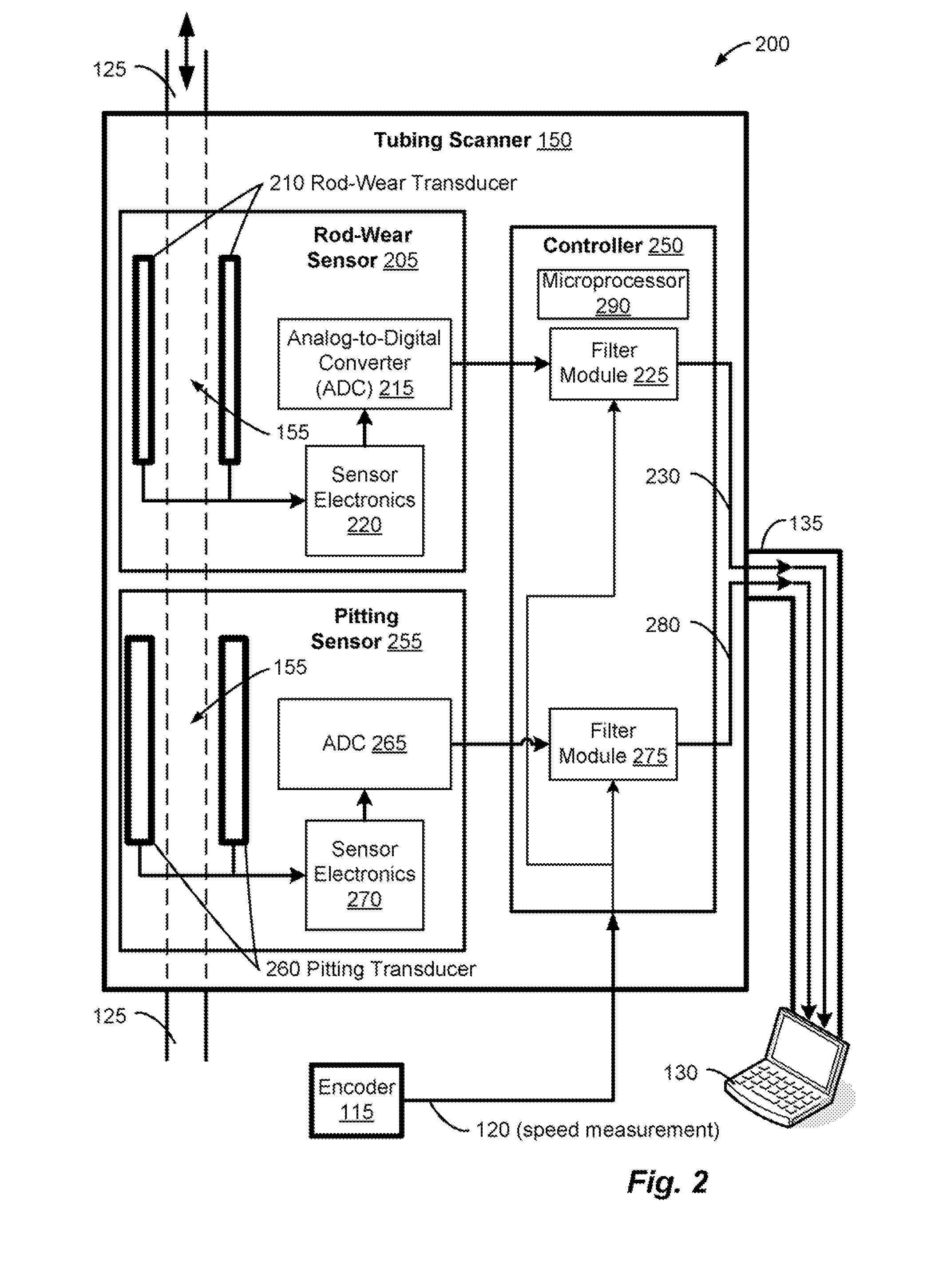

Method and system for interpreting tubing data

An Instrument, such as a wail-thickness, rod-wear, or pitting sensor, can monitor tubing as a field service crew extracts the tubing from an oil well or inserts the tubing into the well. A computer-based system can process data from the instrument to evaluate the validity of the data. Validating the data can comprise determining whether any features, structures, or patterns present in the data correlate with actual tubing defects or were caused by a condition unrelated to tubing quality, such as signal noise. The computer-based system can also analyze the data to deduce information about the performance of the well or to determine the well's operating state or status. For example, the data analysis can determine whether the well's fluids have a chemical condition that should be treated or whether a detrimental harmonic oscillation has been occurring in the well's mechanical pumping system.

Owner:KEY ENERGY SERVICES

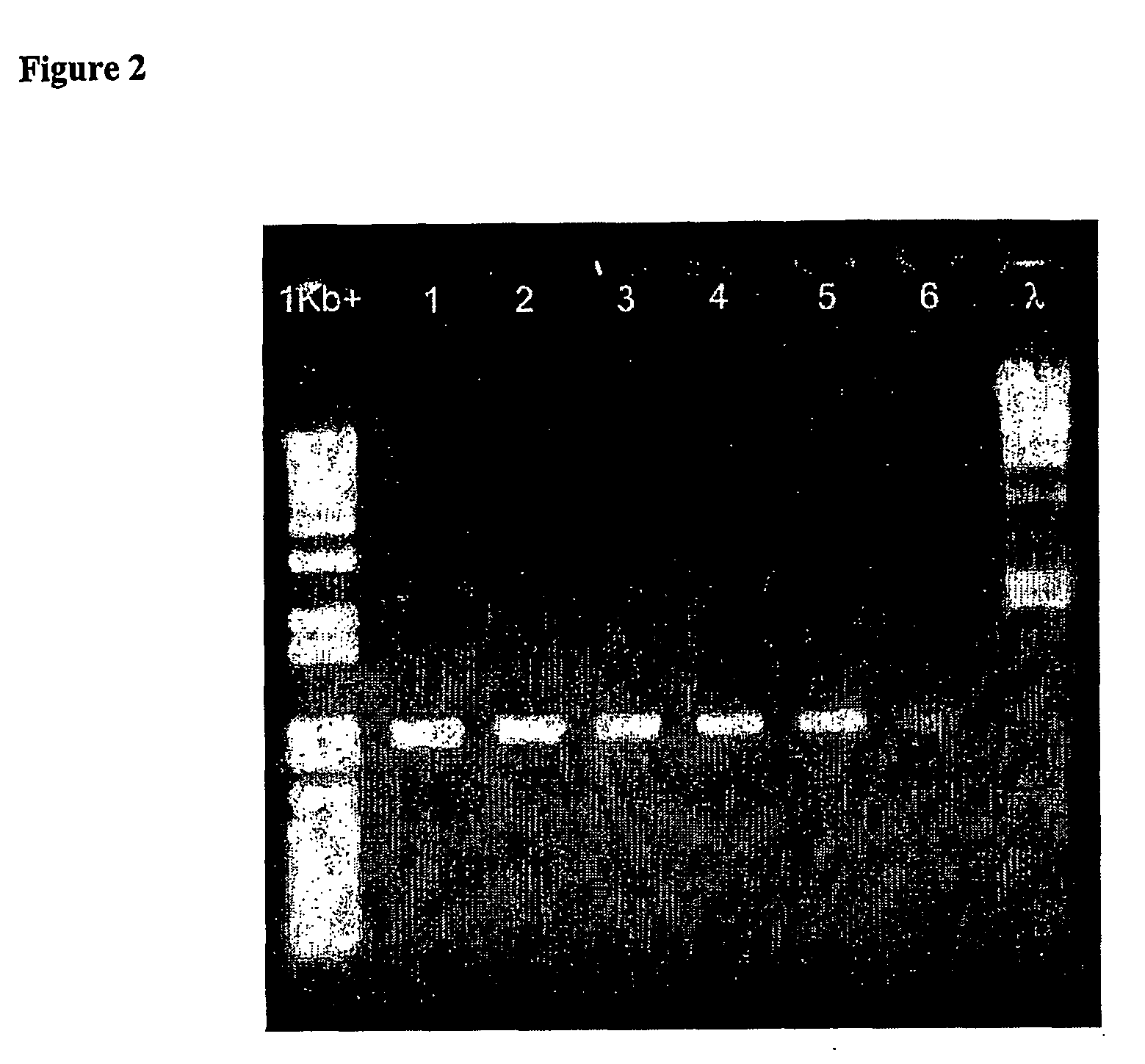

Dna amplification and sequencing in collapsible emulsions

InactiveUS20060068390A1Avoid difficultyAvoid investmentMicrobiological testing/measurementFermentationEmulsionChemical reaction

The present invention relates to a method of performing a chemical reaction, in particular a small-scale chemical reaction. The method involves the use of two (or more) phases which, when formed into an emulsion, have the characteristic of being subject to “collapse” under certain physical or chemical conditions such that the discontinuous phase dispersed in the emulsion becomes a substantially continuous phase—the chemical reaction taking place in the newly-formed continuous phase.

Owner:NUCLEICS

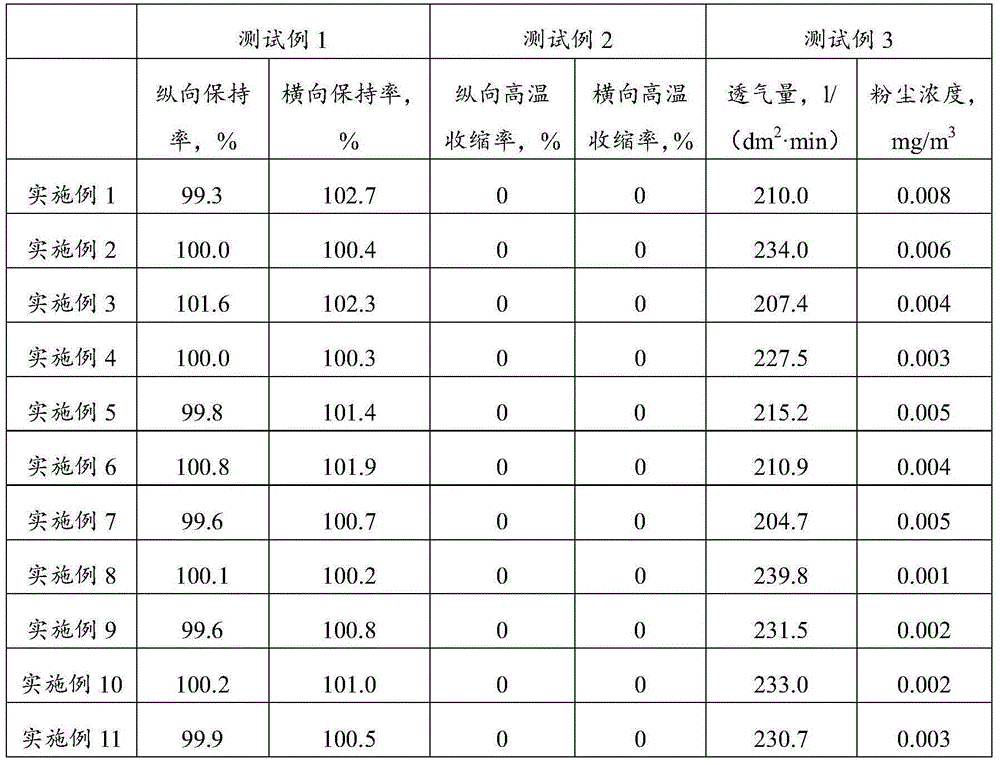

Composite elastic filament core-spun yarn fabric and preparation method thereof

InactiveCN102454004AElasticWon't breakFilament/thread formingWoven fabricsPolyethylene terephthalatePolyethylene terephthalate glycol

The invention relates to a composite elastic filament core-spun yarn fabric and a preparation method thereof. The wefts of the composite elastic filament core-spun yarn fabric are elastic filament core-spun yarns, the warps of the composite elastic filament core-spun yarn fabric are elastic filament core-spun yarns or non-elastic yarns, and the elastic filament core-spun yarn is prepared from a PTT(polytrimethylene terephthalate) / PET (polyethylene terephthalate) parallelly composite elastic filament serving as a core yarn and natural fibers and / or chemical fibers serving as coating fibers, wherein the weight ratio of the core yarn to the coating fiber is (3:7)-(7:3). The weft flotation line of the fabric has 1-4 intersection points, and the fabric is prepared by virtue of a core-spun yarn spinning process, a weaving process and a dyeing and finishing process. The fabric is prepared by coating the PTT / PET parallelly composite elastic filament with cotton fibers and the like with good comfortability, thereby meeting the requirements of elasticity and comfortability. In the subsequent processing and using of the fabric, the elastic structure of the product provided by the invention is not destroyed by mechanical, thermal and chemical conditions. Therefore, the product provided by the invention has the advantage of durable weft-direction elasticity.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +1

Method and system for interpreting tubing data

An instrument, such as a wall-thickness, rod-wear, or pitting sensor, can monitor tubing as a field service crew extracts the tubing from an oil well or inserts the tubing into the well. A computer-based system can process data from the instrument to evaluate the validity of the data. Validating the data can comprise determining whether any features, structures, or patterns present in the data correlate with actual tubing defects or were caused by a condition unrelated to tubing quality, such as signal noise. The computer-based system can also analyze the data to deduce information about the performance of the well or to determine the well's operating state or status. For example, the data analysis can determine whether the well's fluids have a chemical condition that should be treated or whether a detrimental harmonic oscillation has been occurring in the well's mechanical pumping system.

Owner:KEY ENERGY SERVICES

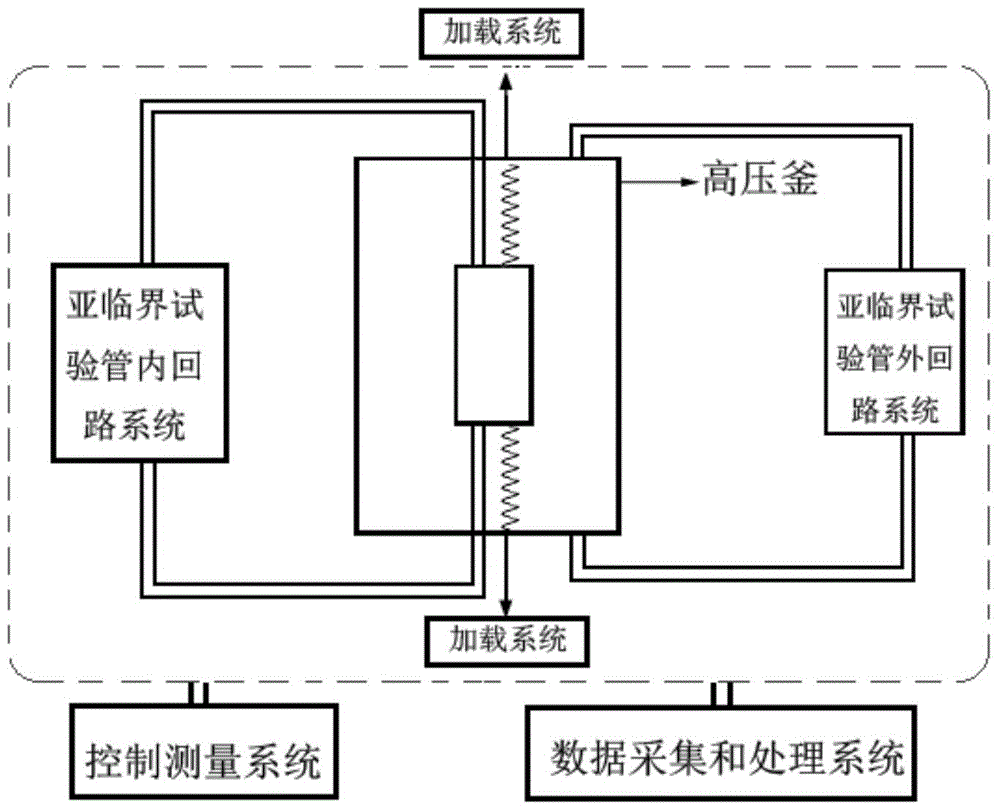

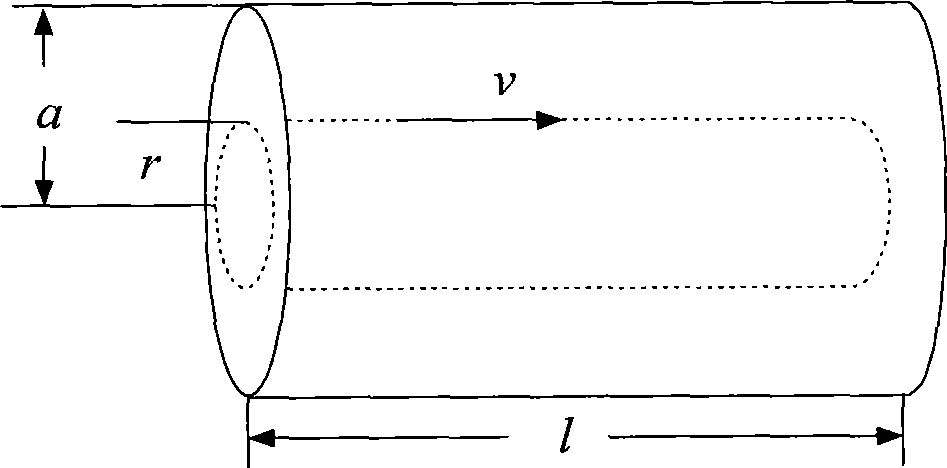

High-temperature and high-pressure water vapor environment structural material testing device

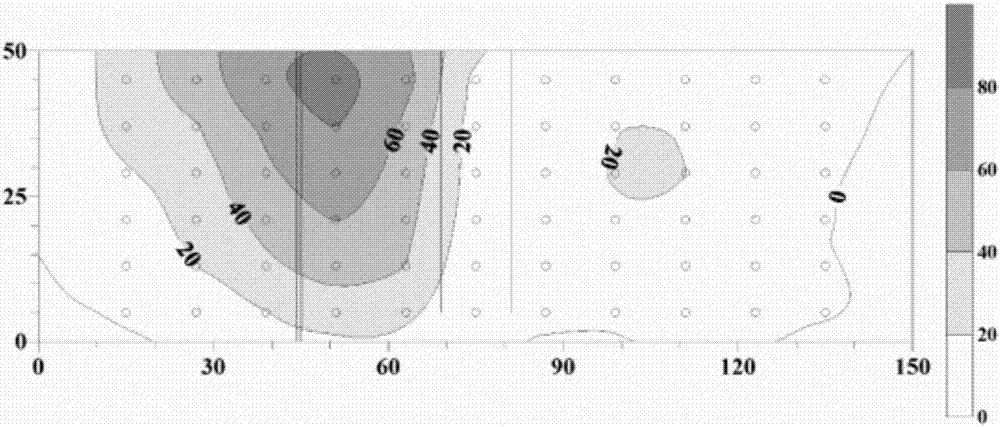

ActiveCN104458400AWeather/light/corrosion resistanceInvestigating abrasion/wear resistancePressurized water reactorData acquisition

The invention discloses a high-temperature and high-pressure water vapor environment structural material testing device. The testing device is provided with a pipe, wherein high-temperature water flows inside and outside the pipe. The testing device comprises an autoclave, a test tube loading system, a loop system inside a test tube, a loop system outside the test tube, a controlling and measuring system and a data acquisition and processing system. The testing device which can be used for simulating the temperature, pressure, flow velocity, water chemical conditions, load and the like of a high-temperature and high-pressure water vapor environment structural material is applicable to tests in the aspects of corrosion, stress corrosion, corrosion fatigue, flow accelerated corrosion and the like of tubular specimens through complex flow and complex load coupling effect. Especially, the working conditions of different flow, different inner-side and outer-side temperatures, different pressures and different water chemistry in a heat exchange tube of a steam generator in a nuclear reaction pressurized-water reactor can be simulated to carry out related testing and research on the heat exchange tube.

Owner:UNIV OF SCI & TECH BEIJING

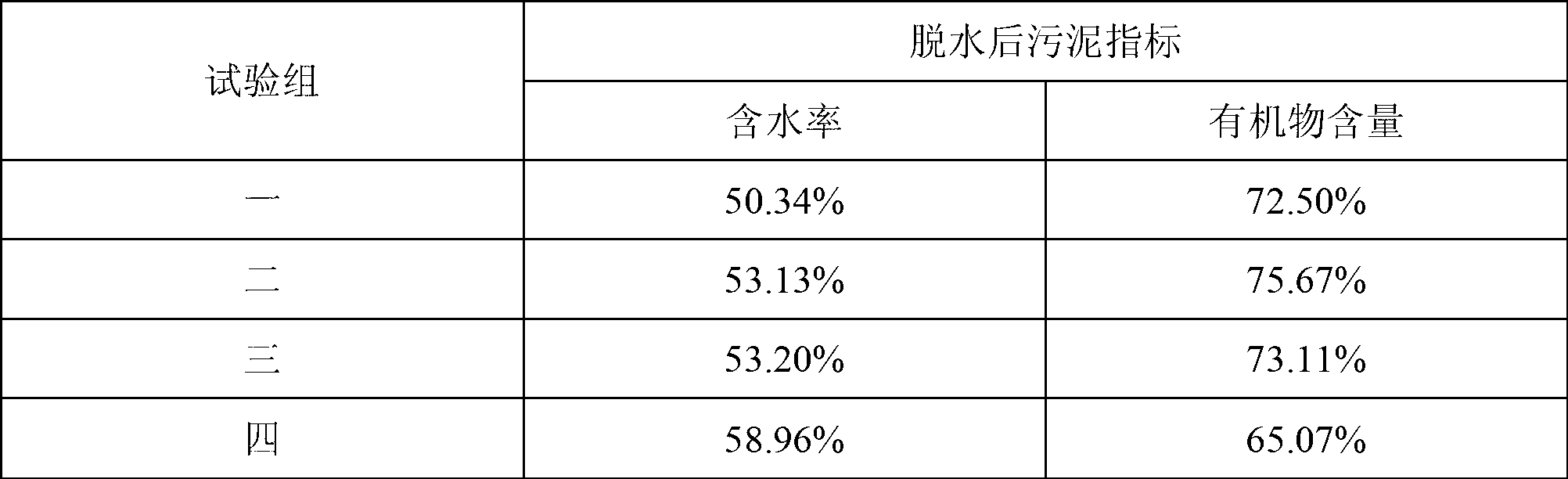

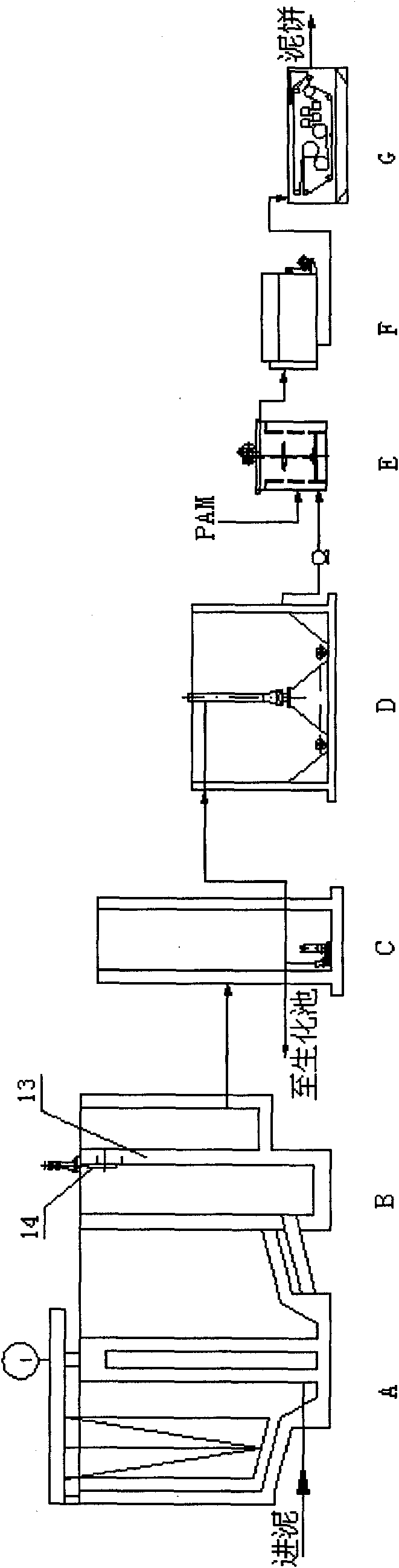

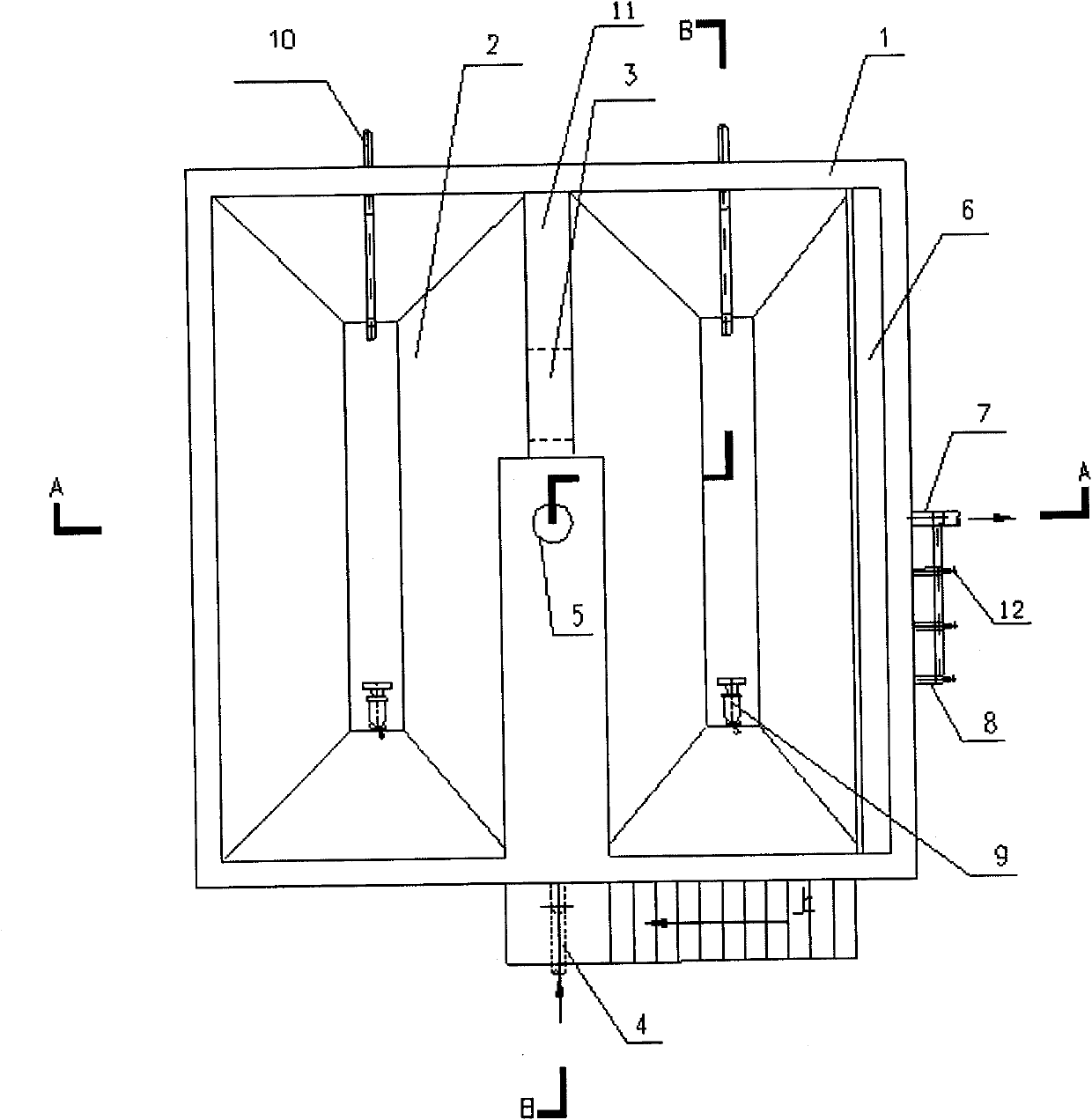

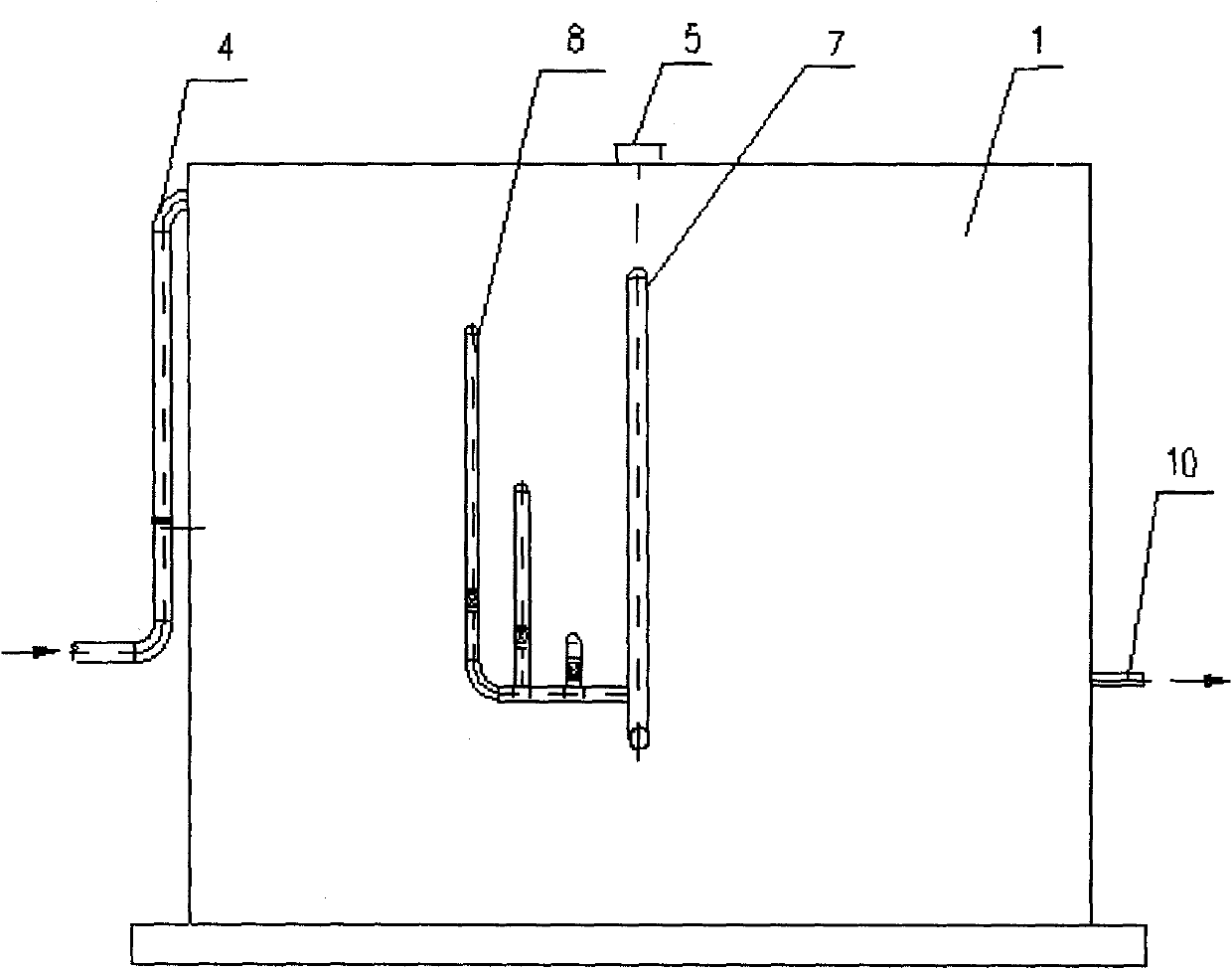

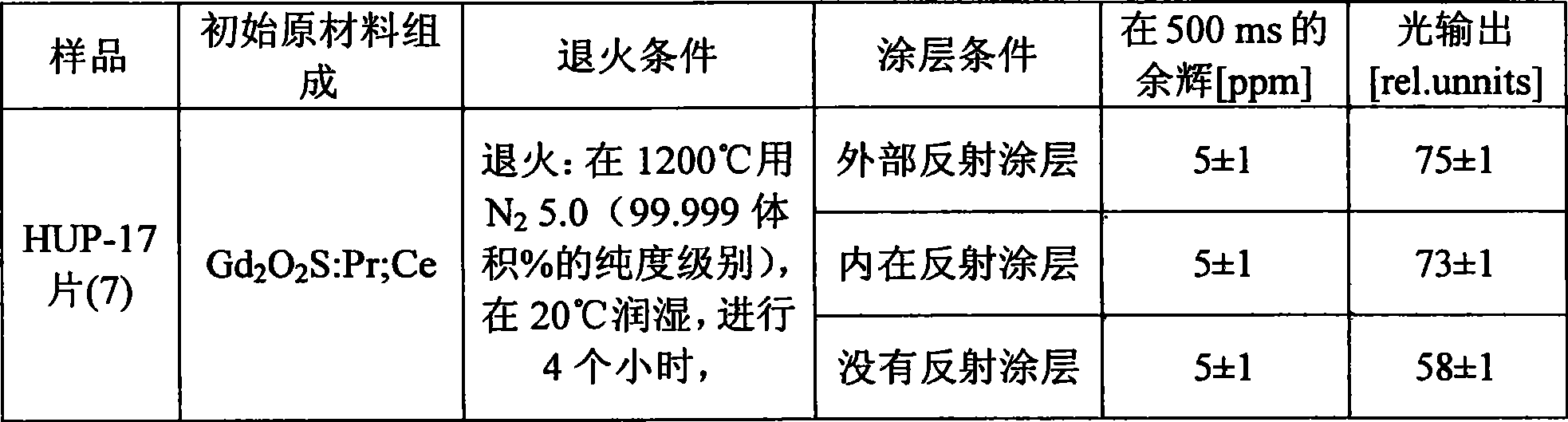

Conditioner for combinedly conditioning sludge and method for dehydrating sludge through utilizing conditioner

InactiveCN103011548AReduce moisture contentImprove dehydration effectSludge treatment by de-watering/drying/thickeningPhysical conditioningChemical condition

The invention relates to a conditioner for combinedly conditioning sludge and a method for dehydrating sludge through utilizing the conditioner, and in particular relate to a conditioner for conditioning the sludge before dehydration and a method for dehydrating the sludge through utilizing the conditioner, belonging to the field of an urban sewage and sludge treatment technology. The conditioner and the method are used for solving the problems of high delivered sludge water content, large pharmaceutical chemicals dosage, low heat value after sludge dehydration and high sludge dehydration cost of the conventional sludge dehydration. The conditioner for combinedly conditioning sludge consists of a separately packaged chemical conditioner and a separately packaged physical conditioner. The method for dehydrating the sludge comprises the following steps: 1, chemical conditioning; 2, physical conditioning; and 3, sludge sheet frame filter pressing and dehydrating to obtain the dehydrated sludge. The conditioner and the method have the advantages that the dehydrated sludge water content is lower than 60%; the chemical conditioning drug dosage is small, the physical conditioning adopts economic wood chips, and the total dosage cost is low; and the dehydrated sludge has high heat value. The conditioner and the method can be used for efficiently dehydrating wastewater and sludge.

Owner:NAT ENG RES CENT OF URBAN WATER RESOURCE

Nanometer fiber filter material and preparation method thereof

InactiveCN105040271AFilament/thread formingMonocomponent copolyamides artificial filamentPorosityCross-link

The invention relates to a nanometer fiber filter material. The nanometer fiber filter material is characterized by comprising a filter base material and a nanometer fiber layer formed on the filter base material, wherein the mass ratio of the filter base material to the nanometer fiber layer is 100:1-600:1. The nanoscale fiber material layer is composited on the surface of a traditional textile through an electrostatic spinning technology; the nanometer fiber fineness ranges from dozens of nanometers to hundreds of nanometers; fibers are cross-linked in an intricating mode; ultra-high magnitude-order nanoscale micro-holes exist, and the porosity is larger than 90%; the thickness of the fiber layer can be designed and machined according to the requirements of different products; PM2.5 and dust with the diameter larger than 2.5 microns can be totally filtered out, zero emission is achieved, different raw materials can be selected to machine the nanometer fiber layer according to the work condition and the characteristics of composited materials, and meanwhile the requirements for filtering precision, work condition temperature, chemical conditions and other aspects can be met. The running resistance of finished products is low, and filtering speed is high. The service life is long, the nanometer fiber filter material can be repeatedly used, and therefore running cost is greatly reduced, and higher cost performance is achieved.

Owner:SHANGHAI TANLON FIBER CO LTD

Sludge dehydration treatment technology

ActiveCN101767922AConform to the internal relationship of concentration progressionImprove concentrationSludge treatment by de-watering/drying/thickeningSludge cakeFiltration

The invention relates to a sludge dehydration treatment technology which includes the steps as follows: residual active sludge is treated for concentration sequentially in a continuous gravity concentration tank and an intermittent sludge concentration tank, then put in a chemical conditioning tank and guided into a tumbling centrifugal concentrator for further concentration after being chemically conditioned, and finally put into a belt filter press to be dehydrated to become sludge cake. The sludge dehydration treatment technology of the invention aims at the residual active sludge property characteristics to strengthen the concentration effect before mechanical dehydration and has the advantages of little addition dosage in dehydration, sludge cake chickening, low moisture content in sludge cake, easy washing of filtration fabric not stuck by sludge, low solid content in separation medium, and high solid recovery rate.

Owner:四川蓉信开工程设计有限公司

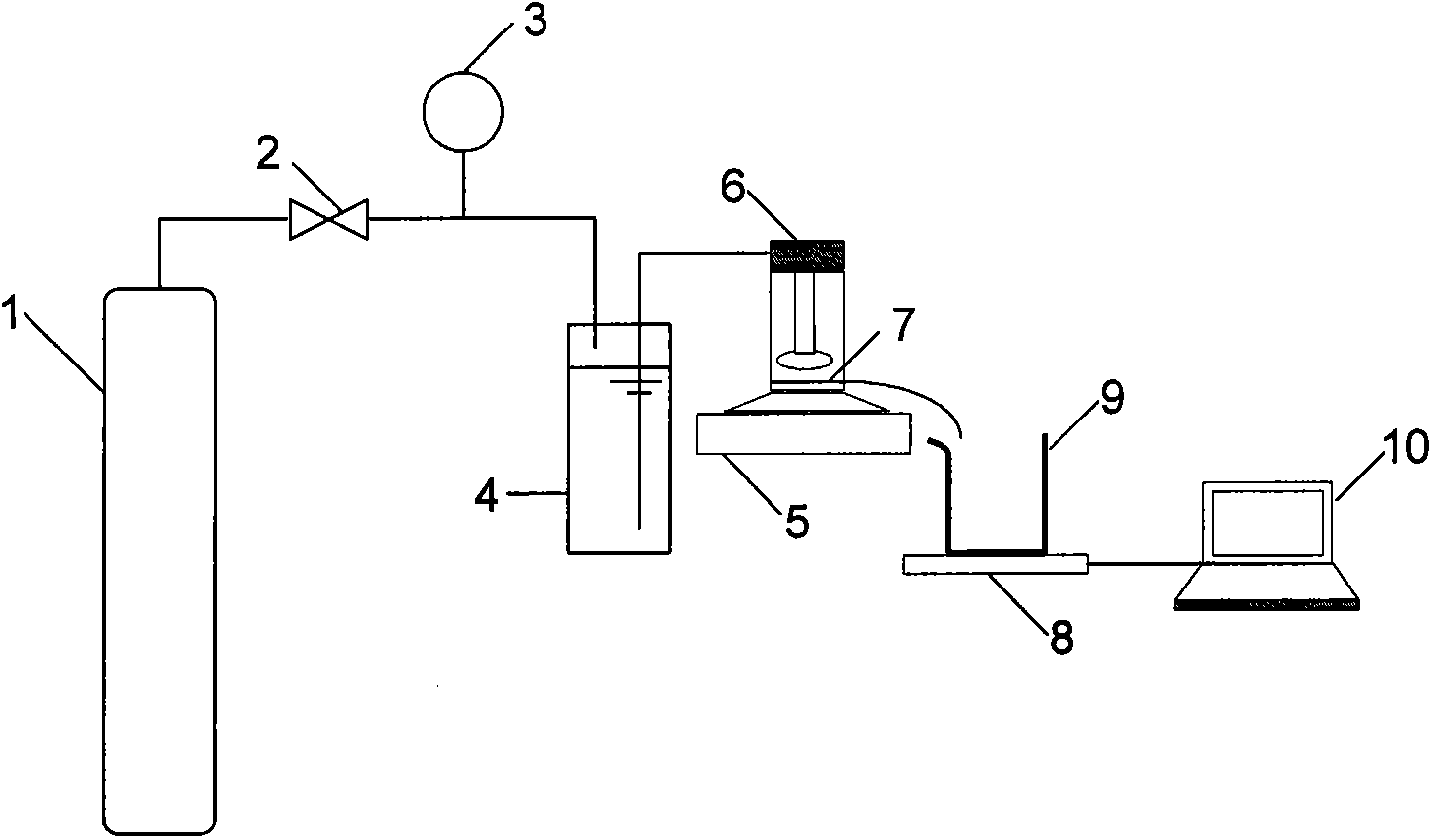

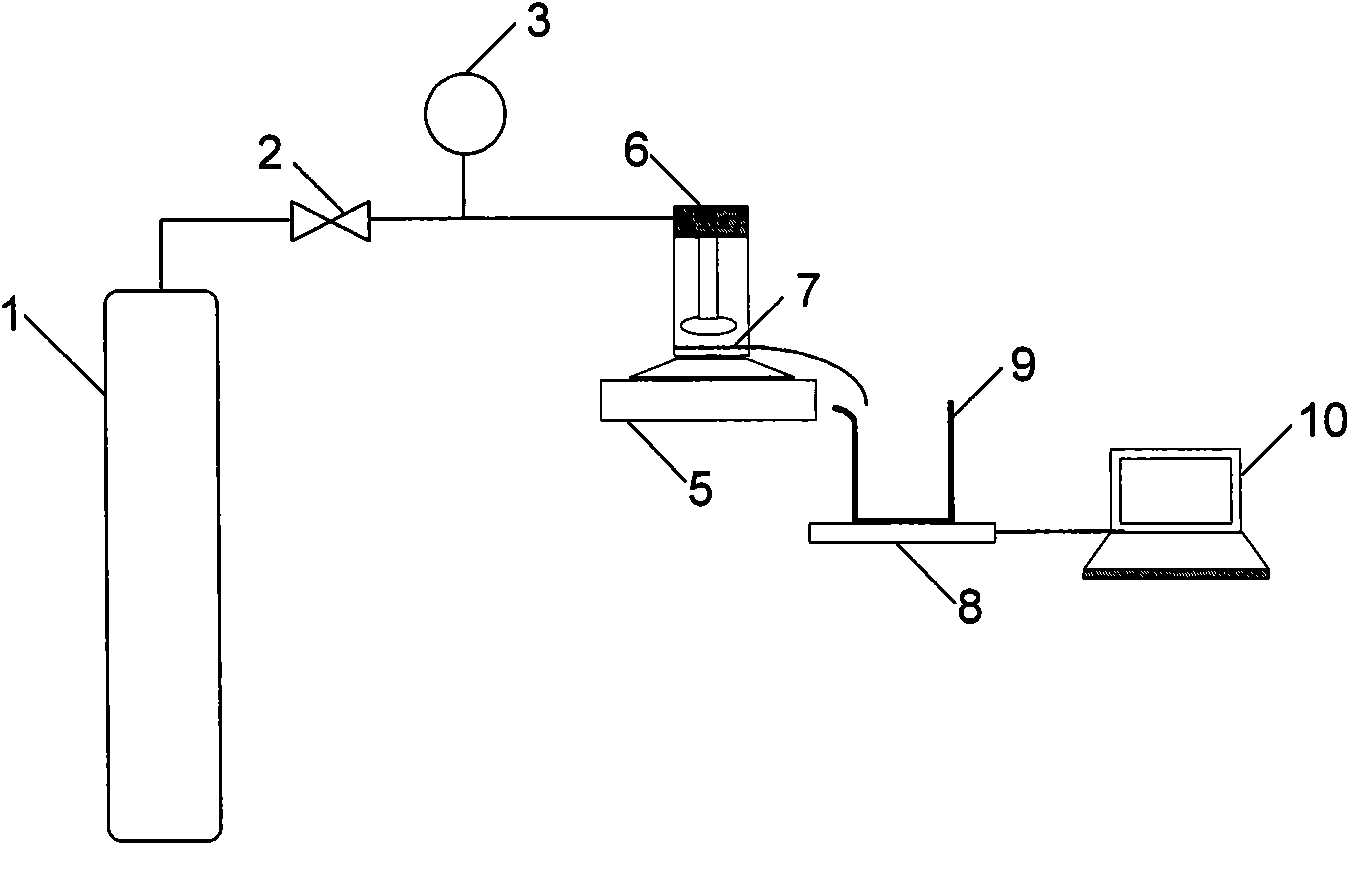

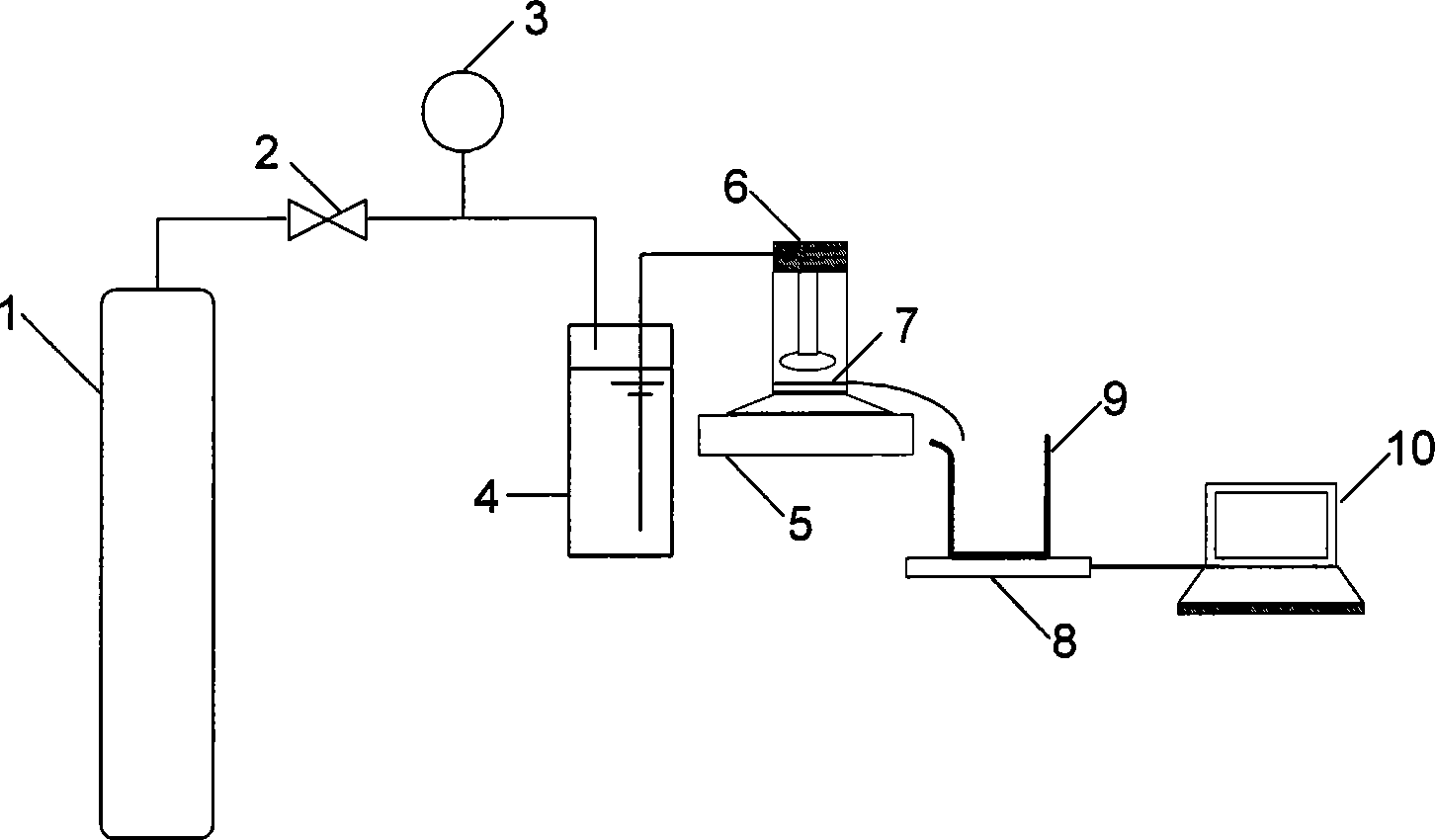

Method evaluating membrane chemical cleaning recovery performance

InactiveCN102580546ASolve the problem of time-consuming and laborious selectionTimely responseSemi-permeable membranesRecovery performanceChemical condition

The invention discloses a method for evaluating membrane bioreactor (MBR) membrane chemical cleaning recovery performance, which comprises the steps of arranging a stirring type ultrafiltering cup on a magnetic stirrer, connecting the stirring type ultrafiltering cup with a sealed container, connecting the sealed container with a pressure reduction regulation valve, connecting the pressure reduction regulation valve with a nitrogen steel bottle, installing a pressure meter on an air outlet of the pressure reduction regulation valve, connecting a water outlet of the stirring type ultrafiltering cup with a balance, and connecting the balance with a computer. A small evaluation device is used for evaluating initial membrane resistance R1 of a membrane, membrane resistance R2 after the membrane is polluted and membrane resistance R3 after the membrane is chemically cleaned, and then the chemical cleaning recovery performance of the membrane which is cleaned on chemical conditions is judged after slurry is filtered. The method is simple in operation, low in cost and capable of quickly judging membrane chemical cleaning recovery performance, choosing appropriate chemical cleaning chemicals and confirming optimized cleaning schemes.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

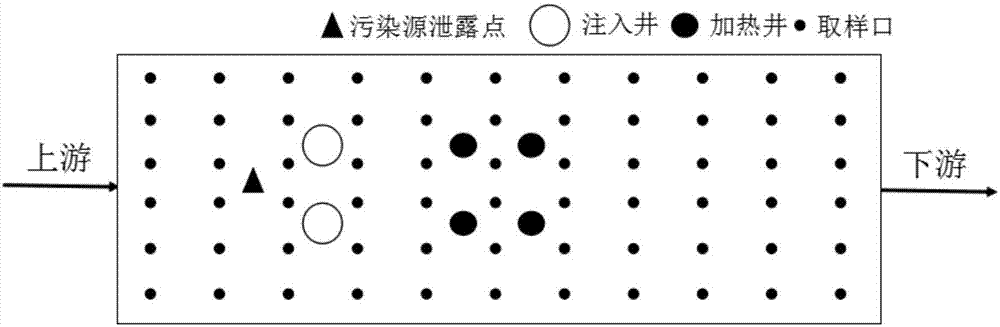

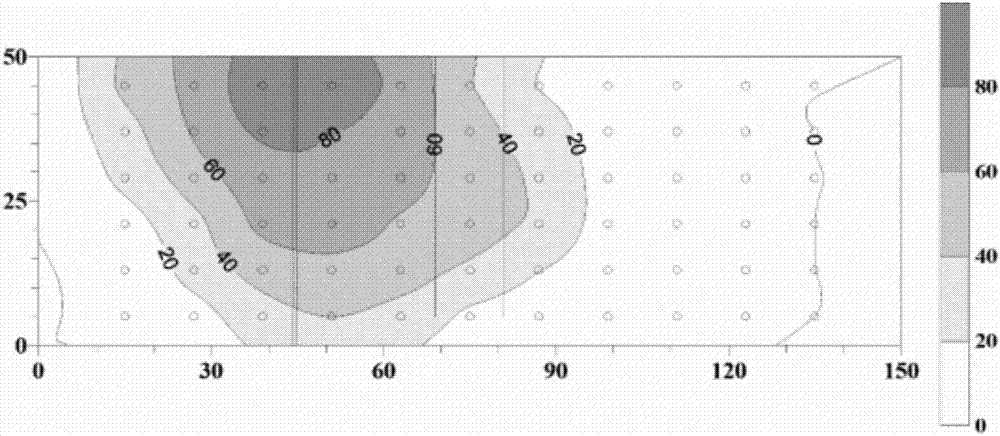

Method for in-situ reduction restoration of polluted groundwater

ActiveCN106966481AImprove reducibilityRealization of generationWater treatment parameter controlContaminated groundwater/leachate treatmentFormatePersulfate

The invention relates to a method for in-situ reduction restoration of polluted groundwater. In a groundwater pollution zone, by injecting formate and persulfate into an underground environment through two injection wells and performing thermal activation on the persulfate and the formate, carbon dioxide ion free radicals with high reducibility are prepared to reduce heavy metals and chlorinated organic pollutants and remove target polluted components, so as to achieve an aim of restoration. According to the method provided by the invention, activation is realized by heating without externally adding transition metals, and the generation of free radicals and the removal of pollutants can be achieved under the condition that chemical conditions including a pH value, a dissolved oxygen content and the like of the groundwater are not adjusted. A carbon dioxide free radical is a high-reducibility free radical, reacts quickly and efficiently with the pollutants, and can be widely applied to restoration of underground polluted environments.

Owner:JILIN UNIV

Bismuth-zirconium alloy

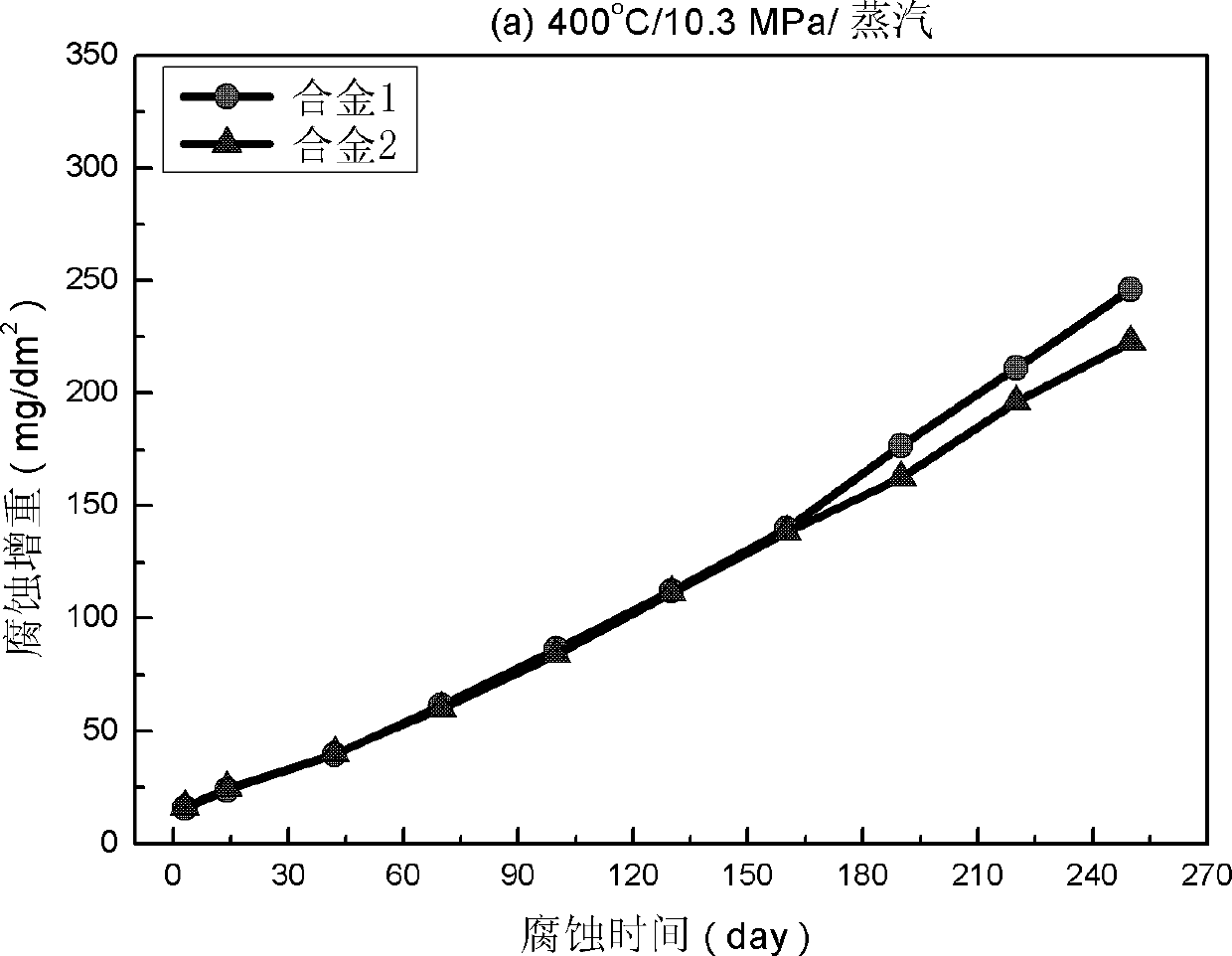

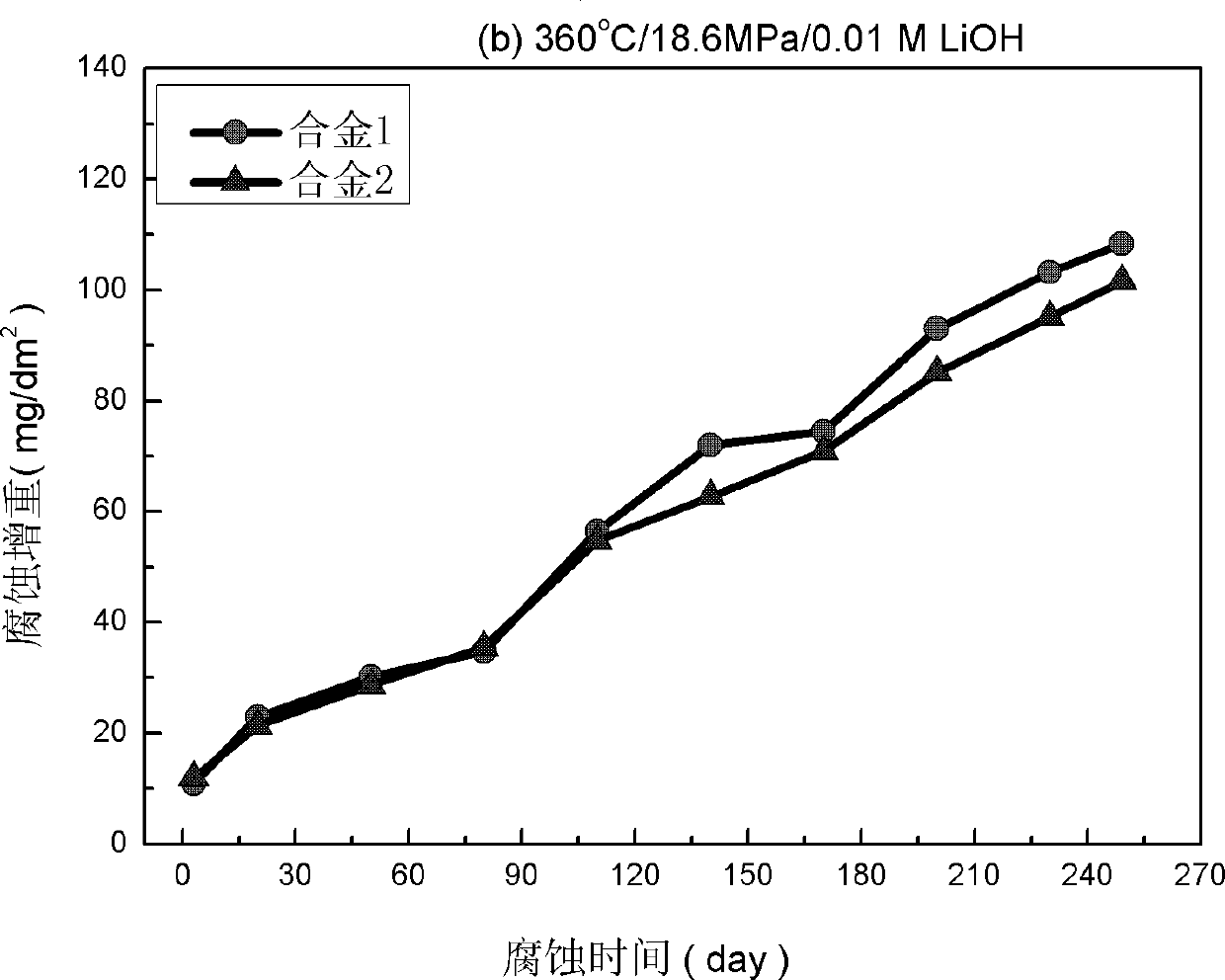

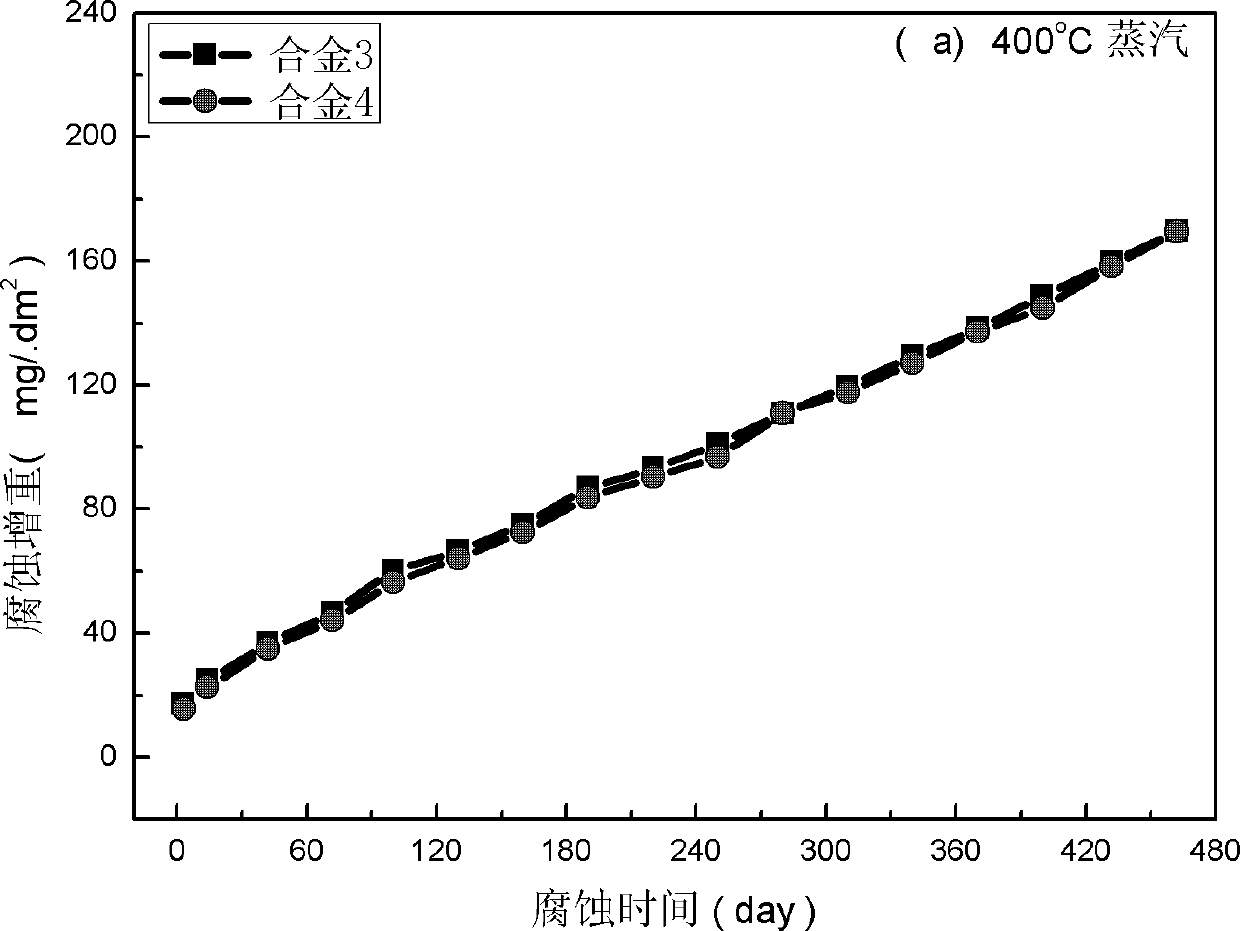

InactiveCN102433465AImprove corrosion resistanceCorrosion weight gain reductionPressurized water reactorChemical condition

The invention discloses a bismuth-zirconium alloy, which consists of the following components in percentage by weight: 0.4 to 1.0 percent of Sn, 0.2 to 1.2 percent of Nb, 0.2 to 0.4 percent of Fe, 0.05 to 0.3 percent of Cr, 0.005 to 0.4 percent of Bi, and the balance of Zr and inevitable impurities. The bismuth-zirconium alloy shows excellent corrosion resistance under two hydro-chemical conditions, namely 0.01 mol / L LiOH aqueous solution at the temperature of 360 DEG C and under the pressure of 18.6MPa and superheated steam at the temperature of 400 DEG C and under the pressure of 10.3MPa; and the corrosion resistance of the bismuth-zirconium alloy is obviously superior to that of a ZIRLO alloy. The bismuth-zirconium alloy can be used as a material for reactor core structures such as fuel element jackets, grillages and the like in pressurized water reactors of nuclear power plants.

Owner:国核宝钛锆业股份公司 +1

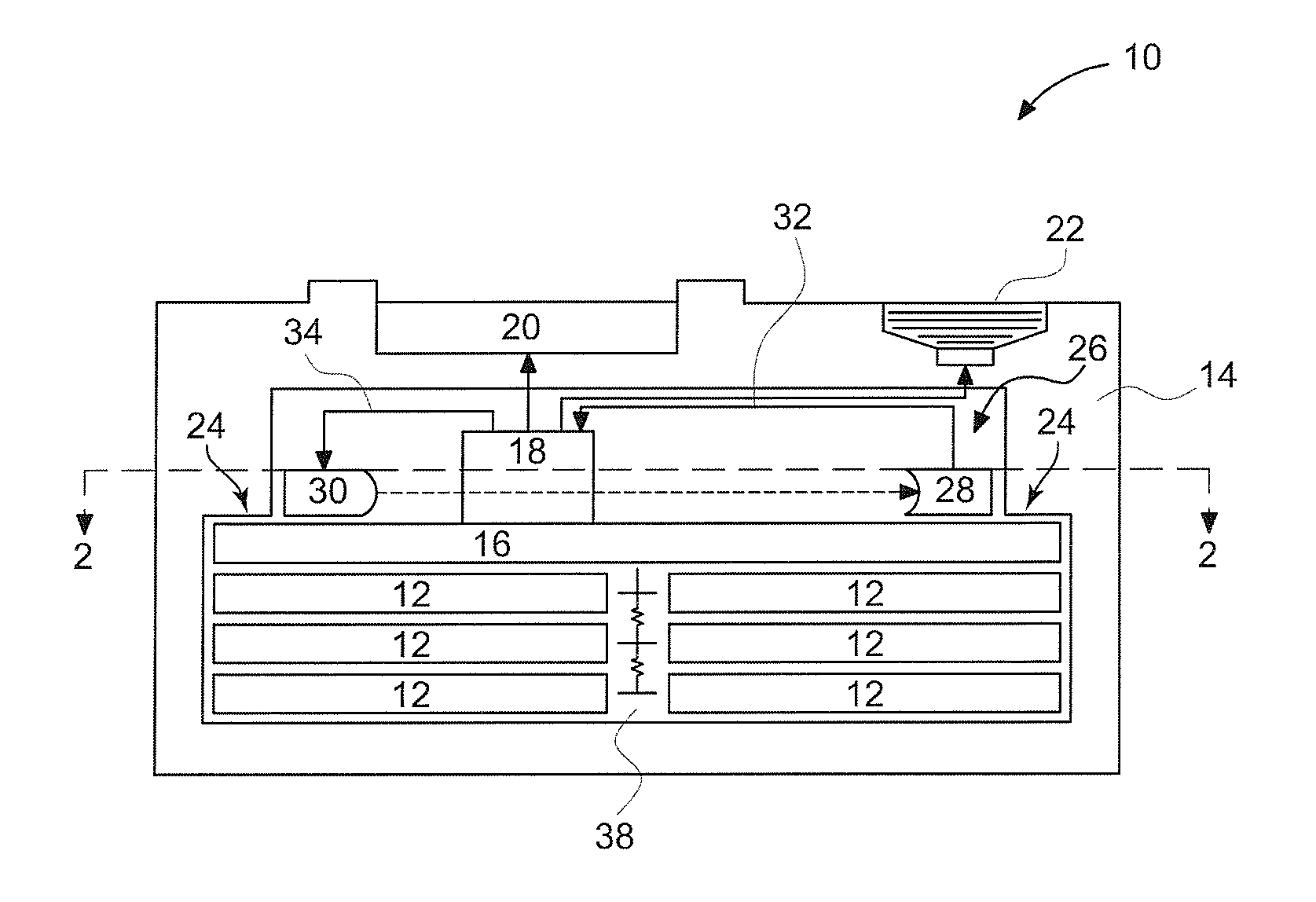

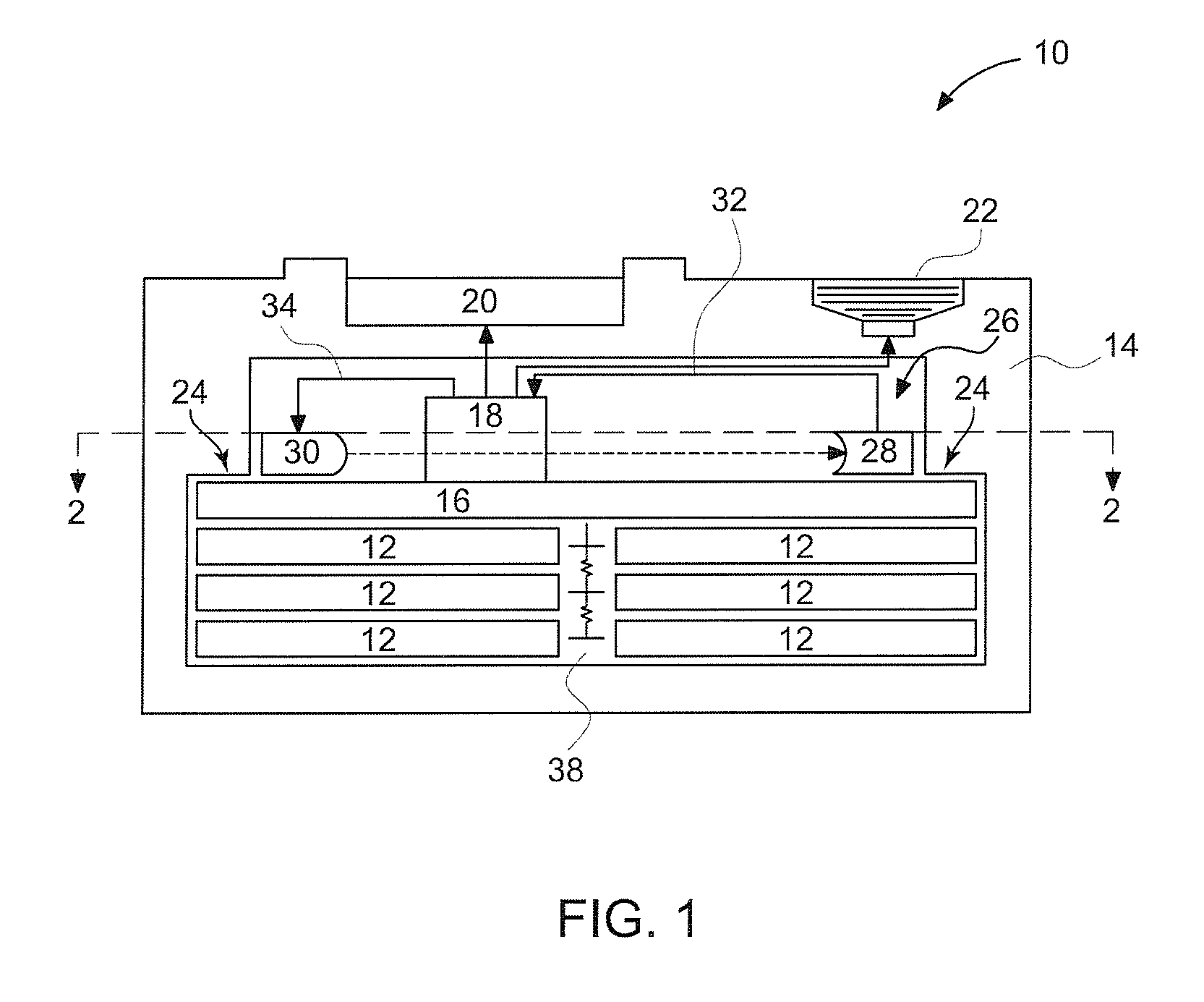

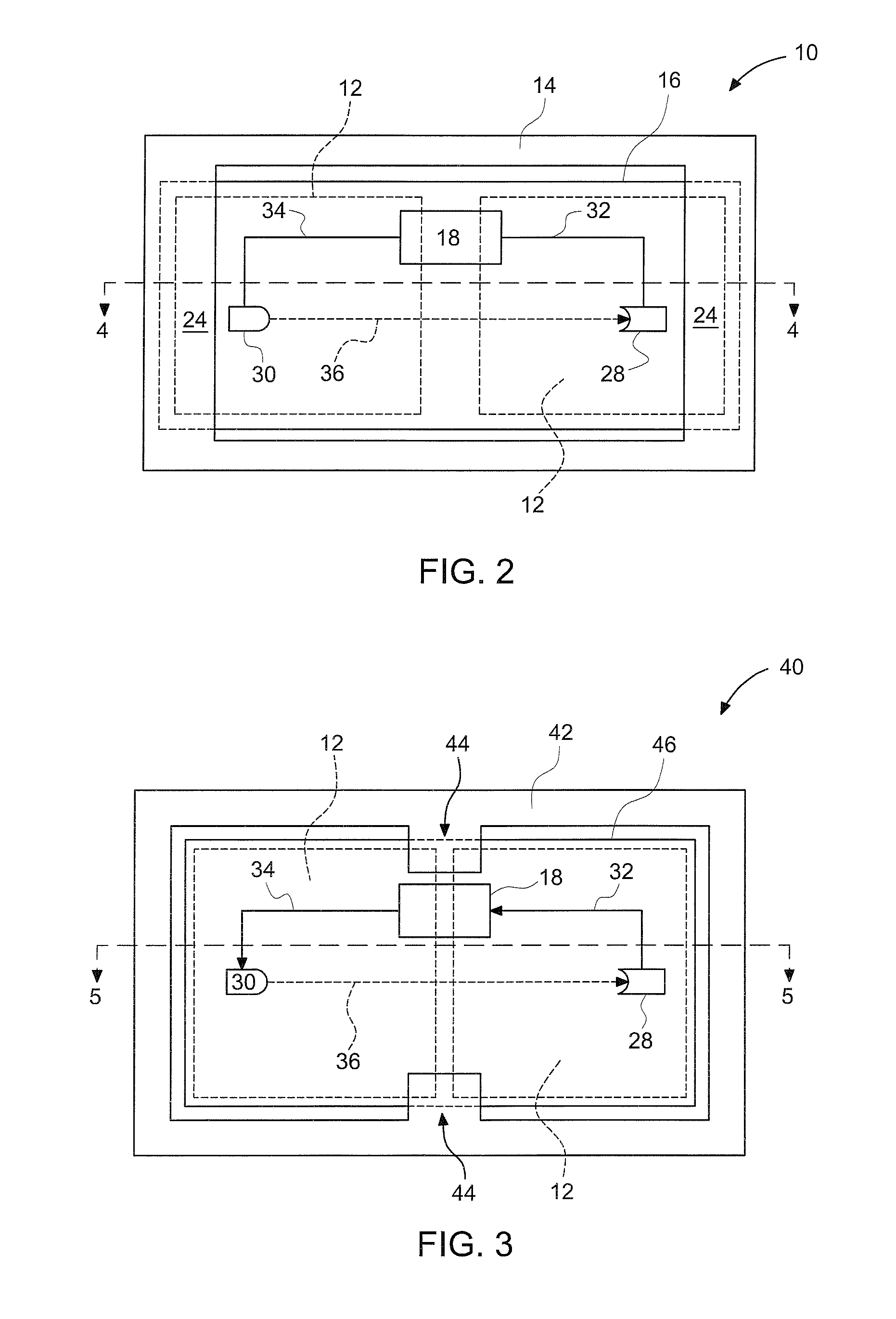

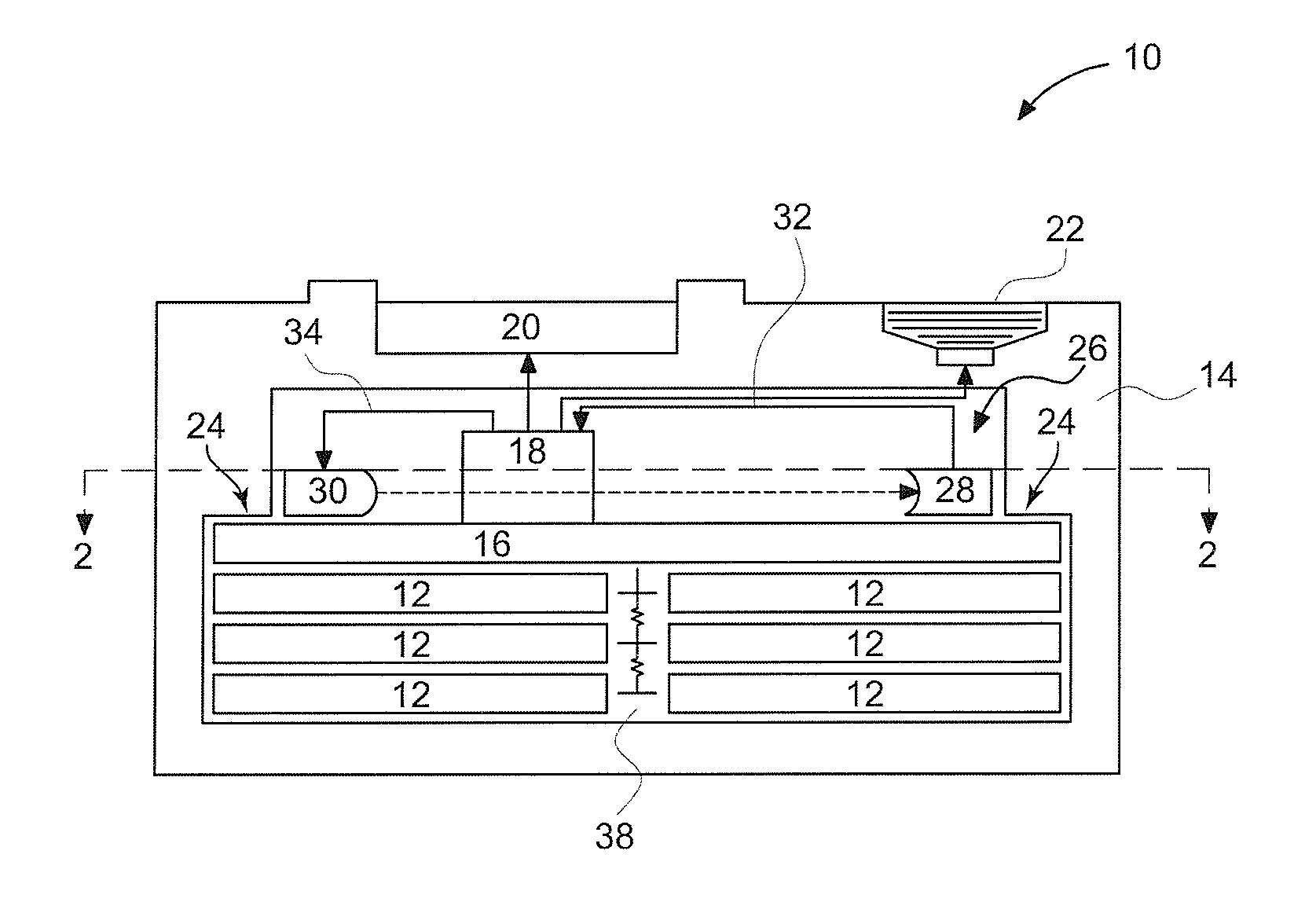

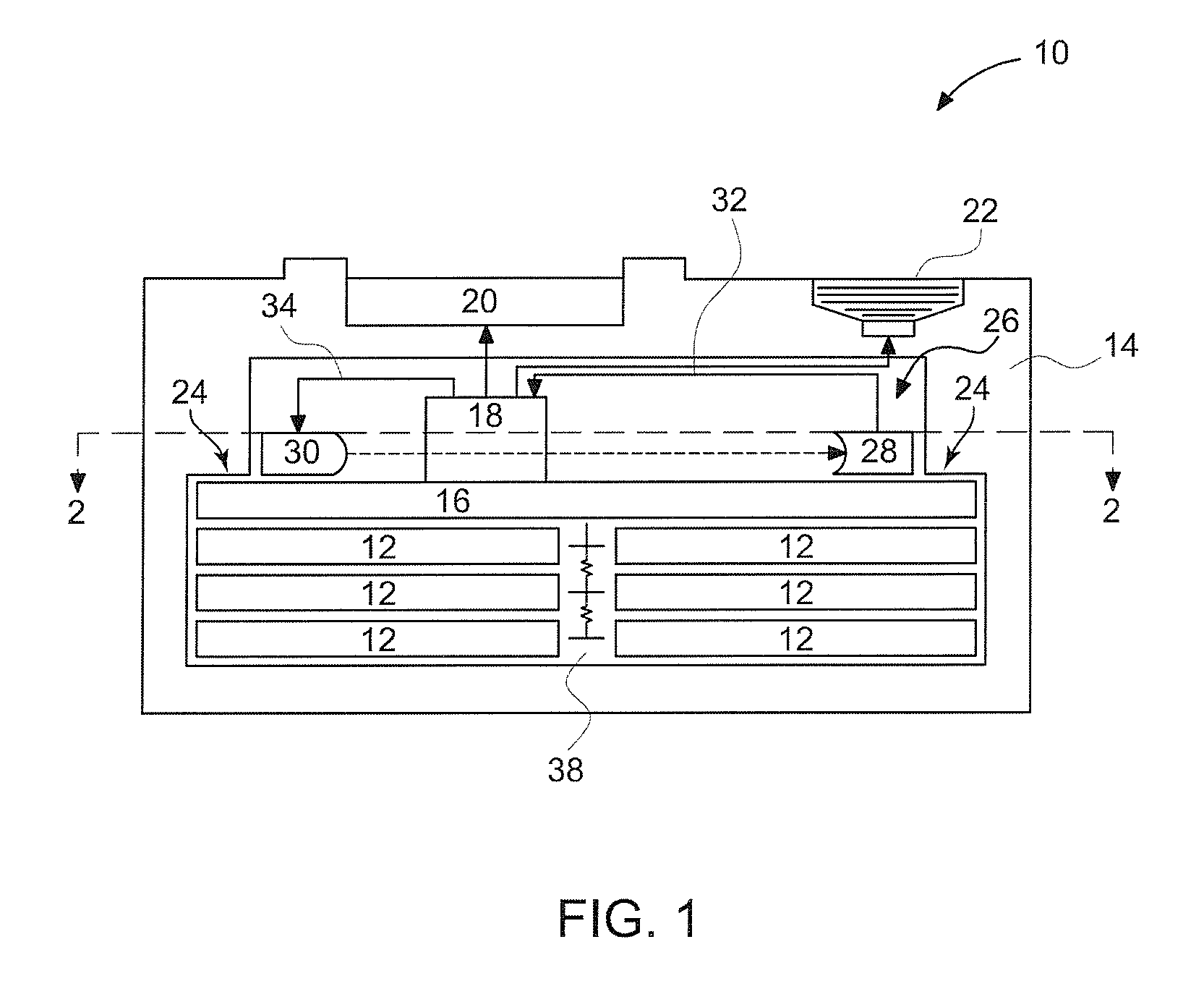

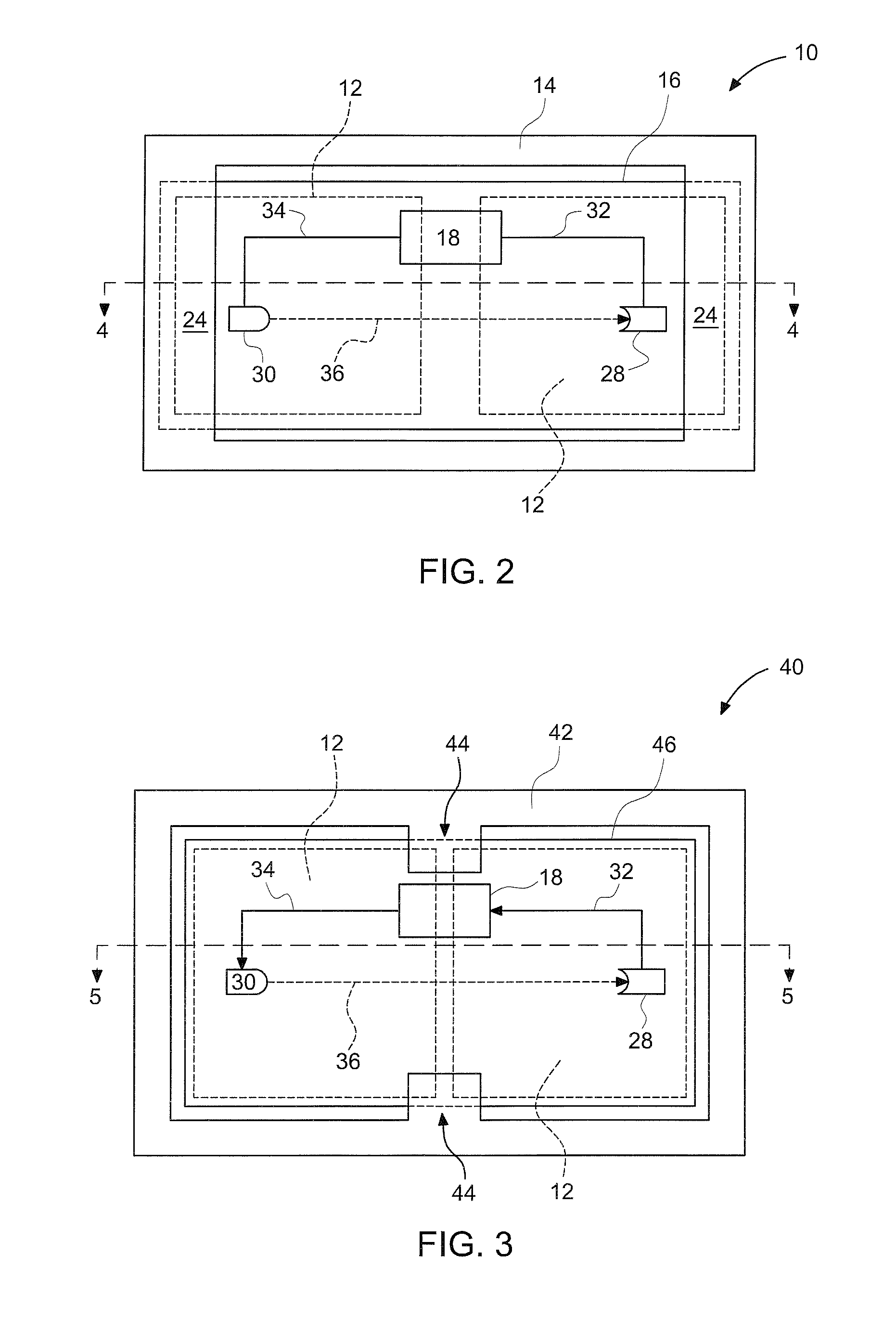

Device and method of determining safety in a battery pack

InactiveUS8395519B2Cells structural combinationSecondary cells charging/dischargingElectrical batteryChemical condition

A battery pack includes at least one battery cell that expands and contracts in relation to the chemical conditions of the battery cell. A substrate is configured to contact the at least one battery cell. A sensor is attached to the substrate and the sensor produces a signal indicative of the displacement of the substrate. A controller is communicatively connected to the sensor such that the controller receives the signal from the sensor. The controller processes the signal to produce an indication of a status of the battery cell. A method of monitoring battery safety includes movably securing a substrate across at least one cell of a battery. A displacement of the substrate is measured. The measured displacement is processed with a controller to identify a safety status of the at least one cell. An output device is operated with a controller to provide an indication of the safety status of the at least one cell of the battery.

Owner:VYAIRE MEDICAL CONSUMABLES LLC

Ecological organic fertilizer

InactiveCN102838390AGood conditionImprove biological characteristicsBacillus licheniformisChemical condition

The invention discloses an ecological organic fertilizer comprising a base material and a nutrient solution according to a weight ratio of (800-1200):1; the base material comprises the following components in parts by weight: 0-90 parts of pig manure, 0-6 parts of chicken manure, 0-8 parts of bean dregs, 0-4 parts of wheat bran, 0-3 parts of sugar, 0-2 parts of distillers' grains, 0-19 parts of brewer's grain and 0-4 parts of corn starch, wherein all the parts by weight cannot be zero simultaneously; the nutrient solution comprises lactobacillus series, yeast group series, photosynthetic bacteria series, gram positive actinomycete groups, fermentation series filamentous bacteria, bacillus subtilis, bacillus natto, lactobacillus plantarum, bacillus licheniformis, high-activity enzyme and somatomedin. With the adoption of the ecological organic fertilizer, the physical and chemical conditions and the biological characteristic of soil are effectively improved, the soil is aged, and the green manure supply property and the buffer property of the soil are enhanced; the organic fertilizer is rich in organic substance and various nutrient elements to provide nutrition for crops, and thus, the organic fertilizer can promote the growth of the crops and improve the quality of agricultural products; and the organic fertilizer is beneficial to crop absorption, so that the utilization ratio of the fertilizer is increased.

Owner:CHENGDU JIAJIAMEI FOOD

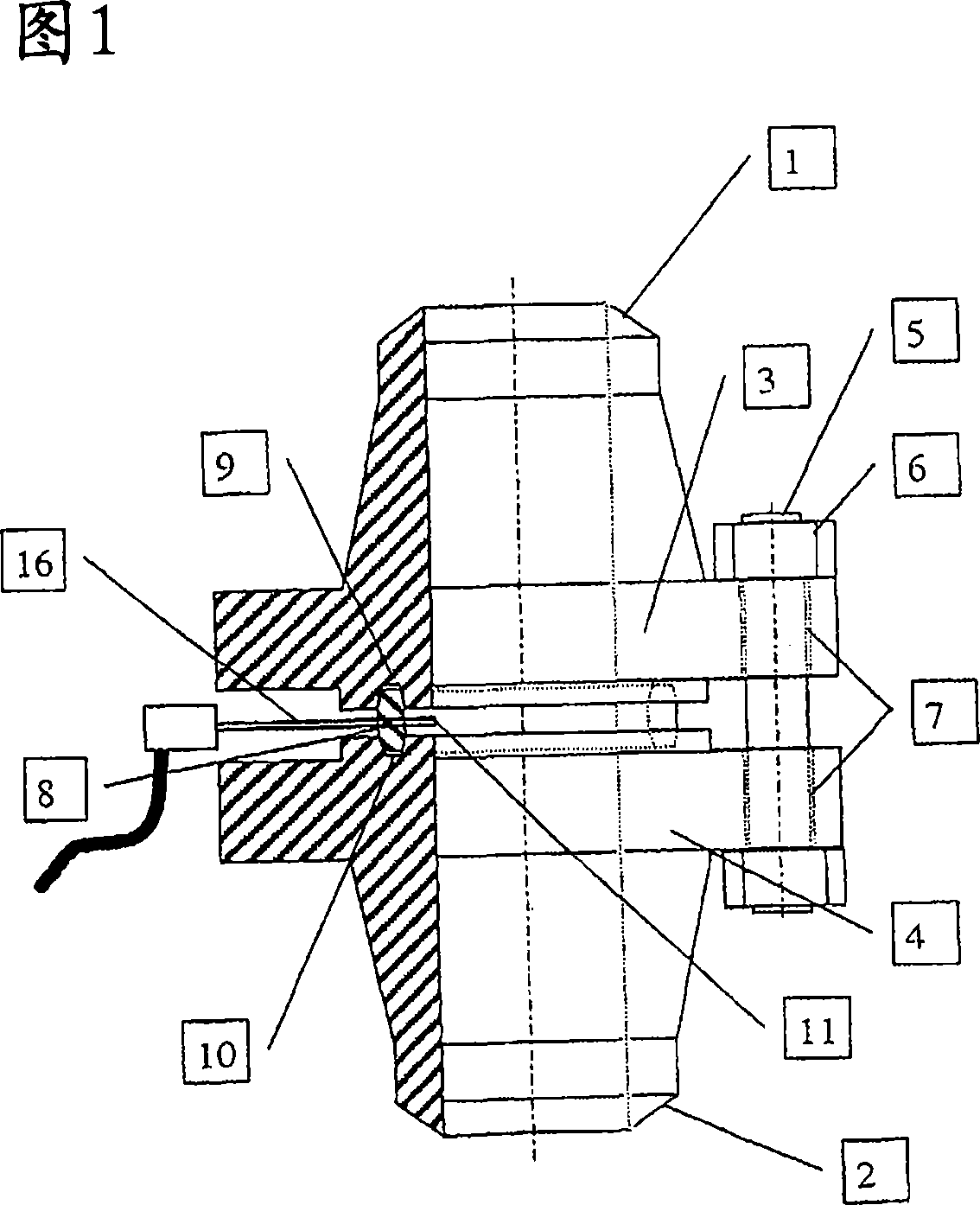

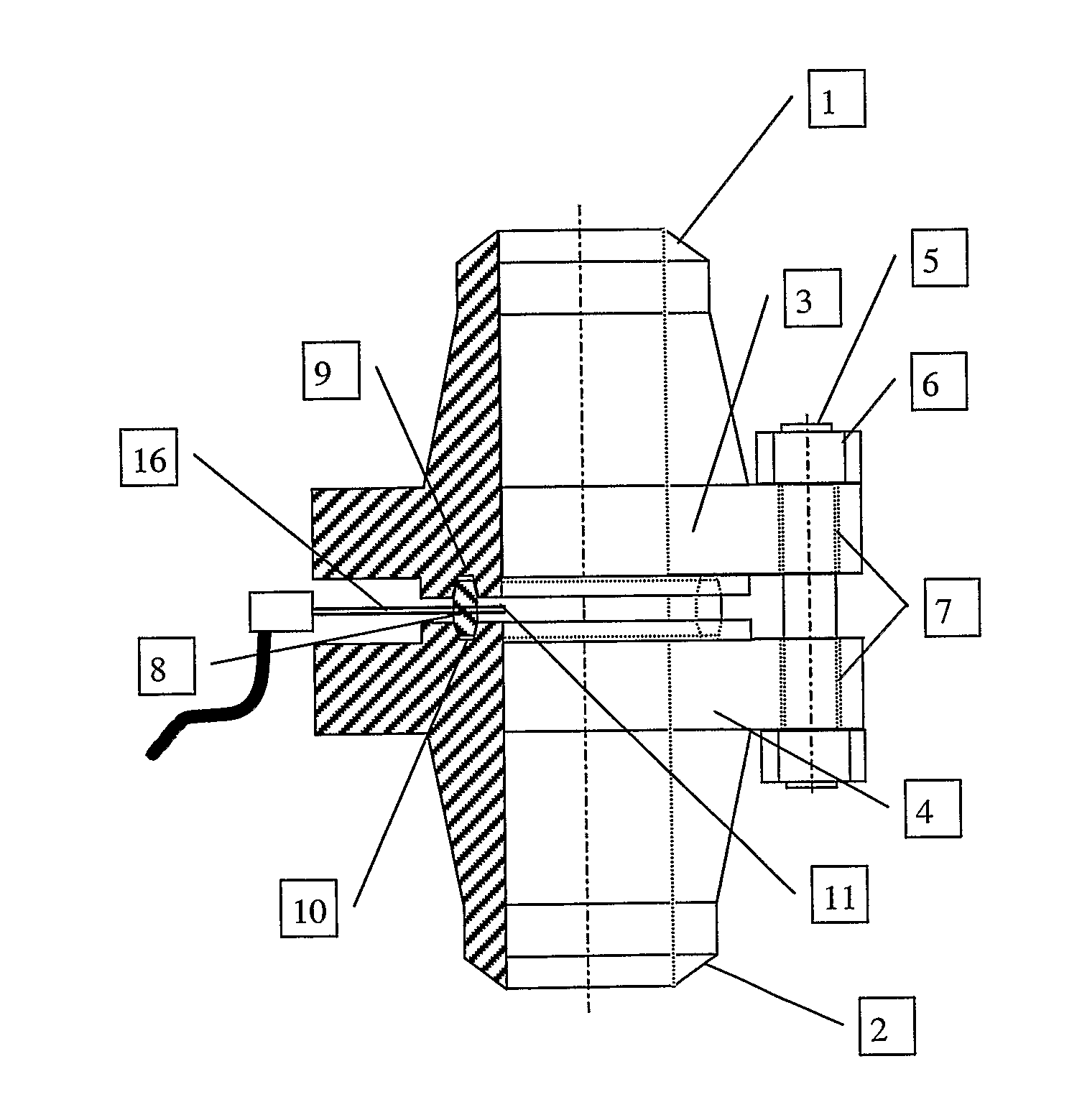

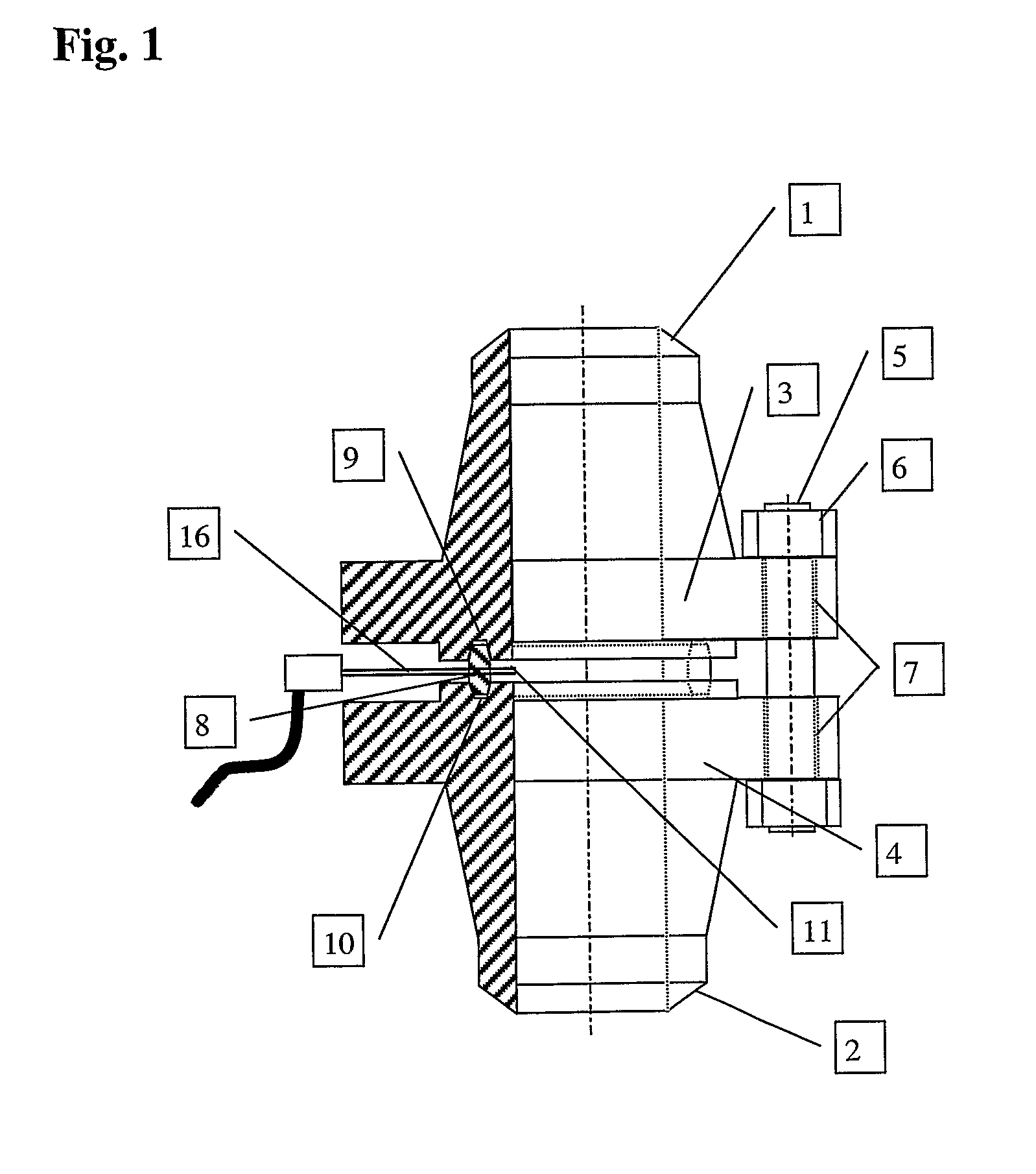

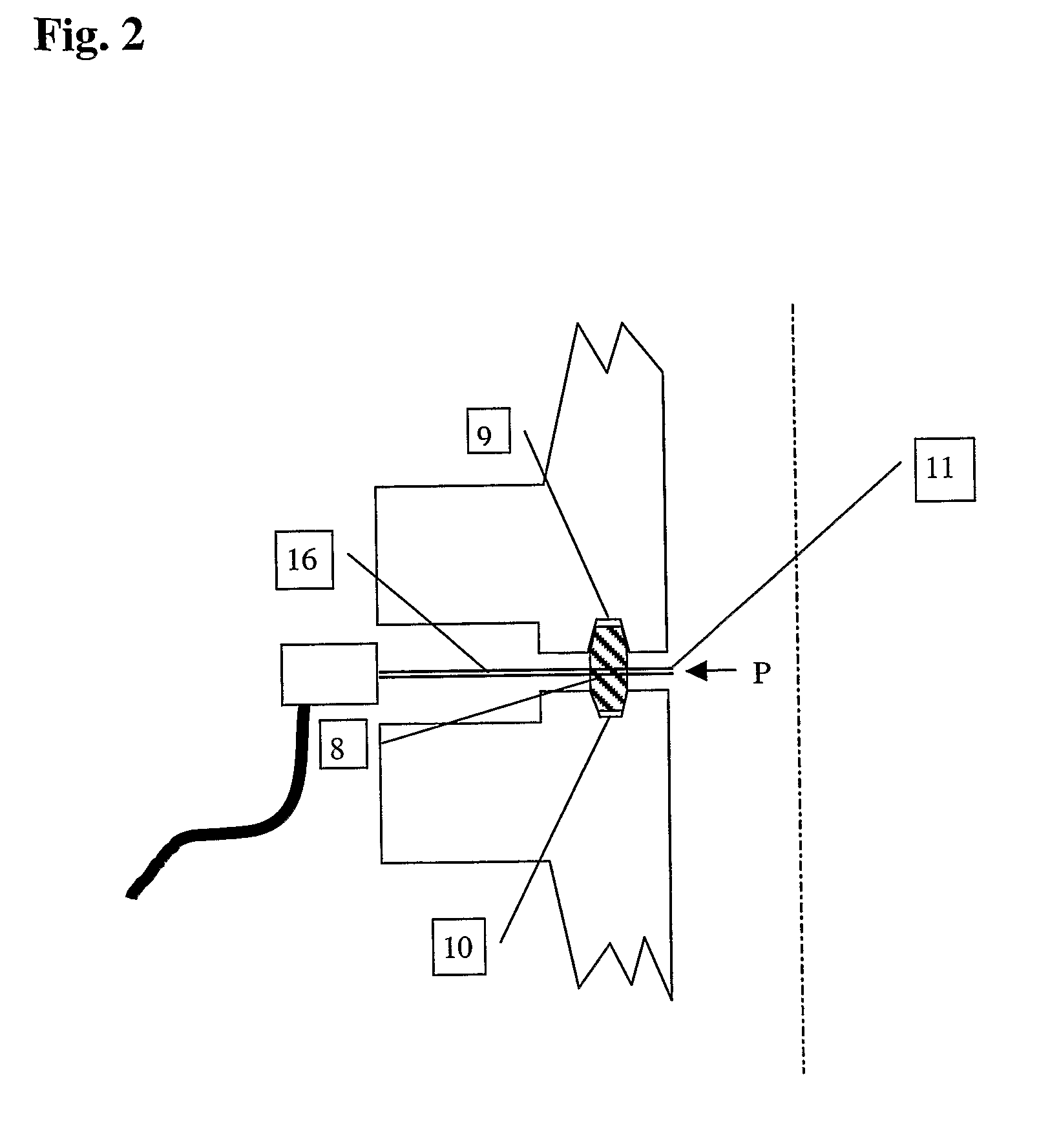

Arrangement or provision of a sensor or probe for the measuring of a condition in a pipe or the like

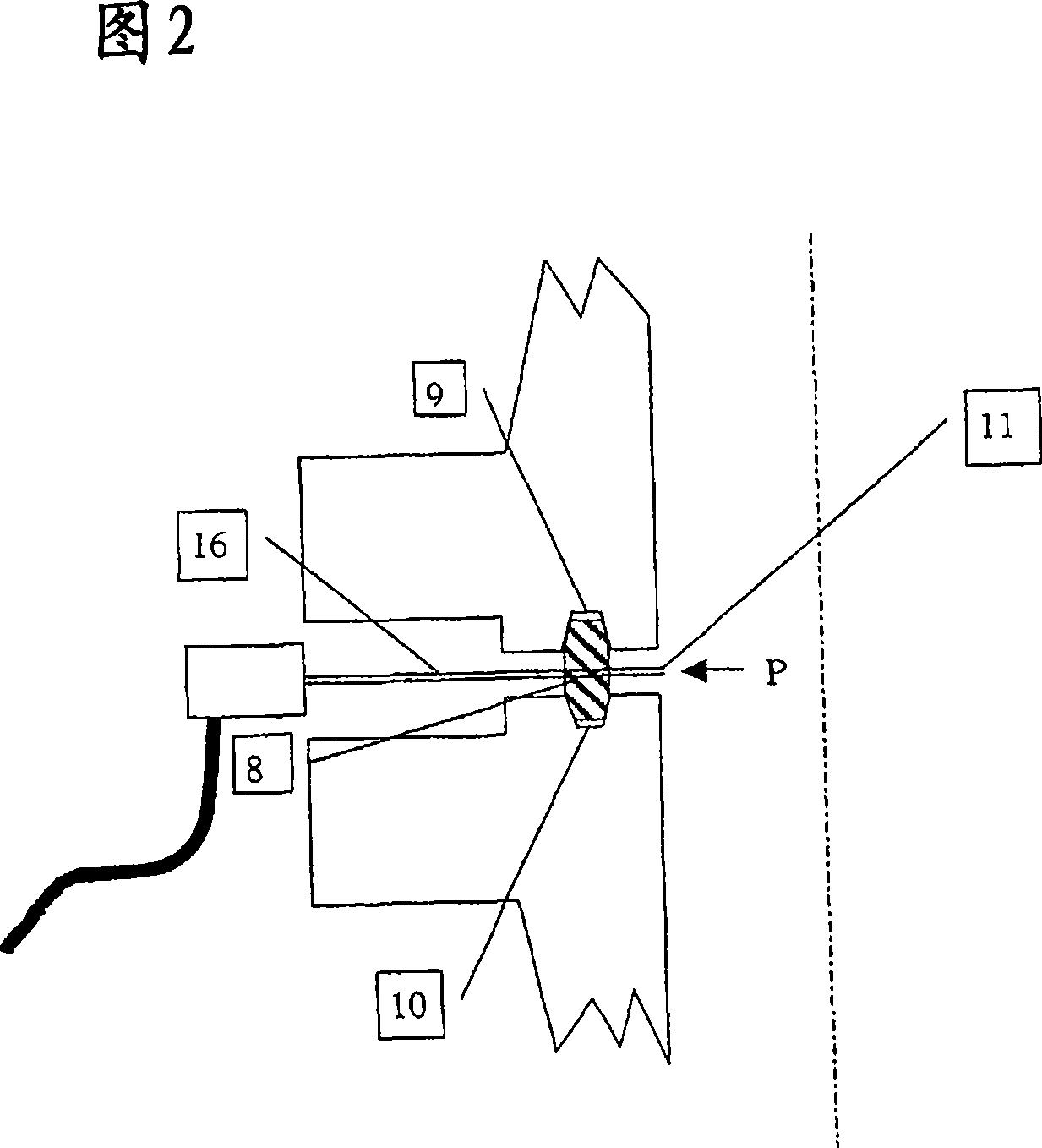

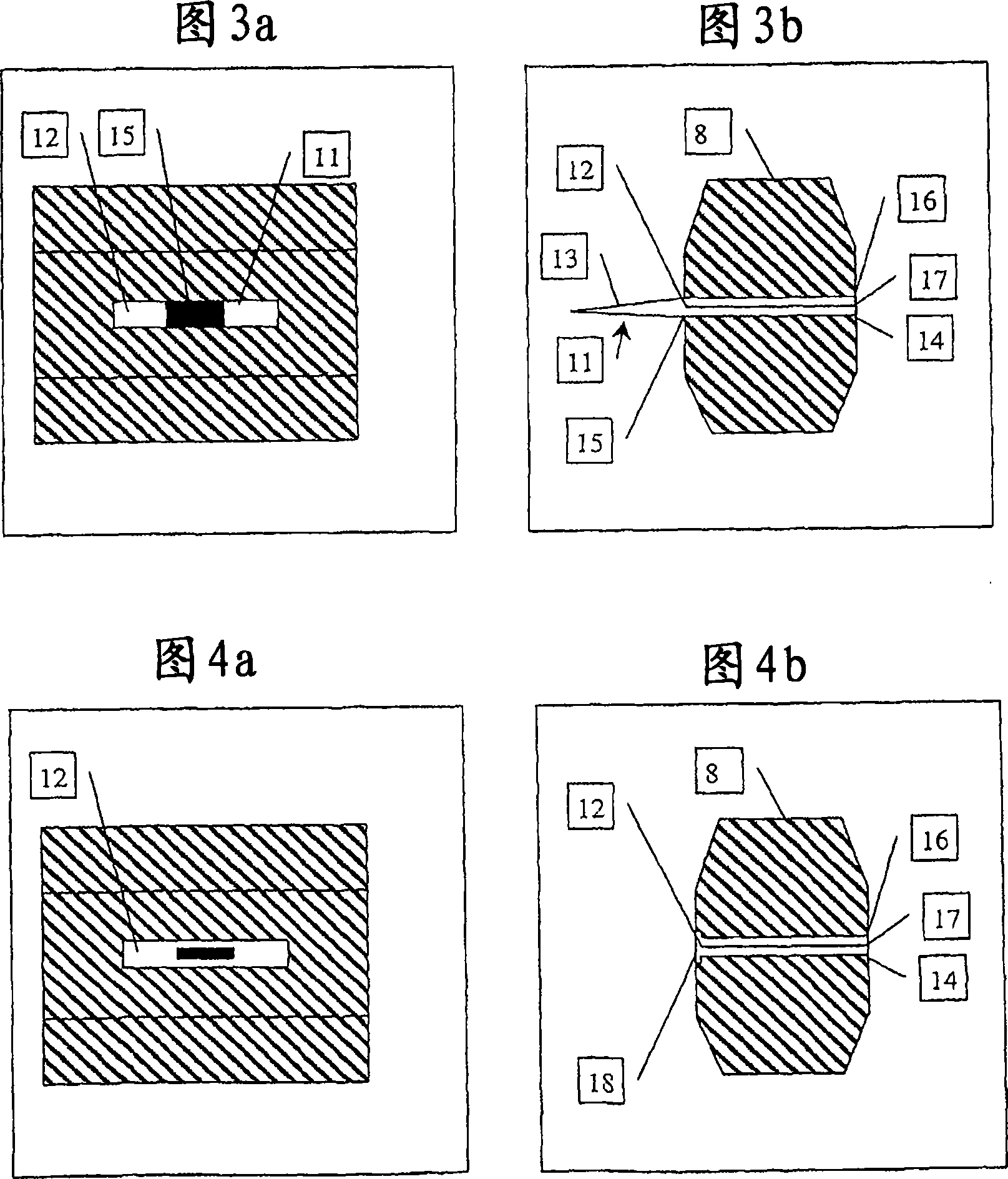

An arrangement or provision of a sensor or probe (11) for the measuring of a physical or chemical condition such as pressure, temperature or corrosion in a pipe (1, 2), tank or tubular container being provided with a connection such as a flange connection (3,4) between the pipe, tank or tubular sections. The sensor or probe (11) is provided in conjunction with a gasket such as a ring gasket (8) which is used as a seal between the pipe (1, 2), tank or tubular sections. The probe or sensor element is provided on an inner face of the ring gasket facing the inside of the pipe, tank or tubular sections. Electrical connectors (16) for transforming signals from the probe or sensor element (11) are provided in a bore or bores (14) that stretches from the sensor or probe and through the gasket or ring gasket (8) and to the outside of the gasket.

Owner:NORSK HYDRO ASA

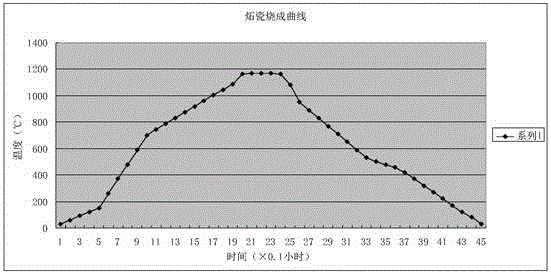

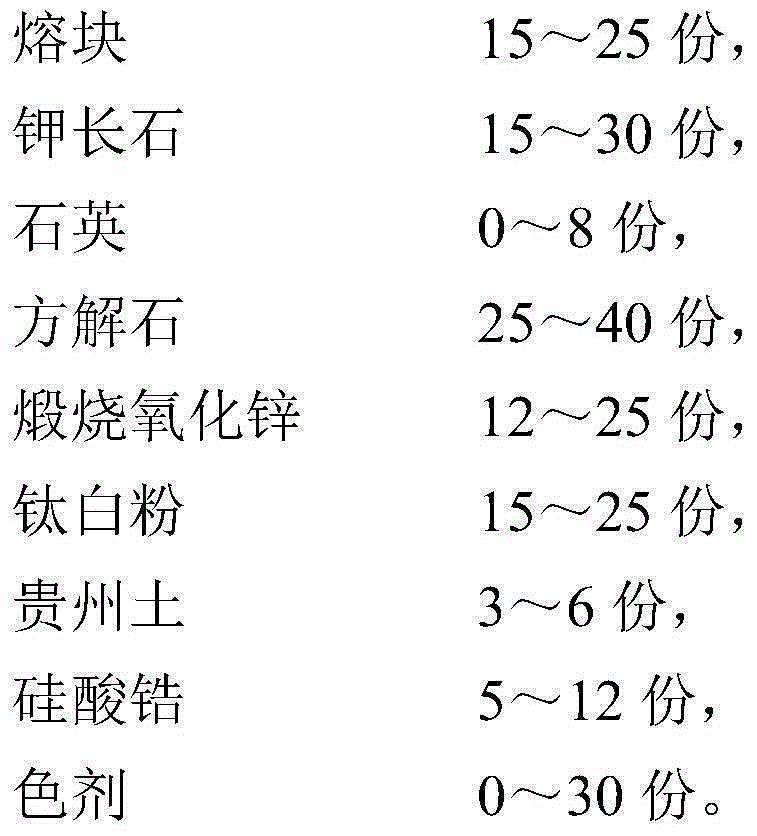

Low-temperature matte reaction glaze and production method thereof

The invention discloses a low-temperature matte reaction glaze and a production method thereof. The glaze is prepared from following raw materials, by weight, 5-25 parts of frit, 15-30 parts of potassium feldspar, 0-8 parts of quartz, 25-40 parts of calcite, 12-25 parts of calcined zinc oxide, 15-25 parts of titanium dioxide, 3-6 parts of kaolin from Guizhou, 5-12 parts of zirconium silicate and 0-30 parts of toners. According to the low-temperature matted reaction glaze and production method thereof, the calcite and the titanium dioxide are used to achieve a low-temperature sub-reaction effect, then the zirconium silicate is used for stabilizing the glaze, thereby ensuring the effects of the glaze, namely, the effects of the low-temperature oxidizing flame matted reaction glaze (transmutation glaze). A single-layer reaction glaze (transmutation glaze) stoneware product prepared from the glaze is suitable for large-scale production conditions at present and can be produced stably. Meanwhile, physical and chemical conditions, such as thermal-stability, dissolving of lead and cadmium, glaze surface hardness and the like, of the stoneware product meet the national household stoneware standard.

Owner:HUNAN HUALIAN CHINA IND

Arrangement or provision of a sensor or probe for the measuring of a condition in a pipe or the like

An arrangement or provision of a sensor or probe (11) for the measuring of a physical or chemical condition such as pressure, temperature or corrosion in a pipe (1, 2), tank or tubular container being provided with a connection such as a flange connection (3,4) between the pipe, tank or tubular sections. The sensor or probe (11) is provided in conjunction with a gasket such as a ring gasket (8) which is used as a seal between the pipe (1, 2), tank or tubular sections. The probe or sensor element is provided on an inner face of the ring gasket facing the inside of the pipe, tank or tubular sections. Electrical connectors (16) for transforming signals from the probe or sensor element (11) are provided in a bore or bores (14) that stretches from the sensor or probe and through the gasket or ring gasket (8) and to the outside of the gasket.

Owner:NORSK HYDRO ASA

Wet metallurgical method with comprehensive reclamation, basically no three wastes and zero discharge

The invention discloses a wet metallurgical method with comprehensive reclamation, basically no three wastes and zero discharge, and belongs to the fields of wet metallurgy and environmental friendliness. Aiming at the problems that the conventional wet metallurgical process can only reclaim partial valuable elements serving as commodities and produces a large amount of waste water, waste slag and waste gas so as to cause resource waste and generate environmental hazards, the invention provides the new wet metallurgical method. The method is characterized in that: scattered components, rare components, rare earth, noble metals and other valuable components can reach optimal leaching rate and enter the solution by adopting a high-strength leaching agent such as a high acid oxidation and complexing leaching agent or a high alkali oxidation and complexing leaching agent and using high-strength physical and chemical conditions such as high-temperature and high-pressure leaching. By high-strength leaching, the filtered and washed leached slag reaches the standards of raw materials of building materials or standards for making of iron, aluminum and the like and other chemical raw materials. In order to achieve comprehensive, effective and economic separation and purification and make auxiliary materials such as the leaching agent and the like not wasted, recycle of leachate and waste water is adopted, so that the purposes of comprehensive reclamation, basically no three wastes and zero discharge are basically fulfilled. Therefore, the wet metallurgical technology is more economic, more effective, energy-saving and environment-friendly.

Owner:王钧

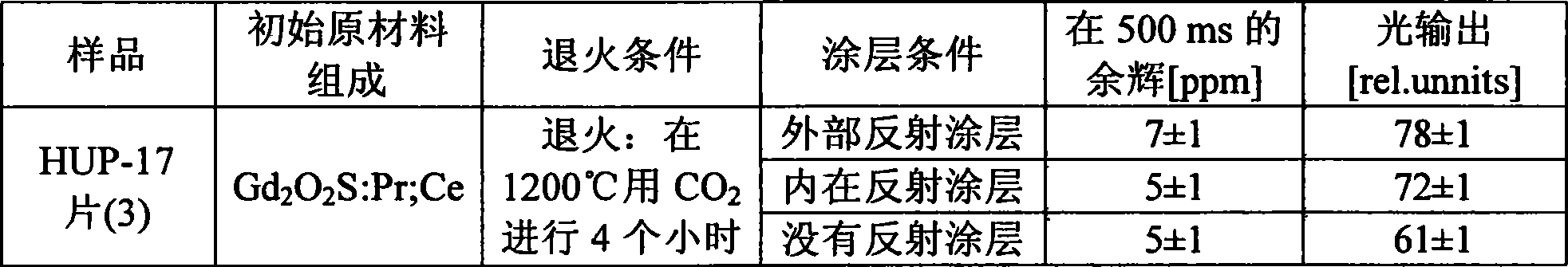

Scintillation element, scintillation array and method for producing the same

InactiveCN101371163AReduce afterglowImprove collection efficiencyRadiation intensity measurementChemical conditionReflective layer

A scintillation element comprises a scintillation material, and a reflective layer, wherein the reflective layer is formed as an intrinsic part of the scintillation material. Preferably, a plurality of scintillation elements may be arranged to form a scintillation array. A method for producing a scintillation element comprises providing a scintillation material, and producing a reflective layer at the scintillation material by exposing the scintillation material to physical and / or chemical conditions in such a way that the reflective layer is formed out of a part of the scintillation material.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Sludge chemical conditioning deep dewatering method

InactiveCN108358431ALittle change in pHReduce the amount of changeSludge treatment by de-watering/drying/thickeningSludgeChemical condition

The invention discloses a sludge chemical conditioning deep dewatering method, which comprises the following steps that after sludge in a sewage plant is subjected to concentration treatment, polyferric silicate sulfate (PFSS) is added according to 1 to 2 percent of the dry sludge quantity for primary conditioning; then, PDADMA (poly dimethyl diallyl ammonium chloride) is added according to 1.5 to3 percent of the absolute dry sludge quantity for secondary conditioning; after the two kinds of chemicals are added, and the reaction is completed, the conditioned sludge is pumped into a high-pressure elastic extraction machine or a diaphragm plate frame press filtering machine for press filtering deep dewatering; the water content of mud cake after the press filtering is lowered to a value being 60 percent or below. The sludge chemical conditioning deep dewatering method has the advantages that only two kinds of chemicals FPFSS and PDADMA are added; in addition, the total adding quantity of the two kinds of two chemicals does not exceed 5 percent of the absolute dry sludge quantity; the chemical adding quantity is obviously reduced; no dry powder chemical is added; the pH value changeon the sludge is small, so that the organic matter and heat value content of the sludge after the dewatering is higher; the method is favorable for various purposes such as various kinds of compost, land utilization and garden greening.

Owner:SHANGHAI TECHASE ENVIRONMENT PROTECTION

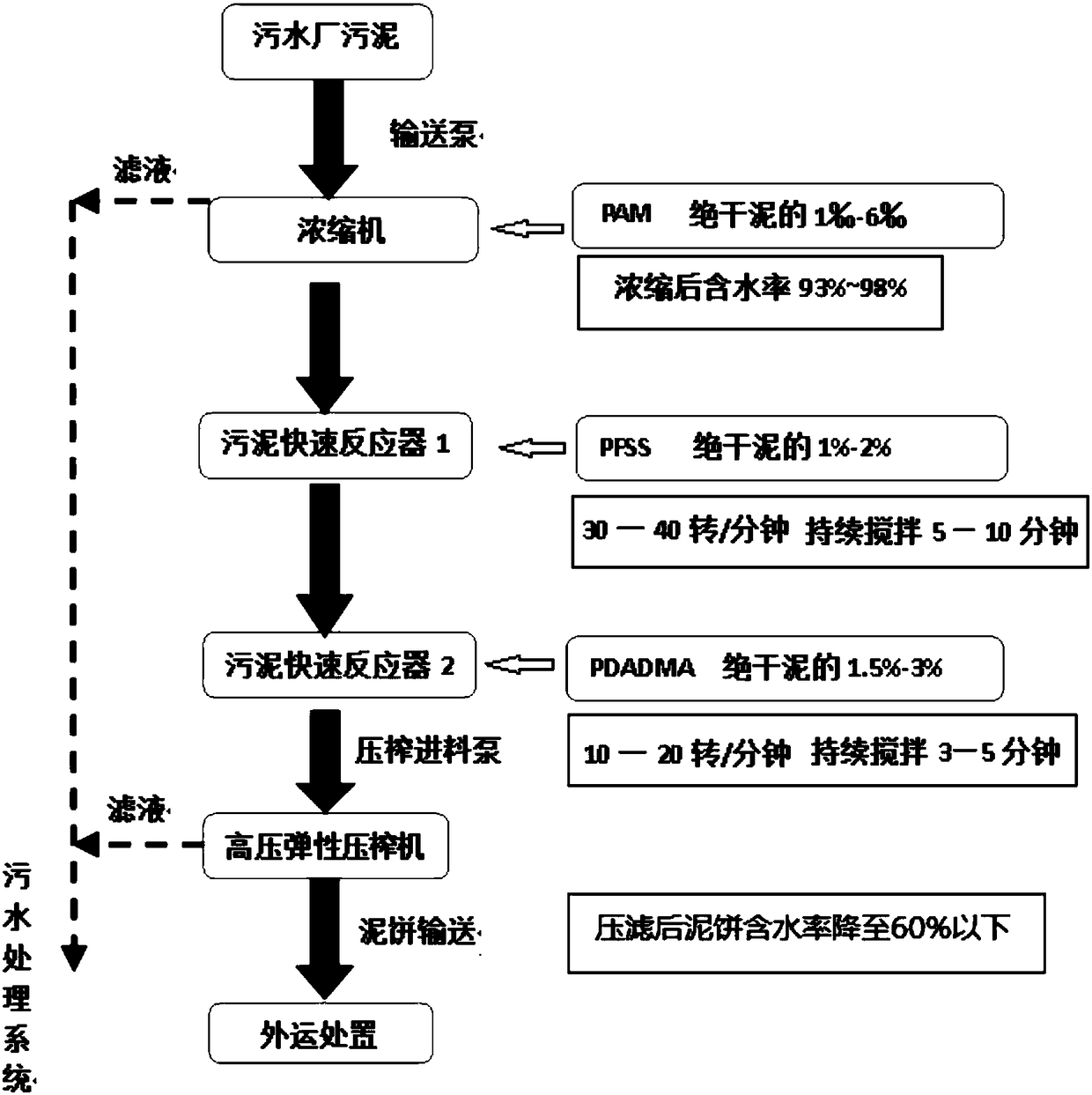

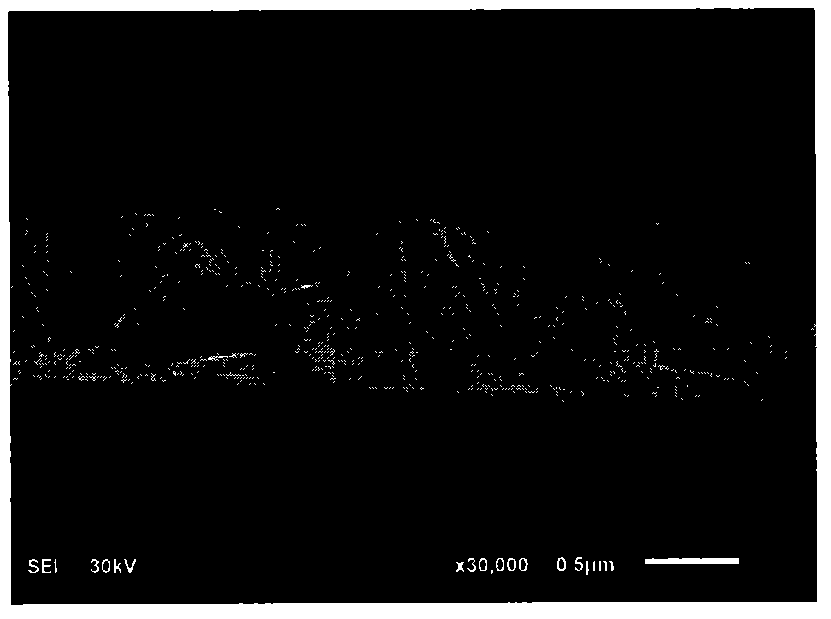

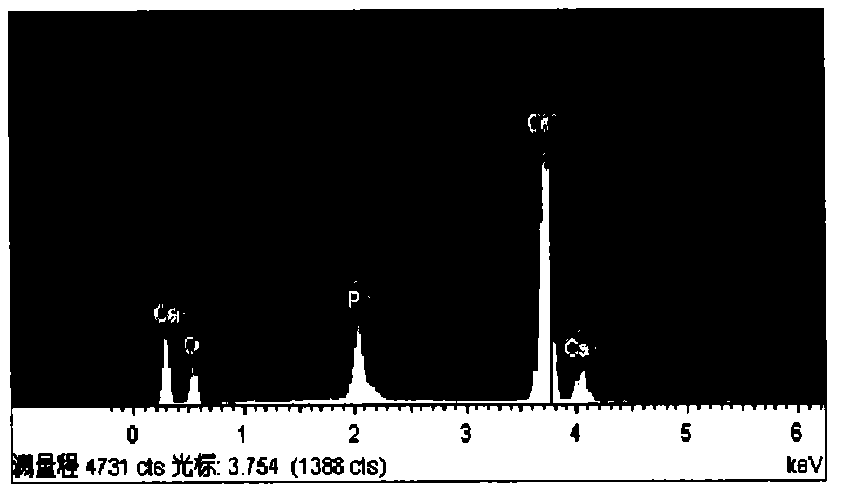

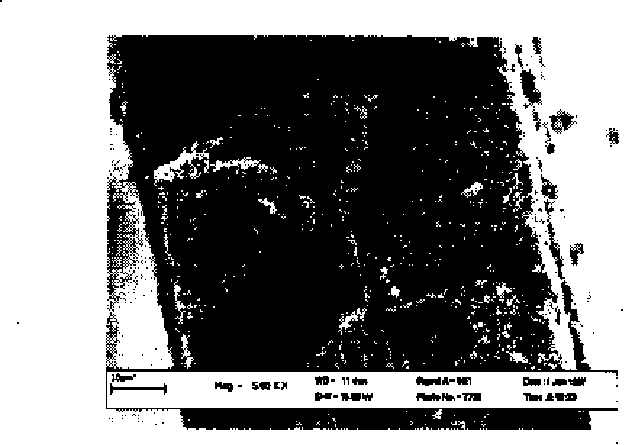

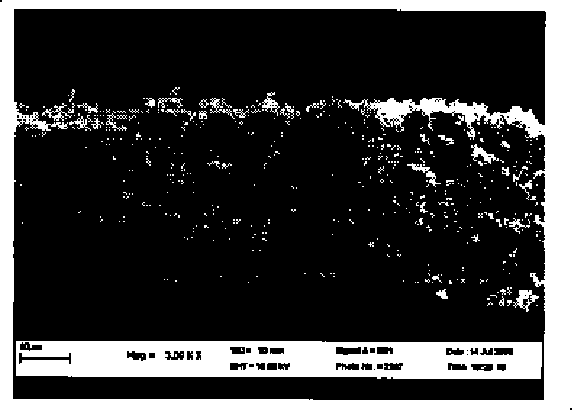

Sample preparation method for measuring aluminium electrolysis capacitor electric pole foil microscopic appearance

InactiveCN101210863AEasy accessAccurately obtainedPreparing sample for investigationSurface/boundary effectAluminium electrolysisChemical condition

A sampling method for observing microstructure of electrode foil used in an aluminum electrolytic capacitor comprises the following steps of: (1) cutting a sample; (2) electrolytic polishing; and (3) detecting. The invention can conveniently, rapidly and accurately obtain the electronic microscope picture reflecting the microstructure of electrode foil, so being particularly suitable for observation and detection of the microstructure of electrode foil. The invention establishes a foundation for studying the relationship of electrochemistry conditions and the microstructure of electrode foil, and provides a guarantee for developing capacitor-used electrode foil with high specific capacity, low resistance and high stability.

Owner:XINJIANG JOINWORLD CO LTD

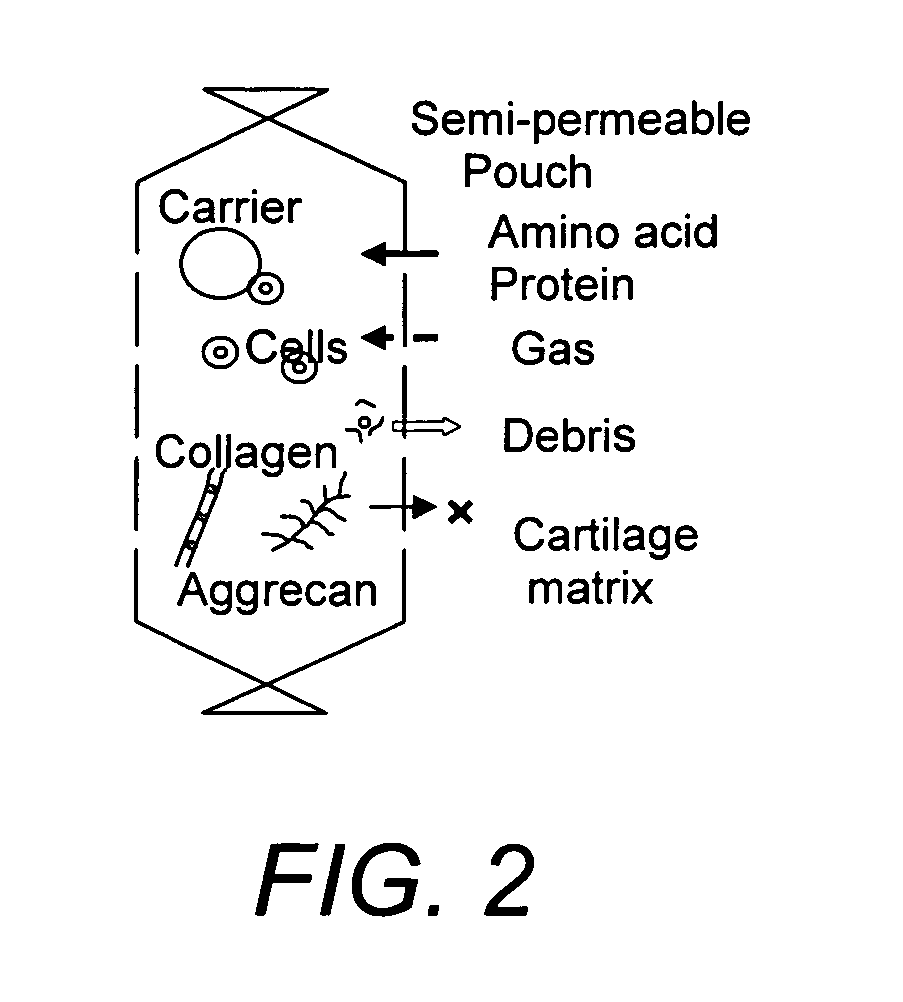

Amorphous cell delivery vehicle treated with physical/physicochemical stimuli

Provided are compositions and methods for in vitro generation and in vivo use of tissue for the repair of defective tissue, especially cartilage. Chondrocytes or other cells are cultured in vitro in a biodegradable amorphous carrier within the confines of a space bounded by a semi-permeable membrane with a molecular weight cut-off of greater than 100 kDa. The culture can be subjected to physical / physicochemical conditions that mimic in vivo conditions of the tissue in need of repair or replacement. In one embodiment the invention provides an amorphous preparation of chondrocytes and their extracellular products, suitable for injection.

Owner:THE BRIGHAM & WOMEN S HOSPITAL INC

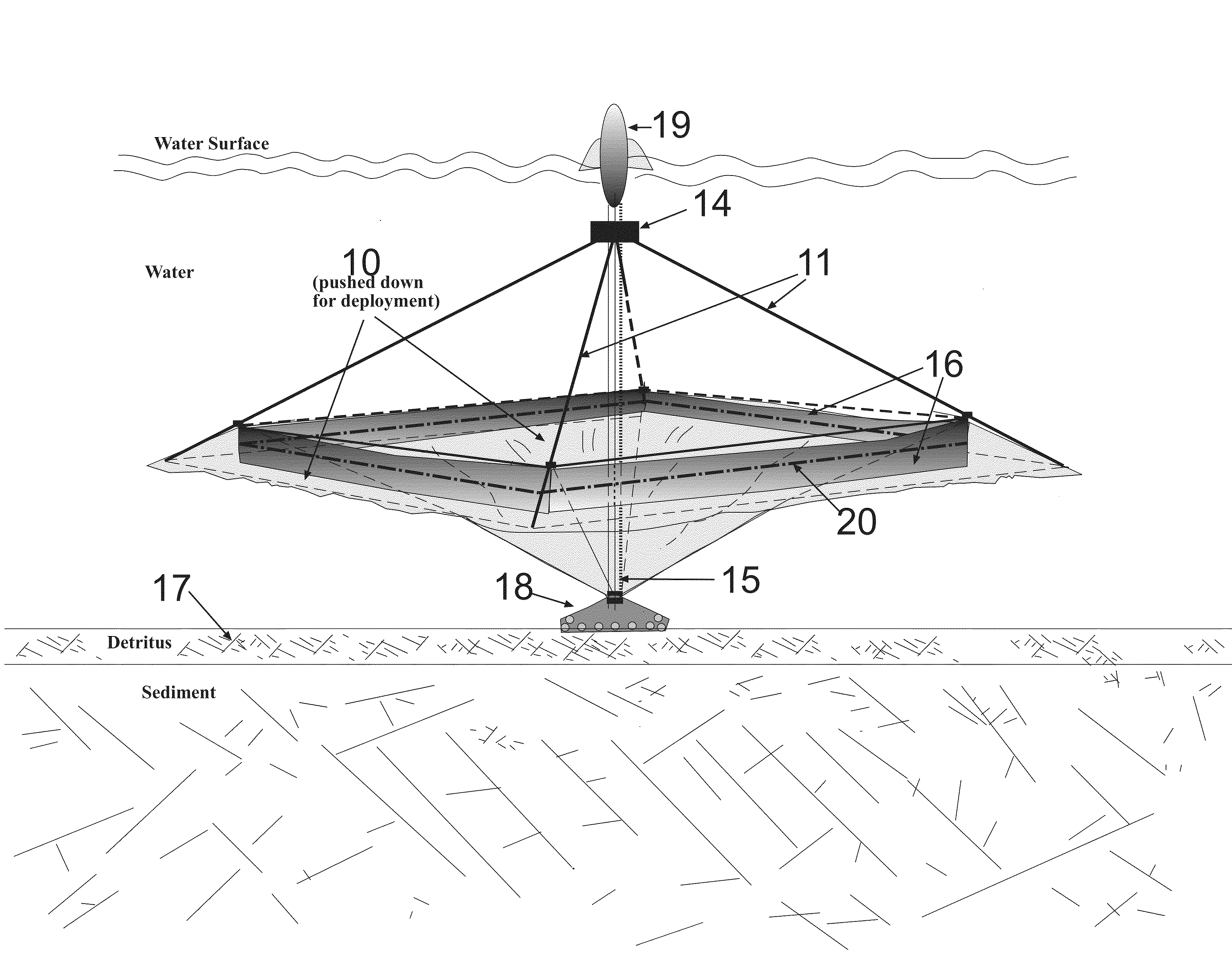

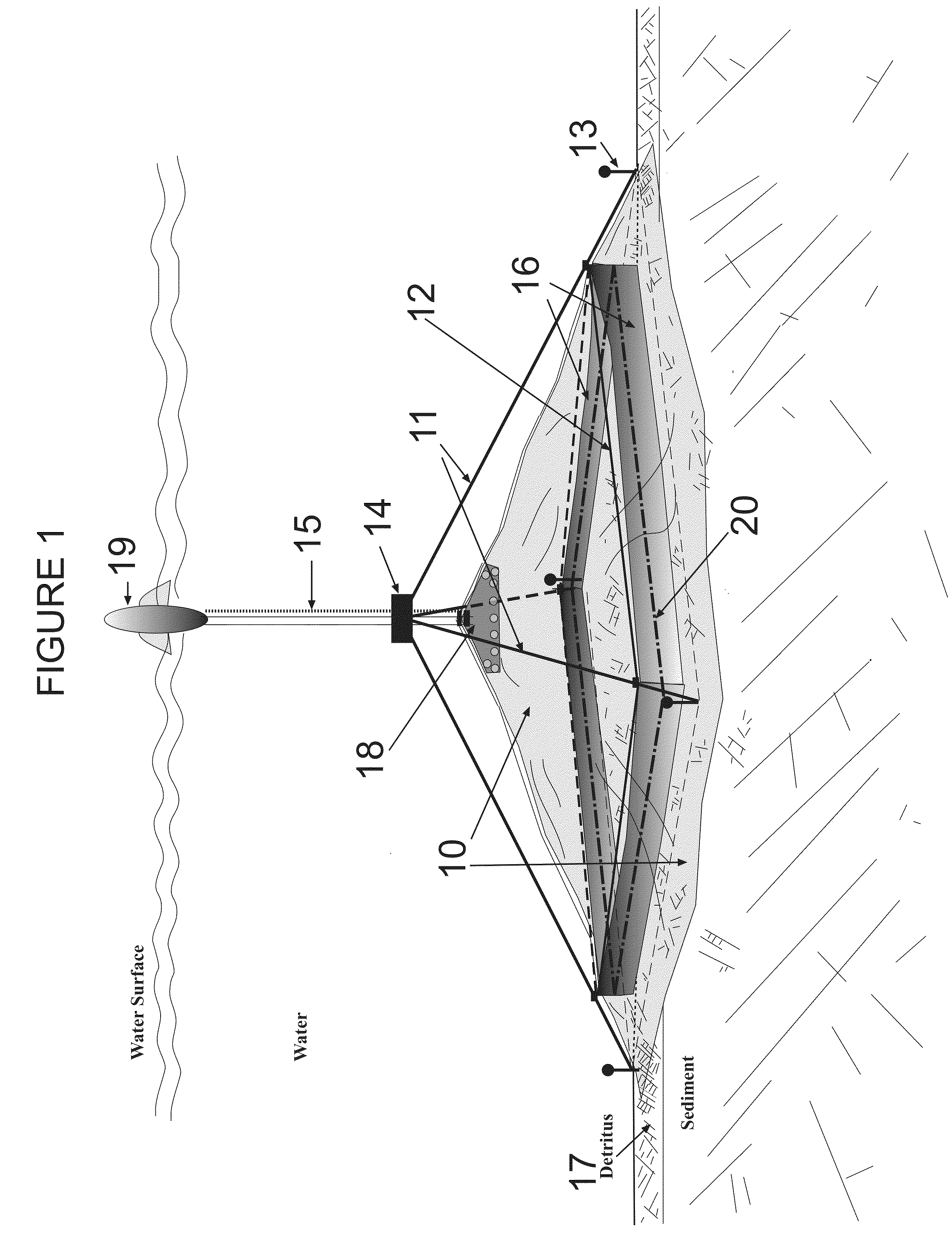

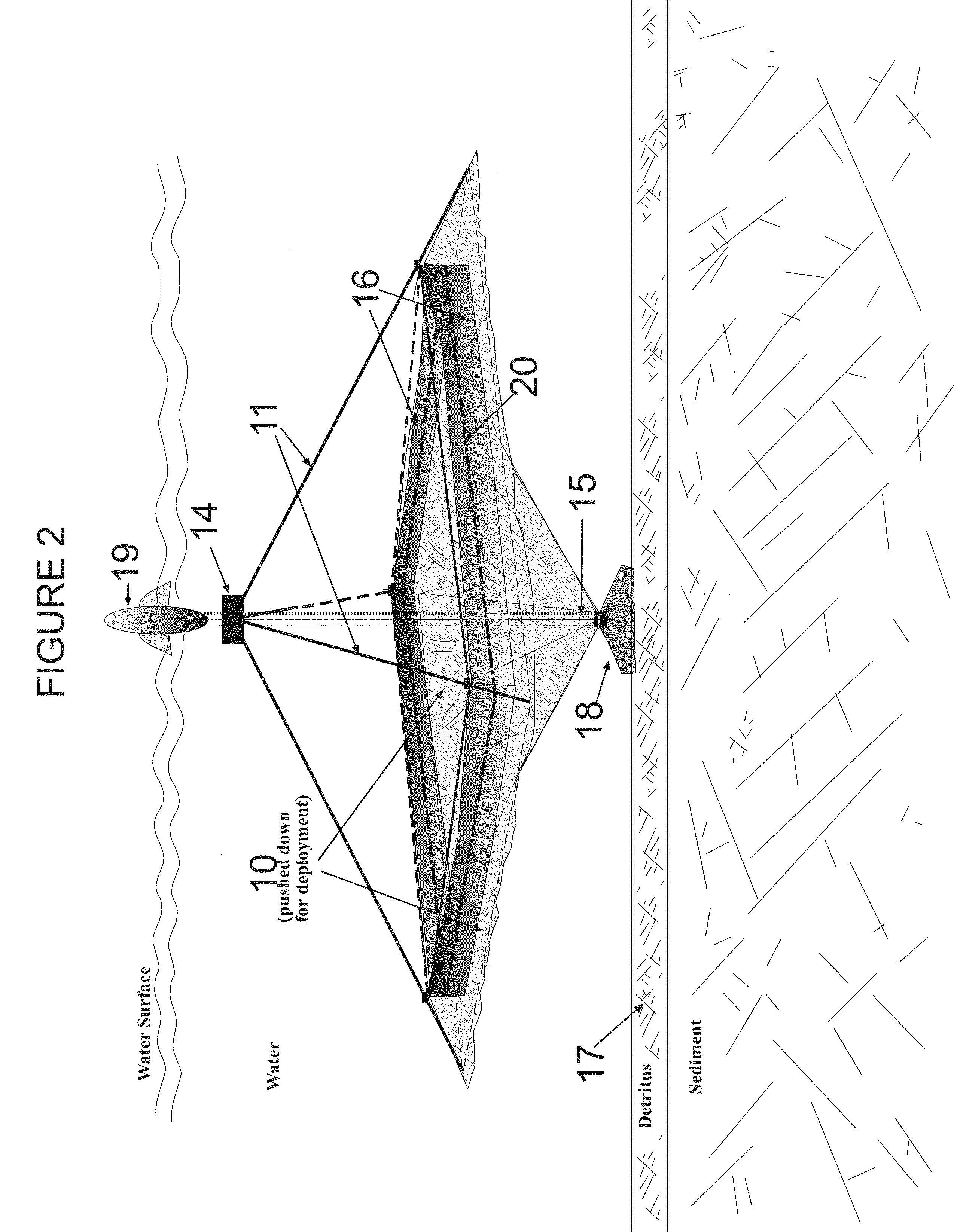

Collapsible Aquatic Sediment Enclosure and Process for Removal of Contaminants

ActiveUS20150023734A1Minimizes physical disturbanceLimit amount of potential damageWater cleaningContaminated soil reclamationZebra musselWater volume

The primary function of the collapsible enclosure is to capture, isolate, and allow for the permanent removal of otherwise easily dispersed contaminates in aquatic sediments and detritus of water bodies. Once deployed, the collapsible enclosure creates an isolated volume of water above these media. Contaminated sediments and detritus covered by the enclosure can then be efficiently removed either by their dissociation from sediment and detritus and into a soluble form within the enclosed water volume or by suspension of contaminated sediments and detritus within the enclosure. The dissolved or suspended contaminants within the enclosure could then be removed by an external pump, for treatment or disposal of recovered water and solids.This invention can also control invasive, noxious or nuisance densities of aquatic plants and animals (such as zebra mussels) by placing enclosures over the area of concern and creating appropriate physical or chemical conditions within the enclosure.

Owner:P POD TECH

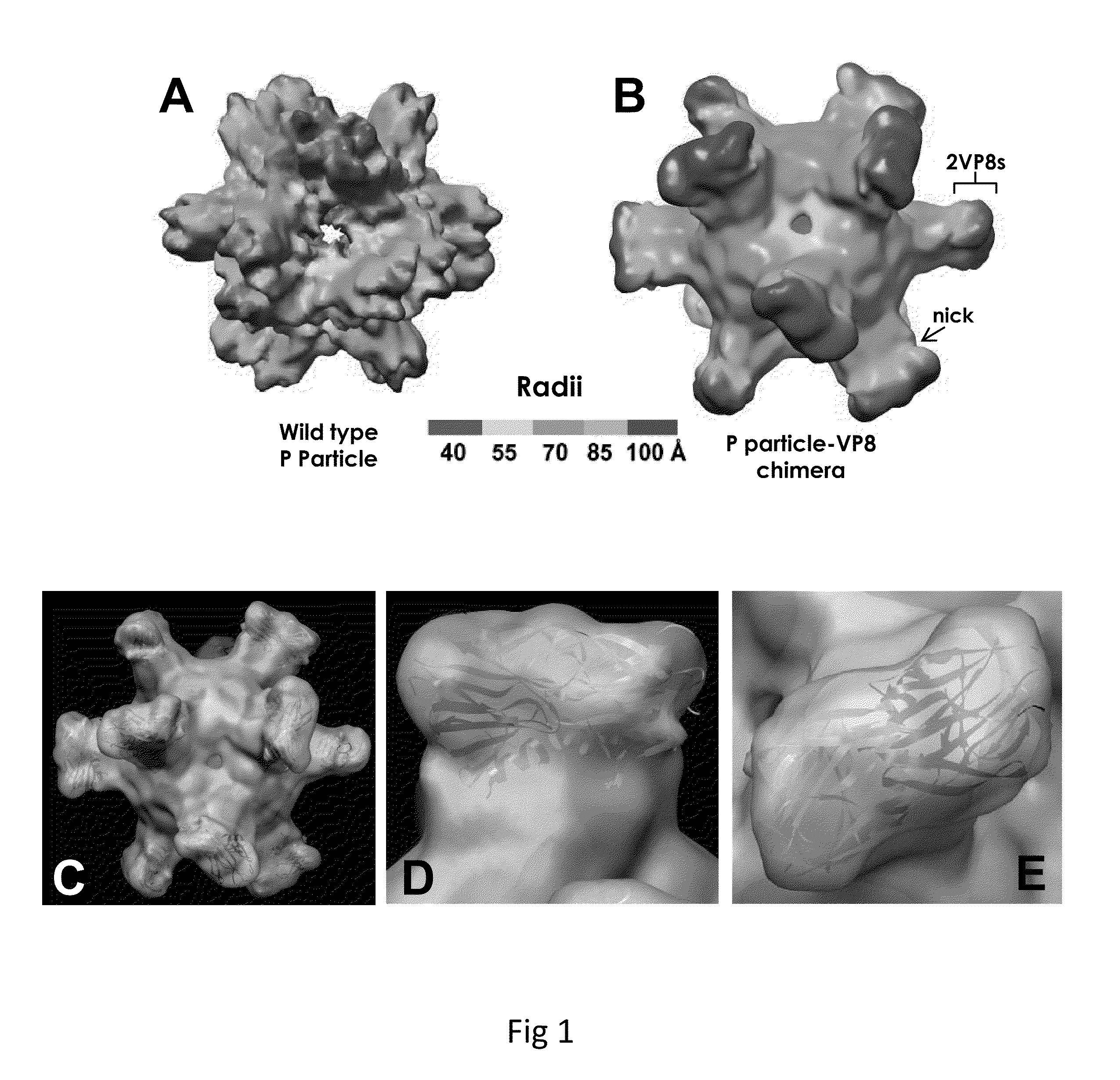

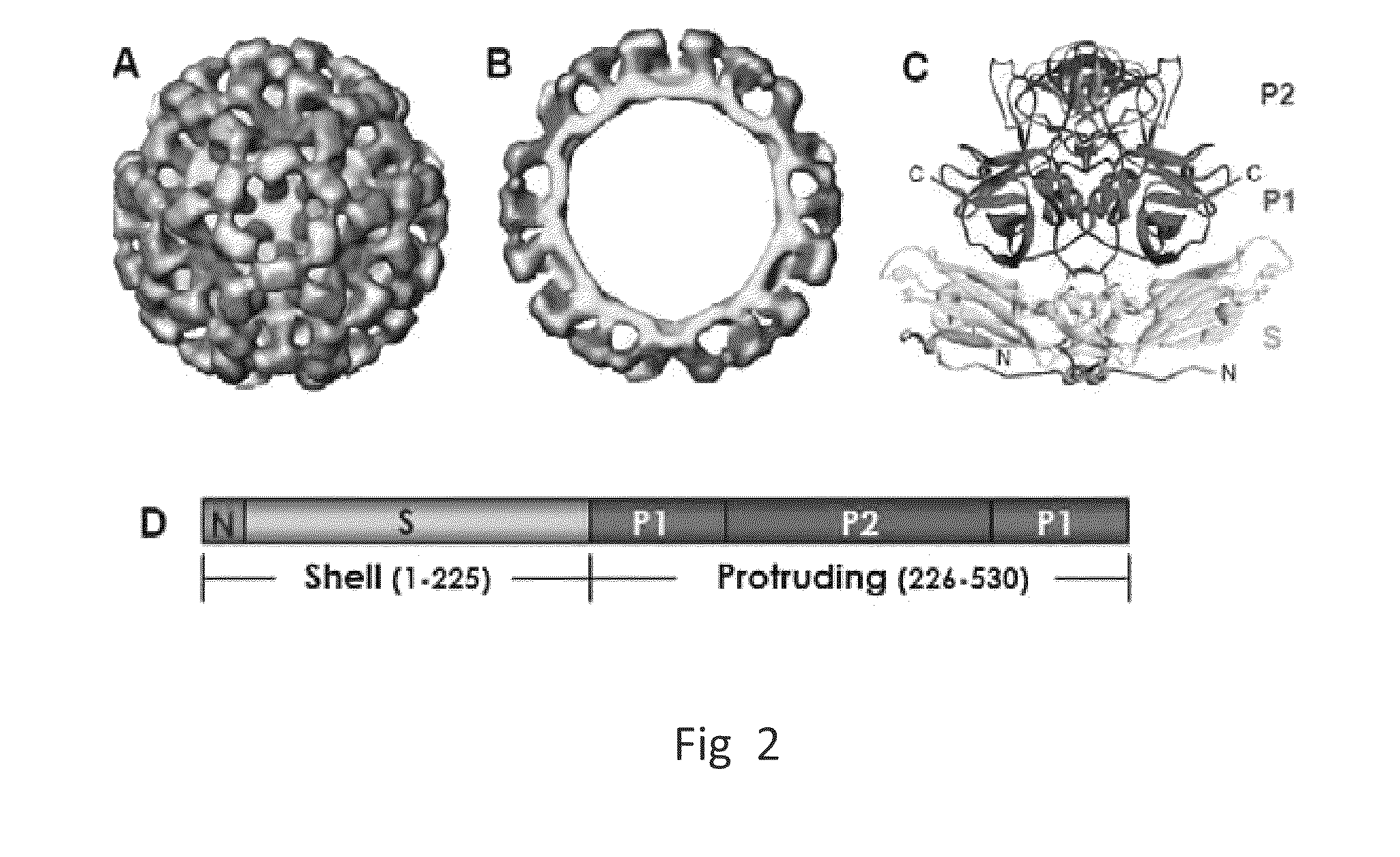

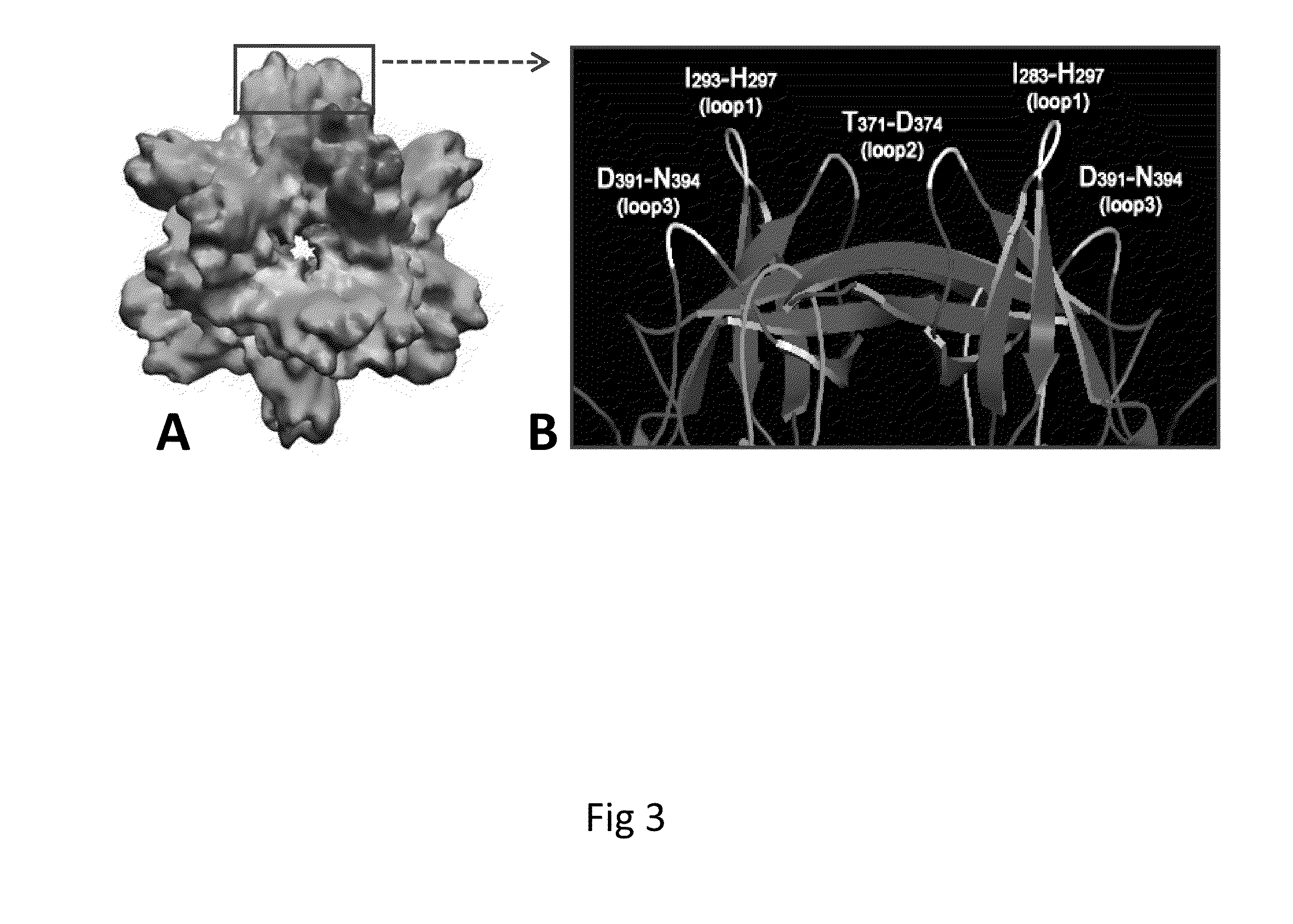

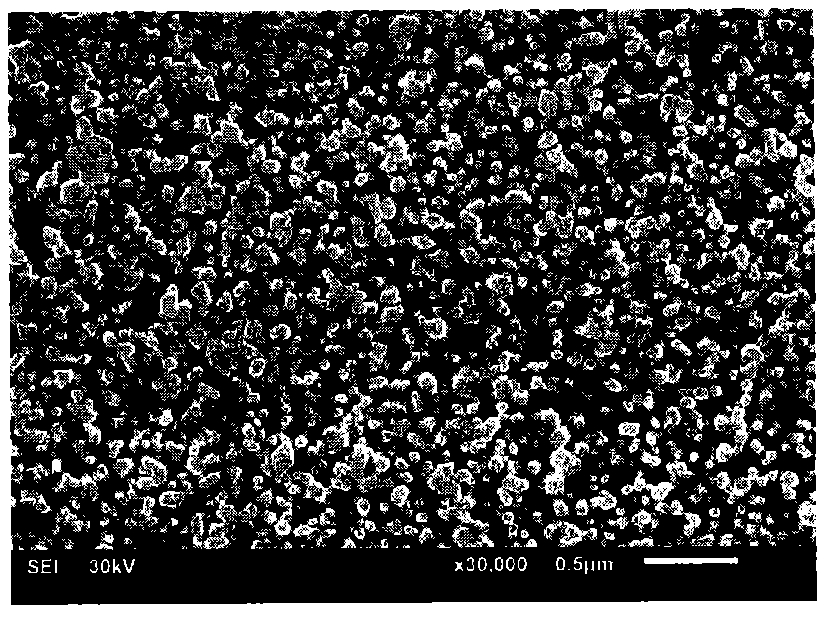

Antigen-norovirus P-domain monomers and dimers, antigen-norovirus P-particle molecules, and methods for their making and use

ActiveUS8486421B2Easy to produceImproving immunogenicitySsRNA viruses positive-sensePeptide/protein ingredientsDiseaseAntigen

A substituted Norovirus capsid protein monomer, having only the P-domain and called an antigen-Norovirus P-domain monomer, includes a foreign antigen inserted into one or more of three surface loops present on each P-domain monomer by molecular cloning. The antigen-P-domain monomer can assemble spontaneously into an octahedral form, called an antigen-Norovirus P-particle, that is composed of 24 copies of the antigen-P-domain monomer. Each substituted P-domain monomer will contain one to three copies of the foreign antigen, for a total of 24-72 antigen copies on each antigen-P-particle. The antigen-P-particle is useful in methods for diagnosing, immunizing and treating individuals infected with a foreign virus, for example Rotavirus, and can serve as a carrier for presentation of foreign antigens for development of novel vaccines against many infectious and non-infectious diseases. The substituted Norovirus P-particles can be readily produced in E. coli and yeast, are highly stable and tolerate a wide range of physio-chemical conditions. A modified Norovirus P-domain monomer includes one or more restriction recognition sites inserted within one or more of the three loops of the P-domain monomers, to provide user-friendly cloning cassettes for conveniently inserting candidate foreign antigens into the surface loops. The P-particle-VP8 chimeras may also serve as a dual vaccine against both rotavirus and norovirus.

Owner:CHILDRENS HOSPITAL MEDICAL CENT CINCINNATI

Preparation method of high-orientation nanometer hydroxyapatite crystalline colloidal array

The invention relates to a preparation method of a high-orientation nanometer hydroxyapatite crystalline colloidal array. The method comprises the following steps of: (1) dipping a cleaned substrate material into a hot alkali solution, taking the substrate material out when the substrate material is treated by the hot alkali solution for certain time, cleaning the substrate material using deionized water, and drying the cleaned substrate material; (2) dipping the dried substrate material into a calcium salt solution, taking the substrate material out after reaction for certain time, and directly drying the substrate material without cleaning; and 3) vertically dipping the again dried substrate material into a phosphate solution, keeping the substrate material in the phosphate solution at certain pH (Potential of Hydrogen) and temperature for certain time, then taking the substrate material out, cleaning the substrate material using deionized water, and drying the cleaned substrate material to obtain the high-orientation nanometer hydroxyapatite crystalline colloidal array. The method provided by the invention achieves the formation and structure control of the nanometer hydroxyapatite crystalline colloidal array by changing chemical conditions, is stable in process, low in cost and capable of achieving large-scale production, and has wide application values to the fields of material surface modification, biological information detection, disease diagnosis and the like.

Owner:星途(常州)碳材料有限责任公司

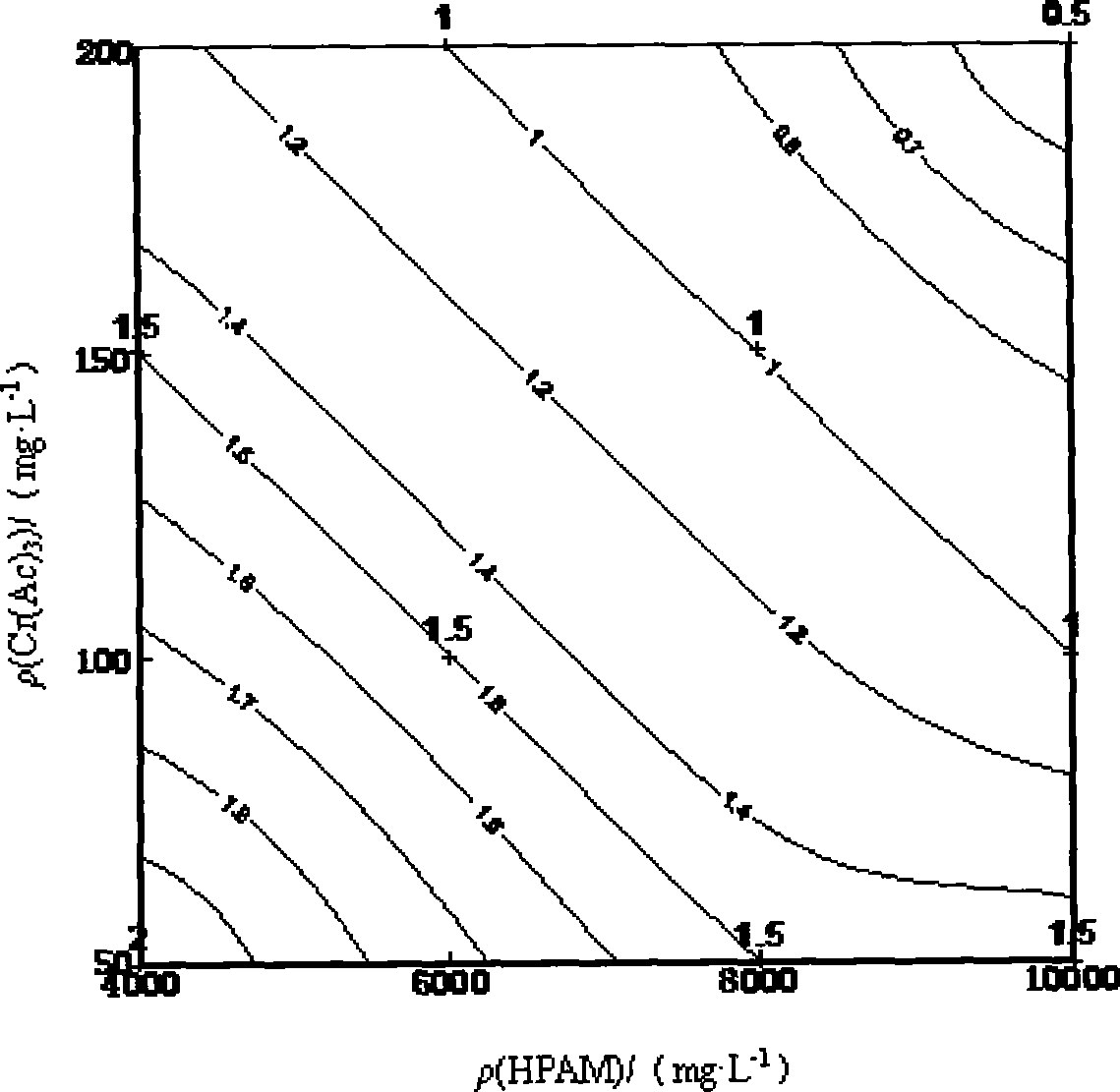

Preparation of jelly glue dispersion for oil reservoir deep liquid diverting

InactiveCN101434835AReduce penetrationPlay the role of deep profile adjustmentDrilling compositionPeristaltic pumpChemical condition

The invention provides a preparation method of a jelly glue dispersion in-depth fluid flowing diverting agent, comprising the specific steps as follows: during a process when the jelly glue is formed by mixing part of hydrolyzed polyacrylamide and chromium acetate, a peristaltic pump applies a certain shearing force to a gelation system so as to lead the gelation system to form the jelly glue dispersion rather than integrated jelly glue. The jelly glue dispersion prepared by the method consists of jelly glue particles and water; and the particle diameter of the jelly glue dispersion can be controlled by adjusting the shearing speed. The jelly glue dispersion can be injected into the in-depth reservoirs; the adsorption and detention of the jelly glue dispersion particles in the hole can reduce the permeability of the high-permeability area, leads the subsequently injected liquid to be turned to the low-permeability area, and has the function of in-depth profile modification. The in-depth fluid flowing diverting agent has the advantages of low viscosity, good fluidity, good stability, long validity period, and the like, is insensitive to shearing and physical and chemical conditions of the reservoir, has controllable dimension, can design the diameter of the jelly glue dispersion with the aim of different stratums, and prevents blocking the stratum percolation surfaces.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Electrolytic capacitor aluminum foil oxidation film stripping liquid and microscopic appearance measurement method

ActiveCN101211697AEasy accessAccurately obtainedElectrolytic capacitorsPreparing sample for investigationCapacitanceElectrolysis

The invention relates to an oxide film stripper of the aluminium foil for electrolytic capacitor and a method for measuring the micro-morphology. The oxide film stripper is the alkaline aqueous solution mainly containing the sodium hydroxide and the sodium phosphate. The method for measuring the micro-morphology of the aluminium foil for electrolytic capacitor of the formed foil is implemented following the first step of stripping the oxide film, the second step of sampling and the third step of detection. The method for measuring the micro-morphology of the aluminium foil for electrolytic capacitor of the unformed foil is implemented following the first step of formation treatment, the second step of stripping the oxide film, the third step of sampling and the fourth step of detection. The adoption of the invention can conveniently, quickly and accurately obtain the electronic microscope photograph in which the micro-morphology of the unformed or / and formed aluminium foil is shown, thus the invention is in particular suitable for the observation and detection of the micro-morphology of the formed foil or / and unformed foil, which lays the first stone for researching the connection between the electrochemical condition and the micro-morphology of the electrode foil and provides the guarantee for researching and developing the high specific capacitance, low impedance and high stability electrode foil for capacitor.

Owner:XINJIANG JOINWORLD CO LTD

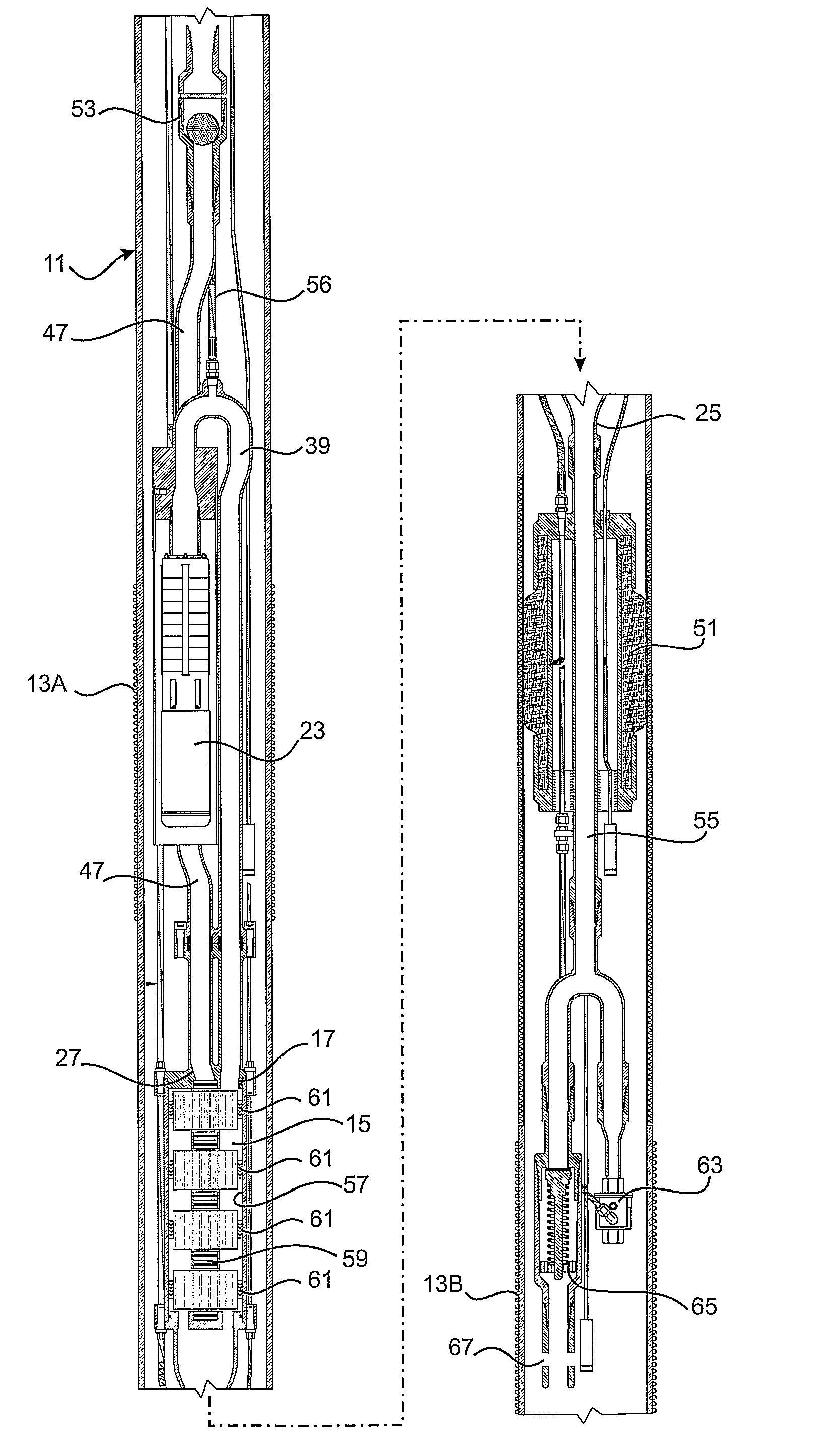

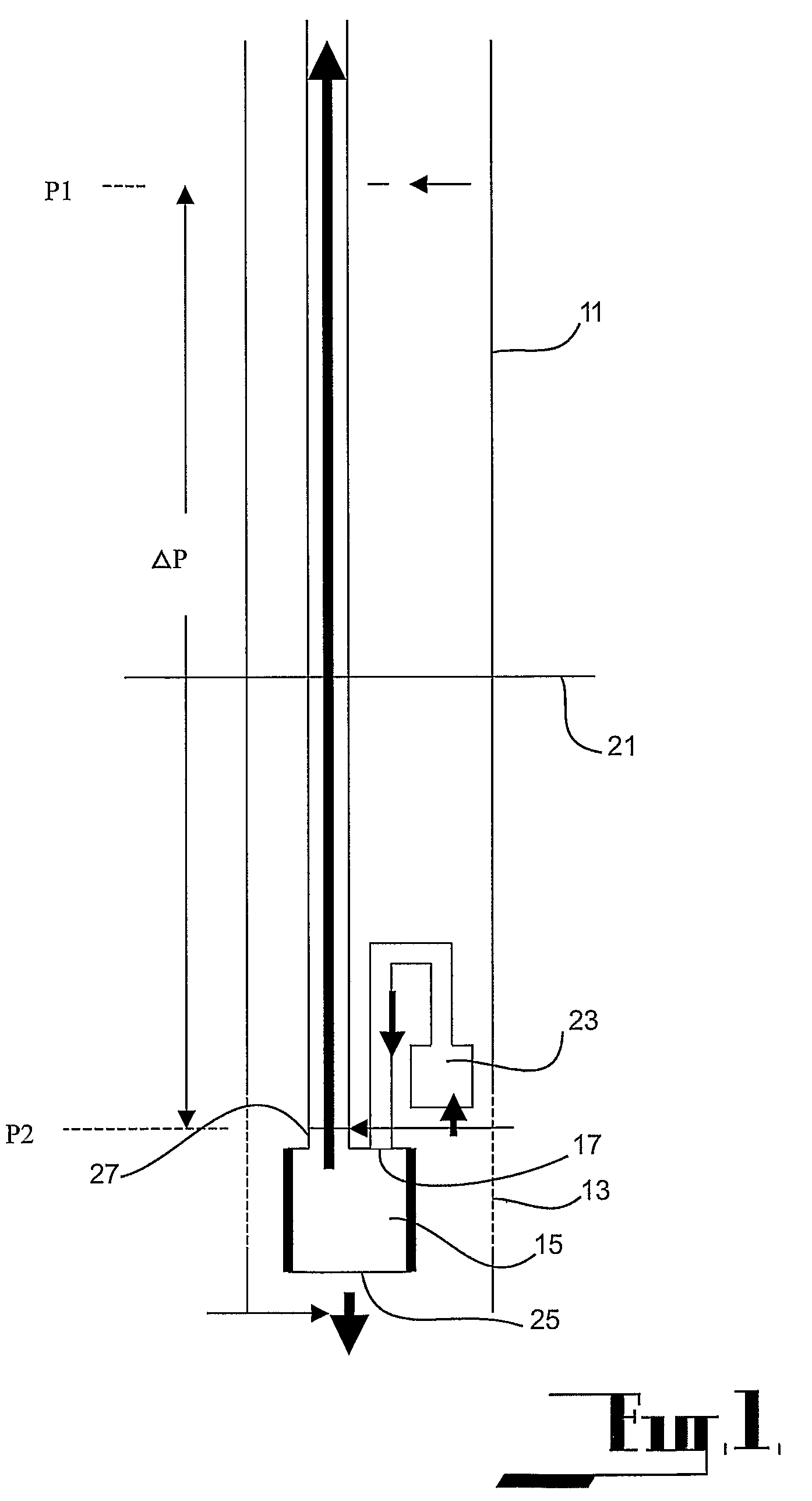

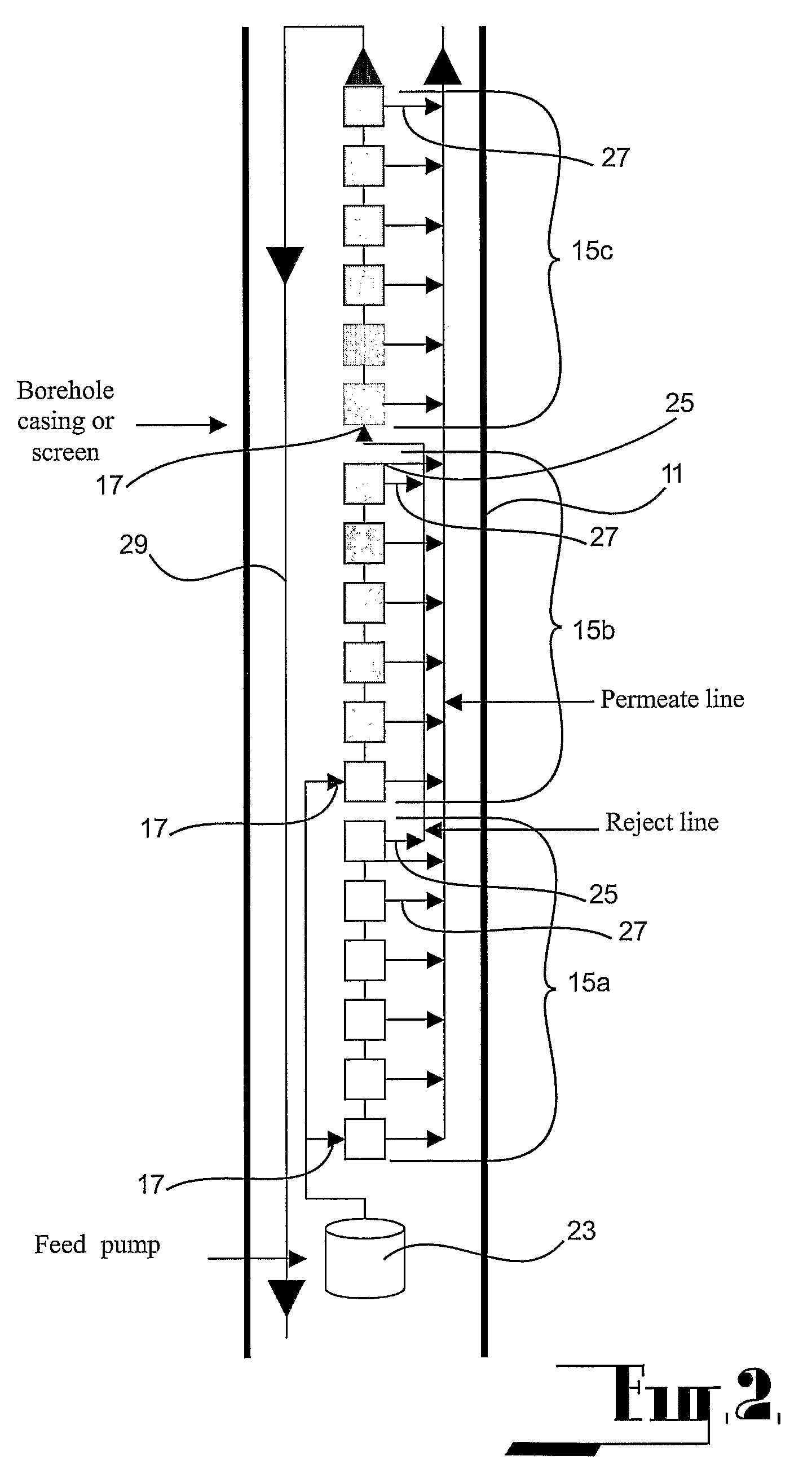

Water desalination

ActiveUS7520981B2Avoid reactionAvoid problemsWater cleaningGeneral water supply conservationWater desalinationChemical condition

An in situ desalination apparatus comprising a reverse osmosis unit (15) having a reverse osmosis medium, the reverse osmosis unit in use to be located within a body of water under ambient bio-physico-chemical conditions often different from those at the surface, the unit having an inlet (17) opening to one side of the reverse osmosis medium, in use the inlet to be located below the upper surface of a body of water, the unit having a concentrate outlet (25) opening to the one side of the reverse osmosis medium and opening into the exterior of the unit at a position spaced below the inlet to return concentrate into the water body, the unit having a permeate outlet (27) opening to the other side of the reverse osmosis medium, the permeate outlet communicating with a delivery line extending from the body of water, a pump (23) between body of water and the reverse osmosis unit and adapted to pressurize the water located at the one side of the reverse osmosis medium.

Owner:DESALN8

Device and Method of Determining Safety in a Battery Pack

InactiveUS20120126991A1Material analysis by electric/magnetic meansCells structural combinationChemical conditionOutput device

A battery pack includes at least one battery cell that expands and contracts in relation to the chemical conditions of the battery cell. A substrate is configured to contact the at least one battery cell. A sensor is attached to the substrate and the sensor produces a signal indicative of the displacement of the substrate. A controller is communicatively connected to the sensor such that the controller receives the signal from the sensor. The controller processes the signal to produce an indication of a status of the battery cell. A method of monitoring battery safety includes movably securing a substrate across at least one cell of a battery. A displacement of the substrate is measured. The measured displacement is processed with a controller to identify a safety status of the at least one cell. An output device is operated with a controller to provide an indication of the safety status of the at least one cell of the battery.

Owner:VYAIRE MEDICAL CONSUMABLES LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com