Arrangement or provision of a sensor or probe for the measuring of a condition in a pipe or the like

A detector and sensor technology, applied in the field of flange joints, can solve expensive and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

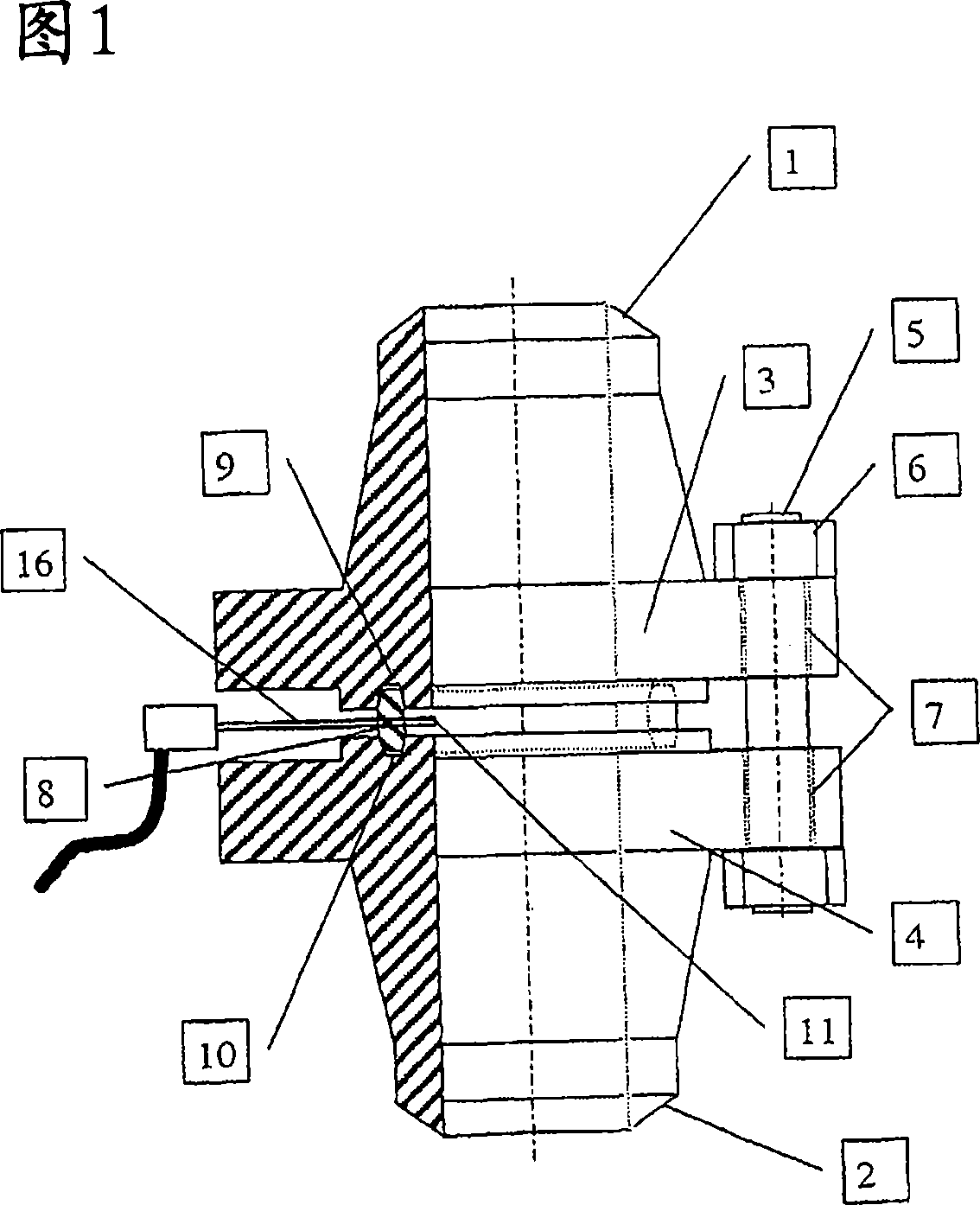

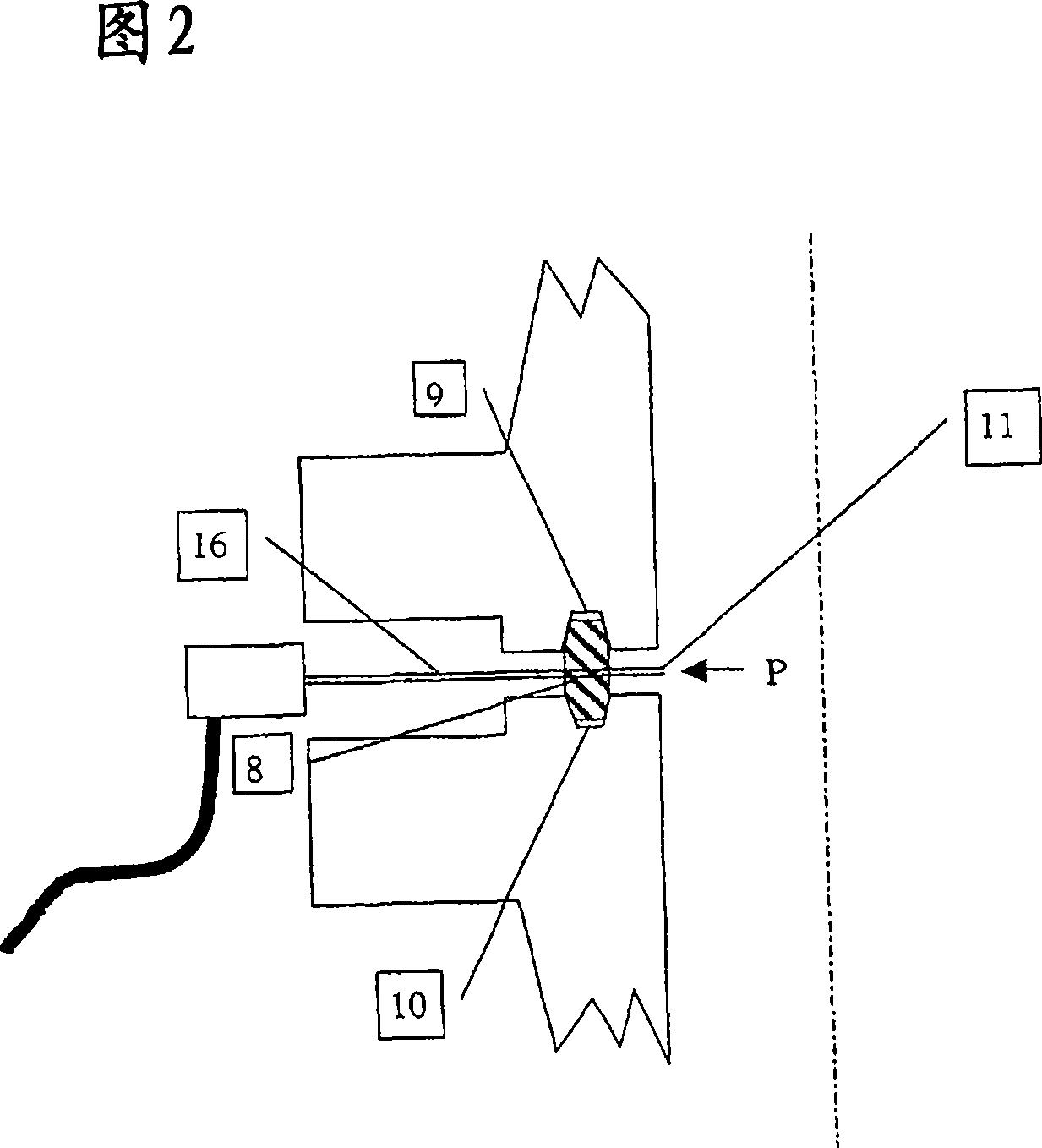

[0014] Figures 1 and 2 show the flange connection between the two pipe ends 1 and 2 described above. The flanges 3, 4 are tightly held together by bolts 5 and nuts 6 which are arranged in through holes 7 in the flanges. Annular gaskets 8 are provided between the flanges in grooves 9 and 10 in the respective flanges 3 and 4 to obtain a tight seal between the two flanges. The main inventive feature of the present application is the construction and arrangement of the sensor 11 within the gasket 8 . The sensor may be any type of sensor element that measures pressure, temperature, changes in conductivity or resistance due to corrosion or erosion of the sensor element.

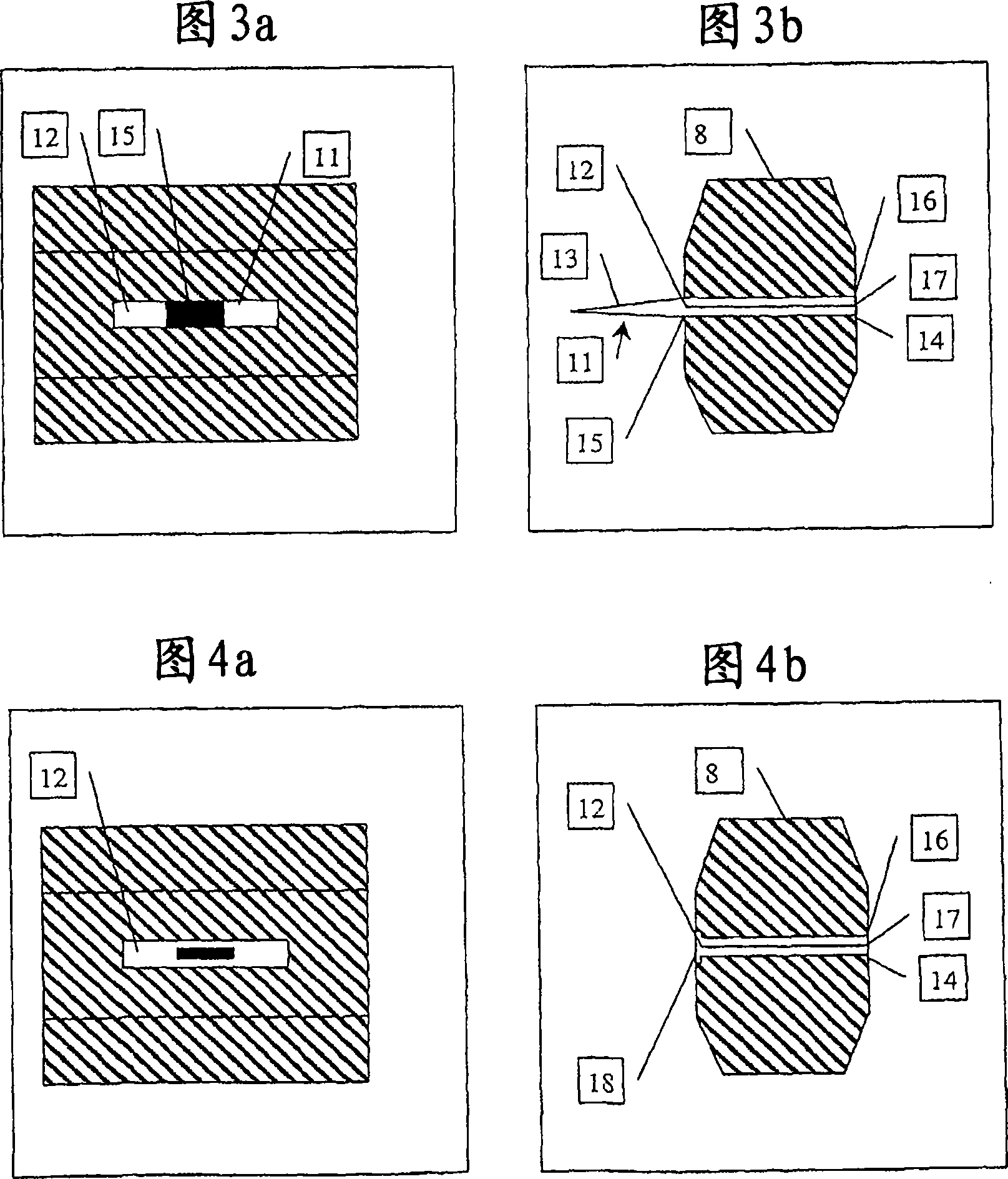

[0015] Accompanying drawing 3 a) and b) represent the figure of the gasket 8 with sensor as shown in accompanying drawing 1 and 2 on an enlarged scale, wherein a) is seen from the inner side (inner wall) of the gasket, b) is its cross-section . The sensor element 8 shown in the figure is a double-sided diaphragm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com