Preparation of jelly glue dispersion for oil reservoir deep liquid diverting

A liquid flow diversion and jelly technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems that water-swelling particles cannot adapt to deep injection, cannot fully utilize pre-crosslinked particles, and the liquid is volatile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

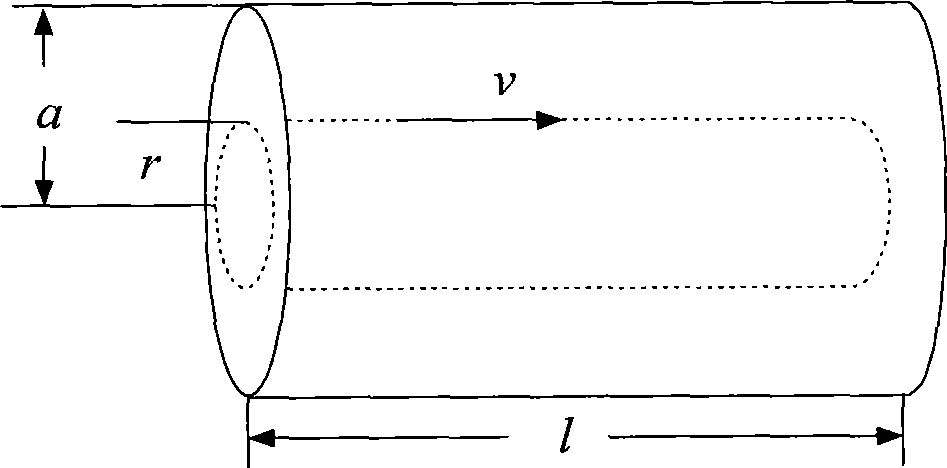

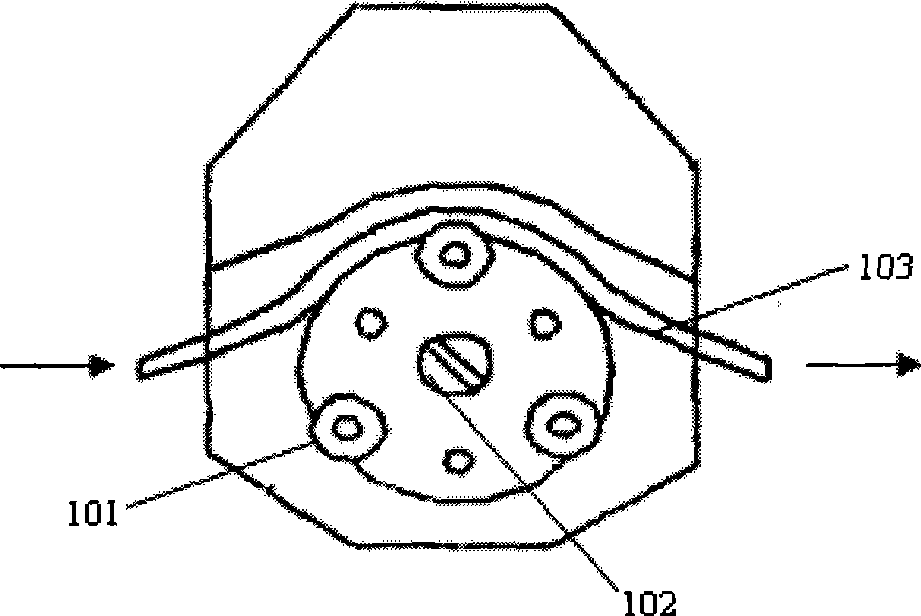

[0060] Embodiment 1: prepare mass concentration in 100mL beaker and be 8000mg L -1 HPAM and 25mg·L -1 Cr(Ac) 3 According to the requirements of the shear rate, adjust the speed of the peristaltic pump to 10rpm, quickly suck the prepared tube flow shear cross-linking system into the silicone hose, connect the two ends of the hose, and place In a constant temperature water bath at 30°C, shear at a constant speed for 4 hours to the end. The liquid in the silicone tube was taken out, diluted 3 times, and stirred at 90° C. for 4 hours to obtain the required jelly dispersion.

[0061] Similarly, the rotation speed of the peristaltic pump was adjusted from low to high to 30, 50, 80, 100, 150 rpm, and the corresponding jelly dispersions were sequentially obtained according to the method in Example 1. Measure the hydrodynamic diameter d of jelly dispersion with Malvem Zetasizer 3000 HSa dynamic light scattering instrument, measure the result as follows Figure 4 As shown, the avera...

Embodiment 2

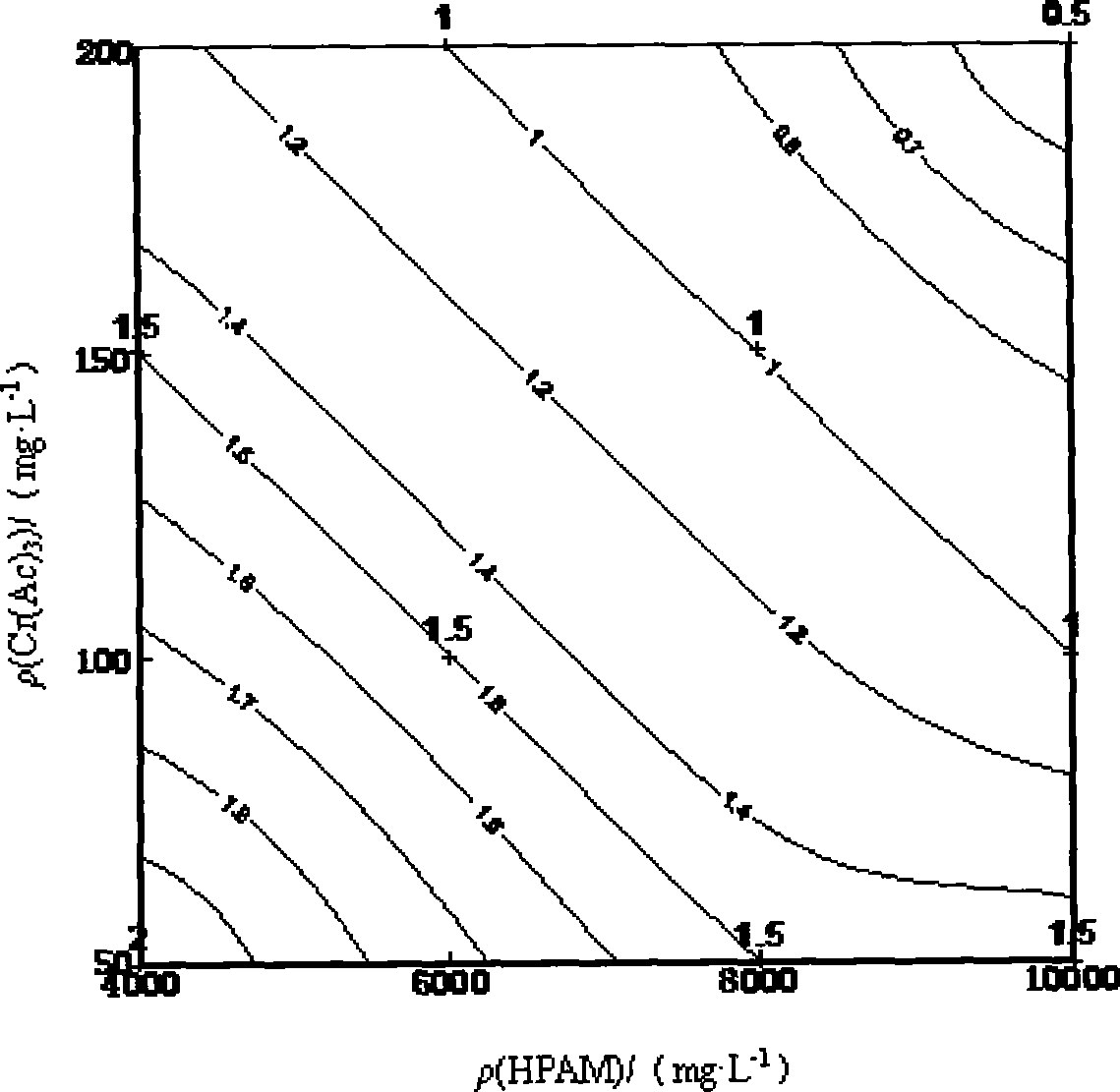

[0063] Embodiment 2: prepare mass concentration respectively in 100mL beaker and be 4000mg L -1 HPAM and 25mg·L -1 Cr(Ac) 3 and 8000mg·L -1 HPAM and 25mg·L -1 Cr(Ac) 3 Two kinds of tube flow shear crosslinking systems, according to the requirements of the shear rate, adjust the speed of the peristaltic pump to 40rpm (that is, 176s -1 ), quickly suck the prepared tube flow cross-linking system into the silicone tube respectively. Butt the two ends of the hose, place it in a constant temperature water bath at 30°C, and shear at a constant speed for 4 hours until the end. The liquid in the silicone tube was taken out, diluted 3 times with water, and stirred at 90° C. for 4 hours to obtain two required jelly dispersions. The microscopic morphology of the two jelly dispersions was determined by atomic force microscopy, as Figure 6 , Figure 7 shown. From Figure 6 It can be seen that the shape of the jelly dispersion in the solution is mainly in the form of columns or st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com